Professional Documents

Culture Documents

Section 4A: General Specifications

Uploaded by

Jarry PotterOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Section 4A: General Specifications

Uploaded by

Jarry PotterCopyright:

Available Formats

SECTION 4A

HYDRAULIC BRAKES

CAUTION:Disconnectthenegativebatterycablebeforeremovingorinstallinganyelectricalunitorwhena

toolorequipmentcouldeasilycomeincontactwithexposedelectricalterminals.Disconnectingthiscable

willhelppreventpersonalinjuryanddamagetothevehicle.TheignitionmustalsobeinLOCKunless

otherwisenoted.

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-1 Maintenance and Repair . . . . . . . . . . . . . . . . . . . 4A-10

General Specifications . . . . . . . . . . . . . . . . . . . . . 4A-1 On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . . . . . 4A-10

Fastener Tightening Specifications . . . . . . . . . . . 4A-2 Manual Bleeding the Brakes . . . . . . . . . . . . . . . 4A-10

Component Locator . . . . . . . . . . . . . . . . . . . . . . . . 4A-3 Pressure Bleeding the Brakes . . . . . . . . . . . . . . 4A-13

Brake System (ABS) . . . . . . . . . . . . . . . . . . . . . . . 4A-3 Brake Hose Rear . . . . . . . . . . . . . . . . . . . . . . . . . 4A-14

Brake System (Non-ABS) . . . . . . . . . . . . . . . . . . 4A-4 Brake Hose Front . . . . . . . . . . . . . . . . . . . . . . . . 4A-15

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-5 Stoplamp Switch . . . . . . . . . . . . . . . . . . . . . . . . . 4A-17

Brake System Testing . . . . . . . . . . . . . . . . . . . . . . 4A-5 Brake Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-19

Brake Hose Inspection . . . . . . . . . . . . . . . . . . . . . 4A-5 General Description and System

Warning Lamp Operation . . . . . . . . . . . . . . . . . . . 4A-5 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-21

Brake Lamp Warning Circuit Diagnosis . . . . . . . 4A-6 Warning Lamp Operation . . . . . . . . . . . . . . . . . . 4A-21

SPECIFICATIONS

GENERAL SPECIFICATIONS

1.6 DOHC Engine 2.0 DOHC Engine

Application Millimeters Inches Millimeters Inches

Brake Drums:

Inside Diameter 200.00 7.87 - -

Maximum Rebore Diameter 201.00 7.91 - -

Out-of-Round 0.050 0.002 - -

Front Brake Rotors:

Discard Thickness 22.00 0.87 22.00 0.87

Lateral Runout (Installed) 0.030 0.001 0.030 0.001

Rotor Diameter 265.00 10.43 265.00 10.43

Rotor Thickness (New) 24.00 0.95 24.00 0.95

Thickness Variation 0.010 0.001 0.03 0.0011

Rear Brake Rotors:

Discard Thickness - - 8.4 0.33

Lateral Runout (Installed) - - 0.100 0.004

Rotor Diameter - - 258.00 10.16

Rotor Thickness (New) - - 10.40 0.41

Thickness Variation - - 0.010 0.0004

Master Cylinder:

Bore Diameter (Nominal) 22.22 0.875 23.81 0.937

Bore Diameter (Maximum) 22.29 0.878 23.86 0.937

DAEWOO J-100 BL2 / BL3

4A -- 2 HYDRAULIC BRAKES

GENERAL SPECIFICATIONS (Cont’d.)

1.6 DOHC Engine 2.0 DOHC Engine

Application Millimeters Inches Millimeters Inches

Caliper:

Minimum Piston Diameter (Front) 54.00 0.0393 57.00 2.244

Minimum Piston Diameter (Rear) - - 35.00 1.377

Wheel Cylinder Diameter:

Maximum 19.11 0.750 - -

Nominal 19.05 0.753 - -

FASTENER TIGHTENING SPECIFICATIONS

Application NSm Lb-Ft Lb-In

Bleeder Screw 6 - 53

Brake Lines 16 12 -

Brake Pedal-to-Pedal Bracket Hex Nut 18 13 -

Front Disc Brake Hose-to-Caliper Bolt 40 30 -

Rear Disc Brake Hose-to-Caliper Bolt 32 24 -

DAEWOO J-100 BL2 / BL3

HYDRAULIC BRAKES 4A -- 3

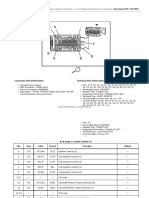

COMPONENT LOCATOR

BRAKE SYSTEM (ABS)

B207A001

1 RH Rear Brake Hose 10 Front Brake Pipe

2 RH 3rd Rear Brake Pipe 11 LH Front Brake Hose

3 Clip 12 Connector

4 2nd Rear Brake Pipe (A) 13 1st Rear Brake Pipe (A)

5 2nd Front Brake Pipe 14 1st Front Brake Pipe

6 RH Front Brake Hose 15 1st Rear Brake Pipe (B)

7 2nd Rear Brake Pipe (B) 16 LHD Master Cylinder/Booster Assembly

8 ABS Modulator 17 LH Rear Brake Hose

9 Bracket 18 LH 3rd Rear Brake Pipe

DAEWOO J-100 BL2 / BL3

4A -- 4 HYDRAULIC BRAKES

BRAKE SYSTEM (NON-ABS)

B207A002

1 RH Rear Brake Hose 9 LH Front Brake Hose

2 RH 3rd Rear Brake Pipe 10 Connector

3 Clip 11 1st Rear Brake Pipe (A)

4 2nd Rear Brake Pipe 12 1st Front Brake Pipe

5 2nd Front Brake Pipe 13 1st Rear Brake Pipe (B)

6 RH Front Brake Hose 14 LHD Master Cylinder/Booster Assembly

7 2nd Rear Brake Pipe 15 LH Rear Brake Hose

8 Front Brake Pipe 16 LH 3rd Rear Brake Pipe

DAEWOO J-100 BL2 / BL3

HYDRAULIC BRAKES 4A -- 5

DIAGNOSIS D Check for a binding pedal linkage and for an incorrect

pushrod length. If both of these parts are in satisfac-

tory condition, disassemble the master cylinder and

BRAKE SYSTEM TESTING check for an elongated or swollen primary cylinder or

Brakes should be tested on a dry, clean, reasonably piston seals. If swollen seals are found, substandard

smooth and level roadway. A true test of brake perfor- or contaminated brake fluid should be suspected. If

mance cannot be made if the roadway is wet, greasy, or contaminated brake fluid is found, all the components

covered with loose dirt whereby all tires do not grip the should be disassembled and cleaned, and all the

road equally. Testing will also be adversely affected if the rubber components should be replaced. All of the

roadway is crowned so as to throw the weight so roughly pipes must also be flushed.

that the wheels tend to bounce. Improper brake fluid, or mineral oil or water in the fluid,

Test the brakes at different vehicle speeds with both light may cause the brake fluid to boil or cause deterioration

and heavy pedal pressure; however, avoid locking the of the rubber components. If the primary piston cups in

brakes and sliding the tires. Locked brakes and sliding the master cylinder are swollen, then the rubber parts

tires do not indicate brake efficiency since heavily have deteriorated. This deterioration may also be evi-

braked, but turning, wheels will stop the vehicle in less denced by swollen wheel cylinder piston seals on the

distance than locked brakes. More tire-to-road friction is drum brake wheels.

present with a heavily-braked, turning tire than with a If deterioration of rubber is evident, disassemble all the

sliding tire. hydraulic parts and wash the parts with alcohol. Dry

Because of the high deceleration capability, a firmer these parts with compressed air before reassembly to

pedal may be felt at higher deceleration levels. keep alcohol out of the system. Replace all the rubber

There are three major external conditions that affect parts in the system, including the hoses. Also, when

brake performance: working on the brake mechanisms, check for fluid on the

linings. If excessive fluid is found, replace the linings.

D Tires having unequal contact and grip of the road will

cause unequal braking. Tires must be equally in- If the master cylinder piston seals are in satisfactory

flated, and the tread pattern of the right and the left condition, check for leaks or excessive heat conditions.

tires must be approximately equal. If these conditions are not found, drain the fluid, flush the

master cylinder with brake fluid, refill the master cylin-

D Unequal loading of the vehicle can affect the brake

der, and bleed the system. Refer to “Manual Bleeding

performance since the most heavily loaded wheels

the Brakes” or “Pressure Bleeding the Brakes” in this

require more braking power, and thus more braking

section.

effort, than the others.

D Misalignment of the wheels, particularly conditions of BRAKE HOSE INSPECTION

excessive camber and caster, will cause the brakes

to pull to one side. The hydraulic brake hoses should be inspected at least

twice a year. The brake hose assembly should be

To check for brake fluid leaks, hold constant foot pres- checked for road hazard damage, cracks, chafing of

sure on the pedal with the engine running at idle and the the outer cover, and for leaks or blisters. Inspect the

shift lever in NEUTRAL. If the pedal gradually falls away hoses for proper routing and mounting. A brake hose

with the constant pressure, the hydraulic system may that rubs on a suspension component will wear and

be leaking. Perform a visual check to confirm any sus- eventually fail. A light and a mirror may be needed for

pected leaks. an adequate inspection. If any of the above conditions

Check the master cylinder fluid level. While a slight drop are observed on the brake hose, adjust or replace the

in the reservoir level results from normal lining wear, hose as necessary.

an abnormally low level indicates a leak in the system.

The hydraulic system may be leaking either internally or WARNING LAMP OPERATION

externally. Refer to the procedure below to check the

This brake system uses a BRAKE warning lamp located

master cylinder. Also, the system may appear to pass

in the instrument panel cluster. When the ignition switch

this test while still having a slight leak. If the fluid level is

is in the START position, the BRAKE warning lamp

normal, check the vacuum booster pushrod length. If an

should glow and go OFF when the ignition switch re-

incorrect pushrod length is found, adjust or replace the

turns to the RUN position.

rod.

The following conditions will activate the BRAKE lamp:

Check the master cylinder using the following procedure:

D Parking brake applied. The light should be ON when-

D Check for a cracked master cylinder casting or brake

ever the parking brake is applied and the ignition

fluid leaking around the master cylinder. Leaks are in-

switch is ON.

dicated only if there is at least one drop of fluid.

A damp condition is not abnormal. D Low fluid level. A low fluid level in the master cylinder

will turn the BRAKE lamp ON.

DAEWOO J-100 BL2 / BL3

4A -- 6 HYDRAULIC BRAKES

BRAKE LAMP WARNING CIRCUIT DIAGNOSIS

B107A011

Test Description 12. If the other checks have been properly performed

The number(s) below refer to step(s) on the diagnostic and the brake warning lamp is off after disconnect-

table. ing the electronic brake control module (EBCM)

J1 connector, the EBCM is faulty.

1. When the ignition is turned ON, the brake warning

lamp should initially illuminate and then dim for ABS 19. If the brake warning lamp does not operate while

equipped vehicles. This is done as a bulb check. On performing any of the functions, the fault should be

vehicles that are not equipped with ABS, the brake in the ignition feed to the circuit.

warning lamp should only illuminate when either the 24. This step determines if the problem is in the ignition

brake fluid reservoir is low or the parking brake is ap- feed to the circuit or in the instrument cluster.

plied. 30. The brake warning lamp should illuminate when

7. The brake fluid level switch is a normally open jumpering the parking brake connector to ground.

switch. If the brake warning lamp is off after dis- 32. If the brake warning lamp is on after jumpering the

connecting the switch, the brake fluid level switch brake fluid level switch terminals, the switch is faulty.

is stuck closed.

9. If the brake warning lamp is still on after disconnect-

ing the parking brake switch, there is a short to

ground in the wire to the parking brake switch.

DAEWOO J-100 BL2 / BL3

HYDRAULIC BRAKES 4A -- 7

Brake Lamp Warning Circuit Diagnosis

Step Action Value(s) Yes No

Turn the ignition ON.

1 - Go to Step 2 Go to Step 18

Is the brake warning lamp always on?

Check the ABS warning lamp.

2 - Go to Step 3 Go to Step 4

Is the ABS warning lamp also on?

Use a scan tool to check for diagnostic trouble

codes (DTCs) and follow the procedures for any

3 DTCs found. -

Is the lamp still on? Go to Step 4 System OK

Release the parking brake fully.

4 - System OK Go to Step 5

Is the lamp off?

Check the brake fluid level.

5 - Go to Step 7 Go to Step 6

Is the fluid level OK?

1. Fill the brake fluid reservoir with clean DOT

3 equivalent hydraulic fluid.

6 -

2. Replace the cap on the fluid reservoir.

Is the lamp on? Go to Step 7 System OK

Disconnect the harness connector from the brake

7 fluid level switch. -

Is the lamp on? Go to Step 9 Go to Step 8

Replace the brake fluid level switch.

8 - System OK -

Is the repair complete?

1. Connect the brake fluid level switch.

9 2. Disconnect the parking brake switch. -

Is the lamp on? Go to Step 11 Go to Step 10

Replace the parking brake switch.

10 - System OK -

Is the repair complete?

Connect the parking brake switch.

11 - Go to Step 12 Go to Step 14

Is the vehicle equipped with ABS?

1. Turn the ignition OFF.

2. Disconnect the electronic brake control module

12 (EBCM) J1 connector. -

3. Turn the ignition ON.

Go to Step 14 Go to Step 13

Is the lamp on?

Replace the electronic brake control module

13 (EBCM). - -

Is the repair complete? System OK

1. Turn the ignition OFF.

2. Connect the EBCM J1 connector.

14 3. Check for a short to ground in the wiring between

the instrument cluster terminal A1 and the brake -

fluid level switch.

Is the problem found? Go to Step 17 Go to Step 15

Check for a short to ground in the wiring between

the instrument cluster terminal A1 and the parking

15 brake switch. -

Is the problem found? Go to Step 17 Go to Step 16

Check for a short to ground in the wiring between

the instrument cluster terminal A1 and the EBCM

16 J1 connector terminal B5. -

Is the problem found? Go to Step 17 Go to Step 18

DAEWOO J-100 BL2 / BL3

4A -- 8 HYDRAULIC BRAKES

Brake Lamp Warning Circuit Diagnosis (Cont’d)

Step Action Value(s) Yes No

Repair the wiring as needed.

17 - System OK -

Is the repair complete?

Check the brake lamp after doing each of the follow-

ing functions:

D Apply the parking brake.

D Remove the cap from the brake fluid reservoir. -

18

D On vehicles equipped with ABS, command the

lamp on using a scan tool.

Does the brake warning lamp operate for all of these

conditions? System OK Go to Step 19

When the operations listed in step 18 were per-

formed, the brake warning lamp did not function. -

19

Did the brake warning lamp fail to light for all of the

operations listed in step 18? Go to Step 20 Go to Step 27

1. Turn the ignition OFF.

20 2. Inspect the kick panel fuse F5. -

Is the fuse OK? Go to Step 22 Go to Step 21

Replace the fuse.

21 - System OK -

Is the repair complete?

Inspect the brake warning lamp bulb.

22 - Go to Step 24 Go to Step 23

Is the bulb OK?

Replace the bulb.

23 - System OK -

Is the repair complete?

1. Disconnect the instrument cluster connector.

2. Turn the ignition ON.

24 3. Measure the voltage at the instrument cluster

connector terminal A5.

Does the voltage measure within the value specified? 11-14 v Go to Step 25 Go to Step 26

1. Turn the ignition OFF.

25 2. Repair the open in the instrument cluster. - -

Is the repair complete? System OK

1. Turn the ignition OFF.

2. Repair the open in the wiring between the

26 instrument cluster connector terminal A5 and the - -

ignition switch.

Is the repair complete? System OK

Apply the parking brake again.

27 Does the parking brake warning lamp operate with -

the parking brake applied? Go to Step 28 Go to Step 30

Remove the brake fluid reservoir cap.

28 Does the parking brake warning lamp operate with -

the cap from the brake fluid reservoir removed? Go to Step 29 Go to Step 32

Check for an open between the instrument cluster

connector terminal A1 and the EBCM J1 connector -

29 terminal B5.

Is the problem found? Go to Step 17 Go to Step 13

1. Turn the ignition ON.

2. Disconnect the parking brake switch.

30 3. Jumper the parking brake switch connector -

terminal to ground.

Is the lamp on? Go to Step 10 Go to Step 31

DAEWOO J-100 BL2 / BL3

HYDRAULIC BRAKES 4A -- 9

Brake Lamp Warning Circuit Diagnosis (Cont’d)

Step Action Value(s) Yes No

1. Turn the ignition OFF.

2. Repair the open in the wire between the

31 instrument cluster connector terminal A1 and the - -

parking brake switch connector terminal.

Is the repair complete? System OK

1. Disconnect the brake fluid level switch.

2. Turn the ignition ON.

32 3. Jumper the brake fluid level switch connector -

terminals.

Is the lamp on? Go to Step 8 Go to Step 33

1. Turn the ignition OFF.

2. Connect a test light between battery positive and

33 the BRN/WHT wire terminal of the brake fluid -

level switch.

Is the test light on? Go to Step 34 Go to Step 35

Repair the open in the wiring between ground and

34 the brake fluid level switch. - -

Is the repair complete? System OK

Repair the open in the wiring between the instru-

ment cluster connector terminal A1 and the brake - -

35 fluid level switch.

Is the repair complete? System OK

DAEWOO J-100 BL2 / BL3

4A -- 10 HYDRAULIC BRAKES

MAINTENANCE AND

REPAIR

ON-VEHICLE SERVICE

MANUAL BLEEDING THE BRAKES

(Left-Hand Drive Shown, Right-Hand Drive

Similar)

1. Remove the booster reserve by applying the brakes

several times with the engine OFF until all the reserve

is depleted.

B107A012

Important: If the master cylinder is known or suspected

to have air in the bore, then it must be bled before any

wheel cylinder or caliper is bled.

2. Fill the master cylinder reservoir with brake fluid.

Keep the master cylinder at least one-half full of fluid

during the bleeding operation.

A107A002

3. Disconnect the front brake line(s) at the master

cylinder.

4. Allow the brake fluid to fill the master cylinder until

it begins to flow from the front pipe connector port.

5. Connect the front brake line(s) to the master cylinder.

Tighten

Tighten the brake lines to 16 NSm (12 lb-ft).

B107A001

DAEWOO J-100 BL2 / BL3

HYDRAULIC BRAKES 4A -- 11

6. Slowly push and hold the brake pedal one time.

B107A012

7. Loosen the front brake line at the master cylinder to

purge air from the cylinder.

8. Tighten the brake line (as in step 5), and then re-

lease the brake pedal slowly. Wait 15 seconds be-

fore proceeding to the next step.

9. Repeat the sequence, including the 15-second wait,

until all the air is removed from the master cylinder

bore.

B107A001

Notice: Care must be taken to prevent brake fluid from

contacting any painted surface to prevent damage to the

paint finish.

10. After all the air has been removed at the forward

connection(s), bleed the master cylinder at the rear

(cowl) connection(s) in the same manner as with the

front connections.

B107B002

DAEWOO J-100 BL2 / BL3

4A -- 12 HYDRAULIC BRAKES

Important: For vehicles equipped with a non-antilock

braking system, the bleeding sequence is as follows:

right rear, left front, left rear and right front. For ABS ve-

hicles, refer to Section 4F, Antilock Brake System for the

correct sequence and bleeding procedure.

11. Attach a transparent tube over the valve. Allow the

tube to hang submerged in brake fluid in a trans-

parent container.

A107A006

12. Slowly push and hold the brake pedal one time.

13. Remove the bleeder valve dust cover and loosen

the bleeder screw to purge the air from the cylinder.

14. Tighten the bleeder screw.

Tighten

Tighten the bleeder screw to 6 NSm (53 lb-in).

15. Slowly release the brake pedal. Wait 15 seconds

before proceeding with the next step.

Important: Rapid pumping of the brake pedal pushes

the master cylinder secondary piston down the bore in a

manner that makes it difficult to bleed the system.

16. Repeat the sequence, including the 15-second wait,

until all the air is removed. It may be necessary to

repeat the sequence 10 or more times to remove all

the air.

B107A002 17. Locate the front bleeder caps.

18. Proceed to bleed the front brakes following the ap-

propriate sequence, beginning with step 12.

19. Check the brake pedal for sponginess. Repeat the

entire bleeding procedure to correct this condition.

20. Replace the bleeder valve dust cover.

A107A008

DAEWOO J-100 BL2 / BL3

HYDRAULIC BRAKES 4A -- 13

PRESSURE BLEEDING THE BRAKES

Notice: Pressure bleeding equipment must be of the di-

aphragm type. It must have a rubber diaphragm be-

tween the air supply and the brake fluid to prevent air,

moisture, oil, and other contaminants from entering the

hydraulic system. Contamination could lead to deterio-

ration of the braking components and loss of braking ac-

tion.

1. Disconnect the master cylinder electrical connector.

2. Remove the master cylinder reservoir cap.

A107A009

3. Connect the bleeder with the adapter to the master

cylinder reservoir.

4. For vehicles with the antilock braking system (ABS),

locate and remove the hydraulic modulator bleeder

valves. Refer to Section 4F, Antilock Brake System.

5. Charge the bleeder ball to 140 to 172 kPa (20 to

25 psi).

6. Connect the line to the adapter. Open the line valve.

7. Raise and suitably support the vehicle.

Important: The bleeding sequence is as follows: right

rear, left front, left rear and right front.

8. Attach the bleeder hose to the bleeder valve. Sub-

merge the opposite end of the hose in a clean

container partially filled with brake fluid.

9. Open the bleeder valve one-half to three-fourths

turn and allow the fluid to flow until no air is seen in

A107A006

the fluid.

Notice: After the bleeding operation, the brake reservoir

may be pressurized. While disconnecting the bleeder

hose or the unthreaded adapter cap, cover the cap and

the connection with a shop towel to protect painted

surfaces from contact with the brake fluid.

10. Inspect the brake pedal for sponginess. Repeat the

entire bleeding procedure to correct this condition.

B107A012

DAEWOO J-100 BL2 / BL3

4A -- 14 HYDRAULIC BRAKES

BRAKE HOSE REAR

Removal Procedure

1. Raise and suitably support the vehicle.

2. Disconnect the brake line from the disc brake hose

at the wheel housing bracket on each side of the ve-

hicle.

3. Remove the brake hose retainer.

B107A003

4. Remove the rear disc brake hose retainer and the

brake hose from the bracket on the steering knuckle

shaft.

5. Remove the rear disc brake hose from the caliper.

B107A004

6. Remove the rear drum brake line from the brake hose

bracket on the wheel housing and the steering

knuckle shaft.

7. Remove the brake hose retainers and then the brake

hose from the wheel housing bracket and the bracket

on the steering knuckle shaft.

B107A005

DAEWOO J-100 BL2 / BL3

HYDRAULIC BRAKES 4A -- 15

Installation Procedure

1. Install the rear drum brake hose to the wheel housing

bracket, and to the steering knuckle shaft bracket on

each side of the vehicle.

2. Connect the brake line to the brake hose.

Tighten

Tighten the brake line to 16 NSm (12 lb-ft).

B107A005

3. Install the rear disc brake hose to the caliper.

Tighten

Tighten the rear disc brake hose-to-caliper bolt to

32 NSm (24 lb-ft).

4. Install the rear disc brake hose and retainer on the

bracket on the steering knuckle shaft

5. Install the rear disc brake line to the brake hose on

the wheel housing bracket.

Tighten

Tighten the brake line to 16 NSm (12 lb-ft).

6. Lower the vehicle.

7. Bleed the brake system. Refer to “Manual Bleeding

the Brakes” in this section.

8. Check the brake system for leaks.

B107A003

BRAKE HOSE FRONT

Removal Procedure

1. Raise and suitably support the vehicle.

2. Disconnect the brake line from the brake hose sup-

port bracket on the wheel housing on each side of the

vehicle.

3. Remove the retainer.

B107A006

DAEWOO J-100 BL2 / BL3

4A -- 16 HYDRAULIC BRAKES

4. Disconnect the brake hose from the “C” bracket on

the steering knuckle shaft.

B107A007

5. Remove the bolt from the brake caliper.

6. Remove the seal rings and the disc brake hose.

B107D002

Installation Procedure

1. Install the new disc brake hose to the caliper with new

seal rings and the bolt.

Tighten

Tighten the front disc brake hose-to-caliper bolt to

40 NSm (30 lb-ft).

B107D002

DAEWOO J-100 BL2 / BL3

HYDRAULIC BRAKES 4A -- 17

2. Slide the brake hose on the steering knuckle shaft “C”

bracket.

B107A007

3. Connect the brake line to the brake hose on the wheel

housing bracket on each side of the vehicle.

Tighten

Tighten the brake line to 16 NSm (12 lb-ft).

4. Lower the vehicle.

5. Bleed the brake system. Refer to “Manual Bleeding

the Brakes” in this section.

6. Check the brake system for leaks.

B107A006

STOPLAMP SWITCH

(Left-Hand Drive Shown, Right-Hand Drive

Similar)

Removal Procedure

1. Disconnect the negative battery cable.

2. Remove the trim panel.

B107A008

DAEWOO J-100 BL2 / BL3

4A -- 18 HYDRAULIC BRAKES

3. Disconnect the stoplamp switch from the plug con-

nector.

4. Turn the switch. Remove the switch from the brake

pedal bracket.

A107A019

Installation Procedure

1. Place the stoplamp switch into the plug connector.

2. Twist the stoplamp switch into the brake pedal brack-

et hole.

B107A013

3. Depress the brake pedal and pull the switch plunger

to its maximum setting to adjust the switch.

4. Release the plunger and pull up on the pedal.

5. Install the trim panel.

6. Connect the negative battery cable.

B107A008

DAEWOO J-100 BL2 / BL3

HYDRAULIC BRAKES 4A -- 19

BRAKE PEDAL

(Left-Hand Drive Shown, Right-Hand Drive

Similar)

Removal Procedure

1. Remove the trim panel from the instrument panel.

2. Remove the stoplamp switch. Refer to “Stoplamp

Switch” in this section.

3. Disconnect the retainer and the spring clip from the

pushrod.

B107A009

4. Remove the hex nut and the washer.

5. Remove the brake pedal, exposing the brake booster

pushrod and the pedal-to-dash panel bracket.

B107A010

6. Remove the brake pedal cover.

C107A014

DAEWOO J-100 BL2 / BL3

4A -- 20 HYDRAULIC BRAKES

Installation Procedure

1. Install a new brake pedal cover, if needed.

2. Coat the pedal shaft with grease.

3. Position the brake pedal on the pedal-to-dash panel

bracket and the pedal shaft.

4. Place the hex nut and the washer on the pedal shaft.

Tighten

Tighten the brake pedal-to-pedal bracket hex nut to

18 NSm (13 lb-ft).

5. Install the pushrod to the pedal with the spring clip

and the retainer.

B107A009

6. Install the anti-rattle spring on the shaft in its original

position.

7. Connect the stoplamp switch by twisting it into the

pedal bracket.

8. Connect the stoplamp switch connector.

A107A019

9. Install the trim panel.

B107A008

DAEWOO J-100 BL2 / BL3

HYDRAULIC BRAKES 4A -- 21

GENERAL DESCRIPTION should illuminate. It should go off when the ignition

switch returns to the ON position.

AND SYSTEM OPERATION The following conditions will activate the BRAKE warn-

ing lamp:

WARNING LAMP OPERATION D The lamp should be on whenever the parking brake is

This brake system uses a BRAKE warning lamp located applied and the ignition switch is in the ON position.

in the instrument panel cluster. When the ignition switch D A low fluid level in the master cylinder will turn the

is in the START position, the BRAKE warning lamp BRAKE lamp on.

DAEWOO J-100 BL2 / BL3

You might also like

- Kia K2500 PDFDocument100 pagesKia K2500 PDFcamilo100% (6)

- Toyota Wiring DiagramDocument140 pagesToyota Wiring DiagramThîńt Ýan PâingNo ratings yet

- Motor 5.0L (4v)Document463 pagesMotor 5.0L (4v)matiasalejandroNo ratings yet

- 2gnt 420a OverhaulDocument62 pages2gnt 420a OverhaulElsa Elizabeta Dekovic100% (1)

- Service Manual Ve d12Document32 pagesService Manual Ve d12ramsi17100% (1)

- Expedition 2010Document405 pagesExpedition 2010Alejandro Luna Olmos100% (1)

- Mitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Document61 pagesMitsubishi Engine 4DQ3 4DQ30 Service Manual 99609-50000Miroslav TabakovskiNo ratings yet

- 2. Forsthoffer's Rotating Equipment Handbooks: PumpsFrom Everand2. Forsthoffer's Rotating Equipment Handbooks: PumpsRating: 1 out of 5 stars1/5 (1)

- 4g93 Lancer EngineDocument52 pages4g93 Lancer Enginecsberny98% (45)

- 2002 PDFDocument80 pages2002 PDFlungu mihaiNo ratings yet

- 06 - Adjustments, Clearances and Wear Limits Updated 11302020Document11 pages06 - Adjustments, Clearances and Wear Limits Updated 11302020Sofwat SanjayaNo ratings yet

- 3A92 Engine ManualDocument70 pages3A92 Engine ManualOTOMOTIF KEKINIAN CHANELLNo ratings yet

- Engine 4m40 PDFDocument142 pagesEngine 4m40 PDFRaka100% (17)

- 16 Samss 504Document45 pages16 Samss 504Abdullah GhannamNo ratings yet

- SpecificationsDocument427 pagesSpecificationsjose pena100% (1)

- Linked PDFDocument116 pagesLinked PDFroparts cluj100% (1)

- Edge SE 2013 3.7LDocument1,107 pagesEdge SE 2013 3.7LAlbertoNo ratings yet

- Engnie Ford Escape 2008 V6 3.0LDocument260 pagesEngnie Ford Escape 2008 V6 3.0Lnghia phan van100% (1)

- TVL CSS 4TH Module FinalDocument26 pagesTVL CSS 4TH Module FinalHilton D. CalawenNo ratings yet

- Bearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsFrom EverandBearings And Bearing Metals: A Treatise Dealing with Various Types of Plain Bearings, the Compositions and Properties of Bearing Metals, Methods of Insuring Proper Lubrication, and Important Factors Governing the Design of Plain BearingsRating: 4 out of 5 stars4/5 (1)

- Training Manual - S8000 Complete (Tier 3) PDFDocument26 pagesTraining Manual - S8000 Complete (Tier 3) PDFJUNA RUSANDI S100% (2)

- EADocument14 pagesEAanggieNo ratings yet

- Training Manual - S8000 Complete (Tier 3) PDFDocument26 pagesTraining Manual - S8000 Complete (Tier 3) PDFJUNA RUSANDI S100% (1)

- Engine Overhaul: Group 11BDocument74 pagesEngine Overhaul: Group 11BToponari MedveNo ratings yet

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- 50, 50 Special, 51, and 55: Workshop ManualDocument58 pages50, 50 Special, 51, and 55: Workshop ManualRobNo ratings yet

- ITR 20 005 ITER Electrical HandbookDocument65 pagesITR 20 005 ITER Electrical Handbookwudineh debebeNo ratings yet

- (Mitsubishi 3.0l V6 6G7 Engine d2010-01-30) 11ADocument55 pages(Mitsubishi 3.0l V6 6G7 Engine d2010-01-30) 11Ascribd951dbircs100% (1)

- NH 86572172 PreviewDocument51 pagesNH 86572172 PreviewAmanda NunesNo ratings yet

- Engine Torque Settings and Spec's 3.0L V6 SCDocument4 pagesEngine Torque Settings and Spec's 3.0L V6 SCMario MaravillaNo ratings yet

- Eba 4G0063511F en 170731Document112 pagesEba 4G0063511F en 170731Anonymous Hl9mmKTdn80% (5)

- Kia K2500 Service Manual - Engine Mechanical System-1Document100 pagesKia K2500 Service Manual - Engine Mechanical System-1Arnev SalvianNo ratings yet

- Manual TransaxleDocument61 pagesManual TransaxleJaime Garcia SolisNo ratings yet

- Motor DieselDocument93 pagesMotor Dieselzaka_czNo ratings yet

- Impreza Service ManualDocument95 pagesImpreza Service ManualTaxiarhis ZoubosNo ratings yet

- Dates Gear and Camshaft PDFDocument1 pageDates Gear and Camshaft PDFDimitrijs SilinsNo ratings yet

- 303-01c Engine - V8 (4V)Document94 pages303-01c Engine - V8 (4V)Darren ANo ratings yet

- Air Intake and Exhaust System: Service Data IntercoolerDocument29 pagesAir Intake and Exhaust System: Service Data IntercoolerARIF DEPREZINo ratings yet

- 2346 Santa Fe D4eaDocument93 pages2346 Santa Fe D4eaJmb BravoNo ratings yet

- Ts90, Ts100, Ts110 Repair ManualDocument34 pagesTs90, Ts100, Ts110 Repair Manualclayden1955No ratings yet

- Edge SPRT 2011 3.7LDocument763 pagesEdge SPRT 2011 3.7LJulian Auto-Todo TupizaNo ratings yet

- Aumatic TransmissionDocument26 pagesAumatic TransmissionЮра ПетренкоNo ratings yet

- Cylinder Head/Valve: Valveseatinspection/Refacing 9-17Document28 pagesCylinder Head/Valve: Valveseatinspection/Refacing 9-17orly pocoateNo ratings yet

- 038 - Disc BrakesDocument114 pages038 - Disc BrakesGedas GvildysNo ratings yet

- SM 16Document18 pagesSM 16vadim vadimNo ratings yet

- FG Engine v8 4vDocument98 pagesFG Engine v8 4vjaydopsnortonNo ratings yet

- Chapter25 SERVICE SPECIFICATION PDFDocument34 pagesChapter25 SERVICE SPECIFICATION PDFalvaro garciaNo ratings yet

- Brake+system New ModelDocument30 pagesBrake+system New ModelTimkenNo ratings yet

- T200 Series Medium Pressure: Installation, Operation & MaintenanceDocument32 pagesT200 Series Medium Pressure: Installation, Operation & MaintenanceSecrétariat CbeNo ratings yet

- Service SpecificationsDocument47 pagesService SpecificationsXuân VinhNo ratings yet

- Explorer Sport Trac 2010Document382 pagesExplorer Sport Trac 2010bryanNo ratings yet

- Engine Mechanical: Group 11CDocument30 pagesEngine Mechanical: Group 11CAndy A.S.No ratings yet

- Escape 2009Document316 pagesEscape 2009Esaú Iván Montenegro OchoaNo ratings yet

- Terracan Break SystemDocument139 pagesTerracan Break Systemjanuar1983No ratings yet

- 5.4 L 3V Sfi MTDocument356 pages5.4 L 3V Sfi MTguachicutaNo ratings yet

- The Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationFrom EverandThe Design of Modern Microwave Oscillators for Wireless Applications: Theory and OptimizationNo ratings yet

- Manual Transaxle Drive Axle: Section 3BDocument17 pagesManual Transaxle Drive Axle: Section 3BJarry PotterNo ratings yet

- Bumpers and Fascias: Section 9ODocument14 pagesBumpers and Fascias: Section 9OJarry PotterNo ratings yet

- Interior Trim: Section 9GDocument25 pagesInterior Trim: Section 9GJarry PotterNo ratings yet

- Glass and Mirrors: Section 9LDocument18 pagesGlass and Mirrors: Section 9LJarry PotterNo ratings yet

- Cruise Control System: Section 9UDocument19 pagesCruise Control System: Section 9UJarry PotterNo ratings yet

- Lighting Systems: Section 9BDocument51 pagesLighting Systems: Section 9BJarry PotterNo ratings yet

- Audio Systems: Section 9FDocument15 pagesAudio Systems: Section 9FJarry PotterNo ratings yet

- Seats: Section 9HDocument17 pagesSeats: Section 9HJarry PotterNo ratings yet

- Remote Keyless Entry and Perimeter/Ultrasonic Anti-Theft SystemDocument27 pagesRemote Keyless Entry and Perimeter/Ultrasonic Anti-Theft SystemJarry PotterNo ratings yet

- Waterleaks: Section 9IDocument6 pagesWaterleaks: Section 9IJarry PotterNo ratings yet

- Body Front End: Section 9RDocument14 pagesBody Front End: Section 9RJarry PotterNo ratings yet

- Windnoise: Section 9JDocument2 pagesWindnoise: Section 9JJarry PotterNo ratings yet

- Squeaks and Rattles: Section 9KDocument3 pagesSqueaks and Rattles: Section 9KJarry PotterNo ratings yet

- Doors: Section 9PDocument31 pagesDoors: Section 9PJarry PotterNo ratings yet

- MTCO 1324 Owners ManualDocument24 pagesMTCO 1324 Owners ManualJarry PotterNo ratings yet

- Body Wiring System: Section 9ADocument11 pagesBody Wiring System: Section 9AJarry PotterNo ratings yet

- J 8bDocument82 pagesJ 8bJarry PotterNo ratings yet

- Operating Manual Adsorption Dryer DPS 120-630: Version: 11/2010/DEDocument64 pagesOperating Manual Adsorption Dryer DPS 120-630: Version: 11/2010/DEMendoud SofianeNo ratings yet

- 1 OCC Catalog Reduced Size Final 34Document444 pages1 OCC Catalog Reduced Size Final 34Rohan RajagopalNo ratings yet

- CF 72service ManualDocument69 pagesCF 72service ManualwoanzhoshiaNo ratings yet

- Service Manual DP-8020 - SeriesDocument498 pagesService Manual DP-8020 - SeriesАлексей АвдеевNo ratings yet

- UniGear ZS2 Catalogue V1 MEDDocument26 pagesUniGear ZS2 Catalogue V1 MEDkjkljkljlkjljlkNo ratings yet

- EXCAR Battery EX51878 Manual (Beta Version)Document11 pagesEXCAR Battery EX51878 Manual (Beta Version)Sayed KhlileNo ratings yet

- SubMonitor ManualDocument20 pagesSubMonitor ManualAdrian CantaragiuNo ratings yet

- Osti Ia F Mats v032113Document25 pagesOsti Ia F Mats v032113EvaldoGualbertoNo ratings yet

- User Manual Sliding Door AutomationDocument25 pagesUser Manual Sliding Door AutomationnarpatiNo ratings yet

- Disconnecting Snap To Connect FittingsDocument4 pagesDisconnecting Snap To Connect Fittingsbenjir shuvoNo ratings yet

- InstructionsDocument128 pagesInstructionsyonesNo ratings yet

- RT3 Straight BladeDocument34 pagesRT3 Straight Bladecamohunter71No ratings yet

- Wasabi 360 Ultra X360Phat Installation Guide v1.2Document11 pagesWasabi 360 Ultra X360Phat Installation Guide v1.2nabashNo ratings yet

- Upper Limb Catalogue Web PDFDocument174 pagesUpper Limb Catalogue Web PDFanjelikaNo ratings yet

- Grade 6 Performance Task TleDocument6 pagesGrade 6 Performance Task TlepatrixiaNo ratings yet

- Inspection and Testing Plan: (Insert Project Name)Document10 pagesInspection and Testing Plan: (Insert Project Name)vin ssNo ratings yet

- Introduction To Arduino - First Quarter - Sy 2021-2022Document122 pagesIntroduction To Arduino - First Quarter - Sy 2021-2022Prek DereqNo ratings yet

- PF2010 Digital Power Meter User'S ManualDocument65 pagesPF2010 Digital Power Meter User'S Manualjesus sanchezNo ratings yet

- Ethernet/Ip™ Communication Unit Kv-Ep02: Instruction ManualDocument4 pagesEthernet/Ip™ Communication Unit Kv-Ep02: Instruction ManualNinh LêNo ratings yet

- Apple PLW 300 320 & LW 4 600 PS Service SourceDocument172 pagesApple PLW 300 320 & LW 4 600 PS Service SourceDaniele MocciNo ratings yet

- HT806PH Home Theater PDFDocument43 pagesHT806PH Home Theater PDFSudarPratamaNo ratings yet

- PC 800Document9 pagesPC 800Mohammed Azhar67% (3)

- Very-High-Accuracy Amplified Voltage Output Transducer: - 20 OR NPT ConnectionsDocument2 pagesVery-High-Accuracy Amplified Voltage Output Transducer: - 20 OR NPT Connectionsguna8825No ratings yet

- Model Dc-200 Series Lever Equipped Industrial Low-Mount WinchesDocument26 pagesModel Dc-200 Series Lever Equipped Industrial Low-Mount Winchesimagex5No ratings yet

- 2012 Chevrolet Volt X2Document5 pages2012 Chevrolet Volt X2Men PanhaNo ratings yet

- bp2517 Triaxial CCLD Accelerometer Types 4529-BDocument8 pagesbp2517 Triaxial CCLD Accelerometer Types 4529-BategNo ratings yet