Professional Documents

Culture Documents

NFC-2016 313

Uploaded by

avivekprasathCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

NFC-2016 313

Uploaded by

avivekprasathCopyright:

Available Formats

1–314 FIRE CODE

Table 52.1 Battery Requirements

Nonrecombinant Batteries Recombinant Batteries Other

Flooded

Flooded Nickel-Cadmium Valve-Regulated Lithium Metal

Requirement Lead-Acid (Ni-Cd) Lead–Acid (VRLA) Lithium-Ion Polymer

Safety caps Venting caps Venting caps Self-resealing No caps No caps

flame-arresting caps

Thermal runaway Not required Not required Required Not required Required

management

Spill control Required Required Not required Not required Not required

Neutralization Required Required Required Not required Not required

Ventilation Required Required Required Not required Not required

Signage Required Required Required Required Required

Seismic control Required Required Required Required Required

Fire detection Required Required Required Required Required

52.3 Safety Features. gate capacity exceeding 1000 gal (3785 L) shall be provided

with spill control to prevent the flow of liquids to adjoining

52.3.1 Safety Venting. Batteries shall be provided with safety

areas.

venting caps as follows in 52.3.1.1 through 52.3.1.3.

52.3.1.1 Nonrecombinant Batteries. Vented lead-acid, nickel- 52.3.4.2* An approved method and materials for the control

cadmium, or other types of nonrecombinant batteries shall be of a spill of electrolyte shall be provided that will be capable of

provided with safety venting caps. controlling a spill from the single largest vessel.

52.3.1.2 Recombinant Batteries. VRLA or other types of 52.3.4.3 VRLA, lithium-ion, lithium metal polymer, or other

sealed, recombinant batteries shall be equipped with self- types of sealed batteries with immobilized electrolyte shall not

resealing flame-arresting safety vents. require spill control.

52.3.1.3 Lithium-ion and lithium metal polymer batteries 52.3.5 Neutralization.

shall not require safety venting caps. 52.3.5.1* An approved method to neutralize spilled electro-

52.3.2 Thermal Runaway. VRLA, lithium-ion, and lithium lyte shall be provided.

metal polymer battery systems shall be provided with a listed 52.3.5.2 For nonrecombinant batteries and VRLA batteries,

device or other approved method to preclude, detect, and the method shall be capable of neutralizing a spill from the

control thermal runaway. largest battery to a pH between 7.0 and 9.0.

52.3.3 Location and Occupancy Separation.

52.3.5.3 Lithium-ion and lithium metal polymer batteries

52.3.3.1 Battery systems shall be permitted in the same room shall not require neutralization.

as the equipment that they support.

52.3.6* Ventilation. For flooded lead-acid, flooded nickel-

52.3.3.2 Battery systems shall be housed in a noncombus- cadmium, and VRLA batteries, ventilation shall be provided

tible, locked cabinet or other enclosure to prevent access by for rooms and cabinets in accordance with the mechanical

unauthorized personnel unless located in a separate equip- code and one of the following:

ment room accessible only to authorized personnel.

(1) The ventilation system shall be designed to limit the maxi-

52.3.3.3 In other than assembly, educational, detention and mum concentration of hydrogen to 1.0 percent of the

correction facilities, health care, ambulatory health care, day total volume of the room during the worst-case event of

care centers, residential board and care, and residential occu- simultaneous “boost” charging of all the batteries, in ac-

pancies, battery systems shall be located in a room separated cordance with nationally recognized standards.

from other portions of the building by a minimum of a 1-hour (2) Continuous ventilation shall be provided at a rate of not

fire barrier. less than 1 ft3/min/ft2 (5.1 L/sec/m2) of floor area of the

52.3.3.4 In assembly, educational, detention and correction room or cabinet.

facilities, health care, ambulatory health care, day care cen- 52.3.6.1 Lithium-ion and lithium metal polymer batteries

ters, residential board and care, and residential occupancies, shall not require ventilation.

battery systems shall be located in a room separated from

other portions of the building by a minimum of a 2-hour fire 52.3.7 Environment. The battery environment shall be con-

barrier. trolled or analyzed to maintain temperature in a safe operat-

ing range for the specific battery technology used.

52.3.4 Spill Control.

52.3.8 Signs.

52.3.4.1 Rooms, buildings, or areas containing free-flowing

liquid electrolyte in individual vessels having a capacity of 52.3.8.1 Doors or accesses into the following shall be pro-

more than 55 gal (208 L) or multiple vessels having an aggre- vided with approved signs:

2015 Edition

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- 360 00 CC SPC 00010 CDocument20 pages360 00 CC SPC 00010 CavivekprasathNo ratings yet

- ES-2!63!0001, Typical Electrical Installation Details, PowerDocument19 pagesES-2!63!0001, Typical Electrical Installation Details, Poweravivekprasath100% (1)

- 360 00 CC PLN 00034 - DDocument1 page360 00 CC PLN 00034 - DavivekprasathNo ratings yet

- LV Kahramaa Single Core Tds-Upto JuneDocument1 pageLV Kahramaa Single Core Tds-Upto JuneavivekprasathNo ratings yet

- 60-41-El-Sld-00001 50 Foc Joc SLDDocument1 page60-41-El-Sld-00001 50 Foc Joc SLDavivekprasathNo ratings yet

- Project: Cable Sizing CalculationDocument9 pagesProject: Cable Sizing CalculationavivekprasathNo ratings yet

- Oil FilledDocument38 pagesOil FilledavivekprasathNo ratings yet

- UPS System SchematicDocument3 pagesUPS System SchematicavivekprasathNo ratings yet

- 1.0. General Standards: Central Inverter Emergency Lighting SystemDocument6 pages1.0. General Standards: Central Inverter Emergency Lighting SystemavivekprasathNo ratings yet

- DS-KM LV SINGLECORE - PVC Latest Spec From June OnwardsDocument2 pagesDS-KM LV SINGLECORE - PVC Latest Spec From June OnwardsavivekprasathNo ratings yet

- Electric Drive For Pumps: Generators, and Shall Be Marked As Complying With NEMADocument1 pageElectric Drive For Pumps: Generators, and Shall Be Marked As Complying With NEMAavivekprasathNo ratings yet

- Regulations For The Installation of Electrical Wiring EleDocument121 pagesRegulations For The Installation of Electrical Wiring EleKrishna Sankar100% (1)

- UC XLPE CatalogueDocument80 pagesUC XLPE CatalogueNICHOLASNo ratings yet

- (Engineering Standard) (Standard Template) Project Document & Drawing Index (Discipline)Document5 pages(Engineering Standard) (Standard Template) Project Document & Drawing Index (Discipline)avivekprasathNo ratings yet

- 3DS Max CommandsDocument1 page3DS Max CommandsavivekprasathNo ratings yet

- NXC15KVA Battery Cabinet DetailsDocument1 pageNXC15KVA Battery Cabinet DetailsavivekprasathNo ratings yet

- Schneider Protection GuideDocument76 pagesSchneider Protection GuideahmedhamzehNo ratings yet

- Cable CalculationDocument2 pagesCable CalculationavivekprasathNo ratings yet

- Rev MV SLD 2316-El-B2-1-0 PDFDocument1 pageRev MV SLD 2316-El-B2-1-0 PDFavivekprasathNo ratings yet

- Microsoft Excel 2007 Keyboard Shortcuts 1Document3 pagesMicrosoft Excel 2007 Keyboard Shortcuts 1Dhaval LagwankarNo ratings yet

- QP Latest Vendor List QFM-DT-017-05 Rev 0 2010-02-23 PVL List ApprovedDocument78 pagesQP Latest Vendor List QFM-DT-017-05 Rev 0 2010-02-23 PVL List Approvedavivekprasath40% (5)

- Austin Hughes and Bill Drury (Auth.) Electric Motors and Drives. Fundamentals, Types and Applications 2013Document123 pagesAustin Hughes and Bill Drury (Auth.) Electric Motors and Drives. Fundamentals, Types and Applications 2013megamaster2010No ratings yet

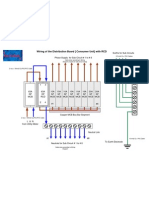

- DB Internal WiringDocument1 pageDB Internal WiringavivekprasathNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Notam AbbreviationDocument39 pagesNotam Abbreviationthebigkahuna81No ratings yet

- Forgot Apple ID Password-CompressedDocument1 pageForgot Apple ID Password-CompressedNilesh NileshNo ratings yet

- Jive to Twist - A history of iconic social dancesDocument5 pagesJive to Twist - A history of iconic social dancesHanz Christian PadiosNo ratings yet

- Gender Representation in A Prescribed Efl Textbook of Junior High School in IndonesiaDocument15 pagesGender Representation in A Prescribed Efl Textbook of Junior High School in IndonesiaJasa Skripsi AmanahNo ratings yet

- Chapter 1Document37 pagesChapter 1bhawesh agNo ratings yet

- Rehabili-Tation of THE Surround - Ings of Santa Maria de Alcobaça MonasteryDocument2 pagesRehabili-Tation of THE Surround - Ings of Santa Maria de Alcobaça MonasteryTashi NorbuNo ratings yet

- Ultimate Success Guide - Sue Hines PDFDocument450 pagesUltimate Success Guide - Sue Hines PDFBoubacar DialloNo ratings yet

- MKT 460 CH 1 Seh Defining Marketing For The 21st CenturyDocument56 pagesMKT 460 CH 1 Seh Defining Marketing For The 21st CenturyRifat ChowdhuryNo ratings yet

- School Kills Curiosity and Promotes Bad BehaviorDocument2 pagesSchool Kills Curiosity and Promotes Bad BehaviorThư AnhNo ratings yet

- Wa0000.Document3 pagesWa0000.Surya SiddarthNo ratings yet

- Emissionbooklet 2019 PDFDocument210 pagesEmissionbooklet 2019 PDFSmriti SinghNo ratings yet

- Pahlavi Yasna and Visprad (E. B. N. Dhabhar) - TextDocument597 pagesPahlavi Yasna and Visprad (E. B. N. Dhabhar) - TextLalaylaNo ratings yet

- Ge 2 - Purposive Communication: 1st Exam Mechanics & GuidelinesDocument8 pagesGe 2 - Purposive Communication: 1st Exam Mechanics & GuidelinesCarl Monte de RamosNo ratings yet

- Individual and Group Dynamics: Managing Diversity at Cityside Financial ServicesDocument7 pagesIndividual and Group Dynamics: Managing Diversity at Cityside Financial ServicesxxxNo ratings yet

- Dlsu Conyo CompressDocument11 pagesDlsu Conyo CompressGabrielNo ratings yet

- National Institute of Technology Durgapur: Mahatma Gandhi Avenue, Durgapur 713 209, West Bengal, IndiaDocument2 pagesNational Institute of Technology Durgapur: Mahatma Gandhi Avenue, Durgapur 713 209, West Bengal, IndiavivekNo ratings yet

- IFMP Mutual Fund Distributors Certification (Study and Reference Guide) PDFDocument165 pagesIFMP Mutual Fund Distributors Certification (Study and Reference Guide) PDFPunjabi Larka100% (1)

- New SEM Socio Economic Segmentation Tool ExplainedDocument3 pagesNew SEM Socio Economic Segmentation Tool ExplainedanzaniNo ratings yet

- I Have Studied Under Many Efficient Teachers and I Have Learnt A Lot From ThemDocument1 pageI Have Studied Under Many Efficient Teachers and I Have Learnt A Lot From ThemSHENNIE WONG PUI CHI MoeNo ratings yet

- Bertolt BrechtDocument8 pagesBertolt Brechtjavier_1978No ratings yet

- Phrases for Fluent English Speech and WritingDocument2 pagesPhrases for Fluent English Speech and WritingmolesagNo ratings yet

- 2006 Cio Toolkit What To Do in The First 100 Days of Your New Job GartnerDocument24 pages2006 Cio Toolkit What To Do in The First 100 Days of Your New Job Gartnermaxlaroche0% (1)

- MCQ History and Developement Accounting in MalaysiaDocument12 pagesMCQ History and Developement Accounting in MalaysiasyibiezNo ratings yet

- Case 3-1 Southwest AirlinesDocument2 pagesCase 3-1 Southwest AirlinesDebby Febriany86% (7)

- Government of Punjab: Walk in InterviewDocument7 pagesGovernment of Punjab: Walk in InterviewJeshiNo ratings yet

- 5 Explanation of Pratikramana Sutra Uvasaggaharam StotraDocument83 pages5 Explanation of Pratikramana Sutra Uvasaggaharam Stotrajinavachan67% (3)

- A Clean, Well-Lighted Place EssayDocument7 pagesA Clean, Well-Lighted Place EssayAdrianNo ratings yet

- Factors that Increase Obedience and Causes of DisobedienceDocument4 pagesFactors that Increase Obedience and Causes of Disobedienceatif adnanNo ratings yet

- Missionary Sisters of Our Lady of Fatima v. AlzonaDocument12 pagesMissionary Sisters of Our Lady of Fatima v. AlzonaChristine MontefalconNo ratings yet

- Marketing Planning & Application: Submitted To Sir Bilal KothariDocument20 pagesMarketing Planning & Application: Submitted To Sir Bilal KothariSAIF ULLAHNo ratings yet