Professional Documents

Culture Documents

Feltesst

Uploaded by

Daren Llamado EncisoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Feltesst

Uploaded by

Daren Llamado EncisoCopyright:

Available Formats

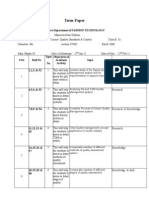

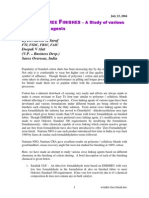

SOLVING GUIDING PROBLEMS ON

FORMING FABRICS

Handheld technology for felts and fabrics

WHITE PAPER

MAXIMIZING RUNNABILITY

Solving guiding problems on forming fabrics

When a forming fabric doesn’t want to run straight it usually causes many problems and

costs. In the worst case it actually runs into the machine frame and the fabric is completely

destroyed. But also continuous strong guiding corrections lead to excessive fabric wear

and hence high costs. This article explains the principles of forming fabric guiding and

gives the papermaker tips on how to systematically solve guiding problems.

The principle of fabric guiding The importance of friction

In the loop of each fabric there is one roll equipped with The friction created between the guide roll and the forming

the task to keep the fabric running straight: the guiding fabric is the key of the guiding process. When one edge

roll. One side of the guiding roll, usually at the tending of the fabric encounters friction, it will be slowed down

side of the machine, can be moved in the running a little. This again will generate a cross direction force in

direction of the machine. the fabric, moving it toward the side with more friction.

Please note that this applies for all items contacting the

fabric; therefore a misaligned suction box can cause

tremendous guiding problems too!

There are several ways to increase the friction on

the guide roll:

1. Increasing the fabric tension;

2. Increasing the angle of wrap on the guide roll;

3. Increasing the diameter of the guide roll

(thereby increasing the contact area);

4. Increasing roll softness.

Water reduces friction

Apart from the 4 points mentioned above, another critical

consideration in maintaining friction is the amount of

water on and around the guide roll. Water acts as a lubri-

cant and when it becomes trapped between the roll and

the fabric and it drastically reduces the guide system’s

effectiveness. Since fabric showering is critical to the

total paper making operation, showering changes are

normally used as a last resort to improve fabric guiding.

The fabric will always travel toward the side of the guide Wire tension

roll that it contacted first. In figure 1A this is the right As mentioned before, guiding is directly controlled by

hand side or drive side (DS) of the machine. In figure 1B surface friction between the fabric and the guide roll.

the left edge of the fabric reaches the guide roll first and Surface friction in its turn is strongly affected by the fabric

moves the fabric to the left or tending side (TS) of the tension; the higher the fabric tension, the more surface

machine. friction and hence a more responsive guiding system.

WWW.FELTEST.COM Feltest Equipment BV 2015 ®

WHITE PAPER

MAXIMIZING RUNNABILITY

If experiencing guiding problems, always check for the roll hardness. These rolls typically need to be reground

correct operation tension on your fabric. Check the every 2-3 years.

tension on both sides of the machine (TS and DS) and

at the same position, for example before the guiding roll. Polyamide yarns in the fabric

Tension differences between the two sides are usually In a forming fabric, the yarns in cross machine direction

related to either misalignments or the forming fabric are usually made of polyester and/or polyamide. Polyamide

itself, but should always be resolved. is more wear resistant and helps to increase the fabric

life. However, the friction coefficient between polyamide

Angle of wrap around the guide roll and the guiding roll is about 30% less than with polyester

The larger the angle of wrap around the guide roll, the yarns. This means that the previous remarks on tension,

higher the effectiveness of the guiding system. The mini- wrap angle and roll cover are even more important for

mum wrap angle varies a bit with the length of the fabric. forming fabrics with high polyamide content.

For longer fabrics, like on Fourdrinier machines, a wrap

angle of at least 25° (figure 2) is needed to adequately Drill and twill patterns

guide a fabric. For shorter fabrics, like top formers or gap Sometimes a guiding situation occurs where the fabric

formers, it can also be a little less to avoid a hyper-sensi- guides one way with the stock off and in the other

tive control system. direction when the stock is on. This situation is normally

caused by one of two possibilities.

Misalignment of a vacuum element

A misaligned vacuum element will cause the fabric to

guide, with the stock off, towards its leading edge.

When the stock is applied and the vacuum becomes

effective, the fabric tends to guide in the other direction.

Figure 2 This usually requires a severe and fast adjustment by

the guiding system to keep the fabric running properly.

Always check for proper alignment of especially the

Location of the guide roll in the machine vacuum elements when this phenomenon occurs.

The location of the guide roll on some (older) machines

can contribute to guiding problems. When the guide roll Drilled suction box covers

is adjacent to the stretch roll, either on the ingoing or If there is no misalignment and the machine has suction

outgoing side, the wrap angle will change when the boxes with drilled covers, then the latter in combination

stretch roll moves. with the fabric design may cause the guiding problems.

When a relatively short fabric is installed, as in the There is a twill pattern in every woven cloth: it is actually

example in figure 3, the wrap angle will decrease and the diagonal pattern caused by the cross-over points in

hence guiding problems may occur. Ideally the guide roll the weaving process. When this fabric twill pattern and

is positioned between two stationary rolls. the suction box drill pattern match, the fabric will have

a tendency, when vacuum is applied, to guide in that

direction (figure 4).

Figure 3

Guiding roll cover

Roll cover material and its hardness are critical in main-

taining adequate friction between fabric and guide roll.

Rubber-covered rolls with a hardness of 20 P&J are

recommended for guiding today’s fabrics.

However, because rubber rolls tend to harden over time,

which reduces the friction between guide roll and fabric,

periodic roll grinds are necessary to maintain the correct Figure 4

WWW.FELTEST.COM Feltest Equipment BV 2015 ®

WHITE PAPER

MAXIMIZING RUNNABILITY

To eliminate the possibility, the best option is to replace If replacing the covers is not possible, the second best

the drilled suction box covers with slotted ones. This option is to alternate the drill pattern angle in successive

will not only reduce the guiding problem, but it will also suction boxes. The last suction box in running direction

reduce fabric wear and improve the dewatering capacity should have the drill angle opposite to the twill angle of

of the suction box. the fabric.

Troubleshooting list for guiding problems

1. Check the guide roll mechanism

2. Check the function (and position) of the guide plate

3. Increase the wire tension

4. Shut off the flooded nip shower and …

5. … increase pressure of the needle showers

6. Close or reduce lubrication showers near the guiding roll

7. Check the suction box deckles, couch roll deckles and pick up roll deckles

8. Eliminate pumping of the wet box/vacufoil (do not translate)

9. Reduce power consumption

10. Check the shaking mechanism

11. Check the drill and twill pattern (at the last suction box)

12. Check the water treatment of the lubrication showers

13. During a stop: check the roll surface of the guide roll (20 P&J)

14. During a stop: check the alignment of all the elements touching the fabric

The base for this white paper was an article from an unidentified author. It has been edited and brought up-to-date by Mr. Marcel Lensvelt,

Managing Director of Feltest Equipment BV.

WWW.FELTEST.COM Feltest Equipment BV 2015 ®

WHITE PAPER

MAXIMIZING RUNNABILITY

Feltest Originals®

AIRSPEED/2 BODYCOOLING

CALIPER PROFILER CAPTO

REALSPEED TENSIOMASTER

TENSIO+

Feltest Originals®

ST

The products of Feltest Equipment

S*

E

BV are designed and constructed

AL

LT

IN

to be as safe as possible for their

FE

IG

OR

intended use.

Contact

Telephone: +31 313 652 215

Email: info@feltest.com

Website: www.feltest.com

WWW.FELTEST.COM Feltest Equipment BV 2015 ®

Feltest is an independent supplier of easy-to-use handheld tools and provider of in-depth knowledge on innovative

technology for optimizing the performance of Paper Machine Clothing like forming fabrics, press felts and dryer

screens. We are the first choice of Pulp and Paper mills worldwide to help maximize the runnability of paper machines

and significantly reduce operational costs. Our customers calculate payback time in minutes rather than months or

years. All our products are designed to protect workers, ensuring their safety and comfort to the highest degree. The

performance data from our precision instruments lead to informed, fact based decisions that result in a better bottom

line for the paper mill. Our global mission is to strengthen the position of the pulp & paper industry and its marvelous

product as a crucial step in building a true circular economy. More info: www.feltest.com

WWW.FELTEST.COM Feltest Equipment BV 2019 ®

You might also like

- AERO2289 Tensiles LabFinalDocument23 pagesAERO2289 Tensiles LabFinalShanaka JayasekaraNo ratings yet

- Roving FrameDocument8 pagesRoving FrameSyed Inamullah Shah0% (1)

- Solitudes in Silk: A Patan TaleDocument91 pagesSolitudes in Silk: A Patan TaleAayush VyasNo ratings yet

- Expertip 4 Tips For Dryer Fabric GuidingDocument3 pagesExpertip 4 Tips For Dryer Fabric GuidingnotengofffNo ratings yet

- Expertip 4 Tips On Forming Fabric GuidingDocument4 pagesExpertip 4 Tips On Forming Fabric GuidingnotengofffNo ratings yet

- Expertip 6 Bowing Narrowing and DistortionDocument4 pagesExpertip 6 Bowing Narrowing and DistortionnotengofffNo ratings yet

- Filament Yarn Sizing PDFDocument3 pagesFilament Yarn Sizing PDFamar9247No ratings yet

- Green University of Bangladesh: Department of Textile EngineeringDocument9 pagesGreen University of Bangladesh: Department of Textile EngineeringGreen University TextileNo ratings yet

- Sizing (Slashing)Document46 pagesSizing (Slashing)Nikhil Nani100% (1)

- Non FabricsDocument10 pagesNon FabricsthanikaivimalNo ratings yet

- Filament Yarn Sizing Why We Need To Size Filament Yarn?Document3 pagesFilament Yarn Sizing Why We Need To Size Filament Yarn?RAHEEL JAVEDNo ratings yet

- Technical Bulletin: Wet Processing of 100% Cotton Knitted FabricsDocument11 pagesTechnical Bulletin: Wet Processing of 100% Cotton Knitted FabricsRafayMalikNo ratings yet

- Fabric Bowing & Skewing - Textile SchoolDocument5 pagesFabric Bowing & Skewing - Textile Schoolmithun77No ratings yet

- Expertip Tension Part 1Document5 pagesExpertip Tension Part 1notengofffNo ratings yet

- 2009 Issue 4 IPPTA Article 02Document8 pages2009 Issue 4 IPPTA Article 02Lev BNo ratings yet

- How Far Automatic?: Mechanized SpreadingDocument4 pagesHow Far Automatic?: Mechanized SpreadingPrabhuti ChauhanNo ratings yet

- Belts NotesDocument18 pagesBelts NotesnattydreadfathelahNo ratings yet

- Metering Size PressDocument22 pagesMetering Size PressDaud ZamanNo ratings yet

- Drawframe 180127102625 PDFDocument103 pagesDrawframe 180127102625 PDFSantoshNo ratings yet

- Preparation For Combing: Top Nipper PlateDocument13 pagesPreparation For Combing: Top Nipper PlateAshvin PaunikarNo ratings yet

- Gar 3Document15 pagesGar 3raiyanduNo ratings yet

- Draw FrameDocument11 pagesDraw FrameTemesgen RegassaNo ratings yet

- Bowing & SkewingDocument3 pagesBowing & SkewingtextiletipsbyrajatNo ratings yet

- TROUBLE SHOOTING GUIDE Blanket SurfaceDocument6 pagesTROUBLE SHOOTING GUIDE Blanket SurfaceLai NguyenNo ratings yet

- Mechanical FinishesDocument36 pagesMechanical FinishesReetu SriNo ratings yet

- Warp Tension Analysis of Narrow Fabric Weaving and Designing of Tension Compensator To Avoid Start Up MarksDocument7 pagesWarp Tension Analysis of Narrow Fabric Weaving and Designing of Tension Compensator To Avoid Start Up Marksyogesh123789No ratings yet

- FSA Y.navina RK - NaveenaDocument36 pagesFSA Y.navina RK - NaveenachocolateNo ratings yet

- Textile FinishingDocument21 pagesTextile FinishinganowartexNo ratings yet

- Pavitra IA SanforizationDocument13 pagesPavitra IA SanforizationPavitra KhandelwalNo ratings yet

- A Study On The Effect of Weft Knitted Structures and Stitch Length On The Pilling Behavior of Weft Knitted FabricsDocument8 pagesA Study On The Effect of Weft Knitted Structures and Stitch Length On The Pilling Behavior of Weft Knitted FabricsNasrin AkterNo ratings yet

- FINAL, CTB - White - Paper - Washboarding - 221014 PDFDocument4 pagesFINAL, CTB - White - Paper - Washboarding - 221014 PDFcefageswNo ratings yet

- 19 Yarn Requirement For KnittingDocument3 pages19 Yarn Requirement For KnittingJosé Kors100% (1)

- Roving FrameDocument4 pagesRoving FrameShailendra MishraNo ratings yet

- Fabric and Apparel Performance Testing ProtocolDocument23 pagesFabric and Apparel Performance Testing Protocolzoomerfins22No ratings yet

- Group 1 Filament WindingDocument6 pagesGroup 1 Filament Winding林丽莹No ratings yet

- Draw Frame1Document26 pagesDraw Frame1Sajib IglesiasNo ratings yet

- Sizing-Impact of Process Parameter On Beam Quality and Similarly On Loom PerformanceDocument15 pagesSizing-Impact of Process Parameter On Beam Quality and Similarly On Loom PerformanceSaad KhanNo ratings yet

- Winding 4Document26 pagesWinding 4Abdul AzizNo ratings yet

- Dorlastan in Circular KnittingDocument11 pagesDorlastan in Circular KnittingdineshkeswaniNo ratings yet

- Showering in The Wire and Press Section - in Which Direction PDFDocument20 pagesShowering in The Wire and Press Section - in Which Direction PDFF Cikal AntariksaNo ratings yet

- Yarn Waxing XXXXXXXDocument23 pagesYarn Waxing XXXXXXXTamer Farouk Khalifa100% (1)

- Assignment Yarn IIDocument9 pagesAssignment Yarn IISohag TexbartaNo ratings yet

- Effect of Pile Density On Physical Properties of Terry Towel FabricDocument4 pagesEffect of Pile Density On Physical Properties of Terry Towel FabricshobsundarNo ratings yet

- Types of SpreadsDocument5 pagesTypes of SpreadsGulam RasoolNo ratings yet

- Roller Coating Application TechniquesDocument4 pagesRoller Coating Application TechniquesAnujNo ratings yet

- Characteristics of Sewing ThreadDocument14 pagesCharacteristics of Sewing ThreadTuan Nguyen Minh50% (2)

- Textile FinishingDocument21 pagesTextile FinishinganowartexNo ratings yet

- Fabric Assurance by Simple TestingDocument5 pagesFabric Assurance by Simple Testingsenthilkumar7374No ratings yet

- Research About Manufacturing ProcessesDocument6 pagesResearch About Manufacturing ProcessesArturo Herrera HdzNo ratings yet

- Drafting Waves of SliversDocument4 pagesDrafting Waves of Sliversnalaka.sampathNo ratings yet

- Center For Textile Function, MPSTME, NMIMSDocument29 pagesCenter For Textile Function, MPSTME, NMIMSCHetan ChaudhariNo ratings yet

- 09 Cleaning DevicesDocument8 pages09 Cleaning DevicesJerry HukyNo ratings yet

- Defects Their Causes and Remedial Measures in Terry Fabric MsDocument6 pagesDefects Their Causes and Remedial Measures in Terry Fabric MsMeri Pehli VideoNo ratings yet

- #20 Troubleshooting Belting and Conveyor Component Problems Related To Material BuildupDocument2 pages#20 Troubleshooting Belting and Conveyor Component Problems Related To Material BuildupSanatha AgungNo ratings yet

- Technology of Denim Production: Part-V (Finishing of Grey Denim Fabric)Document22 pagesTechnology of Denim Production: Part-V (Finishing of Grey Denim Fabric)ranjan349100% (2)

- Effect of Weaves On The Fabric PropertyDocument7 pagesEffect of Weaves On The Fabric Propertypuja_14100% (2)

- Draw Management: Executive SummaryDocument13 pagesDraw Management: Executive SummaryJose HernandezNo ratings yet

- Needle Shower Review Highlights, James E. Stein, JR WeavexxDocument5 pagesNeedle Shower Review Highlights, James E. Stein, JR WeavexxmariabertoloniNo ratings yet

- (Autex Research Journal) A Statistical Approach For Obtaining The Controlled Woven Fabric WidthDocument5 pages(Autex Research Journal) A Statistical Approach For Obtaining The Controlled Woven Fabric WidthHafez HawasNo ratings yet

- Little Blue Whale by CrochetwawaDocument6 pagesLittle Blue Whale by CrochetwawaGigi Elena Ordóñez100% (1)

- Alok Industries Final Report 2010-11.Document117 pagesAlok Industries Final Report 2010-11.Ashish Navagamiya0% (1)

- Consumer Behaviour Towards Branded WatchesDocument58 pagesConsumer Behaviour Towards Branded WatchesSingh GurpreetNo ratings yet

- FST 359 Term PaperDocument3 pagesFST 359 Term PaperpunitvashishtNo ratings yet

- Weaving Chapter4d Jacquard2Document33 pagesWeaving Chapter4d Jacquard2Alvarin CsboyNo ratings yet

- 2 Recommendation For Reduction of Water Consumption in Dyeing Process in Knit Concern Group LTDDocument4 pages2 Recommendation For Reduction of Water Consumption in Dyeing Process in Knit Concern Group LTDGolam Rabbi SagorNo ratings yet

- Chapter Two: Company OverviewDocument14 pagesChapter Two: Company OverviewAminur Rahman KhanNo ratings yet

- Neighbors CarverDocument4 pagesNeighbors CarverMary FNo ratings yet

- Jewel UpdateDocument5 pagesJewel UpdateImtiaz JewelNo ratings yet

- Adap Trolls Ramón - IngDocument4 pagesAdap Trolls Ramón - IngAleyda Bonfil LeónNo ratings yet

- Industrial Attachment ReportDocument163 pagesIndustrial Attachment ReportAtik U Bhuiyan100% (2)

- RX300 Installation Manual ENGDocument88 pagesRX300 Installation Manual ENGMuhammad AliNo ratings yet

- Alien Facehugger UK UpdateDocument6 pagesAlien Facehugger UK UpdateBruno Fonvieille100% (1)

- Garment Exporters ReportDocument93 pagesGarment Exporters Reportsakmac1983No ratings yet

- Sapphire Group PakistanDocument3 pagesSapphire Group PakistanBilal Asif100% (2)

- Clothing ShukuraDocument11 pagesClothing Shukuratreehays90No ratings yet

- An Economic Analysis of Shinepukur Ceramics LimitedDocument35 pagesAn Economic Analysis of Shinepukur Ceramics LimitedifazkhNo ratings yet

- Eco Safe Natural Dyes & Application On Textile Materials - TarafderDocument8 pagesEco Safe Natural Dyes & Application On Textile Materials - TarafderAnne CalyxNo ratings yet

- Baby Cot Blanket Crochet Pattern FreeDocument26 pagesBaby Cot Blanket Crochet Pattern FreeFitriyanti Nuur KhasanahNo ratings yet

- A Shirt in The MarketDocument7 pagesA Shirt in The MarketsonynmurthyNo ratings yet

- Parttern LayoutDocument10 pagesParttern LayoutAbdulrasheed AdeolaNo ratings yet

- Wrinkle Free FinishingDocument4 pagesWrinkle Free FinishingkreeshnuNo ratings yet

- A Needle Pulling Thread Issue 58 March 2022Document102 pagesA Needle Pulling Thread Issue 58 March 2022Erpepehillo100% (1)

- Industrialattachmentofviyellatexgroup 140511100625 Phpapp02 PDFDocument106 pagesIndustrialattachmentofviyellatexgroup 140511100625 Phpapp02 PDFNazmul Alam ShameemNo ratings yet

- Craft Ideas and Restaurant PDFDocument55 pagesCraft Ideas and Restaurant PDFmessapos100% (1)

- Ancient Egypt - Flax and LinenDocument8 pagesAncient Egypt - Flax and LinenMax BergerNo ratings yet

- Indian Home Textile Sector - Sector IC Report - 28-03-2024 - SystematixDocument51 pagesIndian Home Textile Sector - Sector IC Report - 28-03-2024 - SystematixAnindo ChakrabortyNo ratings yet

- CandyDocument32 pagesCandyNEWNo ratings yet

- 16 Century Bankers and Merchants: Room 7: Fairs, Trade - 16 CDocument2 pages16 Century Bankers and Merchants: Room 7: Fairs, Trade - 16 CCésar Saldaña PuertoNo ratings yet