Professional Documents

Culture Documents

NDC Analytique Ot3439

Uploaded by

Ben Abdallah Becem0 ratings0% found this document useful (0 votes)

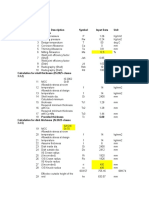

4 views3 pagesThis document contains calculations for the thickness of an anolyte header according to various standards. It determines that the minimum required thickness is 5.11 mm based on input parameters like inside diameter, design pressure, and tensile strength test results. A second calculation determines the minimum welding thickness is 3.18 mm based on similar input parameters and test results. The proposed and minimum required thicknesses meet the standards.

Original Description:

Original Title

NDC ANALYTIQUE OT3439

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains calculations for the thickness of an anolyte header according to various standards. It determines that the minimum required thickness is 5.11 mm based on input parameters like inside diameter, design pressure, and tensile strength test results. A second calculation determines the minimum welding thickness is 3.18 mm based on similar input parameters and test results. The proposed and minimum required thicknesses meet the standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views3 pagesNDC Analytique Ot3439

Uploaded by

Ben Abdallah BecemThis document contains calculations for the thickness of an anolyte header according to various standards. It determines that the minimum required thickness is 5.11 mm based on input parameters like inside diameter, design pressure, and tensile strength test results. A second calculation determines the minimum welding thickness is 3.18 mm based on similar input parameters and test results. The proposed and minimum required thicknesses meet the standards.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Date 01/04/2022

DN400 ANOLYTE HEADER Rev 0

GCER REF OT3439-22

THICKNESS CALCULATION NOTE

EN13121-3/ DIN 16965-5 / 16966-8

CLIENT:CMI TECH5I

0 Issued For Review B.BA A.BS N.BO

Rev Description Elaborated By Checked By Approved By

Thickness Calculation

1 As per DIN 16965-5

2 Input Data

3 Symb Value Unit

4

5 Inside Diameter d2 = 400 mm

6 Design Pressure p = 10 bar

7 Design Factor of Safety FS = 6

8

9

10

11

12

13

14

15

16

17

18

19 RESULTS

20 Wovens FW (2FW+UD 90°)

21 Hoop Ultimate Tensile Strength σzul = 295 MPa GCER TEST

22 Axial Ultimate Tensile Strength σzul = 120 MPa GCER TEST

23 Layer Thickness Lt = 1,36

24 Mechanical Structure Layers number 4 Layers

25 Proposed Thickness t = 5,44 mm

26

27 Minimum Required Thickness (Hoop Direction) s4-1 = 5,11 mm

28 Minimum Required Thickness (Axial Direction) s4-2 = 11,26 mm

29

30

31

32 Retained Thickness s4 = 5,11 mm

33

34

35

36

37

38

39

Welding Thickness Calculation

1 As per DIN 16966-8

2 Input Data

3 Symb Value Unit

4

5 Inside Diameter d2 = 400 mm

6 Exterior diameter d3 = 423,02 mm

7 Design Pressure p = 10 bar

8 Design factor of Safety FS = 6

9 Chemical Barrier CB = 6,3 mm

10 Mechanical Thickness ML = 5,11 mm

11

12

13

14

15

16

17

18

19

20 Wovens WR (T800)

21 Ultimate Tensile Strength σ zul = 380 MPa GCER TEST

22 Layer Thickness Lt = 0,8

23 Mechanical Structure Layers number 4 Layers

24 Production uncertainty factor S1 = 2

25 Shear Strength τ = 15 MPa

26 Maximum gap between the ends of pipes L1 2 mm

27 Proposed Thickness t = 3,2 mm

28 Minimum required Thickness (RM1) s5 = 3,18 mm

29 Minimum required Length L = 172,00 mm

30

31

32

33

34

35

36

37

38

39

You might also like

- Calculation of Wall Thickness MAWP API 5l x52 (Rev-2)Document21 pagesCalculation of Wall Thickness MAWP API 5l x52 (Rev-2)YusepSúarðiNo ratings yet

- Frame ConnectionsDocument14 pagesFrame ConnectionsShawkat Ali KhanNo ratings yet

- Typ Base PlateDocument19 pagesTyp Base Platehardik033No ratings yet

- Typ Base PlateDocument19 pagesTyp Base PlateHabibur RahmanNo ratings yet

- Kirby - Typ Base PlateDocument19 pagesKirby - Typ Base PlateNitesh Singh100% (1)

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- Compression Member LSMDocument1 pageCompression Member LSMSuman NakarmiNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- F-0201 Special Blind Calculation (N9)Document2 pagesF-0201 Special Blind Calculation (N9)rustamriyadiNo ratings yet

- Piping Calculation Program For ASME B31 1 CodeDocument3 pagesPiping Calculation Program For ASME B31 1 CodeAMIT100% (2)

- EJ CalculationDocument16 pagesEJ CalculationAmit NayakNo ratings yet

- DatasheetDocument2 pagesDatasheetnirmalNo ratings yet

- Calc' Diesel Fuel (Rev)Document10 pagesCalc' Diesel Fuel (Rev)joko_tm02No ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Pipe Wall Thickness Calculation ASME B31.8Document16 pagesPipe Wall Thickness Calculation ASME B31.8DikaAnindyajati100% (2)

- Stiffeners: (MM) (MM) (MM)Document4 pagesStiffeners: (MM) (MM) (MM)Md Ahsanul KabirNo ratings yet

- Design Procedure For Aes He PDFDocument30 pagesDesign Procedure For Aes He PDFRyan Goh Chuang HongNo ratings yet

- Calculation Noozle - Heat ExchangerDocument6 pagesCalculation Noozle - Heat Exchangercalinvasco190670No ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument1 pageS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- Pall Flange 3 - June 2020Document15 pagesPall Flange 3 - June 2020גרבר פליקסNo ratings yet

- Silo CalsDocument6 pagesSilo CalsYakubuNo ratings yet

- TCC94 Two Way Slabs TablesDocument5 pagesTCC94 Two Way Slabs TablesMihai JNo ratings yet

- Ceb804 Assign 1 PDFDocument22 pagesCeb804 Assign 1 PDFRandhir ChandNo ratings yet

- 297 - Pipe and Shell Design Tool Ver E4.01 MMDocument1 page297 - Pipe and Shell Design Tool Ver E4.01 MMBAHADIRNo ratings yet

- CK Tourqe CalculationDocument7 pagesCK Tourqe Calculationamit amity100% (1)

- Bolt Up CalculationDocument12 pagesBolt Up CalculationAniket GaikwadNo ratings yet

- NIC Components NSRN SeriesDocument5 pagesNIC Components NSRN SeriesNICCompNo ratings yet

- Steel Column Base PlateDocument17 pagesSteel Column Base PlateVAN HUNG TRANNo ratings yet

- Engineering Services LTD: CalculationDocument29 pagesEngineering Services LTD: CalculationtomNo ratings yet

- Design of Baseplate and Anchor Bolt - InstrumentationDocument6 pagesDesign of Baseplate and Anchor Bolt - InstrumentationParchuri PraveenNo ratings yet

- Pvi Mod.2 Calculation SheetDocument1 pagePvi Mod.2 Calculation SheetMehdi KeikhosravyNo ratings yet

- FFB4Document8 pagesFFB4prajjwal patidarNo ratings yet

- CivilBay Engineering XXX Design Project Shear Connection Shear-1 PDFDocument9 pagesCivilBay Engineering XXX Design Project Shear Connection Shear-1 PDFhemantcabhaleNo ratings yet

- Fin Plate ConnectionDocument2 pagesFin Plate ConnectionSudhakar Krishnamurthy100% (1)

- Spot Welding Strength CalculationDocument14 pagesSpot Welding Strength CalculationVenkateswaran venkateswaranNo ratings yet

- Shear Connection - Is 800-ModifiedDocument159 pagesShear Connection - Is 800-ModifiedDarshan Panchal100% (1)

- Shell CalculationsDocument3 pagesShell CalculationsBaher Elsheikh100% (7)

- Beam To Beam-Fin PlateDocument105 pagesBeam To Beam-Fin PlateGasthuri Devi100% (1)

- Design of Purlin & Runner-Ro-Final-Rev-0Document8 pagesDesign of Purlin & Runner-Ro-Final-Rev-0Sabrina ImloulNo ratings yet

- Gaskets - Graphite PDFDocument4 pagesGaskets - Graphite PDFSH1961No ratings yet

- Larsen & Toubro Limited: 1. Sectional PropertiesDocument8 pagesLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNo ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument1 pageAS4041 ASME B31 - 3 Pipe Wall ThicknesselleNo ratings yet

- 18261d2004 - Cad Internal LabDocument2 pages18261d2004 - Cad Internal LabnihildevunuriNo ratings yet

- Calculation Sheet: Design PhilosophyDocument18 pagesCalculation Sheet: Design PhilosophyrammohanNo ratings yet

- Branch RF CalcDocument6 pagesBranch RF CalcHarish Harish0% (1)

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFRakeshNo ratings yet

- API 650 RF Pad Calculation PDFDocument1 pageAPI 650 RF Pad Calculation PDFBimal DeyNo ratings yet

- F To G: 1 To 2: Spreadsheets To BS 8110 & EC2Document3 pagesF To G: 1 To 2: Spreadsheets To BS 8110 & EC2Cioabla BogdanNo ratings yet

- 05 CalDocument53 pages05 Calnatarajan RavisankarNo ratings yet

- Tes Tring Cover CalculationDocument7 pagesTes Tring Cover CalculationAhmad FaujiNo ratings yet

- EC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Document7 pagesEC2-BE-dubble Reinforced Beams SLS-crackwidth Rev6Dong LINo ratings yet

- Connection No: 34: LOADS (Worst Case Group No.112 & Element No.1120800)Document10 pagesConnection No: 34: LOADS (Worst Case Group No.112 & Element No.1120800)Stephen JamesNo ratings yet

- App 1 Cylindrical Shells - ASMEDocument2 pagesApp 1 Cylindrical Shells - ASMEwassim2014No ratings yet

- 03) PIPE193.7x8 V-BRACE - GUSSET PLT.Document114 pages03) PIPE193.7x8 V-BRACE - GUSSET PLT.Civil StructureNo ratings yet

- Design of Tension MembersDocument16 pagesDesign of Tension MembersElisha ShindeNo ratings yet

- Problem Input: Particulars UnitDocument43 pagesProblem Input: Particulars UnitChinmay PatilNo ratings yet

- 3 JSA For SealantDocument11 pages3 JSA For SealantAkbar SyahrezaNo ratings yet

- Concrete: KARDAN UniversityDocument49 pagesConcrete: KARDAN UniversityBibek BhattaraiNo ratings yet

- GED 104 Contemporary World - Reviewer ofDocument2 pagesGED 104 Contemporary World - Reviewer ofsiriusNo ratings yet

- Air Conditioning System Using Vehicle SuspensionDocument1 pageAir Conditioning System Using Vehicle SuspensionNikhil Lincoln0% (1)

- Potato ProjectDocument10 pagesPotato Projectkillerfox70No ratings yet

- NBP HR PlanDocument38 pagesNBP HR Planmuhammad qasim100% (1)

- Vampire Cortex Prime Conversion V.1Document38 pagesVampire Cortex Prime Conversion V.1Jeferson MoreiraNo ratings yet

- Lambert Ansc 491 Field Report Final 1Document10 pagesLambert Ansc 491 Field Report Final 1api-585093321No ratings yet

- DEVELOPMENT, UNDERDEVELOPMENT, POVERTY - Sample Research Proposal - SMUDocument6 pagesDEVELOPMENT, UNDERDEVELOPMENT, POVERTY - Sample Research Proposal - SMUEira ShahNo ratings yet

- Error Code Copier CanonDocument7 pagesError Code Copier Canonkaka_afie100% (12)

- CBAHI-2024-SurveyAgend 3 Days-1Document14 pagesCBAHI-2024-SurveyAgend 3 Days-1rhferanielNo ratings yet

- Dialogue Unit 8: Example of A DialogueDocument4 pagesDialogue Unit 8: Example of A DialogueIsfaNo ratings yet

- Department of Labor: 01 022Document6 pagesDepartment of Labor: 01 022USA_DepartmentOfLaborNo ratings yet

- Sloping Agricultural Land TechnologyDocument12 pagesSloping Agricultural Land TechnologyBe ChahNo ratings yet

- Final Exam Review Notes PDFDocument160 pagesFinal Exam Review Notes PDFDung TranNo ratings yet

- Lifestyle Management & Skill DevelopmentDocument53 pagesLifestyle Management & Skill DevelopmentRana SinghNo ratings yet

- Unit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 FinishDocument8 pagesUnit 1.14 - Shackles: 1.1 Body and Pin Forging 1.2 Heat Treatment 1.3 Finisheetua100% (2)

- BAI GIANG 75T English For TourismDocument35 pagesBAI GIANG 75T English For TourismRose DNNo ratings yet

- Cable TerminationDocument2 pagesCable TerminationElectrical RadicalNo ratings yet

- Introduction EM Waves WorksheetDocument3 pagesIntroduction EM Waves WorksheetUmer AbdullahNo ratings yet

- Nestle Brand AuditDocument71 pagesNestle Brand Auditapi-290866074100% (1)

- Old MacDonald LyricsDocument5 pagesOld MacDonald LyricsMarieNo ratings yet

- Total Physical ResponseDocument7 pagesTotal Physical ResponseDesak RossyanaNo ratings yet

- Ventura, Mary Mickaella R. - p.49 - Statement of Financial PositionDocument5 pagesVentura, Mary Mickaella R. - p.49 - Statement of Financial PositionMary VenturaNo ratings yet

- Fuse (Electrical) - WikipediaDocument14 pagesFuse (Electrical) - WikipediaNisar AhmedNo ratings yet

- Andhra Pradesh Medical Council: See Section-15C of A.P Medical Practitioners Registration (Amendment) Act, 2013Document3 pagesAndhra Pradesh Medical Council: See Section-15C of A.P Medical Practitioners Registration (Amendment) Act, 2013kirank_11No ratings yet

- New Form 12BBDocument2 pagesNew Form 12BBramanNo ratings yet

- AHA - Working On Slope RoofDocument2 pagesAHA - Working On Slope RoofTopsun EnergyNo ratings yet

- A Brief Note On Plants of Medicinal Importance To LivestockDocument84 pagesA Brief Note On Plants of Medicinal Importance To LivestockSunil100% (1)

- Lapres ProteinDocument65 pagesLapres ProteinPutri AnggreaniNo ratings yet