Professional Documents

Culture Documents

Heat Exchanger Design

Uploaded by

siva sankarOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Exchanger Design

Uploaded by

siva sankarCopyright:

Available Formats

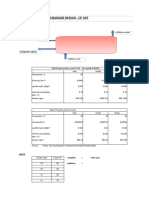

DESIGN OF A HEAT EXCHANGER

Date:17/01/2014

UOM

COLUMN DIA mm 700

MAXIMUM ALLOVABLE BOIL UP RATE LPH 3500

SOLVENT TO BE DISTILLED Solvent THF

DENSITY OF THE SOLVENT kg/M3 888

VISCOSITY OF THE SOLVENT Cp

BOILING POINT OF THE SOLVENT(T1) O

C 66

MAXI,UM ALLOVABLE BOIL UP RATE kg/Hr 3108

SPECIFIC HEAT OF SOLVENT KCAL\Kg 0.5

LATENT HEAT OF SOLVENT KCAL\Kg 92.5

RT WATER IN(t1) O

C 30

RT WATER OUT(t2) O

C 35

DISTILLATE OUT(T2) O

C 38

SPECIFIC HEAT OF WATER KCAL\Kg 1

ΔT1=T1-t2 O

C 31

ΔT2=T2-t1 O

C 8

LMTD=ΔT1-ΔT2/ln(ΔT1/ΔT2) O

C 17.0

LENGTH OF THE TUBE M 1.5

DIA OF THE TUBE IN 0.75

ASSUME OVERALL HEAT TRANSFER KCAL\Kg 350

HEAT LOAD Q1 = Mλ KCAL\Kg 287490

HEAT LOAD Q2= MCpΔTLN KCAL\Kg 26386.71

TOTAL HEAT LOAD Q= Q1+ Q2 KCAL\Kg 313876.71

R=(T1-T2)/(t2-t1) 5.6

S=(t2-t1)/(T1-t1) 0.139

CONSIDER 1 SHELL PASS AND 4 TUBE SIDE PASSES

FT= (SQRT(R2+1)* LN ((1-S)/(1-RS)))/

((R-1)*LN((2-S(R+1-SQRT(R2+1)))/(2-S(R+1+SQRT(R2+1))) 0.903268

LMTD CORRECTION FACTOR O

C 15.3373676

AREA OF THE CONDENSER M2 58.47

NO OF TUBES N 651

FOR TRIANGULAR PITCH PT= 1.25 DO

NO OF 1 2 4 6 8

PASSES

K1 0.319 0.249 0.175 0.0743 0.3685

n1 2.142 2.207 2.285 2.499 2.675

FOR SQUARE PITCH PT= 1.25 DO

NO OF 1 2 4 6 8

PASSES

K1 0.215 0.156 0.158 0.0402 0.0331

n1 2.207 2.291 2.263 2.617 2.643

DIAMETER OF PIPE D0 IN 1.05

DIAMETER OF PIPE D0 mm 26.67

BUNDLE DIAMETER FOR 4 PASSES TRIANGULAR PITCH= DB= D0(Nt/K1)^(1/n1)

BUNDLE DIAMETER mm 974.2

BUNDLE DIAMETER M 0.97

USE A SPLIT RING FLOATING TYPE

BUNDLE DIAMETER CLEARANCE mm 70

BUNDLE DIAMETER CLEARANCE M 0.07

SHELL DIAMETER M 1.044

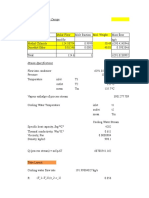

TUBE SIDE COEFFICIENT

MEAN WATER TEMPERATURE= ( t1 +t2)/2 O

C 32.5

TUBE CROSSSECTIONAL AREA mm2 285.14

TUBES PER PASS N 163

TOTAL FLOW AREA m2 0.046411324

WATER FLOW RATE=Q/(Cp*(RT out-RT in)) kg/Hr 62775.34147

WATER FLOW RATE KG/S 17.43759485

WATER MASS VELOCITY=WATER FLOWRATE/FLOW AREA KG/S-M2 375.7185413

DENSITY OF WATER kg/M3 995

LINEAR MASS VELOCITY M/S 0.38

hi specially for water is given by

hi=4200*(1.35+0.02*(Avg water temp))* (linear mass velociy)^0.8/

(di)^0.2

TUBE SIDE HEAT TRANSFER COEFFICIENT W/m2 0C 2137.627006

VISCOSITY OF WATER Ns/m2 0.8

THERMAL CONDUCTIVITY W/m C 20

0.59

REYNOLDS NUMBER = (ρdV)/µ Re 8805.9

PRANDTL NUMBER = (Cp µ)/k Pr 5.7

L/di L/di 80

FROM GRAPH NO 12.23 Pg NO:665 Jh Jh 0.0041

hi = (K/di)*Jh*Re*Pr^0.33*(µ/µw)^0.14 hi 2017.062274

SHELL SIDE HEAT TRNSFER COEFFICIENT

CHOOSE BAFFLE SPACING MM 194.8386086

TUBE PITCH MM 33.3375

CROSSFLOW AREA AS M2 0.041

MASS VELOCITY Kg/M S 21.21742613

2

EQUIVALENT DIAMETER = De=(1.10/d0)*(P -(0.917* do )

t

2 2

mm 18.9370335

MEAN SHEL SIDE TEMPERATURE O

C 52

DENSITY OF THE SOLVENT kg/M3 888

VISCOSITY Ns/m2 0.55

HEAT CAPACITY KJ/Kg 0C 2.1

THERML CONDUCTIVITUY W/m2 0C 0.15

RENOLDS NUMBER =(GDE/µ) Re 730.5365625

PRANDTL NUMBER = (Cp µ)/k Pr 7.626666667

CHOOSE 25% BAFFLE CUT FROM FIG 12.29 JH 0.018

WITH OUT THE ISCOSITY CORRECTION TERM hS 203.6405428

ESTIMATE WALL TEMPERATURE

MEAN TEMPERATURE DIFFERENCE ACROSS ALL RESISTANCE C

0

36

OVERALL HEAT TRANSFER COEFFICIENT

THERMAL CONDUCTIVITY OF

You might also like

- Condenser CalculationsDocument9 pagesCondenser CalculationsAngelo Imbo100% (2)

- VAL 080 Validation Master Plan Sample PDFDocument3 pagesVAL 080 Validation Master Plan Sample PDFsiva sankar100% (1)

- Validation Master Plan PDFDocument33 pagesValidation Master Plan PDFsiva sankar50% (2)

- Horizontal Cylindrical Tank Volume and Level CalculatorDocument5 pagesHorizontal Cylindrical Tank Volume and Level CalculatorWaleed EmaraNo ratings yet

- SCR Heat Exchanger Design 2018 For NO PHASE CHANGEDocument37 pagesSCR Heat Exchanger Design 2018 For NO PHASE CHANGEAnonymous 1uUqRkc9p8100% (1)

- Equipment Qualification Plan (EQP) : Agilent Enterprise Edition Compliance ServicesDocument22 pagesEquipment Qualification Plan (EQP) : Agilent Enterprise Edition Compliance Servicessiva sankarNo ratings yet

- POL007 Computer System Validation v2.0 PDFDocument7 pagesPOL007 Computer System Validation v2.0 PDFsiva sankarNo ratings yet

- Installation, Operational and Performance Qualification of Equipment - Instrument. - Pharmaceutical Guidance PDFDocument6 pagesInstallation, Operational and Performance Qualification of Equipment - Instrument. - Pharmaceutical Guidance PDFsiva sankarNo ratings yet

- A Study of Boundary Layer Characteristics of Turbomachines Blade Rows and Their Relation To Over-All Blade Loss PDFDocument5 pagesA Study of Boundary Layer Characteristics of Turbomachines Blade Rows and Their Relation To Over-All Blade Loss PDFmrbookani100% (1)

- Viscous Pipe Experiment: Figure 1-Blower Figure 2 - Pipe and V. MeterDocument3 pagesViscous Pipe Experiment: Figure 1-Blower Figure 2 - Pipe and V. MeterCaleb Kreeger100% (1)

- Remedial Cementing OverviewDocument31 pagesRemedial Cementing OverviewAbdul RehazkNo ratings yet

- Chap 17 - Water InfluxDocument57 pagesChap 17 - Water InfluxSlim.BNo ratings yet

- Thermal Design of Heat ExchangerDocument9 pagesThermal Design of Heat ExchangerNaqqash SajidNo ratings yet

- Memoria ASME-Pressure-Vessel-DesignDocument143 pagesMemoria ASME-Pressure-Vessel-DesignJuan MendozaNo ratings yet

- Heat Exchanger Calculation Version 2Document2 pagesHeat Exchanger Calculation Version 2huangjlNo ratings yet

- Pipe Shell Design ToolDocument1 pagePipe Shell Design Toolep_alfiNo ratings yet

- Elliptical Head Design ToolDocument1 pageElliptical Head Design ToolSudjono BroNo ratings yet

- 8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Document42 pages8.0 Torispherical Head Design Calculation Asme Sec. Viii Div. 1Muhamad Amar Hakimmie Suhaimi100% (1)

- 350 V Pressure Vessel Strength CalculationDocument3 pages350 V Pressure Vessel Strength CalculationTanCM100% (1)

- Tutorial of WRC 107 For Lifting LugsDocument20 pagesTutorial of WRC 107 For Lifting LugsPeterWayNo ratings yet

- Vessel DatasheetDocument1 pageVessel Datasheetsdrtfg100% (1)

- 28 Roark Flat PlatesDocument14 pages28 Roark Flat Platesgutmont0% (1)

- Cone Calculations - AD MerkblatterDocument15 pagesCone Calculations - AD MerkblatterSajal KulshresthaNo ratings yet

- Cone Weight CalculationDocument10 pagesCone Weight CalculationRajesh OwaiyarNo ratings yet

- Shell CalculationsDocument3 pagesShell CalculationsBaher Elsheikh100% (7)

- FRP RF CalcDocument1 pageFRP RF CalcmukeshNo ratings yet

- Tailing LugDocument2 pagesTailing Lugjagannadha varmaNo ratings yet

- Volume Calculation For Pressure Vessel TankDocument2 pagesVolume Calculation For Pressure Vessel Tanksai srikarNo ratings yet

- Nozzle and ReinforcementDocument23 pagesNozzle and ReinforcementAzharyanto Fadhli100% (1)

- Rectangular Tank (With Horizontal Stiffner)Document5 pagesRectangular Tank (With Horizontal Stiffner)DURGAIRAJ100% (1)

- Pressure Vessel Design (Faiz Zelin)Document1 pagePressure Vessel Design (Faiz Zelin)moonstar_dme100% (3)

- Section VIII CalDocument19 pagesSection VIII CalPradeep Kothapalli100% (1)

- Skirt Support TrialDocument11 pagesSkirt Support TrialAbhishek Nag50% (2)

- Half Coil For VersselDocument1 pageHalf Coil For VersselhuangjlNo ratings yet

- Design of Pressure Vessel (Int & Ext)Document394 pagesDesign of Pressure Vessel (Int & Ext)api-3824026100% (8)

- Welded Beam CalculationDocument2 pagesWelded Beam CalculationVeenoyNo ratings yet

- Studding Outlet Calculation - PV Elite 2016Document8 pagesStudding Outlet Calculation - PV Elite 2016Liu YangtzeNo ratings yet

- Nozzle Pipe Length CalculatorDocument5 pagesNozzle Pipe Length CalculatorRyan Goh Chuang HongNo ratings yet

- Saddle CalculationDocument10 pagesSaddle Calculationpharis_chrisNo ratings yet

- Weld Shear Stress Check For FAVID Clips Welded On CladDocument3 pagesWeld Shear Stress Check For FAVID Clips Welded On CladrsubramaniNo ratings yet

- Calculation Sheet: Design CodeDocument1 pageCalculation Sheet: Design CodeCak AndiNo ratings yet

- Design of Lifting Lug: InputsDocument4 pagesDesign of Lifting Lug: InputsBahtiar Anak LaNangNo ratings yet

- Imperial Piping Weight Load Calculation WorkbookDocument13 pagesImperial Piping Weight Load Calculation WorkbookKakoDa100% (1)

- Pressure Vessel WEIGHT PresentDocument17 pagesPressure Vessel WEIGHT PresentErol Aydin100% (3)

- Vdocuments - MX Rectangular Tank CalculationDocument34 pagesVdocuments - MX Rectangular Tank CalculationAtilla TekinNo ratings yet

- Vessel Allowable LoadingsDocument50 pagesVessel Allowable LoadingsfahadfiazNo ratings yet

- Calculator - U Tubes - HSA & QtyDocument4 pagesCalculator - U Tubes - HSA & QtyRey Fiedacan100% (1)

- Limpet Coil DesignDocument10 pagesLimpet Coil Designmaheshspawar0% (1)

- Max Allowable Nozzle LoadDocument1 pageMax Allowable Nozzle Loaddskr fkshNo ratings yet

- Pipe&Shell Design Tool 600KLDocument1 pagePipe&Shell Design Tool 600KLJoshua Rivera100% (1)

- Reinforcement For Multi OpeningsDocument1 pageReinforcement For Multi OpeningsSajal KulshresthaNo ratings yet

- Weight Estimation of Vessels AppsDocument26 pagesWeight Estimation of Vessels Appsdhavalesh1No ratings yet

- Air Coolers HeadsDocument30 pagesAir Coolers HeadsSergio PluchinskyNo ratings yet

- Base Ring Fillet Size CalculationDocument4 pagesBase Ring Fillet Size Calculationmiteshpatel191No ratings yet

- Manual Design Validation CalculationDocument21 pagesManual Design Validation CalculationToniNo ratings yet

- Ibr Stand PipeDocument11 pagesIbr Stand PipeP s JagatheesanNo ratings yet

- Nozzle Reinf Calc (Rough)Document12 pagesNozzle Reinf Calc (Rough)Sajal Kulshrestha100% (1)

- Heat Exchanger DesignDocument8 pagesHeat Exchanger Designkikokiko KarimNo ratings yet

- Greg Heat Loss To SurroundingDocument6 pagesGreg Heat Loss To SurroundingMarta BaptistaNo ratings yet

- TEMA Type E Heat Exchanger DesignDocument8 pagesTEMA Type E Heat Exchanger DesignLEONARDO MOLERO CLEMENTENo ratings yet

- CondenserDocument5 pagesCondensersandeshNo ratings yet

- JR Heat Exchanger DesignDocument14 pagesJR Heat Exchanger Designjanelle ramdahinNo ratings yet

- Design of Shell & Tube HX (Unprotected For Expert Excel Users)Document31 pagesDesign of Shell & Tube HX (Unprotected For Expert Excel Users)ramesh pokhrelNo ratings yet

- The correct mean ΔTDocument4 pagesThe correct mean ΔTManoj ManivasagamNo ratings yet

- TM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)Document13 pagesTM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)jhunkujha11No ratings yet

- Shell Tube Heat Exchanger DesignDocument7 pagesShell Tube Heat Exchanger DesignMakhdoom Ibad HashmiNo ratings yet

- Design of Shell & Tube HXDocument62 pagesDesign of Shell & Tube HXUmirahRashidahNo ratings yet

- Heat Exchanger Calculations: Inside Heat Trasfer CoefficientDocument4 pagesHeat Exchanger Calculations: Inside Heat Trasfer CoefficientBimal DeyNo ratings yet

- Design of Shell & TubeDocument33 pagesDesign of Shell & TubeKathir VelNo ratings yet

- Validating Software For Manufacturing Processes: by David A. Vogel, PH.DDocument10 pagesValidating Software For Manufacturing Processes: by David A. Vogel, PH.Dsiva sankarNo ratings yet

- Guidelines Data Integrity & Computer System Validation: AcknowledgementsDocument40 pagesGuidelines Data Integrity & Computer System Validation: Acknowledgementssiva sankarNo ratings yet

- VAL 125 Guideline For The Development of A Validation Project Plan Sample PDFDocument3 pagesVAL 125 Guideline For The Development of A Validation Project Plan Sample PDFsiva sankarNo ratings yet

- VAL 090 Equipment Validation Guideline Sample PDFDocument2 pagesVAL 090 Equipment Validation Guideline Sample PDFsiva sankarNo ratings yet

- Master Validation Plan SOP and Approval TemplateDocument7 pagesMaster Validation Plan SOP and Approval Templatesiva sankarNo ratings yet

- Reasons, Regulations, and Rules PDFDocument59 pagesReasons, Regulations, and Rules PDFsiva sankarNo ratings yet

- Norman v1 v2 v3 Version 02 Final Feb2009 PDFDocument99 pagesNorman v1 v2 v3 Version 02 Final Feb2009 PDFsiva sankarNo ratings yet

- Key Elements of A QRIS Validation Plan:: Guidance and Planning TemplateDocument22 pagesKey Elements of A QRIS Validation Plan:: Guidance and Planning Templatesiva sankarNo ratings yet

- Planning Permission Validation Checklist 1 PDFDocument2 pagesPlanning Permission Validation Checklist 1 PDFsiva sankarNo ratings yet

- HACCP Systems Validation Draft Guide 2010 PDFDocument24 pagesHACCP Systems Validation Draft Guide 2010 PDFsiva sankarNo ratings yet

- Design Validation Plan - DVPR Template PDFDocument5 pagesDesign Validation Plan - DVPR Template PDFsiva sankarNo ratings yet

- Caballero 0730 PDFDocument37 pagesCaballero 0730 PDFsiva sankarNo ratings yet

- Emergency Shut Down System - Slide 1Document16 pagesEmergency Shut Down System - Slide 1NAVAR PRONo ratings yet

- Science 9 Q3Document8 pagesScience 9 Q3keziaacubNo ratings yet

- Illinois Transient Model PDFDocument77 pagesIllinois Transient Model PDFGustavo LarenzeNo ratings yet

- Culpeper County Water & Sewer Master Plan Compiled 2016-12-06 PDFDocument238 pagesCulpeper County Water & Sewer Master Plan Compiled 2016-12-06 PDFSuddhasattwa BandyopadhyayNo ratings yet

- 2 - Pitot TubeDocument16 pages2 - Pitot TubeHassan El SayedNo ratings yet

- Fluid Statics: Bes 4/L Fluid MechanicsDocument20 pagesFluid Statics: Bes 4/L Fluid MechanicsKurimaw ChuNo ratings yet

- Phasetester VXDocument2 pagesPhasetester VXHassan ManzarNo ratings yet

- Ground WaterDocument29 pagesGround WaterShahadat Hossain100% (2)

- Screw Gas Compressor For SM ProductionDocument4 pagesScrew Gas Compressor For SM ProductionBakti PrasetyoNo ratings yet

- Lessons in Water Treatment and DistributionDocument202 pagesLessons in Water Treatment and DistributionChristian D. Orbe100% (1)

- Carrying Capacity of Drilling MudsDocument10 pagesCarrying Capacity of Drilling MudsHai LinhNo ratings yet

- Calculation Fire Water Demand.Document3 pagesCalculation Fire Water Demand.Anonymous 6S9tcbhNo ratings yet

- Design and Fabrication of Amphibious Bicycle: June 2015Document36 pagesDesign and Fabrication of Amphibious Bicycle: June 2015Amanuel GetachewNo ratings yet

- A Series 7500 Eccentric Disc Butterfly Valve - 2022Document20 pagesA Series 7500 Eccentric Disc Butterfly Valve - 2022Ali Altoukhy100% (1)

- Tugas PP Lanjut Shinta Leonita 0906635772Document5 pagesTugas PP Lanjut Shinta Leonita 0906635772HarryNo ratings yet

- Chapter 15A - Fluids at RestDocument30 pagesChapter 15A - Fluids at Restosborne kachajeNo ratings yet

- Flow Measurement (Basics) : Ashvani Shukla C&I RelianceDocument47 pagesFlow Measurement (Basics) : Ashvani Shukla C&I RelianceDavinci LeonardoNo ratings yet

- 5 Types of Flow MetersDocument2 pages5 Types of Flow Metersabdulkidwai20090% (1)

- FM 3e SM Chap11 PDFDocument87 pagesFM 3e SM Chap11 PDFCAMILO ANDRES ORTIZ ENCISONo ratings yet

- 10m3 Polythene Vertical Water Tank DetailsDocument1 page10m3 Polythene Vertical Water Tank DetailsBilly TalaugonNo ratings yet

- Sand Jetting SystemDocument3 pagesSand Jetting SystemSHINo ratings yet

- Turbine Start-Up SOPDocument17 pagesTurbine Start-Up SOPCo-gen ManagerNo ratings yet

- Shell Helix HX8 ECT C3 5W-30: Main Applications Specifications, Approvals & RecommendationsDocument1 pageShell Helix HX8 ECT C3 5W-30: Main Applications Specifications, Approvals & RecommendationsHunt SekkerNo ratings yet

- Pedal Operated Water Filtration System (Mobifilt) : Research ArticleDocument5 pagesPedal Operated Water Filtration System (Mobifilt) : Research ArticleGajanan MaliNo ratings yet

- Interpave Permeable Pavement GuideDocument80 pagesInterpave Permeable Pavement GuideNiong DavidNo ratings yet

- Lecture 6 - The Bernoulli EquationDocument53 pagesLecture 6 - The Bernoulli EquationThatayamodimo KebueNo ratings yet