Professional Documents

Culture Documents

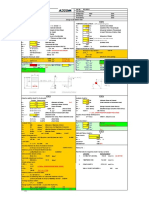

Bellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004

Uploaded by

himsd0 ratings0% found this document useful (0 votes)

9 views4 pagesOriginal Title

NORMAL OPERATION

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views4 pagesBellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004

Uploaded by

himsdCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

LONESTAR INDUSTRIES PAGE 1 OF 4

BELLOWS CALCULATION , UNREINFORCED ASME SEC VIII DIV I APPX 26 EDITION 2004

Customer Name DIPESH ENGINEERING WORKS

Type SINGLE EXPANSION JOINT

Size 200 NB

Tag. no CND-RX08-01

Design Number 2673-R1

Condition NORMAL OPERATION

Type 1 SINGLE

Nominal Bore 200 mm

Pipe OD 219.0 mm

Bellow ID Db = 219 mm

Design Pressure P= 6.12 Kg/cm^2

Design Temperature T= -30 Deg C

Bellow Material A 240 TYP 304

Allowable stress at Working Temp for bellows S= 20000 Psi

Allowable stress at Working Temp for collar Sc = 20000 Psi

Yield Strength at Working Temp for bellows material in

the Annealed condition from the applicable code Syh = 30000 Psi

Yield Strength at Room temp of the actual bellow

material in the Annealed condition from the

certified test report Sym= 30000 Psi

Yield Strength at Room temp of the actual bellow

material in the Annealed condition from the

applicable code Syc= 30000 Psi

Yield strength at design temperature of the

acutal bellows material after completion of bellows

forming and any applicable heat treatment Sy= 2.3*Syh

= 2.3*30000

= 69,000

Modulus of elasticity at Working Temp for bellow Eb= 28732941 Psi

Modulus of elasticity at Room Temp for bellow Eo= 28300000 Psi

Modulus of elasticity at working Temp for collar Ec= 28732941 Psi

Bellow OD = Db + 2nt + 2 * w

= 219+(2*1*0.63)+(2*18)

= 256.26 mm

Depth of Convoluion w= 18 mm

Pitch of Convolution q= 15 mm

Bellow Thickness t= 0.63 mm

Number Of Plys n= 1 nos

Tangent Length Lt= 20 mm

Collar Length Lc= 20 mm

Bellow tangent collar thickness tc= 1 mm

Axial Extention Xe= 3 mm

Axial Compression Xc= 0 mm

Lateral Movement y= 0 mm

Angular Movement θ= 0 Deg

Number of Convolutions N= 6

LONESTAR INDUSTRIES PAGE 2 OF 4

BELLOWS CALCULATION , UNREINFORCED ASME SEC VIII DIV I APPX 26 EDITION 2004

Customer Name DIPESH ENGINEERING WORKS

Type SINGLE EXPANSION JOINT

Size 200 NB

Tag. no CND-RX08-01

Design Number 2673-R1

Condition NORMAL OPERATION

Tangent Diameter Dc= Db + 2nt + tc

= (219+(2*1*0.63)+1)

= 221.26 mm

Mean Dia Dm= Db + w + nt

= 219+18+(1*0.63)

= 237.63 mm

Reduced Thickness tp= t * (Db / Dm) ^ 0.5

= (0.63*(219/237.63)^0.5)

= 0.605 mm

Factor considering the stiffening effect of k= Lt / (1.5 * (Db * t)^0.5)

the attachment weld and the end convolution = 20/(1.5*(219*0.63)^0.5) 1.135

on the pressure capacity of bellow tangent = 1.000

Cross sectional of bellows convolutions Ac= (0.571 * q + 2w )* tp * n

= ((0.571*15)+(2*18))*0.605*1

= 26.962 mm^2

Equivalent axial movement per convolution exe= Xe/N

= 3/6

= 0.500

Equivalent axial movement per convolution exc= Xc/N

= 0/6

= 0.000

ex= exe or exc which ever is greater

ex= 0.500

Equivalent axial movement per convolution ey= (3 * Dm * y / (N * (Lb- X)))

For lateral Deflection = (3*237.63*0)/(6*(90-0))

= 0.000

Lb= q*N

= (15*6)

= 90

Lu= Lb

= 6*15

90

Angular= 0*3.1414/180

= 0 Radians

Equivalent axial movement per convolution eθ= θ * Dm / 2N

For Angular Deflection = 0*237.63/(2*6)

= 0.00

Total equivalent axial movement per convolution e= ex + ey + eθ

= 0.500+0+0

= 0.500

LONESTAR INDUSTRIES PAGE 3 OF 4

BELLOWS CALCULATION , UNREINFORCED ASME SEC VIII DIV I APPX 26 EDITION 2004

Customer Name DIPESH ENGINEERING WORKS

Type SINGLE EXPANSION JOINT

Size 200 NB

Tag. no CND-RX08-01

Design Number 2673-R1

Condition NORMAL OPERATION

C1= (q/2w)= 15/(2*18)

= 0.42

C2= (q/2.2(Dm*tp)^0.5)= 15/(2.2*(237.63*0.605)^0.5)

= 0.57

From Table Cp= 0.6997

From Table Cf= 1.5396

From Table Cd= 1.6385

Material Strength Factor Cm= 3 (For cold Working)

Longitudinal Weld Joint Efficiency for bellow Cwb= 1

Longitudinal Weld Joint Efficiency for collar Cwc= 1

PRESSURE STRESS CALCULATION FOR UNREINFORCED BELLOW

Tangent Circumferential Membrane Stress ( S1 )= P*(Db + n*t)^2 * Lt*Eb*K / (2 * (n*t*Eb*Lt(Db + n*t))

Due to pressure = + (tc*K*Ec*Lc*Dc))

= (6.12*14.2*(219+(1*0.63))^2*20*28732941*1.000) /

(2*(1*0.63*28732941*20*(219 +

(1*0.63))+(1*1.000*28732941*20*221.26)))

= 5,828.29 Psi

Coller Circumferential Membrane Stress ( S1' )= P*(Dc)^2 * Lt * Ec * K / (2 *(n*t*Eb*Lt*(Db + n*t))

Due to pressure = + (tc*K*Ec *Lc*Dc))

(6.12*14.2*221.26^2*20*28732941*1.000) /

(2*(1*0.63*28732941*20*(219+(1*0.63)) +

(1*1.000*28732941*20*221.26)))

= 6,199.05 Psi

End convolution Circumferential ( S2 E )= (q * Dm+(Lt*(Db+n*t))*P/(2*(Ac+n*tp*Lt))

Membrane Stress Due to pressure = (((15*237.63+(20*(219+1*0.63)))*6.12*14.2)/

(2*(26.962+(1*0.605*20)))

= 8,851.31 Psi

Intermediate convolution Circumferential ( S2 I)= q * Dm*P/2*Ac

Membrane Stress Due to pressure = ((15*237.63*6.12*14.2)/(2*26.962))

= 5,744.47 Psi

Bellows Meridional Membrane stress ( S3 )= P*w / (2 * n * tp)

Due to pressure = (6.12*14.2*18)/(2*1*0.605)

= 1,292.79 Psi

Bellows Meridional Bending Stress ( S4 )= (P / 2n) * (w / tp)^2 * Cp

Due to pressure = (6.12*14.2*0.69968/(2*1))*(18/0.605)^2

= 26,911.85 Psi

S3+S4= 1,292.79+26,911.85

= 28,204.64 Psi

CM*SA= 3*20000

= 60,000.00 Psi

EVALUATION

S1 < S 5,828.29 < 20000

S2 E < S 8,851.31 < 20000

S2 I < S 5,744.47 < 20000

S3+S4 < Cm * S 1,292.79 + 26,911.85 < 3 * 20000

S1' < Cwc * Sc 6,199.05 < 1 * 20000

ALL THE CONDITIONS ARE SATISFIED

LONESTAR INDUSTRIES PAGE 4 OF 4

BELLOWS CALCULATION , UNREINFORCED ASME SEC VIII DIV I APPX 26 EDITION 2004

Customer Name DIPESH ENGINEERING WORKS

Type SINGLE EXPANSION JOINT

Size 200 NB

Tag. no CND-RX08-01

Design Number 2673-R1

Condition NORMAL OPERATION

Bellows Meridional Membrane Stress due ( S5 )= Eb * (tp)^2 * e / (2 * w^3 * Cf)

to deflection = (28732941*0.605^2*0.5)/(2*18^3*1.5396)

= 292.82 Psi

Bellows Meridional bending Stress due ( S6 )= 5 * Eb * tp * e / (3 * w^2 * Cd)

to deflection = (5*28732941*0.605*0.5)/(3*18^2*1.63846)

= 27,288.10 Psi

Total Stress ( St )= 0.7*(S3+S4)+(S5+S6)

= 0.7*(1,292.79+26,911.85) +

292.82+27,288.10

= 47,324.17 Psi

LIMITING DESIGN PRESSURE

Based on column Instability (Both ends Rigdly Supported)

Lb/Db= 90 / 219

= 0.411

Transition Point Factor, Cz= (4.72 *N * Kb * q^2 / (Sy * Db * Ac))^0.5

= ((4.72*6*34.099*14.2 * 100 *15^2) /

(69,000*219*26.962))^0.5

= 0.870 > 0.411

Coloumn Stability ( Psc )= (0.87* Ac*Sy / Db*q)*(1-(0.73 * Lb)/(Cz *Db)))

(((0.87*26.962*69,000) /

(219*15*14.2))*(1-((0.73*90))/(0.870*219))))

= 22.733 Kg/cm^2 > 6.12 Kg/cm^2

LIMITING DESIGN PRESSURE

Inplane instability stress ratio δ= S4/(3*S2 I)

= 26,911.85/(3*5,744.47)

= 1.562

Inplane instability stress interaction factor α= 1+ 2*δ^2 +(1-2*δ^2 + 4 * δ^4)^0.5

= 1+(2*1.562^2)+(1-(2*1.562^2) +

(4*1.562^4))^0.5

= 10.344

Inplane Instability ( Psi )= 1.02*Ac*Sy/(Dm**(α)^0.5)

= 1.02*26.962*69,000/(237.63*15*14.2*(10.344)^0.5)

= 11.66 Kg/cm^2 > 6.12 Kg/cm^2

Poison's Ratio(v) = 0.34

Axial Spring Rate ( Kb ) = 3.14 * Dm * Eb * tp^3 * n /(2*(1-v^2)*w^3 * Cf*N)

= (3.14*237.63*28732941*0.605^3*1) /

(2*(1-0.3^2)*14.2 * 100 *18^3*1.5396*6)

= 34.099 Kg/mm

IF((Kg*(Eo/Eb)*St)>65000, (Ko/((Kg*(Eo/Eb)*St)-So))^2 ELSE

Cycle Life ( Nc )=

(Ko/((Kg*(Eo/Eb)*St)-So))^2))

IF((Kg*(Eo/Eb)*St)>65000, Ko=5.2x10 ^6, So=38300 ELSE

=

Ko=6.7x10 ^6, So=30600)

((Kg*(Eo/Eb)*St)= 46611.10 < 65000

(46611.1008615512 < 65000,((6.7* 10^6)/((1 * (28300000 /

=

28732941) * 47,324.17) - 30600))^2)

= 175108 CYCLES

You might also like

- EJ CalculationDocument16 pagesEJ CalculationAmit NayakNo ratings yet

- Pier Cap DesignDocument5 pagesPier Cap DesignsanilNo ratings yet

- Aci Beam Crack Width Top XDocument2 pagesAci Beam Crack Width Top XParthiban ArivazhaganNo ratings yet

- Pier Wall DesignDocument5 pagesPier Wall DesignsanilNo ratings yet

- Tubesheet Calculation: Step 1Document2 pagesTubesheet Calculation: Step 1Bintang LazuardiNo ratings yet

- Beam Design With Crackwidth CalculationDocument16 pagesBeam Design With Crackwidth CalculationFazilat Mohammad ZaidiNo ratings yet

- Aci Beam Crack Width Bot ZDocument2 pagesAci Beam Crack Width Bot ZParthiban ArivazhaganNo ratings yet

- RC Beam Torsion Design BS8110Document2 pagesRC Beam Torsion Design BS8110saman2580No ratings yet

- Design of Precast BeamDocument4 pagesDesign of Precast BeamMUTHUKKUMARAMNo ratings yet

- Middle Wall (All Intermediate Walls)Document3 pagesMiddle Wall (All Intermediate Walls)epe civilNo ratings yet

- Base Slab & Crack Width Check - ACI CodeDocument6 pagesBase Slab & Crack Width Check - ACI CodensureshbabuNo ratings yet

- Design of Inlet ChamberDocument2 pagesDesign of Inlet ChamberRaju SainiNo ratings yet

- 11design of Axially Loaded Column With, Uniaxial MomentDocument3 pages11design of Axially Loaded Column With, Uniaxial MomentJames AswaNo ratings yet

- TM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)Document13 pagesTM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)jhunkujha11No ratings yet

- First Floor RC Slab Design (EN1992)Document5 pagesFirst Floor RC Slab Design (EN1992)Shingirai JoeNo ratings yet

- Beam DesignDocument9 pagesBeam Designمحمد شاويNo ratings yet

- Design of BearingsDocument24 pagesDesign of BearingsFarrukh RizwanNo ratings yet

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- EA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Document2 pagesEA - Check of Punching Shear in Flat Slabs & Raft ACI 318M-14 v1.0Imaduddin KhajaNo ratings yet

- Clien:: Design Calculation of Expansion Bellow As Per App. 5 & 26 of Asme Sec. Viii, Div 1 2004edDocument4 pagesClien:: Design Calculation of Expansion Bellow As Per App. 5 & 26 of Asme Sec. Viii, Div 1 2004edvijay10484No ratings yet

- Anchor Bolt - AISC ASDDocument7 pagesAnchor Bolt - AISC ASDameyyammaiNo ratings yet

- Design Paramters: Structural Analysis Design Report F1 IsolatedDocument1 pageDesign Paramters: Structural Analysis Design Report F1 Isolatedanonymousupldr666No ratings yet

- 5.7 Pile CapDocument2 pages5.7 Pile CapPhilip ChanNo ratings yet

- Beam Referance Solving Units: Existing ConditionsDocument5 pagesBeam Referance Solving Units: Existing ConditionsSUBHA JNo ratings yet

- HDD Calculation - CH 15Document23 pagesHDD Calculation - CH 15Binay Kumar100% (1)

- Design Calculation For Column (Staad Member No. 1219) : Section PropertiesDocument63 pagesDesign Calculation For Column (Staad Member No. 1219) : Section PropertiesSreeraja SreevilasanNo ratings yet

- Beam DesignDocument9 pagesBeam Designujaval shah100% (1)

- Grade Slab ACI 150thkDocument7 pagesGrade Slab ACI 150thkraahul_nNo ratings yet

- RCC14 Crack WidthDocument4 pagesRCC14 Crack WidthFatin Amilin MustaparNo ratings yet

- PC3 QmaxDocument1 pagePC3 QmaxCuong TranNo ratings yet

- Welding Calculation: Job No. Job: Section: Designed By: Sheet No. Subject: DateDocument37 pagesWelding Calculation: Job No. Job: Section: Designed By: Sheet No. Subject: DateMatthew CHANNo ratings yet

- Floating RC Slab Design (EN1992)Document5 pagesFloating RC Slab Design (EN1992)Shingirai JoeNo ratings yet

- Design of Beam: Effective Depth, D D' D'/D Mu/bd2 Me1 Mu, LimDocument8 pagesDesign of Beam: Effective Depth, D D' D'/D Mu/bd2 Me1 Mu, LimVhârÆt Ķħâptäđi KhàdkâNo ratings yet

- Slab Thickness : 0.92 KN 8.825kN/mDocument6 pagesSlab Thickness : 0.92 KN 8.825kN/mhamza hanifNo ratings yet

- Design of Cantilever-BeamDocument8 pagesDesign of Cantilever-BeamDusmanta Kumar BeheraNo ratings yet

- Design of BeamDocument15 pagesDesign of Beamg s venkata subramaniNo ratings yet

- Greenwich Peninsula: Ground Slab - Building B SK 04-Jan-2022 KK - 4464Document4 pagesGreenwich Peninsula: Ground Slab - Building B SK 04-Jan-2022 KK - 4464christi SNo ratings yet

- Appendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Document2 pagesAppendix 10: Base Slab Crack Width Calculation (As Per IS 456: ANNEX: F)Md Nadeem Akhtar100% (1)

- Calculation Sheet: Test Job Member Design For SB2Document2 pagesCalculation Sheet: Test Job Member Design For SB2bungykitNo ratings yet

- FFB4Document8 pagesFFB4prajjwal patidarNo ratings yet

- Sci - Lift Calculation - 1Document6 pagesSci - Lift Calculation - 1Simon LsmNo ratings yet

- Larsen & Toubro Limited: 1. Sectional PropertiesDocument8 pagesLarsen & Toubro Limited: 1. Sectional Propertiesprajjwal patidarNo ratings yet

- Crack WidthDocument5 pagesCrack WidthchanakyaNo ratings yet

- Example 5.1Document6 pagesExample 5.1Aisyah JamalNo ratings yet

- Annexure-2 (Section Design Calcs)Document107 pagesAnnexure-2 (Section Design Calcs)blisscutest beagleNo ratings yet

- Aluminium Cladding DesignDocument2 pagesAluminium Cladding DesigntkofaiNo ratings yet

- Unbraced RC Circular Column Design - Sample Calculation (AS3600)Document4 pagesUnbraced RC Circular Column Design - Sample Calculation (AS3600)Tiam MarapeNo ratings yet

- Torsional Strength As Per 5100.5.2017: Beam DataDocument8 pagesTorsional Strength As Per 5100.5.2017: Beam DataSambhav PoddarNo ratings yet

- Stair Case CalcuationsDocument2 pagesStair Case CalcuationsraghavendraNo ratings yet

- 10 No. 16 MM Diameter Longitudinal Bars: Project Job RefDocument4 pages10 No. 16 MM Diameter Longitudinal Bars: Project Job RefErwin MaguideNo ratings yet

- Isolated FootingsDocument12 pagesIsolated FootingsGovendan GopalakrishnanNo ratings yet

- Design of MACH Deck Panel - Slab (300mm THK)Document7 pagesDesign of MACH Deck Panel - Slab (300mm THK)Sankar AnandNo ratings yet

- Plinth Beams DesignDocument24 pagesPlinth Beams DesignRathinavel VenkateshwaranNo ratings yet

- TCC81 Foundation Pads-2 (343kn - 272kN)Document1 pageTCC81 Foundation Pads-2 (343kn - 272kN)Yap Wei XianNo ratings yet

- Calculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK DataDocument3 pagesCalculation Sheet: 7007 Design For The Slab - Top & Bottom Mesh PP BK Dataasif billalNo ratings yet

- 4.10. Pier Pile Cap Design: BR - CP7-5B (KTM) CH 39+884 To CH 39+954Document3 pages4.10. Pier Pile Cap Design: BR - CP7-5B (KTM) CH 39+884 To CH 39+954saubhagya majhiNo ratings yet

- Braced RC Circular Column Design - Sample Calculation (As 3600)Document5 pagesBraced RC Circular Column Design - Sample Calculation (As 3600)Tiam MarapeNo ratings yet

- Design of Slabs: Input DataDocument6 pagesDesign of Slabs: Input Datagewegw3gNo ratings yet

- BeamDocument4 pagesBeamPraYush RajbhandariNo ratings yet

- K 103 ContentDocument24 pagesK 103 ContentAixa BerchiNo ratings yet

- Bellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004Document4 pagesBellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004himsdNo ratings yet

- Exchanger PDFDocument2 pagesExchanger PDFmujahidali500No ratings yet

- Bellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004Document4 pagesBellows Calculation, Unreinforced Asme Sec Viii Div I Appx 26 Edition 2004himsdNo ratings yet

- Agitator DesignDocument130 pagesAgitator DesignAdrales Kristine75% (4)

- Agitator DesignDocument130 pagesAgitator DesignAdrales Kristine75% (4)

- U.K.Singh Manufacturing ProcessesDocument290 pagesU.K.Singh Manufacturing ProcessesGirish Dey100% (7)

- 61014gb7 PDFDocument4 pages61014gb7 PDFSivateja NallamothuNo ratings yet

- 61014gb7 PDFDocument4 pages61014gb7 PDFSivateja NallamothuNo ratings yet

- Design of Process Equipment - Kanti Mahajan - 2nd EditionDocument337 pagesDesign of Process Equipment - Kanti Mahajan - 2nd Editionhimsd100% (1)

- 05 PumpsDocument80 pages05 PumpsRoberto O'ConnorNo ratings yet

- ASMEBPETube FittingsDocument2 pagesASMEBPETube FittingshimsdNo ratings yet

- Energy Performance Assessment of Heat Exchangers: Overall Heat Transfer Coefficient, UDocument18 pagesEnergy Performance Assessment of Heat Exchangers: Overall Heat Transfer Coefficient, USATISH PAWARNo ratings yet

- U.K.Singh Manufacturing ProcessesDocument290 pagesU.K.Singh Manufacturing ProcessesGirish Dey100% (7)

- Tall Stack Design HelpDocument4 pagesTall Stack Design HelphimsdNo ratings yet

- NR13 em InglesDocument16 pagesNR13 em InglesTaniucha1100% (5)

- Vertical Pressure VesselDocument5 pagesVertical Pressure VesselEnriqueGDNo ratings yet

- 6533 1Document23 pages6533 1Er Ravinder Reddy DevireddyNo ratings yet

- Questions and Answers About (Heat Ex Changers) - FacebookDocument13 pagesQuestions and Answers About (Heat Ex Changers) - FacebookhimsdNo ratings yet

- AVESTA POLARIT - Stainless Steels - Their Properties and Their Suitability For WeldingDocument11 pagesAVESTA POLARIT - Stainless Steels - Their Properties and Their Suitability For Weldingmirza_adil99No ratings yet

- Carmagen 3 10Document4 pagesCarmagen 3 10Srinivas KeshavamurthyNo ratings yet

- Over Voltage ProtectionDocument8 pagesOver Voltage ProtectionPKNo ratings yet

- Chapter 12 STSDocument7 pagesChapter 12 STSCute kittyNo ratings yet

- Pages From Pipenet Transient (Surge)Document2 pagesPages From Pipenet Transient (Surge)absahkahNo ratings yet

- Nadca - Overview of Defets in Die CastingDocument197 pagesNadca - Overview of Defets in Die CastingJayabharath Rajadurai100% (8)

- Cryocooler 2Document3 pagesCryocooler 2nikhil3005No ratings yet

- Reinforcement WorksheetionicbondingDocument2 pagesReinforcement Worksheetionicbondingapi-24977735825% (4)

- Modern Pulley AnalysisDocument16 pagesModern Pulley AnalysisMariappan ArumugamNo ratings yet

- BOA Expansion Joints Guide PDFDocument428 pagesBOA Expansion Joints Guide PDFZoranNo ratings yet

- Oceanography For General Studies UPSC Civil Services Exam: Short Notes PDFDocument71 pagesOceanography For General Studies UPSC Civil Services Exam: Short Notes PDFHari ShankarNo ratings yet

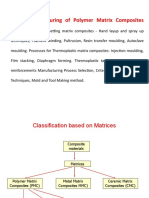

- UNIT-II: Manufacturing of Polymer Matrix CompositesDocument67 pagesUNIT-II: Manufacturing of Polymer Matrix CompositesVsr RaoNo ratings yet

- Lecture 1 Acoustic FundamentalsDocument50 pagesLecture 1 Acoustic FundamentalsDee PijanaNo ratings yet

- Tinuvin 928: Technical Data SheetDocument3 pagesTinuvin 928: Technical Data SheetCarlotta C.No ratings yet

- Advances in Capillary Fluid ModellingDocument11 pagesAdvances in Capillary Fluid ModellingSudarshan AhireNo ratings yet

- Final ResearchDocument29 pagesFinal Researchshubham dhakulkarNo ratings yet

- Breakdown in Electronegative Gases, V-T Characteristics & Post Breakdown Phenomena Post Breakdown PhenomenaDocument22 pagesBreakdown in Electronegative Gases, V-T Characteristics & Post Breakdown Phenomena Post Breakdown PhenomenaAjeng PratiwiNo ratings yet

- N4 Electrotechnics April 2020 MemorandumDocument8 pagesN4 Electrotechnics April 2020 MemorandumPetro Susan BarnardNo ratings yet

- Shielding Gases ACM Vs CO2Document34 pagesShielding Gases ACM Vs CO2ukavathekar100% (2)

- MOOC Plasma Ricci 1aDocument13 pagesMOOC Plasma Ricci 1aJulio Balbin AriasNo ratings yet

- Pump Calcs PreDocument3 pagesPump Calcs PreaberraNo ratings yet

- Training Manual TM2500Document499 pagesTraining Manual TM2500lunadogger90% (29)

- heat-exchangers-TEMA TYPEDocument12 pagesheat-exchangers-TEMA TYPEvaibhavNo ratings yet

- Fiitjee: Solutions To Jee (Advanced) - 2020Document29 pagesFiitjee: Solutions To Jee (Advanced) - 2020Vikash KumarNo ratings yet

- Chapter8 - Design Theory & Procedure PDFDocument407 pagesChapter8 - Design Theory & Procedure PDFJunwhan KimNo ratings yet

- Cognizance Ias: JPSC Mains Answer Writing TestDocument7 pagesCognizance Ias: JPSC Mains Answer Writing TestAnshu RNo ratings yet

- ExtrusionDocument15 pagesExtrusionSaad Ur RehmanNo ratings yet

- In Memoriam Frank LeslieDocument17 pagesIn Memoriam Frank Leslieac.diogo487No ratings yet

- Al. (9), Though The Feature Here Is Less Pronounced. The: ReferencesDocument3 pagesAl. (9), Though The Feature Here Is Less Pronounced. The: ReferencesKrishna KumarNo ratings yet

- Thermal ConductivityDocument5 pagesThermal ConductivitySiva Kumar SalumuriNo ratings yet

- Chapter - Furnaces and RefractoriesDocument36 pagesChapter - Furnaces and Refractorieshasan_waqar2004No ratings yet