Professional Documents

Culture Documents

TM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)

Uploaded by

jhunkujha110 ratings0% found this document useful (0 votes)

2 views13 pagesOriginal Title

TM-CP1-PMT-0070 Att.4_Strength Calculation for Bellows (Sample)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

2 views13 pagesTM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)

Uploaded by

jhunkujha11Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 13

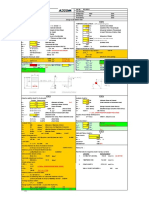

Attachment #4

Sample Strength Calculation for

Bellows Type Expansion Joint

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 166 OF 229

------------------------------------------------------------------------------------------

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 NORMAL OPERATING REV No. : 0

BELLOWS DESIGN ANALYSIS

ASME SECTION VIII DIVISION 1, APPENDIX 26 (2010 ED.+2011 ADD.)

REINFORCED TYPE (SINGLE)

DESIGN PRESSURE D.P= 48.000 (kg/cm2) 4.707 Mpa

DESIGN TEMPERATURE D.T= 400 ℃

BELLOWS MATERIAL SB443(N06625)

ALLOWABLE STRESS (Hot & Cold) Sabc= 22.077 (kg/mm2) 216.501 N/mm2

Sabh= 20.311 (kg/mm2) 199.181 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Eo= 21092.596 (kg/mm2) 206847.711 N/mm2

Eb= 17453.421 (kg/mm2) 171159.586 N/mm2

REINFORCING RING MATERIAL SA266-4

2

ALLOWABLE STRESS (Hot & Cold) Sarc= 14.062 (kg/mm ) 137.898 N/mm2

Sarh= 10.327 (kg/mm2) 101.273 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Erc= 20670.745 (kg/mm2) 202710.757 N/mm2

Er= 17453.421 (kg/mm2) 171159.586 N/mm2

MEAN METAL TEMPERATURE Shell= 5.00 Tube= 149.00 ℃

DIFFERENTIAL THERMAL GROWTH

= (1.152E-05*(5-21)-1.242E-05*(149-21))*4877 Ex= -8.653 mm

CROSS SECTIONAL METAL AREA OF ONE REINFORCE RING Ar= 3000.0 mm2

RATIO OF THE INTERNAL PRESSURE FORCE RESISTED BY THE BELLOWS

= A*Eb/(Ar*Er) R1 = 0.156

CONVOLUTION HEIGHT FACTOR FOR REINFORCED FACTOR

= 0.3-(100/(0.6*(D.P*14.223)^1.5+320))^2 Cr= 0.2999177

DESIGN MOVEMENT CONDITION

COND-----------------AXIAL(mm.)------------------------------LATERAL(mm.)----------------------------------ANGULAR(deg)----------CYCLES-

EXT.= 8.653 COMP.= 0.000 Y= 0.000 Z= 0.000 Θ= 0.000 1000

-(A) IS PRIMARY DESIGN CONDITION

C1= q/(2*w)= 0.5 C2=q/(2.2*(Dm*tp)0.5)= 0.4215

FACTOR 'Cp', 'Cf' & 'Cd' Cp= 0.658 Cf= 1.612 Cd= 1.773

CYLINDRICAL TANGENT INSIDE DIAMETER Db= 1686 mm

MATERIAL THICKNESS t= 3.175 mm

NOMINAL THICKNESS OF BELLOWS AFTER FORMING

(-)10% REDUCTION DUE TO LOW MATERIAL & MANUFACTURING TOLERANCE

= 0.9*t*(Db/Dm)^0.5 tp= 2.80 mm

NUMBER OF PLIES n= 1 Plies

NUMBER OF CONVOLUTIONS N= 3 corr.

PITCH OF BELLOWS CONVOLUTION q= 65 mm

HEIGHT OF BELLOWS CONVOLUTION w= 65 mm

FREE LENGTH OVER CONVOLUTIONS = (q*N) Lb= 195 mm

-EQUIVALENT AXIAL MOVEMENT PER 1(ONE) CONVOLUTION-

Δq TOTAL= 2.88 AXIAL= 2.88 LATERAL=0.00 ANGULAR=0.00 mm

REINFORCING MEMBER CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*Ar)*(1/(R1+1)) S'2= 7.890 (kg/mm2) 77.378 N/mm2

S'2 <= Cwr*Sarh S'2= 77.378 <= Cwr*Sarh= 101.273 O.K!

HKR Co.,Ltd. Prg No.: HKR-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 167 OF 229

------------------------------------------------------------------------------------------

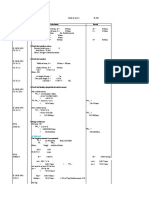

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 NORMAL OPERATING REV No. : 0

BELLOWS DESIGN ANALYSIS

BELLOWS TANGENT CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*(Db+n*t)^2*Lt*Eb*κ/(200*(n*t*Eb*Lt*(Db+n*t)+tc*κ*Ec*Lc*Dc)) S1 = 4.863 (kg/mm2) 47.689 N/mm2

S1 <= Sabh S1= 47.689 <= Sabh= 199.181 O.K!

CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*A)*(R1/(R1+1)) S2= 7.890 (kg/mm2) 77.378 N/mm2

S2 <= Cwb*Sabh S2= 77.378 <= Cwb*Sabh= 199.181 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO PRESSURE

2 2

= (0.85*D.P*(w-Cr*q))/(200*n*tp) S3= 3.314 (kg/mm ) 32.496 N/mm

MERIDIONAL BENDING STRESS DUE TO PRESSURE

= 0.85*D.P/(200*n)*((w-Cr*q)/tp)^2*Cp S4= 35.431 (kg/mm2) 347.457 N/mm2

S3 + S4 <= Kf*Sabh, Kf=3.0 (as formed bellows) S3+S4= 379.95 <= Kf*Sabh= 597.54 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO DEFLECTION

= Eb*tp^2*Δq/(2*(w-Cr*q)^3*Cf) S5= 1.300 (kg/mm2) 12.751 N/mm2

MERIDIONAL BENDING STRESS DUE TO DEFLECTION

= 5*Eb*tp*Δq/(3*(w-Cr*q)^2*Cd) S6= 64.025 (kg/mm2) 627.868 N/mm2

CALCULATED TOTAL STRESS

= 0.7*(S3+S4)+S5+S6 St= 906.586 N/mm2

CALCULATED FATIGUE LIFE CYCLES

= [Ko /{( kg*(Eo/Eb)*St)-So}]^2 Nalw= 3570 Cycles

AXIAL STIFFNESS

= π/(2*(1-vb^2))*(n/N)*Eb*Dm*(tp/(w-Cr*q))^3*(1/Cf) Kb= 2566.476 (Kg/mm) 25168.534 N/mm

MAXIMUM DESIGN PRESSURE BASED ON COLUMN INSTABILITY

= 0.3*π*kb/(N*q)*100 Psc= 1240.434 (kg/cm2) 121.645 Mpa

EFFECTIVE DIA. OF BELLOWS

= Db+w+t*η Dm= 1754.175 mm

PRESSURE THRUST

= Dm2*π*D.P/400 Pt= 1160050.7 (Kg) 11376210.7 N

HKR Co.,Ltd. Prg No.: HKR-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 168 OF 229

------------------------------------------------------------------------------------------

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 SHELL SIDE FULL VACUUM REV No. : 0

BELLOWS DESIGN ANALYSIS

ASME SECTION VIII DIVISION 1, APPENDIX 26 (2010 ED.+2011 ADD.)

REINFORCED TYPE (SINGLE)

DESIGN PRESSURE D.P= 1.050 (kg/cm2) 0.103 Mpa

DESIGN TEMPERATURE D.T= 149 ℃

BELLOWS MATERIAL SB443(N06625)

ALLOWABLE STRESS (Hot & Cold) Sabc= 22.077 (kg/mm2) 216.501 N/mm2

Sabh= 22.076 (kg/mm2) 216.492 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Eo= 21092.596 (kg/mm2) 206847.711 N/mm2

Eb= 20318.639 (kg/mm2) 199257.779 N/mm2

REINFORCING RING MATERIAL SA266-4

2

ALLOWABLE STRESS (Hot & Cold) Sarc= 14.062 (kg/mm ) 137.898 N/mm2

Sarh= 14.062 (kg/mm2) 137.898 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Erc= 20670.745 (kg/mm2) 202710.757 N/mm2

Er= 19896.787 (kg/mm2) 195120.825 N/mm2

MEAN METAL TEMPERATURE Shell= 5.00 Tube= 149.00 ℃

DIFFERENTIAL THERMAL GROWTH

= (1.152E-05*(5-21)-1.242E-05*(149-21))*4877 Ex= -8.653 mm

CROSS SECTIONAL METAL AREA OF ONE REINFORCE RING Ar= 3000.0 mm2

RATIO OF THE INTERNAL PRESSURE FORCE RESISTED BY THE BELLOWS

= A*Eb/(Ar*Er) R1 = 0.159

CONVOLUTION HEIGHT FACTOR FOR REINFORCED FACTOR

= 0.3-(100/(0.6*(D.P*14.223)^1.5+320))^2 Cr= 0.2204839

DESIGN MOVEMENT CONDITION

COND-----------------AXIAL(mm.)------------------------------LATERAL(mm.)----------------------------------ANGULAR(deg)----------CYCLES-

EXT.= 8.653 COMP.= 0.000 Y= 0.000 Z= 0.000 Θ= 0.000 1000

-(A) IS PRIMARY DESIGN CONDITION

0.5

C1= q/(2*w)= 0.5 C2=q/(2.2*(Dm*tp) )= 0.4215

FACTOR 'Cp', 'Cf' & 'Cd' Cp= 0.663 Cf= 1.701 Cd= 1.757

CYLINDRICAL TANGENT INSIDE DIAMETER Db= 1686 mm

MATERIAL THICKNESS t= 3.175 mm

NOMINAL THICKNESS OF BELLOWS AFTER FORMING

(-)10% REDUCTION DUE TO LOW MATERIAL & MANUFACTURING TOLERANCE

= 0.9*t*(Db/Dm)^0.5 tp= 2.80 mm

NUMBER OF PLIES n= 1 Plies

NUMBER OF CONVOLUTIONS N= 3 corr.

PITCH OF BELLOWS CONVOLUTION q= 65 mm

HEIGHT OF BELLOWS CONVOLUTION w= 65 mm

FREE LENGTH OVER CONVOLUTIONS = (q*N) Lb= 195 mm

-EQUIVALENT AXIAL MOVEMENT PER 1(ONE) CONVOLUTION-

Δq TOTAL= 2.88 AXIAL= 2.88 LATERAL=0.00 ANGULAR=0.00 mm

REINFORCING MEMBER CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*Ar)*(1/(R1+1)) S'2= 0.172 (kg/mm2) 1.688 N/mm2

S'2 <= Cwr*Sarh S'2= 1.688 <= Cwr*Sarh= 137.898 O.K!

HKR Co.,Ltd. Prg No.: HKR-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 169 OF 229

------------------------------------------------------------------------------------------

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 SHELL SIDE FULL VACUUM REV No. : 0

BELLOWS DESIGN ANALYSIS

BELLOWS TANGENT CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*(Db+n*t)^2*Lt*Eb*κ/(200*(n*t*Eb*Lt*(Db+n*t)+tc*κ*Ec*Lc*Dc)) S1 = 0.108 (kg/mm2) 1.063 N/mm2

S1 <= Sabh S1= 1.063 <= Sabh= 216.492 O.K!

CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*A)*(R1/(R1+1)) S2= 0.176 (kg/mm2) 1.724 N/mm2

S2 <= Cwb*Sabh S2= 1.724 <= Cwb*Sabh= 216.492 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO PRESSURE

2 2

= (0.85*D.P*(w-Cr*q))/(200*n*tp) S3= 0.081 (kg/mm ) 0.792 N/mm

MERIDIONAL BENDING STRESS DUE TO PRESSURE

= 0.85*D.P/(200*n)*((w-Cr*q)/tp)^2*Cp S4= 0.968 (kg/mm2) 9.491 N/mm2

S3 + S4 <= Kf*Sabh, Kf=3.0 (as formed bellows) S3+S4= 10.28 <= Kf*Sabh= 649.48 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO DEFLECTION

= Eb*tp^2*Δq/(2*(w-Cr*q)^3*Cf) S5= 1.039 (kg/mm2) 10.190 N/mm2

MERIDIONAL BENDING STRESS DUE TO DEFLECTION

= 5*Eb*tp*Δq/(3*(w-Cr*q)^2*Cd) S6= 60.662 (kg/mm2) 594.894 N/mm2

CALCULATED TOTAL STRESS

= 0.7*(S3+S4)+S5+S6 St= 612.281 N/mm2

CALCULATED FATIGUE LIFE CYCLES

= [Ko /{( kg*(Eo/Eb)*St)-So}]^2 Nalw= 22764 Cycles

AXIAL STIFFNESS

= π/(2*(1-vb^2))*(n/N)*Eb*Dm*(tp/(w-Cr*q))^3*(1/Cf) Kb= 2050.957 (Kg/mm) 20113.014 N/mm

MAXIMUM DESIGN PRESSURE BASED ON COLUMN INSTABILITY

2

= 0.3*π*kb/(N*q)*100 Psc= 991.272 (kg/cm ) 97.211 Mpa

EFFECTIVE DIA. OF BELLOWS

= Db+w+t*η Dm= 1754.175 mm

PRESSURE THRUST

= Dm2*π*D.P/400 Pt= 25376.1 (Kg) 248854.6 N

HKR Co.,Ltd. Prg No.: HKR-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 170 OF 229

------------------------------------------------------------------------------------------

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 TUBE SIDE FULL VACUUM REV No. : 0

BELLOWS DESIGN ANALYSIS

ASME SECTION VIII DIVISION 1, APPENDIX 26 (2010 ED.+2011 ADD.)

REINFORCED TYPE (SINGLE)

DESIGN PRESSURE D.P= 48.000 (kg/cm2) 4.707 Mpa

DESIGN TEMPERATURE D.T= 400 ℃

BELLOWS MATERIAL SB443(N06625)

ALLOWABLE STRESS (Hot & Cold) Sabc= 22.077 (kg/mm2) 216.501 N/mm2

Sabh= 20.311 (kg/mm2) 199.181 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Eo= 21092.596 (kg/mm2) 206847.711 N/mm2

Eb= 17453.421 (kg/mm2) 171159.586 N/mm2

REINFORCING RING MATERIAL SA266-4

2

ALLOWABLE STRESS (Hot & Cold) Sarc= 14.062 (kg/mm ) 137.898 N/mm2

Sarh= 10.327 (kg/mm2) 101.273 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Erc= 20670.745 (kg/mm2) 202710.757 N/mm2

Er= 17453.421 (kg/mm2) 171159.586 N/mm2

MEAN METAL TEMPERATURE Shell= 5.00 Tube= 149.00 ℃

DIFFERENTIAL THERMAL GROWTH

= (1.152E-05*(5-21)-1.242E-05*(149-21))*4877 Ex= -8.653 mm

CROSS SECTIONAL METAL AREA OF ONE REINFORCE RING Ar= 3000.0 mm2

RATIO OF THE INTERNAL PRESSURE FORCE RESISTED BY THE BELLOWS

= A*Eb/(Ar*Er) R1 = 0.156

CONVOLUTION HEIGHT FACTOR FOR REINFORCED FACTOR

= 0.3-(100/(0.6*(D.P*14.223)^1.5+320))^2 Cr= 0.2999177

DESIGN MOVEMENT CONDITION

COND-----------------AXIAL(mm.)------------------------------LATERAL(mm.)----------------------------------ANGULAR(deg)----------CYCLES-

EXT.= 8.653 COMP.= 0.000 Y= 0.000 Z= 0.000 Θ= 0.000 1000

-(A) IS PRIMARY DESIGN CONDITION

C1= q/(2*w)= 0.5 C2=q/(2.2*(Dm*tp)0.5)= 0.4215

FACTOR 'Cp', 'Cf' & 'Cd' Cp= 0.663 Cf= 1.701 Cd= 1.706

CYLINDRICAL TANGENT INSIDE DIAMETER Db= 1686 mm

MATERIAL THICKNESS t= 3.175 mm

NOMINAL THICKNESS OF BELLOWS AFTER FORMING

(-)10% REDUCTION DUE TO LOW MATERIAL & MANUFACTURING TOLERANCE

= 0.9*t*(Db/Dm)^0.5 tp= 2.80 mm

NUMBER OF PLIES n= 1 Plies

NUMBER OF CONVOLUTIONS N= 3 corr.

PITCH OF BELLOWS CONVOLUTION q= 65 mm

HEIGHT OF BELLOWS CONVOLUTION w= 65 mm

FREE LENGTH OVER CONVOLUTIONS = (q*N) Lb= 195 mm

-EQUIVALENT AXIAL MOVEMENT PER 1(ONE) CONVOLUTION-

Δq TOTAL= 2.88 AXIAL= 2.88 LATERAL=0.00 ANGULAR=0.00 mm

REINFORCING MEMBER CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*Ar)*(1/(R1+1)) S'2= 7.890 (kg/mm2) 77.378 N/mm2

S'2 <= Cwr*Sarh S'2= 77.378 <= Cwr*Sarh= 101.273 O.K!

HKR Co.,Ltd. Prg No.: HKR-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 171 OF 229

------------------------------------------------------------------------------------------

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 TUBE SIDE FULL VACUUM REV No. : 0

BELLOWS DESIGN ANALYSIS

BELLOWS TANGENT CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*(Db+n*t)^2*Lt*Eb*κ/(200*(n*t*Eb*Lt*(Db+n*t)+tc*κ*Ec*Lc*Dc)) S1 = 4.863 (kg/mm2) 47.689 N/mm2

S1 <= Sabh S1= 47.689 <= Sabh= 199.181 O.K!

CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*A)*(R1/(R1+1)) S2= 7.890 (kg/mm2) 77.378 N/mm2

S2 <= Cwb*Sabh S2= 77.378 <= Cwb*Sabh= 199.181 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO PRESSURE

2 2

= (0.85*D.P*(w-Cr*q))/(200*n*tp) S3= 3.314 (kg/mm ) 32.496 N/mm

MERIDIONAL BENDING STRESS DUE TO PRESSURE

= 0.85*D.P/(200*n)*((w-Cr*q)/tp)^2*Cp S4= 35.685 (kg/mm2) 349.950 N/mm2

S3 + S4 <= Kf*Sabh, Kf=3.0 (as formed bellows) S3+S4= 382.45 <= Kf*Sabh= 597.54 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO DEFLECTION

= Eb*tp^2*Δq/(2*(w-Cr*q)^3*Cf) S5= 1.232 (kg/mm2) 12.083 N/mm2

MERIDIONAL BENDING STRESS DUE TO DEFLECTION

= 5*Eb*tp*Δq/(3*(w-Cr*q)^2*Cd) S6= 66.530 (kg/mm2) 652.439 N/mm2

CALCULATED TOTAL STRESS

= 0.7*(S3+S4)+S5+S6 St= 932.235 N/mm2

CALCULATED FATIGUE LIFE CYCLES

= [Ko /{( kg*(Eo/Eb)*St)-So}]^2 Nalw= 3296 Cycles

AXIAL STIFFNESS

= π/(2*(1-vb^2))*(n/N)*Eb*Dm*(tp/(w-Cr*q))^3*(1/Cf) Kb= 2432.038 (Kg/mm) 23850.146 N/mm

MAXIMUM DESIGN PRESSURE BASED ON COLUMN INSTABILITY

= 0.3*π*kb/(N*q)*100 Psc= 1175.457 (kg/cm2) 115.273 Mpa

EFFECTIVE DIA. OF BELLOWS

= Db+w+t*η Dm= 1754.175 mm

PRESSURE THRUST

= Dm2*π*D.P/400 Pt= 1160050.7 (Kg) 11376210.7 N

HKR Co.,Ltd. Prg No.: HKR-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 172 OF 229

------------------------------------------------------------------------------------------

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 TUBE SIDE STEAM OUT REV No. : 0

BELLOWS DESIGN ANALYSIS

ASME SECTION VIII DIVISION 1, APPENDIX 26 (2010 ED.+2011 ADD.)

REINFORCED TYPE (SINGLE)

DESIGN PRESSURE D.P= 0.000 (kg/cm2) 0.000 Mpa

DESIGN TEMPERATURE D.T= 21 ℃

BELLOWS MATERIAL SB443(N06625)

ALLOWABLE STRESS (Hot & Cold) Sabc= 22.077 (kg/mm2) 216.501 N/mm2

Sabh= 22.077 (kg/mm2) 216.501 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Eo= 21092.596 (kg/mm2) 206847.711 N/mm2

Eb= 21093.341 (kg/mm2) 206855.012 N/mm2

REINFORCING RING MATERIAL SA266-4

2

ALLOWABLE STRESS (Hot & Cold) Sarc= 14.062 (kg/mm ) 137.898 N/mm2

Sarh= 14.062 (kg/mm2) 137.898 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Erc= 20670.745 (kg/mm2) 202710.757 N/mm2

Er= 20671.489 (kg/mm2) 202718.058 N/mm2

MEAN METAL TEMPERATURE Shell= 5.00 Tube= 149.00 ℃

DIFFERENTIAL THERMAL GROWTH

= (1.152E-05*(5-21)-1.242E-05*(149-21))*4877 Ex= -8.653 mm

CROSS SECTIONAL METAL AREA OF ONE REINFORCE RING Ar= 3000.0 mm2

RATIO OF THE INTERNAL PRESSURE FORCE RESISTED BY THE BELLOWS

= A*Eb/(Ar*Er) R1 = 0.159

CONVOLUTION HEIGHT FACTOR FOR REINFORCED FACTOR

= 0.3-(100/(0.6*(D.P*14.223)^1.5+320))^2 Cr= 0.2023438

DESIGN MOVEMENT CONDITION

COND-----------------AXIAL(mm.)------------------------------LATERAL(mm.)----------------------------------ANGULAR(deg)----------CYCLES-

EXT.= 8.653 COMP.= 0.000 Y= 0.000 Z= 0.000 Θ= 0.000 1000

-(A) IS PRIMARY DESIGN CONDITION

C1= q/(2*w)= 0.5 C2=q/(2.2*(Dm*tp)0.5)= 0.4215

FACTOR 'Cp', 'Cf' & 'Cd' Cp= 0.663 Cf= 1.701 Cd= 1.706

CYLINDRICAL TANGENT INSIDE DIAMETER Db= 1686 mm

MATERIAL THICKNESS t= 3.175 mm

NOMINAL THICKNESS OF BELLOWS AFTER FORMING

(-)10% REDUCTION DUE TO LOW MATERIAL & MANUFACTURING TOLERANCE

= 0.9*t*(Db/Dm)^0.5 tp= 2.80 mm

NUMBER OF PLIES n= 1 Plies

NUMBER OF CONVOLUTIONS N= 3 corr.

PITCH OF BELLOWS CONVOLUTION q= 65 mm

HEIGHT OF BELLOWS CONVOLUTION w= 65 mm

FREE LENGTH OVER CONVOLUTIONS = (q*N) Lb= 195 mm

-EQUIVALENT AXIAL MOVEMENT PER 1(ONE) CONVOLUTION-

Δq TOTAL= 2.88 AXIAL= 2.88 LATERAL=0.00 ANGULAR=0.00 mm

REINFORCING MEMBER CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*Ar)*(1/(R1+1)) S'2= 0.000 (kg/mm2) 0.000 N/mm2

S'2 <= Cwr*Sarh S'2= 0.000 <= Cwr*Sarh= 137.898 O.K!

HKR Co.,Ltd. Prg No.: HKR-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 173 OF 229

------------------------------------------------------------------------------------------

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 TUBE SIDE STEAM OUT REV No. : 0

BELLOWS DESIGN ANALYSIS

BELLOWS TANGENT CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*(Db+n*t)^2*Lt*Eb*κ/(200*(n*t*Eb*Lt*(Db+n*t)+tc*κ*Ec*Lc*Dc)) S1 = 0.000 (kg/mm2) 0.000 N/mm2

S1 <= Sabh S1= 0.000 <= Sabh= 216.501 O.K!

CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*A)*(R1/(R1+1)) S2= 0.000 (kg/mm2) 0.000 N/mm2

S2 <= Cwb*Sabh S2= 0.000 <= Cwb*Sabh= 216.501 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO PRESSURE

2 2

= (0.85*D.P*(w-Cr*q))/(200*n*tp) S3= 0.000 (kg/mm ) 0.000 N/mm

MERIDIONAL BENDING STRESS DUE TO PRESSURE

= 0.85*D.P/(200*n)*((w-Cr*q)/tp)^2*Cp S4= 0.000 (kg/mm2) 0.000 N/mm2

S3 + S4 <= Kf*Sabh, Kf=3.0 (as formed bellows) S3+S4= 0.00 <= Kf*Sabh= 649.50 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO DEFLECTION

= Eb*tp^2*Δq/(2*(w-Cr*q)^3*Cf) S5= 1.007 (kg/mm2) 9.873 N/mm2

MERIDIONAL BENDING STRESS DUE TO DEFLECTION

= 5*Eb*tp*Δq/(3*(w-Cr*q)^2*Cd) S6= 61.937 (kg/mm2) 607.395 N/mm2

CALCULATED TOTAL STRESS

= 0.7*(S3+S4)+S5+S6 St= 617.268 N/mm2

CALCULATED FATIGUE LIFE CYCLES

= [Ko /{( kg*(Eo/Eb)*St)-So}]^2 Nalw= 25810 Cycles

AXIAL STIFFNESS

= π/(2*(1-vb^2))*(n/N)*Eb*Dm*(tp/(w-Cr*q))^3*(1/Cf) Kb= 1987.171 (Kg/mm) 19487.487 N/mm

MAXIMUM DESIGN PRESSURE BASED ON COLUMN INSTABILITY

2

= 0.3*π*kb/(N*q)*100 Psc= 960.443 (kg/cm ) 94.187 Mpa

EFFECTIVE DIA. OF BELLOWS

= Db+w+t*η Dm= 1754.175 mm

PRESSURE THRUST

= Dm2*π*D.P/400 Pt= 0.0 (Kg) 0.0 N

HKR Co.,Ltd. Prg No.: HKR-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 174 OF 229

------------------------------------------------------------------------------------------

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 MAWP REV No. : 0

BELLOWS DESIGN ANALYSIS

ASME SECTION VIII DIVISION 1, APPENDIX 26 (2010 ED.+2011 ADD.)

REINFORCED TYPE (SINGLE)

DESIGN PRESSURE D.P= 49.400 (kg/cm2) 4.844 Mpa

DESIGN TEMPERATURE D.T= 400 ℃

BELLOWS MATERIAL SB443(N06625)

ALLOWABLE STRESS (Hot & Cold) Sabc= 22.077 (kg/mm2) 216.501 N/mm2

Sabh= 20.311 (kg/mm2) 199.181 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Eo= 21092.596 (kg/mm2) 206847.711 N/mm2

Eb= 17453.421 (kg/mm2) 171159.586 N/mm2

REINFORCING RING MATERIAL SA266-4

2

ALLOWABLE STRESS (Hot & Cold) Sarc= 14.062 (kg/mm ) 137.898 N/mm2

Sarh= 10.327 (kg/mm2) 101.273 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Erc= 20670.745 (kg/mm2) 202710.757 N/mm2

Er= 17453.421 (kg/mm2) 171159.586 N/mm2

MEAN METAL TEMPERATURE Shell= 5.00 Tube= 149.00 ℃

DIFFERENTIAL THERMAL GROWTH

= (1.152E-05*(5-21)-1.242E-05*(149-21))*4877 Ex= -8.653 mm

CROSS SECTIONAL METAL AREA OF ONE REINFORCE RING Ar= 3000.0 mm2

RATIO OF THE INTERNAL PRESSURE FORCE RESISTED BY THE BELLOWS

= A*Eb/(Ar*Er) R1= 0.156

CONVOLUTION HEIGHT FACTOR FOR REINFORCED FACTOR

= 0.3-(100/(0.6*(D.P*14.223)^1.5+320))^2 Cr= 0.2999243

DESIGN MOVEMENT CONDITION

COND-----------------AXIAL(mm.)------------------------------LATERAL(mm.)----------------------------------ANGULAR(deg)----------CYCLES-

EXT.= 8.653 COMP.= 0.000 Y= 0.000 Z= 0.000 Θ= 0.000 1000

-(A) IS PRIMARY DESIGN CONDITION

C1= q/(2*w)= 0.5 C2=q/(2.2*(Dm*tp)0.5)= 0.4215

FACTOR 'Cp', 'Cf' & 'Cd' Cp= 0.658 Cf= 1.612 Cd= 1.773

CYLINDRICAL TANGENT INSIDE DIAMETER Db= 1686 mm

MATERIAL THICKNESS t= 3.175 mm

NOMINAL THICKNESS OF BELLOWS AFTER FORMING

(-)10% REDUCTION DUE TO LOW MATERIAL & MANUFACTURING TOLERANCE

= 0.9*t*(Db/Dm)^0.5 tp= 2.80 mm

NUMBER OF PLIES n= 1 Plies

NUMBER OF CONVOLUTIONS N= 3 corr.

PITCH OF BELLOWS CONVOLUTION q= 65 mm

HEIGHT OF BELLOWS CONVOLUTION w= 65 mm

FREE LENGTH OVER CONVOLUTIONS = (q*N) Lb= 195 mm

-EQUIVALENT AXIAL MOVEMENT PER 1(ONE) CONVOLUTION-

Δq TOTAL= 2.88 AXIAL= 2.88 LATERAL= 0.00 ANGULAR=0.00 mm

REINFORCING MEMBER CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*Ar)*(1/(R1+1)) S'2= 8.121 (kg/mm2) 79.635 N/mm2

S'2 <= Cwr*Sarh S'2= 79.635 <= Cwr*Sarh= 101.273 O.K!

HKR Co.,LTD. Prg No.: HKE-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 175 OF 229

------------------------------------------------------------------------------------------

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 MAWP REV No. : 0

BELLOWS DESIGN ANALYSIS

BELLOWS TANGENT CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*(Db+n*t)^2*Lt*Eb*κ/(200*(n*t*Eb*Lt*(Db+n*t)+tc*κ*Ec*Lc*Dc)) S1 = 5.005 (kg/mm2) 49.080 N/mm2

S1 <= Sabh S1= 49.080 <= Sabh= 199.181 O.K!

CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*A)*(R1/(R1+1)) S2= 8.121 (kg/mm2) 79.635 N/mm2

S2 <= Cwb*Sabh S2= 79.635 <= Cwb*Sabh= 199.181 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO PRESSURE

2 2

= (0.85*D.P*(w-Cr*q))/(200*n*tp) S3= 3.410 (kg/mm ) 33.444 N/mm

MERIDIONAL BENDING STRESS DUE TO PRESSURE

= 0.85*D.P/(200*n)*((w-Cr*q)/tp)^2*Cp S4= 36.463 (kg/mm2) 357.585 N/mm2

S3 + S4 <= Kf*Sabh, Kf=3.0 (as formed bellows) S3+S4= 391.03 <= Kf*Sabh= 597.54 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO DEFLECTION

= Eb*tp^2*Δq/(2*(w-Cr*q)^3*Cf) S5= 1.300 (kg/mm2) 12.751 N/mm2

MERIDIONAL BENDING STRESS DUE TO DEFLECTION

= 5*Eb*tp*Δq/(3*(w-Cr*q)^2*Cd) S6= 64.026 (kg/mm2) 627.880 N/mm2

CALCULATED TOTAL STRESS

= 0.7*(S3+S4)+S5+S6 St= 914.351 N/mm2

CALCULATED FATIGUE LIFE CYCLES

= [Ko /{( kg*(Eo/Eb)*St)-So}]^2 Nalw= 3487 Cycles

AXIAL STIFFNESS

= π/(2*(1-vb^2))*(n/N)*Eb*Dm*(tp/(w-Cr*q))^3*(1/Cf) Kb= 2566.549 (Kg/mm) 25169.247 N/mm

MAXIMUM DESIGN PRESSURE BASED ON COLUMN INSTABILITY

= 0.3*π*kb/(N*q)*100 Psc= 1240.469 (kg/cm2) 121.649 Mpa

EFFECTIVE DIA. OF BELLOWS

= Db+w+t*η Dm= 1754.175 mm

PRESSURE THRUST

= Dm2*π*D.P/400 Pt= 1193885.5 (Kg) 11708016.9 N

HKR Co.,LTD. Prg No.: HKE-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 176 OF 229

SIZE ------------------------------------------------------------------------------------------

: I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 HY'D TEST REV No. : 0

BELLOWS DESIGN ANALYSIS

ASME SECTION VIII DIVISION 1, APPENDIX 26 (2010 ED.+2011 ADD.)

REINFORCED TYPE (SINGLE)

TEST PRESSURE T.P= 70.040 (kg/cm2) 6.869 Mpa

TEST TEMPERATURE T.T= 21 ℃

BELLOWS MATERIAL SB443(N06625)

YIELD STRESS (Hot & Cold) Sybc= 38.670 (kg/mm2) 379.221 N/mm2

Sybh= 38.670 (kg/mm2) 379.221 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Eo= 21092.596 (kg/mm2) 206847.711 N/mm2

Eb= 21796.427 (kg/mm2) 213749.936 N/mm2

REINFORCING RING MATERIAL A266-4

2

YIELD STRESS (Hot & Cold) Syrc= 26.717 (kg/mm ) 262.007 N/mm2

Syrh= 26.717 (kg/mm2) 262.007 N/mm2

MODULUS OF ELASTICITY(Hot & Cold) Erc= 20670.745 (kg/mm2) 202710.757 N/mm2

Er= 20671.489 (kg/mm2) 202718.058 N/mm2

MEAN METAL TEMPERATURE Shell= - Tube= - ℃

DIFFERENTIAL THERMAL GROWTH

= Ex= 0.000 mm

CROSS SECTIONAL METAL AREA OF ONE REINFORCE RING Ar= 3000.0 mm2

RATIO OF THE INTERNAL PRESSURE FORCE RESISTED BY THE BELLOWS

= A*Eb/(Ar*Er) R1= 0.165

CONVOLUTION HEIGHT FACTOR FOR REINFORCED FACTOR

= 0.3-(100/(0.6*(D.P*14.223)^1.5+320))^2 Cr= 0.2999728

DESIGN MOVEMENT CONDITION

COND-----------------AXIAL(mm.)------------------------------LATERAL(mm.)----------------------------------ANGULAR(deg)----------CYCLES-

EXT.= 0.000 COMP.= 0.000 Y= 0.000 Z= 0.000 Θ= 0.000 1000

-(A) IS PRIMARY DESIGN CONDITION

C1= q/(2*w)= 0.5 C2=q/(2.2*(Dm*tp)0.5)= 0.4215

FACTOR 'Cp', 'Cf' & 'Cd' Cp= 0.658 Cf= 1.612 Cd= 1.773

CYLINDRICAL TANGENT INSIDE DIAMETER Db= 1686 mm

MATERIAL THICKNESS t= 3.175 mm

NOMINAL THICKNESS OF BELLOWS AFTER FORMING

(-)10% REDUCTION DUE TO LOW MATERIAL & MANUFACTURING TOLERANCE

= 0.9*t*(Db/Dm)^0.5 tp= 2.80 mm

NUMBER OF PLIES n= 1 Plies

NUMBER OF CONVOLUTIONS N= 3 corr.

PITCH OF BELLOWS CONVOLUTION q= 65 mm

HEIGHT OF BELLOWS CONVOLUTION w= 65 mm

FREE LENGTH OVER CONVOLUTIONS = (q*N) Lb= 195 mm

-EQUIVALENT AXIAL MOVEMENT PER 1(ONE) CONVOLUTION-

Δq TOTAL= 0.00 AXIAL= 0.00 LATERAL= 0.00 ANGULAR=0.00 mm

REINFORCING MEMBER CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*Ar)*(1/(R1+1)) S'2= 11.429 (kg/mm2) 112.084 N/mm2

S'2 <= Cwr*Syrh*0.9 S'2= 112.084 <= Cwr*Syrh*0.9= 235.806 O.K!

HKR Co.,Ltd. Prg No.: HKR-BELL-A-R

Rabigh Phase II Petrochemical Project Petrochemical-1 Package (CP1) ITEM NO.: P240-E-1023 REV. NO.: 2

P.O. NO.:P-203-1420-2091-KR PAGE 177 OF 229

------------------------------------------------------------------------------------------

SIZE : I.D 1600 SHEET : OF

ITEM No. : P240-E-1023 HY'D TEST REV No. : 0

BELLOWS DESIGN ANALYSIS

BELLOWS TANGENT CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*(Db+n*t)^2*Lt*Eb*κ/(200*(n*t*Eb*Lt*(Db+n*t)+tc*κ*Ec*Lc*Dc)) S1 = 7.435 (kg/mm2) 72.913 N/mm2

S1 <= Sybh*0.9 S1= 72.913 <= Sybh*0.9= 341.299 O.K!

CIRCUMFERENTIAL MEMBRANE STRESS DUE TO PRESSURE

= D.P*Dm*q/(200*A)*(R1/(R1+1)) S2= 12.051 (kg/mm2) 118.184 N/mm2

S2 <= Cwb*Sybh*0.9 S2= 118.184 <= Cwb*Sybh*0.9= 341.299 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO PRESSURE

2 2

= (0.85*D.P*(w-Cr*q))/(200*n*tp) S3= 4.835 (kg/mm ) 47.414 N/mm

MERIDIONAL BENDING STRESS DUE TO PRESSURE

= 0.85*D.P/(200*n)*((w-Cr*q)/tp)^2*Cp S4= 51.691 (kg/mm2) 506.918 N/mm2

S3 + S4 <= Kf*Sybh*0.9, Kf=3.0 (as formed bellows) S3+S4= 554.332 <= Kf*Sybh*0.9= 1023.896 O.K!

MERIDIONAL MEMBRANE STRESS DUE TO DEFLECTION

= Eb*tp^2*Δq/(2*(w-Cr*q)^3*Cf) S5= 0.000 (kg/mm2) 0.000 N/mm2

MERIDIONAL BENDING STRESS DUE TO DEFLECTION

= 5*Eb*tp*Δq/(3*(w-Cr*q)^2*Cd) S6= 0.000 (kg/mm2) 0.000 N/mm2

CALCULATED TOTAL STRESS

= 0.7*(S3+S4)+S5+S6 St= 388.032 N/mm2

CALCULATED FATIGUE LIFE CYCLES

= [Ko /{( kg*(Eo/Eb)*St)-So}]^2 Nalw= 294589 Cycles

AXIAL STIFFNESS

= π/(2*(1-vb^2))*(n/N)*Eb*Dm*(tp/(w-Cr*q))^3*(1/Cf) Kb= 3205.860 (Kg/mm) 31438.752 N/mm

MAXIMUM DESIGN PRESSURE BASED ON COLUMN INSTABILITY

= 0.3*π*kb/(N*q)*100 Psc= 1549.463 (kg/cm2) 151.950 Mpa

EFFECTIVE DIA. OF BELLOWS

= Db+w+t*η Dm= 1754.175 mm

PRESSURE THRUST

= Dm2*π*D.P/400 Pt= 1692707.2 (Kg) 16599787.5 N

HKR Co.,Ltd. Prg No.: HKR-BELL-A-R

You might also like

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Aluminium Cladding DesignDocument3 pagesAluminium Cladding Designjatin100% (1)

- Aluminium Cladding DesignDocument2 pagesAluminium Cladding DesigntkofaiNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Design of PierDocument18 pagesDesign of PierMrinal kayalNo ratings yet

- Element Location: Subject: Made by Design Code: Value Unit: Step 1: Total Service Load (N)Document3 pagesElement Location: Subject: Made by Design Code: Value Unit: Step 1: Total Service Load (N)James AswaNo ratings yet

- BS5400 R.C Design With Crack WidthDocument9 pagesBS5400 R.C Design With Crack WidthWangTF100% (4)

- Beam Design by SP 16 PDFDocument1 pageBeam Design by SP 16 PDFRafeeq khanNo ratings yet

- Ejma 2000Document7 pagesEjma 2000jhunkujha11No ratings yet

- Design of Pile Cap ReinforcementDocument32 pagesDesign of Pile Cap Reinforcementnikhil lokhandeNo ratings yet

- Calculo EjemploDocument52 pagesCalculo EjemplodmagnetoNo ratings yet

- TK-ALCOZAP-2020-01-06-Rev. DDocument65 pagesTK-ALCOZAP-2020-01-06-Rev. DDaniel Gómez100% (1)

- REPORT (3) - MergedDocument29 pagesREPORT (3) - MergedMoustafaNo ratings yet

- Punching ShearDocument14 pagesPunching Shearshamen amarasekaraNo ratings yet

- Doubly Reinforced BeamDocument19 pagesDoubly Reinforced BeamLavender HoneyNo ratings yet

- Ibr Cal PDF FreeDocument11 pagesIbr Cal PDF FreePrasanna UmapathyNo ratings yet

- Wind Pressure Calculation is 875-Part-3-2015-BrkDocument12 pagesWind Pressure Calculation is 875-Part-3-2015-BrkAnkit BhadolaNo ratings yet

- Calculation Sheet For Slug CatcherDocument12 pagesCalculation Sheet For Slug CatcherchumaNo ratings yet

- Lifting Lug Calculation 4april2018Document2 pagesLifting Lug Calculation 4april2018Diosdado Mingi Jr.No ratings yet

- Expansion Bellow Design CalculationDocument4 pagesExpansion Bellow Design Calculationvijay10484No ratings yet

- Structural Design Calculation For WPC PergolaDocument81 pagesStructural Design Calculation For WPC Pergolamaamoun100% (2)

- Base Plate DesignDocument14 pagesBase Plate Designsoumi bhattacharyaNo ratings yet

- KAMC-CW Calc.Document45 pagesKAMC-CW Calc.MoustafaNo ratings yet

- Design of foundation slab sections and reinforcementDocument7 pagesDesign of foundation slab sections and reinforcementsivaraju1No ratings yet

- One Way Slab DesignDocument10 pagesOne Way Slab DesignBijendra PradhanNo ratings yet

- Staff Quarter Type-H DBR for Upper Veda WTP 28-12-2023Document25 pagesStaff Quarter Type-H DBR for Upper Veda WTP 28-12-2023PramodNo ratings yet

- 4.substructure PH 2Document16 pages4.substructure PH 2snehaNo ratings yet

- EC4 English PDFDocument23 pagesEC4 English PDFSever KawaNo ratings yet

- Basement Wall DesignDocument2 pagesBasement Wall DesignArindam RoyNo ratings yet

- 참고자료 8. Lifting-lugDocument37 pages참고자료 8. Lifting-lugaoaaoa1122No ratings yet

- Design of T-BeamDocument6 pagesDesign of T-BeamDineshNo ratings yet

- TOP CHORD AND WEB MEMBER DESIGNDocument11 pagesTOP CHORD AND WEB MEMBER DESIGNjoe kyleNo ratings yet

- Braced RC Circular Column Design - Sample Calculation (As 3600)Document5 pagesBraced RC Circular Column Design - Sample Calculation (As 3600)Tiam MarapeNo ratings yet

- Steel Column Base PlateDocument17 pagesSteel Column Base PlateVAN HUNG TRANNo ratings yet

- Beam DesignDocument6 pagesBeam DesignGeetha MaNo ratings yet

- Spread Beam Calculation-070406Document11 pagesSpread Beam Calculation-070406Ha HoangNo ratings yet

- 1 Input Data: Anchor Type and Size: Hsl-3 M12 or EquivalentDocument4 pages1 Input Data: Anchor Type and Size: Hsl-3 M12 or EquivalentNp PwNo ratings yet

- Steam Drum, Water Wall & Evaporator - VWHA054Document36 pagesSteam Drum, Water Wall & Evaporator - VWHA054Mani SunNo ratings yet

- Anchor Bolt CHKDocument17 pagesAnchor Bolt CHKPriya GNo ratings yet

- Kuantan Cement Plant Engineering Office Beam DesignDocument36 pagesKuantan Cement Plant Engineering Office Beam DesignMuhamad Amirul Md. RazdiNo ratings yet

- Design of RC Rectangular Section NSCP ACI 318Document5 pagesDesign of RC Rectangular Section NSCP ACI 318Nicko Jay BajaoNo ratings yet

- Slab design calculations and steel requirementsDocument2 pagesSlab design calculations and steel requirementsvidudalaraviNo ratings yet

- Project: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)Document8 pagesProject: Proposed Development of 242 Units of 27 Storeys Condominium (Phase 1A-Rc3)pakbilal1100% (1)

- BS5400-R-C-Design-With-Crack-Width SampleDocument1 pageBS5400-R-C-Design-With-Crack-Width SampleAlden CayagaNo ratings yet

- Job: 200, Nawala Road, Narahenpita Colombo - 05, Sri Lanka. Tel: 2808835 To 44 Fax: 2808846 & 47Document55 pagesJob: 200, Nawala Road, Narahenpita Colombo - 05, Sri Lanka. Tel: 2808835 To 44 Fax: 2808846 & 47Shamitha KanchanaNo ratings yet

- Example1 1-StraightsupportedDocument7 pagesExample1 1-StraightsupportedOmar BayouNo ratings yet

- Design of Beam:528 Grade of Concrete: at Right EndDocument7 pagesDesign of Beam:528 Grade of Concrete: at Right EndSudip ShresthaNo ratings yet

- Concourse Slab CouplerDocument1 pageConcourse Slab CouplerghansaNo ratings yet

- L & T Construction: Water, Smart World & Communication ICDocument12 pagesL & T Construction: Water, Smart World & Communication ICMUTHUKKUMARAMNo ratings yet

- Boiler AccesoriesDocument127 pagesBoiler Accesoriesramnath008100% (1)

- RC Stair Design 25Document6 pagesRC Stair Design 25Abel MulugetaNo ratings yet

- Corbel For Bottom Slab of Water Tank Design of Corbel at El+18.266Document2 pagesCorbel For Bottom Slab of Water Tank Design of Corbel at El+18.266mathuNo ratings yet

- Wall Tie 1Document4 pagesWall Tie 1John SmithNo ratings yet

- Unbraced RC Circular Column Design - Sample Calculation (AS3600)Document4 pagesUnbraced RC Circular Column Design - Sample Calculation (AS3600)Tiam MarapeNo ratings yet

- Deck Member Design - AshuDocument11 pagesDeck Member Design - Ashurehan7421No ratings yet

- RC Beam Design Using ACIDocument1 pageRC Beam Design Using ACIdantevariasNo ratings yet

- Heat Exchanger DesignDocument7 pagesHeat Exchanger Designsiva sankarNo ratings yet

- Structural Design of Bored Cast In-Situ PileDocument2 pagesStructural Design of Bored Cast In-Situ PilesathishNo ratings yet

- Reactor Feed/Effluent Exchangers Rajasthan Refinery, Naphtha HDTDocument2 pagesReactor Feed/Effluent Exchangers Rajasthan Refinery, Naphtha HDTAnonymous AyDvqgNo ratings yet

- Beam reinforcement calculation for 3m spanDocument2 pagesBeam reinforcement calculation for 3m spanEr Shiva GuptaNo ratings yet

- JERMS-H-9107 Composite Fluropolymer - Ceramic CoatingsDocument16 pagesJERMS-H-9107 Composite Fluropolymer - Ceramic Coatingsjhunkujha11No ratings yet

- Soil - Std. DrawingDocument76 pagesSoil - Std. Drawingjhunkujha11No ratings yet

- 21100-4-8480-SP-0001 - 0 - Heat Exchangers (E-101)Document41 pages21100-4-8480-SP-0001 - 0 - Heat Exchangers (E-101)jhunkujha11No ratings yet

- Soil - Std. DrawingDocument76 pagesSoil - Std. Drawingjhunkujha11No ratings yet

- Post Weld Heat TreatmentDocument51 pagesPost Weld Heat Treatmenttbmari97% (32)

- Refractory Material Selection For Steelmaking (PDFDrive)Document390 pagesRefractory Material Selection For Steelmaking (PDFDrive)Abdullrahman Alzahrani100% (1)

- Impregnated Board Data SheetDocument8 pagesImpregnated Board Data Sheetgireeshkumarb3874No ratings yet

- 2033 Mapeband Tpe GBDocument4 pages2033 Mapeband Tpe GBasafridisNo ratings yet

- CAEPIPE Technical Reference ManualDocument388 pagesCAEPIPE Technical Reference ManualrtadicherlaNo ratings yet

- STRESS ANALYSIS OF FLUE GAS DUCTSDocument11 pagesSTRESS ANALYSIS OF FLUE GAS DUCTSSergio SmithNo ratings yet

- Material RequirementDocument37 pagesMaterial RequirementHarish ApNo ratings yet

- Structural Sealant Glazing: Standard Guide ForDocument52 pagesStructural Sealant Glazing: Standard Guide ForĐường Nguyễn ThừaNo ratings yet

- ASME B31.3-2016 Leak Test RequirementsDocument5 pagesASME B31.3-2016 Leak Test RequirementsGulzar AliNo ratings yet

- 50M RCC Bridge EsimationDocument8 pages50M RCC Bridge EsimationHoque joynulNo ratings yet

- 342 ALFALAVALConthermManual 0Document353 pages342 ALFALAVALConthermManual 0Reiniel Cirujano AntonioNo ratings yet

- Joints in Pavements PDFDocument2 pagesJoints in Pavements PDFmojeebmashalNo ratings yet

- Technical Information Schoeck Isokorb Type KXTDocument17 pagesTechnical Information Schoeck Isokorb Type KXTCodruta JurcaNo ratings yet

- Piperack Planning GuideDocument4 pagesPiperack Planning GuideryncscNo ratings yet

- Expansion Joint Technical Specification and Data SheetDocument9 pagesExpansion Joint Technical Specification and Data SheetAhmad Dzulfiqar RahmanNo ratings yet

- Concrete Repair and Maintenance Illustrated, PH Emmons - PDFDocument315 pagesConcrete Repair and Maintenance Illustrated, PH Emmons - PDFRotimi OwowaNo ratings yet

- Thermal Design of Shell & TubeDocument41 pagesThermal Design of Shell & Tubepaulo0701No ratings yet

- Plaster Assemblies Chapter 02 Plaster Substrates LathDocument26 pagesPlaster Assemblies Chapter 02 Plaster Substrates LathFare NienteNo ratings yet

- Process Industry Practices Insulation: PIP INIH1000 Hot Insulation Installation DetailsDocument25 pagesProcess Industry Practices Insulation: PIP INIH1000 Hot Insulation Installation DetailsSarwar KhanNo ratings yet

- Hydrocell XL: High Performance, Cross Linked, Closed Cell, Non-Absorbent, Polyethylene Joint Fi LlerDocument2 pagesHydrocell XL: High Performance, Cross Linked, Closed Cell, Non-Absorbent, Polyethylene Joint Fi LlerApoorv MahajanNo ratings yet

- Non Metallic Test Pages From ASME-B31!3!2014Document4 pagesNon Metallic Test Pages From ASME-B31!3!2014Đỗ Thị HuyềnNo ratings yet

- Company Profile SAKETH EXIM LTDDocument25 pagesCompany Profile SAKETH EXIM LTDRahul PatilNo ratings yet

- MeasurIT Red Valve Expansion Joints J1 0802Document3 pagesMeasurIT Red Valve Expansion Joints J1 0802cwiejkowskaNo ratings yet

- Mes PDFDocument674 pagesMes PDFMd Imran Khan SohanNo ratings yet

- Project Standards and Specifications Metallic Expansion Joint Rev01Document4 pagesProject Standards and Specifications Metallic Expansion Joint Rev01hiyeonNo ratings yet

- Vibration, Noise and Seismic SolutionsDocument7 pagesVibration, Noise and Seismic SolutionsaomareltayebNo ratings yet

- E25NAFLON Expansion BellowsDocument22 pagesE25NAFLON Expansion BellowsRezza Octova GochirNo ratings yet

- KDOT Bridge Design Manual Section on Expansion Joints and BearingsDocument54 pagesKDOT Bridge Design Manual Section on Expansion Joints and BearingsbrelightsNo ratings yet

- Spec. For InsulationDocument45 pagesSpec. For InsulationVivek ShettyNo ratings yet

- Piping Flexibility CheckingDocument5 pagesPiping Flexibility Checkingeko123No ratings yet

- Chapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018Document40 pagesChapter 9 Bearings and Expansion Joints: WSDOT Bridge Design Manual M 23-50.18 Page 9-I June 2018aomareltayebNo ratings yet

- Info@posiflex - Co.uk - Tel: +44 (0) 1462 443131 - WWW - Posiflex.co - UkDocument45 pagesInfo@posiflex - Co.uk - Tel: +44 (0) 1462 443131 - WWW - Posiflex.co - UkThái Mai ĐìnhNo ratings yet