Professional Documents

Culture Documents

App 1 Cylindrical Shells - ASME

Uploaded by

wassim20140 ratings0% found this document useful (0 votes)

30 views2 pagesThis document provides specifications for cylindrical shell design according to ASME Code Section VIII, Division 1, Appendix 1-1 from 2017. It lists the design pressure, temperature, material, allowable stress value, diameters, wall thicknesses, joint efficiency, corrosion allowance, manufacturing tolerance, and minimum required thickness for two cylindrical shell designs. It then verifies that the actual thickness is greater than the minimum required thickness for both designs.

Original Description:

Calculation spreachsheet

Original Title

App 1 Cylindrical Shells _ASME

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides specifications for cylindrical shell design according to ASME Code Section VIII, Division 1, Appendix 1-1 from 2017. It lists the design pressure, temperature, material, allowable stress value, diameters, wall thicknesses, joint efficiency, corrosion allowance, manufacturing tolerance, and minimum required thickness for two cylindrical shell designs. It then verifies that the actual thickness is greater than the minimum required thickness for both designs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views2 pagesApp 1 Cylindrical Shells - ASME

Uploaded by

wassim2014This document provides specifications for cylindrical shell design according to ASME Code Section VIII, Division 1, Appendix 1-1 from 2017. It lists the design pressure, temperature, material, allowable stress value, diameters, wall thicknesses, joint efficiency, corrosion allowance, manufacturing tolerance, and minimum required thickness for two cylindrical shell designs. It then verifies that the actual thickness is greater than the minimum required thickness for both designs.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

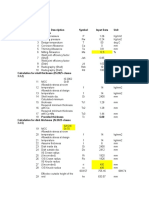

Cylindrical Shells according to ASME Code Section VIII, Division 1,

Appendix 1-1, 2017 Edition

Drawing no.:

Item no:

design pressure P = 1,40 MPa : 203,1 psi

design temperature T = 149,00 °C : 300,2 °F

material SA-403 316L

allowable stress value for the material S = 115,00 N/mm² : 16679,3 psi

outside diameter D = 33,40 mm : 1,3150 in.

nominal wall thickness tn. = 4,55 mm : 0,1791 in.

joint efficiency E E = 0,85

corrosion allowance: c1 = 0,00 mm : 0,0000 in.

manufacturing tolerance c2 = 0,57 mm : 0,0224 in.

outside radius Ro = 16,70 mm : 0,6575 in.

minimum required thickness t

= 0,24 mm : 0,0094 in.

tactual = tn-c1-c2 = 3,98 mm : 0,1567 in.

t ≤ tactual

0,24 mm ≤ 3,98 mm OK

status 1 T:\Design Verifications\00-Vorlagen\Excel\VIII-1\App 1 cylindrical shells

Cylindrical Shells according to ASME Code Section VIII, Division 1,

Appendix 1-1, 2017 Edition

Drawing no.:

Item no:

design pressure P = 1,81 MPa : 262,5 psi

design temperature T = 15,00 °C : 59,0 °F

material SA-403 316L

allowable stress value for the material S = 153,00 N/mm² : 22190,8 psi

outside diameter D = 33,40 mm : 1,3150 in.

nominal wall thickness tn. = 4,55 mm : 0,1791 in.

joint efficiency E E = 0,85

corrosion allowance: c1 = 0,00 mm : 0,0000 in.

manufacturing tolerance c2 = 0,57 mm : 0,0224 in.

outside radius Ro = 16,70 mm : 0,6575 in.

minimum required thickness t

= 0,23 mm : 0,0091 in.

tactual = tn-c1-c2 = 3,98 mm : 0,1567 in.

t ≤ tactual

0,23 mm ≤ 3,98 mm OK

status 1 T:\Design Verifications\00-Vorlagen\Excel\VIII-1\App 1 cylindrical shells

You might also like

- Calculo de Espesores de Tuberias ASME B31.3Document2 pagesCalculo de Espesores de Tuberias ASME B31.3Manuel100% (1)

- Thickness CalcuationDocument6 pagesThickness CalcuationRanjan KumarNo ratings yet

- IBR Design Calculations - FinalDocument6 pagesIBR Design Calculations - Finalshazan100% (1)

- Nozzle CalculationsDocument2 pagesNozzle CalculationsBaher Elsheikh100% (3)

- Thickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWDocument117 pagesThickness Calculation ASME B31.3 (Revised) HP LOOP ELBOWGohar ZamanNo ratings yet

- Pipe Wall Thickness Calculation ASME B31.8Document16 pagesPipe Wall Thickness Calculation ASME B31.8DikaAnindyajati100% (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Abid Ali SAP Resume (Experience)Document3 pagesAbid Ali SAP Resume (Experience)Abid AliNo ratings yet

- Calculation of Flat Covers According To UG-34: Drawing No.: ItemDocument3 pagesCalculation of Flat Covers According To UG-34: Drawing No.: Itemwassim2014No ratings yet

- Calculation AC-01 Eagle NiceDocument3 pagesCalculation AC-01 Eagle NiceJoulee NurimanNo ratings yet

- Pipe Guide and Welding Connection - h150x125x14x8.5Document13 pagesPipe Guide and Welding Connection - h150x125x14x8.5BenchNo ratings yet

- Calc' Diesel Fuel (Rev)Document10 pagesCalc' Diesel Fuel (Rev)joko_tm02No ratings yet

- EN Calculation of Storage TankDocument3 pagesEN Calculation of Storage TanknodyyyNo ratings yet

- Design Calculation of 2 KL Lin Storage Manf Si. No.: Vs/Asme/03 DOC NO.: PVL/VAL/2021 REV. NO.: 0 DATE: 24 SEPTEMBER, 2021Document1 pageDesign Calculation of 2 KL Lin Storage Manf Si. No.: Vs/Asme/03 DOC NO.: PVL/VAL/2021 REV. NO.: 0 DATE: 24 SEPTEMBER, 2021pratyaNo ratings yet

- AS4041 ASME B31 - 3 Pipe Wall ThicknessDocument1 pageAS4041 ASME B31 - 3 Pipe Wall ThicknesselleNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument1 pageS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- Larsen & Toubro Limited: 1. Sectional PropertiesDocument8 pagesLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNo ratings yet

- Calc Wall Thickness B31.8Document1 pageCalc Wall Thickness B31.8panjiajinugroho23No ratings yet

- Piping Calculation Program For ASME B31 1 CodeDocument3 pagesPiping Calculation Program For ASME B31 1 CodeAMIT100% (2)

- Nozzle Check 211039CDocument3 pagesNozzle Check 211039CGaurav BedseNo ratings yet

- PTB E4.3.2 Conical ShellDocument2 pagesPTB E4.3.2 Conical ShellginoNo ratings yet

- Manual Roark FormulaDocument5 pagesManual Roark FormulaPeja JusohNo ratings yet

- Eccentric FootingDocument10 pagesEccentric FootingRishi KumarNo ratings yet

- Exemplo Memorial de CalculoDocument25 pagesExemplo Memorial de CalculoFernando LimaNo ratings yet

- Pipe Wall Thickness CalculationDocument1 pagePipe Wall Thickness Calculationmahesh070No ratings yet

- 6.0 Design of Cylindrical ContainerDocument3 pages6.0 Design of Cylindrical ContainerJayNo ratings yet

- WRC CalculationsDocument20 pagesWRC Calculationsanu radha50% (2)

- WT Calculation - Pipelines With CRA CladDocument6 pagesWT Calculation - Pipelines With CRA CladShankar VadivelNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- Torispherical Head TolvaDocument1 pageTorispherical Head TolvaFabio Augusto Hincapie HenaoNo ratings yet

- Calculation Sheet 03Document2 pagesCalculation Sheet 03kkgcNo ratings yet

- Thickness Calculations For - 406.4 MM Dia of Pipe For Pressure MainDocument1 pageThickness Calculations For - 406.4 MM Dia of Pipe For Pressure MainRamsuNo ratings yet

- Bellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004Document4 pagesBellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004himsdNo ratings yet

- F-0201 Special Blind Calculation (N9)Document2 pagesF-0201 Special Blind Calculation (N9)rustamriyadiNo ratings yet

- 244 31300 15 - enDocument5 pages244 31300 15 - enreza_azadNo ratings yet

- Reinforcement Calculations For Nozzle (N1) : OD ID Thick NessDocument15 pagesReinforcement Calculations For Nozzle (N1) : OD ID Thick NessMuhammad Hassan MaqsoodNo ratings yet

- Calculation AC-1 SunjinDocument3 pagesCalculation AC-1 SunjinJoulee NurimanNo ratings yet

- Project Name: Component Name:water Tank Base M11, V13 Mom Capacity 117.31 Shear Capacity 130.16Document10 pagesProject Name: Component Name:water Tank Base M11, V13 Mom Capacity 117.31 Shear Capacity 130.16Bibek WagleNo ratings yet

- EJ CalculationDocument16 pagesEJ CalculationAmit NayakNo ratings yet

- Beam Design With Crackwidth CalculationDocument16 pagesBeam Design With Crackwidth CalculationFazilat Mohammad ZaidiNo ratings yet

- Allowable Stress SA 285 GR CDocument4 pagesAllowable Stress SA 285 GR Cdianita nurnandaNo ratings yet

- PTB E4.4.2 Conical Shell (2017)Document3 pagesPTB E4.4.2 Conical Shell (2017)NicolaSaviliNo ratings yet

- S-Stamp Calculation Nozzle ShellDocument4 pagesS-Stamp Calculation Nozzle ShellmukeshNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- S.No Description Symbol Input Data Unit Design DataDocument2 pagesS.No Description Symbol Input Data Unit Design DataThiru AnanthNo ratings yet

- MP Condensate Flash VesselDocument4 pagesMP Condensate Flash VesselGanesh BhardwajNo ratings yet

- 07a. MR MDF TECHNICAL DATADocument2 pages07a. MR MDF TECHNICAL DATAsacdawoodNo ratings yet

- RC Beam - CantileverDocument2 pagesRC Beam - CantilevermayphyoNo ratings yet

- Calculation of RC PAD2Document1 pageCalculation of RC PAD2m 418No ratings yet

- Design of Purlin & Runner-Ro-Final-Rev-0Document8 pagesDesign of Purlin & Runner-Ro-Final-Rev-0Sabrina ImloulNo ratings yet

- Head Types DemoDocument12 pagesHead Types DemoAKSHAY BHATKARNo ratings yet

- Joint Efficiency DemoDocument12 pagesJoint Efficiency DemoAKSHAY BHATKARNo ratings yet

- Wall Thickness 2Document18 pagesWall Thickness 2Imam Zulfir RamandhaNo ratings yet

- Blind Calculation - RoarkDocument10 pagesBlind Calculation - Roarkrustamriyadi100% (2)

- Pipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)Document1 pagePipe Wall Thickness Calculation (As Per Asme B31.3 Section 304.1.2)farhadNo ratings yet

- Strip FootingDocument8 pagesStrip FootingAbhay SuwalNo ratings yet

- Slab Reinforcement Considering 1m-StripDocument2 pagesSlab Reinforcement Considering 1m-StripAnonymous ya6gBBwHJFNo ratings yet

- Design of Inlet ChamberDocument2 pagesDesign of Inlet ChamberRaju SainiNo ratings yet

- Pipe Schedule ChartDocument1 pagePipe Schedule Chartwassim2014No ratings yet

- NR13 em InglesDocument16 pagesNR13 em InglesTaniucha1100% (5)

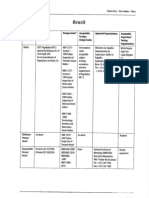

- Brazil Regulation For Pressure EquipmentDocument2 pagesBrazil Regulation For Pressure Equipmentwassim2014No ratings yet

- App 1 Cylindrical Shells - ASMEDocument2 pagesApp 1 Cylindrical Shells - ASMEwassim2014No ratings yet

- Hour MeDocument4 pagesHour MeAshraf RoszoporNo ratings yet

- Senior Piping DesignerDocument2 pagesSenior Piping Designerapi-77709853No ratings yet

- Data Structures and Algorithms: (CS210/ESO207/ESO211)Document23 pagesData Structures and Algorithms: (CS210/ESO207/ESO211)Moazzam HussainNo ratings yet

- Vray Material Settings: COMP 423: Cadd For ArchitectureDocument18 pagesVray Material Settings: COMP 423: Cadd For ArchitectureMarvin GonzalesNo ratings yet

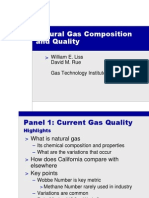

- Gas Technology Institute PresentationDocument14 pagesGas Technology Institute PresentationAris KancilNo ratings yet

- May PMDocument45 pagesMay PMR MathirajNo ratings yet

- HTML Meta TagsDocument4 pagesHTML Meta Tagsmamcapiral25No ratings yet

- FORM Inspection Test Plan MMPDocument8 pagesFORM Inspection Test Plan MMPRicky Stormbringer ChristianNo ratings yet

- What We Offer.: RemunerationDocument8 pagesWhat We Offer.: Remunerationsurabhi mandalNo ratings yet

- Dynamo - WikipediaDocument13 pagesDynamo - WikipediaIKENNANo ratings yet

- TXL 025 12s Datasheet 1 en PDFDocument11 pagesTXL 025 12s Datasheet 1 en PDFJulianCitoNo ratings yet

- Projects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationDocument2 pagesProjects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationAjay DuranNo ratings yet

- 06668967Document10 pages06668967PECMURUGANNo ratings yet

- Realistic Equations of StateDocument94 pagesRealistic Equations of Stateaman09752No ratings yet

- 5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop SchematicsDocument46 pages5e17f Toshiba Satellite l40 Compal La9862p Compal La9862p r10 Laptop Schematicsamier jrs100% (1)

- Mechanical Spring MEDocument89 pagesMechanical Spring MEimranNo ratings yet

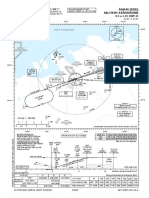

- I/G/O I/G/O A/M/I: Instrument Approach Chart - IcaoDocument1 pageI/G/O I/G/O A/M/I: Instrument Approach Chart - IcaoMIkołaj MorzeNo ratings yet

- Ammendement No.1 - List of Approved VendorsDocument3 pagesAmmendement No.1 - List of Approved VendorsLakhwant Singh KhalsaNo ratings yet

- Mastering Bitcoin PDFDocument282 pagesMastering Bitcoin PDFdoanminhNo ratings yet

- Comparacion Planta Meg - TegpdfDocument18 pagesComparacion Planta Meg - TegpdfJulian RomeroNo ratings yet

- ReleaseNotes MimicsMedical 21.0Document24 pagesReleaseNotes MimicsMedical 21.0陳司瀚No ratings yet

- P45-69Z V3.0 Schematic DiagramDocument10 pagesP45-69Z V3.0 Schematic DiagramAhmed El SharkawyNo ratings yet

- Catalogo TiboxDocument5 pagesCatalogo Tiboxfabiola100% (1)

- Dax Patel CVDocument1 pageDax Patel CVPriyanshNo ratings yet

- Tabl Navegacion Aqua SignalDocument4 pagesTabl Navegacion Aqua SignalNelson Aguirre BravoNo ratings yet

- Random PDFDocument15 pagesRandom PDFgreeblemeebleNo ratings yet

- Ricoh Shotmaster ZoomDocument17 pagesRicoh Shotmaster Zoommanana mappleNo ratings yet

- UNIT - 1 (Data Structure Using C/C++) .: Definition of AlgorithmDocument2 pagesUNIT - 1 (Data Structure Using C/C++) .: Definition of AlgorithmArjun BhargavaNo ratings yet

- Carbon Regeneration KilnsDocument3 pagesCarbon Regeneration KilnsLuis LabradorNo ratings yet

- Top 10 Masturbation Tips From WomenDocument3 pagesTop 10 Masturbation Tips From WomengmeadesNo ratings yet