Professional Documents

Culture Documents

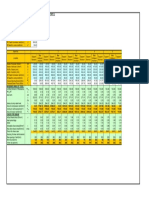

TOP CHORD AND WEB MEMBER DESIGN

Uploaded by

joe kyleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TOP CHORD AND WEB MEMBER DESIGN

Uploaded by

joe kyleCopyright:

Available Formats

TOP CHORD (MO)

MAXIMUM LOAD = 358.413 KN (COMPRESSION)

**Select Section

2L 127 x 127 x 12.7 (mm)

Where:

Ag = 3060 mm2

ry = 39.100 mm

Iy = 4.68 x 106 mm4

kg m 1 KN

Wm = 24.1 (9.81 2) (2.154 m) ( ) = 0.509 KN

m s 1000 N

**Slenderness Ratio

KL

r

Where:

L = Length of Member = 2154 mm

K = Effective Length Factor = 1.0

r = Radius of Gyration = 39.100 mm

KL 1.0(2154 mm)

=

r 39.100 mm

KL

= 55.090

r

**Solve for Cc

2π2 E

Cc = √ Fy

Where:

1000 psi 1 kg 1 in

Fy = 36 ksi ( 1 ksi

)(2.2 lb )(9.81 m/s2 )( 25.4

)2 =

248.818 MPa

E = 200000 MPa

2π2 (200000)

Cc = √ 248.818

Cc = 125.962

KL

**Since r

< Cc, use;

KL 2

( ) Fy

r

Fa =[1- 2Cc2

]F

s

Design of Truss Members | 36

But,

KL KL 3

5 3( ) ( )

r r

Fs = 3

+ 8Cc

- 8Cc3

**Solve for Fa

5 3(55.090) (55.090)3

Fs = 3

+ 8(125.962)

- 8(125.962)3

Fs = 1.820

(55.090)2 248.818

Fa =[1- 2(125.962)2

] 1.820

Fa = 123.638 MPa

**Solve for fa

P + 1.2Wm

fa = Ag

358.413 KN + 1.2(0.509 KN)

fa = 3060 mm2

KN 1000 N

fa = 0.117 mm2

( 1KN

)

fa = 117.328 MPa

Since Fa > fa,

Therefore, L 127 x 127 x 12.7 (mm) GOVERN; SAFE!

DESIGN PARAMETERS:

For Shear

ØRn = Ø(0.5 Fub)mAb

Where:

Ø = 0.75

m = 2 (Double Shear)

1000 psi 1 kg

Fub = 120 ksi ( 1 ksi

)(2.2 lb )(9.81 m/s2 )

1 in

( 25.4

)2

Fub = 829.393 N/mm²

π

Ab = 4

(22 mm)2 = 380.133 mm2

N 1 KN

ØRn = 0.75(0.5)(829.393 mm2

)(2)(380.133 mm2)(1000 N)

KN

ØRn = 236.460 bolt

For Bearing

ØRn = Ø(2.4 Fu)dt

Design of Truss Members | 37

Where:

Ø = 0.75

d = 22 mm

t = 12.700 mm

N 1 KN

ØRn = 0.75(2.4)(400.873 )(22mm)(12.7mm)( )

mm2 1000 N

KN

ØRn = 201.607 bolt

KN KN

ØRn = 236.460 bolt

> 201.607 bolt

Therefore, Bearing Governs.

BOLT SPACING AND EDGE DISTANCE

s = 3d + 1.6 = 3(22 mm) + 1.6 =67.600 mm

Le = s – (d +1.6) = 67.600 – (22 + 1.6) = 44 mm

**Number of Bolts

Pu

N = ØRn

Where:

ØRn = 201.607 KN/bolt

Pu = 358.413 KN

358.413

N = 201.607

N = 1.778 say 2 bolts

**Check Block Shear using 5-22mm

Design of Truss Members | 38

s = 67.600 mm

Le = 44.000 mm

Anv = {314.4 - ⌊4.5(22+1.6)⌋} (12.7)

Anv = 2644.140 mm2

Ant = {44 - ⌊0.5(22+1.6)⌋} (12.7)

Ant = 408.940 mm2

P = FVAnv + FTAnt

FV = 0.3FU = 0.3(400.873 N/mm2) = 120.262 MPa

FT = 0.5FU = 0.5(400.873 N/mm2) = 200.437 MPa

P = (120.262)(2644.140) + (200.437)(408.940)

P = 399956.272 N

P = 399.956 KN

399.956 KN > 358.413 KN

Therefore, Use 5 – 22mm Bolts

WEB MEMBER (Member IH)

MAXIMUM LOAD = 135.008 KN (TENSION)

**Solve for Design Strength

Yielding in the Cross-Section

Øt Tn = Øt Fy Ag

Where:

Øt Tn = Tu = 135.008 KN

Øt = 0.900

Fy = 248.818 MPa

Tu

Ag =

Øt Fy

Design of Truss Members | 39

135008 N

Ag =

0.9(248.818 MPa)

Ag = 602.886 mm2

Fracture in the Net-Section

Øt Tn = øt Fu Ae

Where:

Øt Tn = Tu = 135.008 KN

Øt = 0.750

1000 psi 1 kg

FU = 58 ksi ( )( )(9.81 m/s2 )

1 ksi 2.2 lb

1 in

( )2

25.4

FU = 400.873 N/mm²

Tu

Ae =

Øt Fu

135008 N

Ae =

0.750(400.873 MPa)

Ae = 449.047 mm2

Ae = uAn

Where: u = 0.850

Ae

An =

u

449.047 mm2

An =

0.850

An = 528.290 mm2

Radius of Gyration

L 2320

r = = = 7.733

300 300

SELECT SECTION:

2L 127 x 127 x 12.7 (mm)

Where:

Ag = 3060 mm2

ry = 39.100 mm

Iy = 4.68 x 106 mm4

DESIGN PARAMETERS:

For Shear

Design of Truss Members | 40

ØRn = Ø(0.5 Fub)mAb

Where:

Ø = 0.75

m = 2 (Double Shear)

1000 psi 1 kg

Fub = 120 ksi ( )( )(9.81 m/s2)

1 ksi 2.2 lb

1 in

( )2

25.4

Fub = 829.393 N/mm²

π

Ab = (22 mm)2 = 380.133 mm2

4

N 1 KN

ØRn = 0.75(0.5)(829.393 2

)(2)(380.133mm2)( )

mm 1000 N

KN

ØRn = 236.460

bolt

For Bearing

ØRn = Ø(2.4 Fu)dt

Where:

Ø = 0.75

d = 22 mm

t = 12.700 mm

N 1 KN

ØRn = 0.75(2.4)(400.873 2 )(22mm)(12.7mm)( )

mm 1000 N

KN

ØRn = 201.607

bolt

KN KN

ØRn = 236.460 > 201.607

bolt bolt

Therefore, Bearing Governs.

BOLT SPACING AND EDGE DISTANCE

s = 3d + 1.6 = 3(22 mm) + 1.6 = 67.6 mm

Le = s – (d +1.6) = 67.600 – (22 + 1.6) = 44 mm

**Number of Bolts

Pu

N =

ØRn

Design of Truss Members | 41

Where:

ØRn = 201.607 KN/bolt

Pu = 135.008 KN

135.008

N =

201.607

N = 0.670 say 1 bolt

**Check Block Shear using 2-22mm

s =

67.600 mm

Le = 44.000 mm

Anv = {111.6 - ⌊1.5(22+1.6)⌋} (12.7)

Anv = 967.740 mm2

Ant = {44 - ⌊0.5(22+1.6)⌋} (12.7)

Ant = 408.940 mm2

P = FVAnv + FTAnt

FV = 0.3FU = 0.3(400.873 N/mm2) = 120.262 MPa

FT = 0.5FU = 0.5(400.873 N/mm2) = 200.437 MPa

P = (120.262)(967.740) + (200.437)(408.940)

P = 198349.055 N

P = 198.349 KN

198.349 > 135.008 KN

Therefore, Use 2 – 22mm Bolt

Design of Truss Members | 42

Net area:

An = 3060 – 2(22 + 1.6) 12.7

An = 2460.560 mm2 > 528.290 mm2

Therefore, Use 127 x 127 x 12.7 (mm)

BOTTOM CHORD (MO)

MAXIMUM LOAD = 251.507 KN (TENSION)

**Solve for Design Strength

Yielding in the Cross-Section

Øt Tn = Øt Fy Ag

Where:

Øt Tn = Tu = 251.507 kN

Øt = 0.900

Fy = 248.818 MPa

Tu

Ag = Øt Fy

251507 N

Ag = 0.9(248.818 MPa)

Ag = 1123.119 mm2

Fracture in the Net-Section

Øt Tn = øt Fu Ae

Where:

Øt Tn = Tu = 251.507 kN

Øt = 0.750

1000 psi 1 kg

FU = 58 ksi ( 1 ksi

)(2.2 lb )(9.81 m/s2 )

1 in

( 25.4

)2

FU = 400.873 N/mm²

Tu

Ae = Øt Fu

251507 N

Ae =

0.750(400.873 MPa)

Ae = 836.531 mm2

Ae = uAn

Where: u = 0.850

Design of Truss Members | 43

Ae

An = u

836.531 mm2

An =

0.850

An = 984.154 mm2

Radius of Gyration

L 2320

r = 300

= 300

= 7.733

SELECT SECTION:

2L 127 x 127 x 12.7 (mm)

Where:

Ag = 3060 mm2

ry = 39.100 mm

Iy = 4.68 x 106 mm4

DESIGN PARAMETERS:

For Shear

ØRn = Ø(0.5 Fub)mAb

Where:

Ø = 0.75

m = 2 (Double Shear)

1000 psi 1 kg

Fub = 120ksi ( )( )(9.81m/s2 )

1 ksi 2.2 lb

1 in

( 25.4

)2

Fub = 829.393 N/mm²

π

Ab = 4

(22 mm)2 = 380.133 mm2

N 1 KN

ØRn = 0.75(0.5)(829.393 mm2

)(2)(380.133 mm2)(1000 N)

KN

ØRn = 236.460

bolt

For Bearing

ØRn = Ø(2.4 Fu)dt

Where:

Ø = 0.75

d = 22 mm

t = 12.7 mm

N 1 KN

ØRn = 0.75(2.4)(400.873 mm2

)(22mm)(12.7 mm)(1000 N)

Design of Truss Members | 44

KN

ØRn = 201.607 bolt

KN KN

ØRn = 236.460 bolt

> 201.607 bolt

Therefore, Bearing Governs.

BOLT SPACING AND EDGE DISTANCE

s = 3d + 1.6 = 3(22 mm) + 1.6 = 67.6 mm

Le = s – (d +1.6) = 67.6 – (22 + 1.6) = 44 mm

**Number of Bolts

Pu

N = ØRn

Where:

ØRn = 201.607 KN/bolt

Pu = 251.507 kN

251.507

N =

201.607

N = 1.248 say 2 bolts

**Check Block Shear using 3-22mm

s = 67.600 mm

Le = 44.000 mm

Anv = {179.2 - ⌊2.5(22+1.6)⌋} (12.7)

Anv = 1526.540 mm2

Ant = {44 - ⌊0.5(22+1.6)⌋} (12.7)

Ant = 408.940 mm2

P = FVAnv + FTAnt

FV = 0.3FU = 0.3(400.873 N/mm2) = 120.262 MPa

FT = 0.5FU = 0.5(400.873 N/mm2) = 200.437 MPa

P = (120.262)(1526.540) + (200.437)(408.940)

Design of Truss Members | 45

P = 265551.460 N

P = 265.551 KN

265.551 KN > 251.507 KN

Therefore, Use 3 – 22mm Bolts

Net area:

An = 3060 – 3(22 + 1.6) 12.7

An = 2160.840 mm2 > 984.154 mm2

Therefore, Use 127 x 127 x 12.7 (mm)

Design of Truss Members | 46

You might also like

- Design of Slab and Footing for Proposed TownhouseDocument7 pagesDesign of Slab and Footing for Proposed TownhouseNikolai GongoraNo ratings yet

- Flexural Analysis and Design of Beamns 3Document18 pagesFlexural Analysis and Design of Beamns 3Adil Javed Chaudhary100% (1)

- ROOF PURLIN DESIGN CALCULATIONSDocument2 pagesROOF PURLIN DESIGN CALCULATIONStini871No ratings yet

- RC Balancing Reservoir Slab Design and Reinforcement DetailsDocument7 pagesRC Balancing Reservoir Slab Design and Reinforcement DetailsrahimNo ratings yet

- Design of Two Way Slab: DESIGN FOR 2S-1 and 3S-1Document100 pagesDesign of Two Way Slab: DESIGN FOR 2S-1 and 3S-1Cesar MigoNo ratings yet

- Computation OF Dead Loads: Surigao State College of TechnologyDocument26 pagesComputation OF Dead Loads: Surigao State College of TechnologyRbcabajes ButalonNo ratings yet

- Design TrussDocument9 pagesDesign TrussjaypeeNo ratings yet

- (Estimation of Dead Load) in A 2-Storey Residential House: Ce 115 - Structural Theory IiDocument31 pages(Estimation of Dead Load) in A 2-Storey Residential House: Ce 115 - Structural Theory Iishinichi falcoNo ratings yet

- Alex Ong's Bungalow at Bukit Rimau, Shah Alam:: Reinforced Concrete Restrained Two Way Slab Design To BS 8110Document4 pagesAlex Ong's Bungalow at Bukit Rimau, Shah Alam:: Reinforced Concrete Restrained Two Way Slab Design To BS 8110Anonymous O404LiV4CNo ratings yet

- Column Design - As Per BS CodeDocument16 pagesColumn Design - As Per BS CodeFar AwayNo ratings yet

- Load CalculationDocument6 pagesLoad CalculationbulganinNo ratings yet

- Column & FootingDocument32 pagesColumn & FootingAmol potdarNo ratings yet

- Loads Dead Load: Floor Load Floors RoofDocument22 pagesLoads Dead Load: Floor Load Floors RoofJoshua De LeonNo ratings yet

- Reinforced Concrete Stirrup Design and Shear CalculationsDocument9 pagesReinforced Concrete Stirrup Design and Shear CalculationsClaudine PansacalaNo ratings yet

- Design of Footing For Corner ColumnDocument4 pagesDesign of Footing For Corner ColumnMegatech Engineering ConsultantsNo ratings yet

- Spreadsheets To BS 8110: The Concrete CentreDocument14 pagesSpreadsheets To BS 8110: The Concrete CentreCioabla BogdanNo ratings yet

- Total Weight of Tank and Float 1Document49 pagesTotal Weight of Tank and Float 1Naziemi AhmadNo ratings yet

- MS 1314 Part 3 2004Document19 pagesMS 1314 Part 3 2004Wei Han NgNo ratings yet

- 2 19 Flexural Analysis and Design of RC BeamsDocument22 pages2 19 Flexural Analysis and Design of RC BeamsMohammed Al-HelayelNo ratings yet

- Sta FeDocument22 pagesSta Fegeneveve colasitoNo ratings yet

- Proposed Residential Development: Thirty Stars Investment Group Ltd. Base B1 AMG 1Document1 pageProposed Residential Development: Thirty Stars Investment Group Ltd. Base B1 AMG 1patrick chegeNo ratings yet

- RESIDENTIAL TOWNHOUSE STRUCTURAL DESIGNDocument8 pagesRESIDENTIAL TOWNHOUSE STRUCTURAL DESIGNNick OperarioNo ratings yet

- Design of RoofingDocument10 pagesDesign of RoofingEugene EpiscopeNo ratings yet

- Column Loading:: Distribution of Load On Individual Pile of A Pile GroupDocument16 pagesColumn Loading:: Distribution of Load On Individual Pile of A Pile GroupWRay TanNo ratings yet

- Final Output More SepadaDocument1,298 pagesFinal Output More SepadaJHON CLYDE SEPADANo ratings yet

- RCC53 Column DesignDocument15 pagesRCC53 Column DesignnanivenkatgauravNo ratings yet

- All DesignDocument45 pagesAll Designchandan kumar c gNo ratings yet

- LC PurlinDocument9 pagesLC PurlinRachelle QuilalaNo ratings yet

- Construction Progress Report for Cagayan de Oro Bypass RoadsDocument4 pagesConstruction Progress Report for Cagayan de Oro Bypass RoadsBugas EmelynNo ratings yet

- Detailed Design Design of SlabDocument4 pagesDetailed Design Design of Slabnandheeswaran rNo ratings yet

- Reinforced Concrete Column Design AnalysisDocument8 pagesReinforced Concrete Column Design AnalysisJefreyMatuanMondranoNo ratings yet

- Asphalt Footing3Document37 pagesAsphalt Footing3Bert EngNo ratings yet

- Site Grading, Subgrade Excavate (Cut & Fill) Excavation (Cut) & Backfilling Compacted To 90% MDDDocument13 pagesSite Grading, Subgrade Excavate (Cut & Fill) Excavation (Cut) & Backfilling Compacted To 90% MDDEdgar QuinonesNo ratings yet

- Draft EstimateDocument205 pagesDraft EstimateDan Aragon Retota100% (1)

- FCK Fy B H D D': Grade of Concrete (N/MM) Grade of Reinf Steel (N/MM)Document1 pageFCK Fy B H D D': Grade of Concrete (N/MM) Grade of Reinf Steel (N/MM)Manoj Kumar PalNo ratings yet

- Bukit Keteri (Pg3-Pc2) : Table 3.25: Minimum Percentages of ReinforcementDocument4 pagesBukit Keteri (Pg3-Pc2) : Table 3.25: Minimum Percentages of ReinforcementazwanNo ratings yet

- Design of Retaining Wall ReinforcementDocument7 pagesDesign of Retaining Wall ReinforcementMAGED MOHMMED AHMED QASEMNo ratings yet

- Footing Design and AnalysisDocument5 pagesFooting Design and AnalysisRichelle DandoNo ratings yet

- Stair CaseDocument5 pagesStair CaseMahitha ReddyNo ratings yet

- Column Design CalculationsDocument307 pagesColumn Design CalculationsJuly Mar KobyashiNo ratings yet

- Manyam Dr.s House 2.5Document33 pagesManyam Dr.s House 2.5Durga Rama Swamy KalvakolanuNo ratings yet

- POW Natubo, JasaanDocument85 pagesPOW Natubo, JasaanJayshane KwanNo ratings yet

- Department of Public Works and Highways Laguna II District Engineering OfficeDocument83 pagesDepartment of Public Works and Highways Laguna II District Engineering OfficeThaddeus NavarroNo ratings yet

- Slab DesignDocument25 pagesSlab DesignSabin Leroy HmgnNo ratings yet

- Project Report Granite MineDocument11 pagesProject Report Granite MineSmriti GargNo ratings yet

- Back Up ComputationDocument12 pagesBack Up ComputationAbigail Mae DizonNo ratings yet

- Reinforcement: V, F: Project: Staircase Design - STC 1Document4 pagesReinforcement: V, F: Project: Staircase Design - STC 1zzweirdozzNo ratings yet

- 18ni0040 Tagasaka BridgeDocument108 pages18ni0040 Tagasaka BridgeCheryl OrejasNo ratings yet

- Steel Plan ReferenceDocument16 pagesSteel Plan ReferenceJeremie VallesNo ratings yet

- Main Truss Design DetailsDocument19 pagesMain Truss Design Detailsformwork companyNo ratings yet

- Siaran Khas 1 (SM) November 2017Document45 pagesSiaran Khas 1 (SM) November 2017Jusri Mustafa100% (4)

- St-Herbert Yu-S-1 PDFDocument1 pageSt-Herbert Yu-S-1 PDFSoy DesignoNo ratings yet

- Water Tank Load CalculationDocument2 pagesWater Tank Load CalculationyarmeenaNo ratings yet

- Final Combined Design (Max Mu)Document84 pagesFinal Combined Design (Max Mu)xyzzy blankNo ratings yet

- Load CalculationsDocument2 pagesLoad Calculationsamin tariqNo ratings yet

- Foundation Plan 2Nd Flr. Framg. Plan 3Rd Flr. Framg. Plan P.House Framg. PlanDocument1 pageFoundation Plan 2Nd Flr. Framg. Plan 3Rd Flr. Framg. Plan P.House Framg. Planmark gumamelaNo ratings yet

- Pup Architectural Part 2aDocument179 pagesPup Architectural Part 2aIrie Mae GuzmanNo ratings yet

- Calculation Sheet: Sediment Trap DesignDocument6 pagesCalculation Sheet: Sediment Trap DesignShazreel AmirNo ratings yet

- Steel beam design calculation and checksDocument20 pagesSteel beam design calculation and checksJin ChuanNo ratings yet

- Fy 276 Mpa: Formula For Transferring The Weight of Slab To BeamDocument19 pagesFy 276 Mpa: Formula For Transferring The Weight of Slab To Beamraymark mendozaNo ratings yet

- Design & Construction of Substation 16P Painting System ComplianceDocument103 pagesDesign & Construction of Substation 16P Painting System ComplianceRamil LazNo ratings yet

- Political Engineering and Party Politics in Conflict-Prone SocietiesDocument18 pagesPolitical Engineering and Party Politics in Conflict-Prone SocietiesNashiba Dida-AgunNo ratings yet

- People v. Lagarto, 326 SCRA 693 (2000)Document43 pagesPeople v. Lagarto, 326 SCRA 693 (2000)GioNo ratings yet

- Advanced Presentation Skills: Creating Effective Presentations with Visuals, Simplicity and ClarityDocument15 pagesAdvanced Presentation Skills: Creating Effective Presentations with Visuals, Simplicity and ClarityGilbert TamayoNo ratings yet

- Lineapelle: Leather & Non-LeatherDocument16 pagesLineapelle: Leather & Non-LeatherShikha BhartiNo ratings yet

- 41 PDFsam Redis CookbookDocument5 pages41 PDFsam Redis CookbookHữu Hưởng NguyễnNo ratings yet

- Lecture 29: Curl, Divergence and FluxDocument2 pagesLecture 29: Curl, Divergence and FluxKen LimoNo ratings yet

- Galambos 1986Document18 pagesGalambos 1986gcoNo ratings yet

- College of Physical Therapy Produces Skilled ProfessionalsDocument6 pagesCollege of Physical Therapy Produces Skilled ProfessionalsRia Mae Abellar SalvadorNo ratings yet

- One - Pager - SOGEVAC SV 320 BDocument2 pagesOne - Pager - SOGEVAC SV 320 BEOLOS COMPRESSORS LTDNo ratings yet

- Icelandic Spells and SigilsDocument16 pagesIcelandic Spells and SigilsSimonida Mona Vulić83% (6)

- Millennium Separation ReportDocument3 pagesMillennium Separation ReportAlexandra AkeNo ratings yet

- Admisibility To Object EvidenceDocument168 pagesAdmisibility To Object EvidenceAnonymous 4WA9UcnU2XNo ratings yet

- Stellar Structure and EvolutionDocument222 pagesStellar Structure and Evolutionjano71100% (2)

- Building Primitive Traps & SnaresDocument101 pagesBuilding Primitive Traps & SnaresJoseph Madr90% (10)

- Lean Management AssignmentDocument14 pagesLean Management AssignmentElorm Oben-Torkornoo100% (1)

- Oracle® E-Business Suite: Integrated SOA Gateway Implementation Guide Release 12.2Document202 pagesOracle® E-Business Suite: Integrated SOA Gateway Implementation Guide Release 12.2yadavdevenderNo ratings yet

- TILE FIXING GUIDEDocument1 pageTILE FIXING GUIDEStavros ApostolidisNo ratings yet

- European Business in China Position Paper 2017 2018 (English Version)Document408 pagesEuropean Business in China Position Paper 2017 2018 (English Version)Prasanth RajuNo ratings yet

- Basic LCI To High LCIDocument3 pagesBasic LCI To High LCIIonut VladNo ratings yet

- C11 Strategy DevelopmentDocument30 pagesC11 Strategy DevelopmentPARTI KEADILAN RAKYAT NIBONG TEBALNo ratings yet

- City MSJDocument50 pagesCity MSJHilary LedwellNo ratings yet

- OMR Sheet Has Been Attached at The End: EST Erial ODocument8 pagesOMR Sheet Has Been Attached at The End: EST Erial OSangeeta BansalNo ratings yet

- Act 1&2 and SAQ No - LawDocument4 pagesAct 1&2 and SAQ No - LawBududut BurnikNo ratings yet

- 4 TheEulerianFunctions - 000 PDFDocument16 pages4 TheEulerianFunctions - 000 PDFShorouk Al- IssaNo ratings yet

- Mad LabDocument66 pagesMad LabBalamurugan MNo ratings yet

- 5.a Personal Diet Consultant For Healthy MealDocument5 pages5.a Personal Diet Consultant For Healthy MealKishore SahaNo ratings yet

- Membandingkan Recall 24 Jam Nutri Survey Dengan TkpiDocument7 pagesMembandingkan Recall 24 Jam Nutri Survey Dengan TkpiFransisca SihotangNo ratings yet

- LNG Vaporizers Using Various Refrigerants As Intermediate FluidDocument15 pagesLNG Vaporizers Using Various Refrigerants As Intermediate FluidFrandhoni UtomoNo ratings yet

- Appendix 1 Application FormDocument13 pagesAppendix 1 Application FormSharifahrodiah SemaunNo ratings yet