Professional Documents

Culture Documents

GPT-Installation-Instruction EVOLUTION 08.2022

GPT-Installation-Instruction EVOLUTION 08.2022

Uploaded by

bayu adi dharmaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

GPT-Installation-Instruction EVOLUTION 08.2022

GPT-Installation-Instruction EVOLUTION 08.2022

Uploaded by

bayu adi dharmaCopyright:

Available Formats

GPT Isolation Gasket Installation Instructions

CLEAN & INSPECT FLANGE FACE - Ensure flange face finish

is in accordance with ASME PCC-1 guidelines

1. 5. SUGGESTION

For isolation gaskets

- use the cardboard

included in the

packaging during

installation to help

protect the seals

and isolating materials from damage.

Surface finish - RTJ & RF OK (Additional flange gap may be required)

3.2 - 6.3 R (120 - 250 RA)

Ensure wide enough flange gap and alignment is created BEFORE installing gasket CAUTION: DO NOT DAMAGE

2. 1/8” (3mm) larger than gasket thickness

GRE, COATING, OR SEAL

NOTE: Locate handle

6. between 2 bolt holes

before tightening

Install remaining studs with Always use a torque Never use impact

DO NOT ATTEMPT TO INSTALL GASKET PRIOR TO ALIGNING FLANGES

washers and sleeves wrench or appropriate drivers or hammer

tensioning equipment wrenches! This can

3. cause damage to the

isolation washers,

sleeves, and gaskets.

1

12 5

7. TORQUE IN LEGACY STAR PATTERN

Steel Install sleeve NOTE: For HCS

Apply PIKO-LUBE® 8 9 1. Snug each stud to 10-20 [ft-lb] (14-27 Nm)

DO NOT use metallic G10 washer on stud putting coated washers

washers first

against it through use 2 washers 2. Tighten to 30% of target torque

based lubricants per side

flange face washers 3. Tighten to 70% of target torque

4 3

NOTE: ALWAYS USE NEW BOLTS, NEVER RE-USE WASHERS, SLEEVES OR GASKETS 4. Tighten to 100% of target torque

ONCE INSTALLED 5. Final torque to 100% in circular pattern

4. 10 7

Install sleeves and washers on bottom 6 11

2

half of flange assembly for easy

alignment of type-F gaskets. Installation guidance video

can be found at:

www.gptindustries.com/FIKinstallation

Industries

RECOMMENDED BOLT TORQUE VALUES

Torque Table for GPT Isolating Gaskets

150# 300# 400# 600# 900# 1500# 2500#

Industries

REC MAX* REC MAX* REC MAX* REC MAX* REC MAX* REC MAX* REC MAX*

NPS NPS

ASME B16.5

NOTES: Recommended Values in [ft-lb]

1. All values are calculated assuming a 0.11 coefficient of friction ½ 30 45 30 45 30 45 30 45 95 120 95 120 95 120 ½

and new nuts and studs using non-metallic lubrication. ¾ 30 45 55 90 55 90 55 90 95 140 95 140 95 140 ¾

2. “M” maintenance factor = 0 “Y” minimum design seating stress 1 30 45 55 90 55 90 55 90 155 220 155 220 155 220 1

= 7500 [psi]. For EVOLUTION™ isolating gasket “Y” = 0. 1¼ 30 45 55 90 55 90 55 90 155 255 155 255 230 350 1¼

3. Recommended values are based on 30,000 psi bolt stress. Max 1½ 30 45 05 160 95 160 95 160 230 380 230 380 335 530 1½

values are based on 50,000 psi bolt stress**

2 55 90 55 90 55 90 55 90 155 255 150 245 230 380 2

4. If using both lubricated and coated studs or uncoated bolts

2½ 55 90 95 160 95 160 95 160 230 380 230 380 335 530 2½

with no lubricant, contact GPT for recommended torque values.

3 55 90 95 160 95 160 95 160 155 255 335 560 470 785 3

3½ 55 90 95 160 155 255 155 255 N/A N/A N/A N/A N/A N/A 3½

NOTE: On isolating testing - any isolation testing should be

completed prior to hydro testing in order to prevent media in 4 55 90 95 160 155 255 155 255 335 560 470 785 840 1400 4

line from causing false readings. It’s suggested that isolation be 5 95 160 95 160 155 255 230 380 470 785 840 1400 1370 2170 5

checked with the use of an RF meter as per NACE SP0288-2007 6 95 160 95 160 155 255 230 380 335 560 640 1065 2080 2995 6

standard practice. 8 95 160 155 255 230 380 335 560 640 1065 1085 1805 2080 3155 8

10 155 255 230 380 335 560 470 785 640 1065 1700 2830 4165 6005 10

It should be noted that humidity and other environmental effects

12 155 255 335 560 470 785 470 785 640 1065 2080 3465 5595 8090 12

can cause false isolation readings.

14 230 380 335 560 470 785 640 1065 840 1400 3005 4390 N/A N/A 14

16 230 380 470 785 640 1065 840 1400 1085 1805 4165 6105 N/A N/A 16

For additional assistance please contact our engineering office at

GPT.engineering@gptindustries.com 18 335 560 470 785 640 1065 1085 1805 1700 2830 5595 8900 N/A N/A 18

20 335 560 470 785 840 1400 1085 1805 2080 3465 7320 10730 N/A N/A 20

GPT Industries 22 470 785 840 1400 1085 1805 1370 2280 N/A N/A N/A N/A N/A N/A 22

303.988.1242 24 470 785 840 1400 1370 2280 1700 2830 4165 6945 11765 18060 N/A N/A 24

www.gptindustries.com ASME B16.47 Series A

26 470 785 1085 1805 1370 2280 1700 2830 5595 9325 N/A N/A N/A N/A 26

28 470 785 1085 1805 1700 2830 2080 3465 7320 12200 N/A N/A N/A N/A 28

FOR METRIC TORQUE VALUES - ft-lb

divide ft-lb value by 0.73756

N m = 0.73756 30 470 785 1370 2280 2080 3465 2080 3465 7320 12200 N/A N/A N/A N/A 30

32 840 1400 1700 2830 2080 3465 3005 5005 9370 15615 N/A N/A N/A N/A 32

34 840 1400 1700 2830 2080 3465 3005 5055 11765 19610 N/A N/A N/A N/A 34

* For fire risk service please consider using max values 36 840 1400 2080 3465 2080 3465 4165 6945 11765 19610 N/A N/A N/A N/A 36

38 840 1400 840 1400 1370 2280 3005 5005 11765 19610 N/A N/A N/A N/A 38

**Please note that Recommemed and Max torque values are based

40 840 1400 1085 1805 1700 2830 3005 5005 11765 19610 N/A N/A N/A N/A 40

on bolt stresses of B7, or equivalent studs, Grade 2H hex nuts, and

42 840 1400 1085 1805 1700 2830 4165 6945 11765 19610 N/A N/A N/A N/A 42

A105 or equivalent flange material. For lower strength flanges or

bolts contact GPT Engineering for torque recommendations. 44 840 1400 1370 2280 2080 3465 4165 6945 14540 24235 N/A N/A N/A N/A 44

46 840 1400 1700 2830 2080 3465 4165 6945 17720 29535 N/A N/A N/A N/A 46

The GPT gasket torque calculator is available at 48 840 1400 1700 2830 3005 5005 5595 9325 17720 29535 N/A N/A N/A N/A 48

www.gasketcalculator.gptindustries.com 50 1370 2280 2080 3465 3005 5005 7320 12200 N/A N/A N/A N/A N/A N/A 50

52 1370 2280 2080 3465 3005 5005 7320 12200 N/A N/A N/A N/A N/A N/A 52

54 1370 2280 3005 5005 4165 6945 7320 12200 N/A N/A N/A N/A N/A N/A 54

56 1370 2280 3005 5005 4165 6945 9370 15615 N/A N/A N/A N/A N/A N/A 56

58 1370 2280 3005 5005 4165 6945 9370 15615 N/A N/A N/A N/A N/A N/A 58

60 1370 2280 3005 5005 5595 9325 11765 19610 N/A N/A N/A N/A N/A N/A 60

GPT_INST_002_11.2019

F-950 REV D

You might also like

- Technical Specification and DrawingsDocument10 pagesTechnical Specification and DrawingsIndonesia RayaNo ratings yet

- (Ebook) - How To Frame A House (1914) PDFDocument170 pages(Ebook) - How To Frame A House (1914) PDFWalkinLANo ratings yet

- Valve Magazine, Fall 2021Document44 pagesValve Magazine, Fall 2021GordinhorsNo ratings yet

- Chemical Resistance Guide DerakaneDocument84 pagesChemical Resistance Guide DerakaneBoro TerakolNo ratings yet

- 5 - Threaded Fasteners PDFDocument60 pages5 - Threaded Fasteners PDFPradyunn HoraNo ratings yet

- P 0200 152 LHS 01Document2 pagesP 0200 152 LHS 01Zaidi100% (1)

- Quality Assurance Plan: Sheet MetalDocument2 pagesQuality Assurance Plan: Sheet Metalsabir hussain0% (1)

- Elmeasure Multifunction Meter CatalogDocument4 pagesElmeasure Multifunction Meter CatalogBoddapalli suresh100% (1)

- Sluice Auma Gate - Gad, Data Sheet & Qap - 5mld - M - Doc-02 - r0Document7 pagesSluice Auma Gate - Gad, Data Sheet & Qap - 5mld - M - Doc-02 - r0ankit singlaNo ratings yet

- FERRYNDODocument29 pagesFERRYNDONovie100% (1)

- Eni BookDocument91 pagesEni Bookseptian nurpratamaNo ratings yet

- Intertek Button Battery 2020 UpdateDocument2 pagesIntertek Button Battery 2020 UpdatecanacNo ratings yet

- X StromDocument2 pagesX Stromgc7090No ratings yet

- Dasher-1 H0227-3Document101 pagesDasher-1 H0227-3Rosa María AmoneNo ratings yet

- SM-RI-X Q75 Manual en de FR Es It NLDocument198 pagesSM-RI-X Q75 Manual en de FR Es It NLaliNo ratings yet

- RR - GSTR - DetailsDocument2 pagesRR - GSTR - DetailsBharat EnggNo ratings yet

- SAE J518 Bolt FlangeDocument15 pagesSAE J518 Bolt FlangejoanNo ratings yet

- PSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressDocument6 pagesPSTC-14 - Adhesion of Pressure Sensitive Tapes To Fiberboard at 90°angle and Constant StressChung LeNo ratings yet

- PREN6114Document19 pagesPREN6114malotNo ratings yet

- JW1782BDocument13 pagesJW1782BGustavo AlonsoNo ratings yet

- Document 1Document13 pagesDocument 1Prince SharmaNo ratings yet

- Variable Frequency Vibrators Controlled Through Rotary Switches With Connection ExtractableDocument16 pagesVariable Frequency Vibrators Controlled Through Rotary Switches With Connection ExtractableLucy HernandezNo ratings yet

- Astm A 194 - 2007aDocument12 pagesAstm A 194 - 2007axf zhang100% (1)

- CuNiSi AlloyDocument6 pagesCuNiSi AlloyJdjoNo ratings yet

- Iocl-3030mg (U)Document1 pageIocl-3030mg (U)Vignesh SubramanianNo ratings yet

- Manual de Partes: Generador 6.5 KWDocument23 pagesManual de Partes: Generador 6.5 KWAllison Alsan100% (1)

- I-Et-3010.00-5140-700-P4x-002 - K - Specification For Electrical Material An...Document208 pagesI-Et-3010.00-5140-700-P4x-002 - K - Specification For Electrical Material An...everton maldonadoNo ratings yet

- CM-CS-007 Issue 01 Rev 01 Width of IsleDocument6 pagesCM-CS-007 Issue 01 Rev 01 Width of IsleSevin HassanzadehNo ratings yet

- Identifi Ation: National Aerospace StandardDocument7 pagesIdentifi Ation: National Aerospace StandardGrandiosNo ratings yet

- Dai-El: High Performance FluoroelastomersDocument16 pagesDai-El: High Performance FluoroelastomersAtham MuhajirNo ratings yet

- Fabrications - Guide - SS CORRUGATEDDocument54 pagesFabrications - Guide - SS CORRUGATEDSunil GhosalkarNo ratings yet

- Material TypeDocument1 pageMaterial Typesalikhashmi2013No ratings yet

- FABCO Pipe Catalog PDFDocument24 pagesFABCO Pipe Catalog PDFMohamed AklNo ratings yet

- Waukesha 2015 Power Ratings BrochureDocument8 pagesWaukesha 2015 Power Ratings Brochureyalc66No ratings yet

- MK HoneyWellDocument56 pagesMK HoneyWellKevin MaldeNo ratings yet

- Ferritic Stainless Steels: Soft MagneticDocument4 pagesFerritic Stainless Steels: Soft MagneticMohammadehsan SalarpourNo ratings yet

- IEC 17050 1 2005 EeiDocument21 pagesIEC 17050 1 2005 EeiAlaeddine AbidNo ratings yet

- DVS 2207-13 Soldadura de Termoplasticos - Soldadura de Tubos y Accesorios de PVC-CDocument7 pagesDVS 2207-13 Soldadura de Termoplasticos - Soldadura de Tubos y Accesorios de PVC-CEugenioNo ratings yet

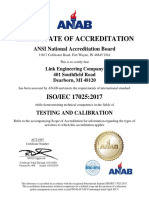

- Link Engineering Dearborn Cert Scope V 008Document8 pagesLink Engineering Dearborn Cert Scope V 008karthegreNo ratings yet

- ORCONDocument2 pagesORCONKarinaNo ratings yet

- Ace Group Rev 7Document1 pageAce Group Rev 7Tezso JacobNo ratings yet

- Metal Work PneumaticDocument939 pagesMetal Work PneumaticDarko MarjanovicNo ratings yet

- Warranty CertificateDocument8 pagesWarranty CertificateankushagarwallNo ratings yet

- ASEAN Rubber Testing Laboratories For Rubber VulcanizatesDocument64 pagesASEAN Rubber Testing Laboratories For Rubber Vulcanizateshery siregarNo ratings yet

- prEN 4172Document6 pagesprEN 4172malotNo ratings yet

- Weco Unions Chicksan Swivel CatalogDocument38 pagesWeco Unions Chicksan Swivel CatalogHarry SuprisnoNo ratings yet

- MGT 7-Annual ReturnDocument14 pagesMGT 7-Annual Returnkalaiselvi venugopalNo ratings yet

- Iso 15077 2020Document11 pagesIso 15077 2020Tomas IglesiasNo ratings yet

- Capron (Honeywell)Document32 pagesCapron (Honeywell)Bart Kemper, P.E.No ratings yet

- Thermal Spraying - Qualification Testing of Thermal Sprayers (ISO 14918:2018)Document16 pagesThermal Spraying - Qualification Testing of Thermal Sprayers (ISO 14918:2018)pushpakNo ratings yet

- Stainless Steel Clamp Union Din 32676Document7 pagesStainless Steel Clamp Union Din 32676Sándor PetrovicsNo ratings yet

- KSB Product Portfolio Valves 2019 PDFDocument72 pagesKSB Product Portfolio Valves 2019 PDFLuka BornaNo ratings yet

- Iso 08504-1Document12 pagesIso 08504-1Akram DriraNo ratings yet

- 1355 403-410-Brusselle Steering Gear Instruction ManualDocument399 pages1355 403-410-Brusselle Steering Gear Instruction Manualnipper7No ratings yet

- PV Syst Report - 15KWp Roof Top Solar PV PlantDocument8 pagesPV Syst Report - 15KWp Roof Top Solar PV PlantstalineleNo ratings yet

- Allied (Catálogo)Document64 pagesAllied (Catálogo)Andrea MacedoNo ratings yet

- WCP and New DecksDocument12 pagesWCP and New DecksForexliveNo ratings yet

- Ficha Condensadora GSX13 McQUAYDocument5 pagesFicha Condensadora GSX13 McQUAYdoubleggNo ratings yet

- EZY Flow X ReferenceDocument380 pagesEZY Flow X ReferencedanielNo ratings yet

- QD Bushings CatalogDocument5 pagesQD Bushings CatalogYuri OrellanoNo ratings yet

- Gasket Seating StressDocument1 pageGasket Seating StressqaiserNo ratings yet

- Mineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsDocument5 pagesMineral Fiber Blanket Thermal Insulation For Commercial and Industrial ApplicationsmansurudinNo ratings yet

- Catalog Eks Tebal + BERAT & PcspackDocument47 pagesCatalog Eks Tebal + BERAT & PcspackmansurudinNo ratings yet

- TENUTE SRL Type TRNDocument7 pagesTENUTE SRL Type TRNmansurudinNo ratings yet

- Fluid Sealing Association Fluid Sealing Association: Standard StandardDocument16 pagesFluid Sealing Association Fluid Sealing Association: Standard StandardmansurudinNo ratings yet

- Rubber-Identification by Infrared Spectrophotometry: Standard Test Methods ForDocument21 pagesRubber-Identification by Infrared Spectrophotometry: Standard Test Methods FormansurudinNo ratings yet

- FEP & PFA Welding Grade Films: F E F W H SDocument2 pagesFEP & PFA Welding Grade Films: F E F W H SmansurudinNo ratings yet

- Standard Size of Rooms in Residential Building and Their LocationsDocument5 pagesStandard Size of Rooms in Residential Building and Their LocationsSirimilla MeharNo ratings yet

- 2014 Modern Hydronic System Designs Hts AshraeDocument41 pages2014 Modern Hydronic System Designs Hts AshraeNagarjun ReddyNo ratings yet

- Sliding Window DetailsDocument18 pagesSliding Window DetailsArif NadafNo ratings yet

- Mbeg1033 201520161Document4 pagesMbeg1033 201520161Ko Ka KunNo ratings yet

- An Overview of API 579-1/ASME FFS-1 Fitness-For-Service Assessment Standard With Applications To Case StudiesDocument57 pagesAn Overview of API 579-1/ASME FFS-1 Fitness-For-Service Assessment Standard With Applications To Case StudiesLeonardo PestanaNo ratings yet

- Glass Wall SystemsDocument24 pagesGlass Wall SystemsFred SalgadoNo ratings yet

- Sprinkler Irrigation SystemDocument17 pagesSprinkler Irrigation SystemSidNo ratings yet

- Anaerobic Digester CoversDocument2 pagesAnaerobic Digester CoversChris QueroNo ratings yet

- Turkish Construction Equipment and MachineryDocument89 pagesTurkish Construction Equipment and MachineryHuseyin TASKIN100% (1)

- Lec-4 Notes On Contracts and TendersDocument18 pagesLec-4 Notes On Contracts and Tendersshahzeb khanNo ratings yet

- Alkali Silica Reaction (Asr)Document29 pagesAlkali Silica Reaction (Asr)SooKevinNo ratings yet

- Preliminary Lab Calculations To Determine Beam Modulus of ElasticityDocument7 pagesPreliminary Lab Calculations To Determine Beam Modulus of ElasticityAlex WallaceNo ratings yet

- Product Offer Letter SAMPLEDocument4 pagesProduct Offer Letter SAMPLESam SamNo ratings yet

- Energy Tracker - 555 PDFDocument4 pagesEnergy Tracker - 555 PDFkrishnan112No ratings yet

- Composite Material Testing For Drones and UAV ApplicationsDocument10 pagesComposite Material Testing For Drones and UAV ApplicationsefowenNo ratings yet

- New Design SheetDocument16 pagesNew Design SheetAnonymous ROHiipW9pNo ratings yet

- Different Types of Building PlansDocument6 pagesDifferent Types of Building PlansSirimilla MeharNo ratings yet

- Vacuum Breaker Valve: DN50-DN500 PN10-16-25Document2 pagesVacuum Breaker Valve: DN50-DN500 PN10-16-25Cirilo SousaNo ratings yet

- ASPE Sump Pump SizingDocument60 pagesASPE Sump Pump Sizingzaqhusanz100% (5)

- Tos 5: Unit 4A: Prestressed ConcreteDocument13 pagesTos 5: Unit 4A: Prestressed ConcreteShyam WanaskarNo ratings yet

- 3 BKM SP MKT Get Ex3600Document2 pages3 BKM SP MKT Get Ex3600Max SashikhinNo ratings yet

- Metallurgy and ShipbuildingDocument3 pagesMetallurgy and Shipbuildingbrandondavis1011No ratings yet

- Giornale 140 Biennale-Session Basso PDFDocument16 pagesGiornale 140 Biennale-Session Basso PDFEnes KurtanovicNo ratings yet

- Opc PPC Fly Ash Study Jan 06 by MR Anil Banchhor and MR S Krishnan 241Document15 pagesOpc PPC Fly Ash Study Jan 06 by MR Anil Banchhor and MR S Krishnan 241Abdul RashidNo ratings yet

- Bayastay Brochure - 2021Document14 pagesBayastay Brochure - 2021Nicholas ZoppaNo ratings yet

- Lodos ActivadosDocument32 pagesLodos Activadosjvan migvelNo ratings yet

- Westen Quasar 24 Spare Parts CatalogueDocument14 pagesWesten Quasar 24 Spare Parts CatalogueBalázs VargaNo ratings yet

- CorrView Piping Technical Bulletin P-01Document14 pagesCorrView Piping Technical Bulletin P-01jjgonzalezquinaNo ratings yet

- 2016 MacDougall - ACI - Measured Load Capacity of Buried PipesDocument12 pages2016 MacDougall - ACI - Measured Load Capacity of Buried PipesAdeel FaisalNo ratings yet