Professional Documents

Culture Documents

Rubber Mat For Low Cost Housing

Uploaded by

Ken Roldan Diamante0 ratings0% found this document useful (0 votes)

3 views2 pagesOriginal Title

Rubber Mat for Low Cost Housing

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views2 pagesRubber Mat For Low Cost Housing

Uploaded by

Ken Roldan DiamanteCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Seismic Behaviour Test of Rubber Base Isolation

using Developed Rubber Mat for Low-cost Housing

Arvie P. Cuamag Kathlyn J. de Guzman Ken Roldan P. Diamante

College of Engineering Education College of Engineering Education College of Engineering Education

University of Mindanao University of Mindanao University of Mindanao

Montevista, Philippines Digos City, Philippines Davao City, Philippines

arviecuamag1425@gmail.com kathlyndeguzman66@gmail.com kdiamante1199@gmail.com

into fragments of various sizes and shapes, combining them

with a small amount of polyurethane, and then hot pressing or

cold forging the mixture to create recycled rubber pads.

I. INTRODUCTION Compared to a steel-reinforced isolator, the rubber and fiber

Different methods have been developed in recent years to reinforcement combination performs better [5]. In light of this,

reduce the cost and weight of seismic isolators for housing the study conducted by [6] came to the conclusion that rubber

structures in developing nations [1]. Since it is intended to and fiber reinforcement exhibit superior performance to steel

allow a building to survive a potentially disastrous seismic reinforcement in isolators. Lead Rubber Bearings are the most

strike by proper initial design or subsequent adjustments, most widely used technology in seismic base isolation, because of its

engineers seek to invent low cost solutions that focus on base technical and economic effectiveness and reliability [5].

isolations. However, producing isolators is quite expensive,

especially when using an isolator as the basis isolator for a The installation of recycled rubber-fiber reinforced bearings

residential building [2]. A cheap rubber base isolation system is challenging and frequently necessitates highly skilled

is suggested as a solution to the problem. Instead of using thick, workers and engineers. Rubber is combined with steel plates to

solid steel plates, the suggested low-cost bearing system makes withstand axial loads of the building, and since different

use of thin, perforated steel plates. Since it has been shown that structures have different loadings, it is important to conduct a

it is difficult to give rubber a second chance and that the thorough analysis to know the limitations of the rubber base

vulcanization process is both extremely polluting and energy isolation system. There is a common seismic device used in the

intensive, prices can be further reduced by substituting natural industry that utilizes the pendulum principle, but it is expensive

rubber with a recycled elastomer [1]. For low-cost houses in to install and only developed countries have manufacturers of

developing countries, Recycled Rubber-Fiber Reinforced this type of foundation seismic isolation. To address post-

Bearings (RR-FRBs) are a significant base isolation device [3]. seismic damage, an approach to develop a more economic and

sustainable foundation seismic isolation can be done.

Recycled Rubber-Fiber Reinforced Bearings (RR-FRBs)

have been validated as base isolation devices in a study by [3]. This study aims to develop a rubber mat out of locally

Their findings highlight the high potential of these inexpensive sourced recycled materials for low-cost houses. Specifically, it

bearings as base isolation devices for residential buildings, aims to assess the seismic behaviour of the developed rubber

confirming the possibility of significantly improving the mat as part of a rubber base isolation system and identify its

seismic performance of common structures by using the RR- safety index through analysis of structural and earthquake load

FRBs, which are inexpensive and simple to manufacture. The components using ETABS.

research on low-cost base isolation systems for residential

dwellings in highly seismic regions is starting with a study on Rubber base isolation has become an established technology

base-isolated residential homes in those areas [2]. Lower costs used over the globe as an anti-seismic safety device for building

can be obtained by: (i) simplifying the installation process of damage protection. Given that the Philippines is known to be

the devices, (ii) reducing energy consumption during seismic prone, the implementation of the study would be

manufacturing process and (iii) using waste and recycled beneficial as to prevent more damages of low-cost houses

materials [4]. Following this concept, by replacing virgin during earthquakes. Moreover, the conduct of the study would

rubber with a recycled, inexpensive elastomer, costs can be also be a helpful tool in contributing to the holistic engineering

further decreased while also reducing the threat posed by the approach of building resilient structures.

growing global supply of rubber trash. The weight and cost of

manufacturing the isolator could be decreased by using flexible The study will focus on developing a low-cost rubber mat

reinforcement, such as fiber [1]. However, rubber cannot be and evaluate its earthquake resilience behaviour and strength

easily reprocessed and is insoluble and infusible due to its using a specific seismic behaviour test. It will assess its

chemical structure and composition, making recycling it effectivity as part of a rubber base isolation system.

difficult [3].

One of the essential methods for the sustainable management

of used tires revealed in the study of [1] is grinding them and

using the rubber particles to create a new environmentally

friendly polymer. These materials are made by grinding rubber

XXX-X-XXXX-XXXX-X/XX/$XX.00 ©20XX IEEE

REFERENCES

[1] F. Cilento, D. Losanno, and L. Piga, “Laboratory characterization of

a reclaimed rubber compound for low-cost elastomeric isolators,”

COMPDYN Proc., vol. 2021-June, pp. 2525–2535, 2021, doi:

10.7712/120121.8655.18969.

[2] H. Sugihardjo, Tavio, and Y. Lesmana, “Behavior of a base-isolated

residential house in a highly seismic region,” Int. J. Appl. Eng. Res.,

vol. 11, no. 14, pp. 8253–8258, 2016.

[3] A. Calabrese, D. Losanno, M. Spizzuoco, S. Strano, and M. Terzo,

“Recycled Rubber Fiber Reinforced Bearings (RR-FRBs)as base

isolators for residential buildings in developing countries: The

demonstration building of Pasir Badak, Indonesia,” Eng. Struct., vol.

192, pp. 126–144, Aug. 2019, doi:

10.1016/J.ENGSTRUCT.2019.04.076.

[4] D. Konstantinidis and J. M. Kelly, “Advances in low-cost seismic

isolation with rubber,” NCEE 2014 - 10th U.S. Natl. Conf. Earthq.

Eng. Front. Earthq. Eng., 2014, doi: 10.4231/D36M33449.

[5] B. T. W. Wijaya and Tavio, “Mechanical properties of Indonesian

rubber for low-cost base isolation,” Int. J. Civ. Eng. Technol., vol.

10, no. 1, pp. 884–890, 2019.

[6] A. Amin, M. Islam, and M. J. Ahamed, “Base isolation of multi-

storied building using lead rubber bearing,” ITEGAM- J. Eng.

Technol. Ind. Appl., vol. 6, no. 26, 2020, doi:

10.5935/jetia.v6i26.697.

You might also like

- Research Paper On BambooDocument8 pagesResearch Paper On Bamboo01shubhamupadhyayNo ratings yet

- ef04f4ed-2123-49c5-8d4f-eeec575b8c28Document10 pagesef04f4ed-2123-49c5-8d4f-eeec575b8c28Thiran Boy LingamNo ratings yet

- Development and Experimental Behavior of HDR Seismic Isolators For Lowrise Residential BuildingsDocument13 pagesDevelopment and Experimental Behavior of HDR Seismic Isolators For Lowrise Residential Buildingsdaniel madrigalNo ratings yet

- Construction and Building Materials: J.M. Pastor, L.D. García, S. Quintana, J. PeñaDocument9 pagesConstruction and Building Materials: J.M. Pastor, L.D. García, S. Quintana, J. PeñaXiomara DiazNo ratings yet

- Behaviour Analysis of Light Weight Concrete With Coconut Shell As A Partial Replacement of Coarse AggregateDocument6 pagesBehaviour Analysis of Light Weight Concrete With Coconut Shell As A Partial Replacement of Coarse AggregateIJRASETPublicationsNo ratings yet

- Artigo Frazão 2018Document38 pagesArtigo Frazão 2018Dimas DelgadoNo ratings yet

- 5IJAEMS NOV 2015 7 TurningNaturalFiberReinforcedCementCompositeasInnovativeAlternativeSustainableConstructionMaterial - AReviewPaper PDFDocument9 pages5IJAEMS NOV 2015 7 TurningNaturalFiberReinforcedCementCompositeasInnovativeAlternativeSustainableConstructionMaterial - AReviewPaper PDFGalih supriyantoNo ratings yet

- لقطة شاشة 2021-11-29 في 8.40.08 مDocument18 pagesلقطة شاشة 2021-11-29 في 8.40.08 مMohammed JassemNo ratings yet

- Coconut Fibre Reinforced Concrete Made With MattressesDocument8 pagesCoconut Fibre Reinforced Concrete Made With MattressesDharma banothuNo ratings yet

- Effect of PolypropyleneDocument18 pagesEffect of PolypropyleneBenharzallah KrobbaNo ratings yet

- Kle College of Engineering and Technology, Chikodi: "Coconut Shells Building Blocks"Document13 pagesKle College of Engineering and Technology, Chikodi: "Coconut Shells Building Blocks"Anand NashiNo ratings yet

- For Outline 1122 345pmDocument6 pagesFor Outline 1122 345pmATHASIA KAYE DORADONo ratings yet

- CHAPTER2 - Carbon Fiber For Building Resistance LiteratureDocument4 pagesCHAPTER2 - Carbon Fiber For Building Resistance LiteraturejohnphilipmendinaNo ratings yet

- Structural Behaviour of Composite Sandwich PanelsDocument16 pagesStructural Behaviour of Composite Sandwich PanelsvasfidNo ratings yet

- 2012 Glass-Basaltepoxy Hybrid Composites For Marine ApplicationsDocument9 pages2012 Glass-Basaltepoxy Hybrid Composites For Marine ApplicationsAhmed TahaNo ratings yet

- 9 ArticleText 5 1 10 20190603Document7 pages9 ArticleText 5 1 10 20190603hhNo ratings yet

- Study of Flexural Strength and Flexural Modulus of Reinforced Concrete Beams With Raffia Palm FibersDocument8 pagesStudy of Flexural Strength and Flexural Modulus of Reinforced Concrete Beams With Raffia Palm FibersPremier PublishersNo ratings yet

- Journal of Cleaner Production: Alireza Kashani, Tuan Duc Ngo, Priyan Mendis, Jay R. Black, Ailar HajimohammadiDocument11 pagesJournal of Cleaner Production: Alireza Kashani, Tuan Duc Ngo, Priyan Mendis, Jay R. Black, Ailar HajimohammadiMarianaNo ratings yet

- Journal For Kalai Publication.Document12 pagesJournal For Kalai Publication.Kalai ArasanNo ratings yet

- Experimental Study On Stabilization of Clay Soil Using Coir FibreDocument13 pagesExperimental Study On Stabilization of Clay Soil Using Coir FibreElaMazlanNo ratings yet

- Chapter One 1.0 1.1 Background of StudyDocument45 pagesChapter One 1.0 1.1 Background of StudyUzoma FrancisNo ratings yet

- AGUWAADocument6 pagesAGUWAANana Kofi Adu-BoaheneNo ratings yet

- FiberglassDocument9 pagesFiberglassJennifer CharlesNo ratings yet

- Application and Analysis of Waste Plastic As A Effective Pavement MaterialsDocument34 pagesApplication and Analysis of Waste Plastic As A Effective Pavement MaterialsPrashanthryakamNo ratings yet

- Sawdust Brick A Quantitative Study On Sawdust Substitute For Concrete Brick ProductionDocument21 pagesSawdust Brick A Quantitative Study On Sawdust Substitute For Concrete Brick ProductionChristian Andre FloresNo ratings yet

- Studies On Stabilized Mud Block As A Construction MaterialDocument6 pagesStudies On Stabilized Mud Block As A Construction MaterialIJIRAE- International Journal of Innovative Research in Advanced Engineering100% (1)

- Durability Properties of Banana Fibre ReDocument7 pagesDurability Properties of Banana Fibre ReSajjad AhmadNo ratings yet

- 2 4 Ce225 Research - Paper Group 4Document7 pages2 4 Ce225 Research - Paper Group 4JEAN KATHLEEN SORIANONo ratings yet

- A Study of Adding Recycled Rubber Tire As Substitute Aggregate On Gravel RevisionDocument12 pagesA Study of Adding Recycled Rubber Tire As Substitute Aggregate On Gravel RevisionJo Crisley T. PasayanNo ratings yet

- Light Weight Aggregate Concrete by Using Coconut Shell: S. A. Kakade, Dr. A. W. DhawaleDocument3 pagesLight Weight Aggregate Concrete by Using Coconut Shell: S. A. Kakade, Dr. A. W. DhawaleGelo LibanNo ratings yet

- Ijser: Use of Coconut Husk Fiber For Improved Compressive and Flexural Strength of Con-CreteDocument7 pagesIjser: Use of Coconut Husk Fiber For Improved Compressive and Flexural Strength of Con-CreteMark leeNo ratings yet

- Major Stage 1Document11 pagesMajor Stage 1Vinay JanjiralaNo ratings yet

- Mechanical Performance and Durability of Treated Palm Fiber Reinforced MortarsDocument12 pagesMechanical Performance and Durability of Treated Palm Fiber Reinforced MortarsexowilzNo ratings yet

- Materials 16 04457Document17 pagesMaterials 16 04457Mithun KanishkaNo ratings yet

- Alternative Low-Cost Building Material - Ar - Vidya & Ar - RadhaDocument7 pagesAlternative Low-Cost Building Material - Ar - Vidya & Ar - RadhaPrasadNo ratings yet

- Karel Guillermo Chapter 1Document4 pagesKarel Guillermo Chapter 1Princess Karel GuillermoNo ratings yet

- Design of Low Cost Roofing Tiles Using Agricultural WasteDocument4 pagesDesign of Low Cost Roofing Tiles Using Agricultural WasteBirkure AjayNo ratings yet

- Construction and Building Materials: S. Jeeva Chithambaram, Sanjay KumarDocument8 pagesConstruction and Building Materials: S. Jeeva Chithambaram, Sanjay KumarKartickPaiNo ratings yet

- Enhancement The Strength of Conventional Concrete by Using Nylon FibreDocument4 pagesEnhancement The Strength of Conventional Concrete by Using Nylon FibreinventyNo ratings yet

- Papercrete4 PDFDocument9 pagesPapercrete4 PDFPrasad TekadeNo ratings yet

- Tella HND Project - Determination of Engineering Properties of Sandcrete Block Using Different Grade of CementDocument77 pagesTella HND Project - Determination of Engineering Properties of Sandcrete Block Using Different Grade of CementDavid TellaNo ratings yet

- Performance Indices For A Simulated Strawbale - SB - Masonry Sprayed With Fibre ReinforcedDocument10 pagesPerformance Indices For A Simulated Strawbale - SB - Masonry Sprayed With Fibre ReinforceddkataleNo ratings yet

- Construction and Building Materials: Haydar Aygün, Finian MccannDocument13 pagesConstruction and Building Materials: Haydar Aygün, Finian MccannSovendra KumarNo ratings yet

- Performance Analysis of Fiber Reinforced Concrete Using Experimental Method, Etabs and Optimization by Taguchi MethodDocument8 pagesPerformance Analysis of Fiber Reinforced Concrete Using Experimental Method, Etabs and Optimization by Taguchi Methodanon_789699787No ratings yet

- Cellular Light Weight Concrete Using Glass FiberDocument5 pagesCellular Light Weight Concrete Using Glass Fibermidhila vkNo ratings yet

- Department of Chemical EngineeringDocument7 pagesDepartment of Chemical EngineeringAngelyn de LaraNo ratings yet

- Development of Rail Pads From Recycled Polymers For BallastedDocument14 pagesDevelopment of Rail Pads From Recycled Polymers For BallastedOficina técnica HermacastiNo ratings yet

- FiberglassDocument17 pagesFiberglassHemali Shah100% (1)

- Comparative Study of Sisal Fibre and Glass Fibre Reinforced Concrete - A ReviewDocument6 pagesComparative Study of Sisal Fibre and Glass Fibre Reinforced Concrete - A ReviewIJRASETPublicationsNo ratings yet

- Chapter 2 FinalDocument20 pagesChapter 2 FinalMariel Erica RootNo ratings yet

- Reduction of Thermal Cracking in Concrete Through The Use of Coal Ash As A Partial Replacement For OPCDocument5 pagesReduction of Thermal Cracking in Concrete Through The Use of Coal Ash As A Partial Replacement For OPCInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Concrete Using Coconut ShellsDocument4 pagesConcrete Using Coconut ShellsUmange RanasingheNo ratings yet

- Effect of Limestone Powder Substitution On Mechanical Properties and Durability of Slender Precast Components of Structural MortarDocument10 pagesEffect of Limestone Powder Substitution On Mechanical Properties and Durability of Slender Precast Components of Structural MortarJaime Andres Alvarez Castellar estudianteNo ratings yet

- Uniqueness of Mud Architecture: International Research Journal of Engineering and Technology (IRJET)Document6 pagesUniqueness of Mud Architecture: International Research Journal of Engineering and Technology (IRJET)Shrutie PatilNo ratings yet

- Experimental Study On Sisal Fiber Reinforced Concrete With Addition of Fly AshDocument7 pagesExperimental Study On Sisal Fiber Reinforced Concrete With Addition of Fly AshIJRASETPublicationsNo ratings yet

- Natural Aggregates Used For Light Weight Concrete A Review2020IOP Conference Series Materials Science and EngineeringDocument10 pagesNatural Aggregates Used For Light Weight Concrete A Review2020IOP Conference Series Materials Science and EngineeringJoe Alcantara RomeroNo ratings yet

- AhmedDocument8 pagesAhmedmarcos Perez PinoNo ratings yet

- 797-Article Text-1270-1-10-20221223Document7 pages797-Article Text-1270-1-10-20221223blhibtissem033No ratings yet

- Review Paper On Development of Polymer Composite Material and Its CharacterisationDocument5 pagesReview Paper On Development of Polymer Composite Material and Its CharacterisationLuminita Ana OprutaNo ratings yet

- A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessFrom EverandA Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture Toughness: A Comparative Study of Mechanical Properties of Zinc Acrylate Epoxy nanocomposites Reinforced by AL2O3 and Cloisite®30B and Their Mixture: Tensile Strength and Fracture ToughnessNo ratings yet

- Unit-1 High and Low Demand TacticsDocument7 pagesUnit-1 High and Low Demand TacticsYash RajNo ratings yet

- AdgenpsfDocument63 pagesAdgenpsfsupport ofoqsolutionsNo ratings yet

- Chart Title: Bin FrequencyDocument6 pagesChart Title: Bin FrequencyTran KhoaNo ratings yet

- Application For Repatriation and CitizenshipDocument4 pagesApplication For Repatriation and CitizenshipMasterNo ratings yet

- Kernels For Edge Dominating Set: Simpler or Smaller: Abstract. A Kernelization For A Parameterized Computational ProblemDocument2 pagesKernels For Edge Dominating Set: Simpler or Smaller: Abstract. A Kernelization For A Parameterized Computational ProblemSebastian David Ariza CollNo ratings yet

- Lessons in Business Statistics Prepared by P.K. ViswanathanDocument52 pagesLessons in Business Statistics Prepared by P.K. ViswanathanLloyd LamingtonNo ratings yet

- Procedure On Handling of Complaints and AppealsDocument10 pagesProcedure On Handling of Complaints and Appealsndayiragije JMVNo ratings yet

- Supplemental ERAS Application Guide 8.31.2021 - 1Document18 pagesSupplemental ERAS Application Guide 8.31.2021 - 1Shreyas YakkaliNo ratings yet

- ITM-Midwest Health IT Risks ControlsDocument18 pagesITM-Midwest Health IT Risks ControlsPrabhat SinghNo ratings yet

- Conditional Positional Encodings For Vision TransformersDocument13 pagesConditional Positional Encodings For Vision Transformerstadeas kellyNo ratings yet

- Webinar - Java From Scratch - Stationery - SDA Albania by Protik - 01 - 12 - 2020Document26 pagesWebinar - Java From Scratch - Stationery - SDA Albania by Protik - 01 - 12 - 2020Dany ThorbackNo ratings yet

- Security GovernanceDocument5 pagesSecurity GovernanceQaiser KhanNo ratings yet

- 11 AlarmsDocument62 pages11 AlarmsvaldoNo ratings yet

- Demo DATA ANALYSISDocument31 pagesDemo DATA ANALYSISHanah Mae AlvarezNo ratings yet

- C7011VP Ced V4Document80 pagesC7011VP Ced V4David MountsNo ratings yet

- Okken Switchboard: Nguyen The Vinh - Consultant EngineerDocument47 pagesOkken Switchboard: Nguyen The Vinh - Consultant EngineerNguyễn Nhật ÁnhNo ratings yet

- LogDocument13 pagesLogWahono Bagoes Adjie WibowoNo ratings yet

- 05 Descriptive Statistics - DistributionDocument5 pages05 Descriptive Statistics - DistributionAce ChoiceNo ratings yet

- Developing With Graphics - Free Pascal WikiDocument26 pagesDeveloping With Graphics - Free Pascal WikideviNo ratings yet

- 01-10 DHCPv6 Configuration PDFDocument68 pages01-10 DHCPv6 Configuration PDFHamoud BourjNo ratings yet

- The Ultimate ChatGPT Guide For Beginners (Snippet)Document44 pagesThe Ultimate ChatGPT Guide For Beginners (Snippet)chen mlNo ratings yet

- Manual Spectro-GuideDocument74 pagesManual Spectro-GuidenasikroadNo ratings yet

- Fencing Drawing-Proposal As On 15.02.2023Document1 pageFencing Drawing-Proposal As On 15.02.2023Bittudubey officialNo ratings yet

- Introduction: Science, Technology and Society: Name: Geneveve B. Abaricia Course & Year: BSED1 ENGLISH - C.EDocument5 pagesIntroduction: Science, Technology and Society: Name: Geneveve B. Abaricia Course & Year: BSED1 ENGLISH - C.EClaire Mariah Igualada100% (1)

- Lamaran Kerja WWF (English)Document1 pageLamaran Kerja WWF (English)Afan Dwi AnwarNo ratings yet

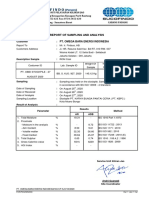

- Report of Sampling and Analysis: Pt. Omega Bara Energi IndonesiaDocument1 pageReport of Sampling and Analysis: Pt. Omega Bara Energi IndonesiaNor Habibi WibowoNo ratings yet

- Unoriginal Prusa DryboxDocument28 pagesUnoriginal Prusa DryboxAlejandra RusakNo ratings yet

- Assingnment No. 4Document4 pagesAssingnment No. 4Devendra ChaturvediNo ratings yet

- Keysight 5G - End - To - End - Solution - v2Document61 pagesKeysight 5G - End - To - End - Solution - v2Study Baby100% (1)

- Instructions Pico BBDocument66 pagesInstructions Pico BBnop samNo ratings yet