Professional Documents

Culture Documents

Rohm Sensorshld1-Evk-101 BRD Rev01 2016-03-24

Uploaded by

Anirudh VNOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Rohm Sensorshld1-Evk-101 BRD Rev01 2016-03-24

Uploaded by

Anirudh VNCopyright:

Available Formats

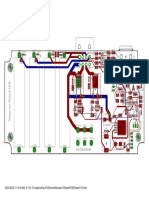

ART FILM - L01_TOP

COMPANY NAME:

LAYER: 01 UNLESS OTHERWISE

SPECIFIED DIMENSIONS

PRIMARY-SIDE ROHM SEMICONDUCTOR USA ARE IN INCHES

DESIGNER: PTEC PROJECT NAME:

TOLERANCES

CHECKER: ROHM SEMICONDUCTOR SENSORSHLD1-EVK-101 DECIMAL ANGLE

X .1 30

DATE: 2016-03-24 PROJECT NUMBER: REV. XX .03 MACH FINISH

XXX .010

JOB#: NUMBER 01

ART FILM - L01_TOP

ART FILM - L02_BOTTOM

JOB#: NUMBER 01 XXX .010

XX .03 MACH FINISH

DATE: 2016-03-24 PROJECT NUMBER: REV. X .1 30

CHECKER: ROHM SEMICONDUCTOR SENSORSHLD1-EVK-101 DECIMAL ANGLE

TOLERANCES

DESIGNER: PTEC

PROJECT NAME:

ARE IN INCHES

SECONDARY-SIDE ROHM SEMICONDUCTOR USA SPECIFIED DIMENSIONS

UNLESS OTHERWISE

LAYER: 02 COMPANY NAME:

ART FILM - L02_BOTTOM

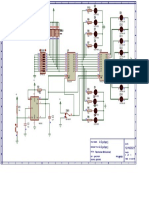

ART FILM - SILK_TOP

8 H3

10 3

R11

R12

R13

R14

R15

R16

R39

R17

R33

R18

R10

R19

R20

R21

R22

R23

R24

R25

R26

R9

R8

U16

7 CORNER ACCEL 7 4

C30

4

C24

C31

C25

10 10

U13

CORNER ACCEL TEMPERATURE PRESSURE

HALL

5 4 9 11 C2 3

R1 C5

8

U4

6

C1

3 C3

4 5

U2 5 3

U11

Designed in CA. c 2016

U1

PN: ROHM_SENSORSHLD1-EVK-101

U8 9 GYRO

C11

C21

R41

8

ACCEL+MAG MEM

6

H1

16

16

R42 C19

R34

5 5

10 C36

C12

C17

C22

C38 C10

U18

5

5 6

R43 C35 C7 C8

R46 U5

4 3 10 U6 U7

U17 6

5 4

3

C34

U19 4 5 4 C9 Pb

2

8 C37 5

R45 9 10 8 8 R37

C32 7 4

C33 UV COLOR R40

C6 ALS/PROX CORNER ACCEL

R44 CORNER ACCEL

A

C D1 7 4 7 4

6 C23

C28

C26

C29

C27

R36

R35

10

3 4 R38 10

U14 U15

R27

R28

R29

R30

R31

U12 4 H2

8 6

COMPANY NAME:

SILKSCREEN UNLESS OTHERWISE

SPECIFIED DIMENSIONS

PRIMARY-SIDE ROHM SEMICONDUCTOR USA ARE IN INCHES

DESIGNER: PTEC PROJECT NAME:

TOLERANCES

CHECKER: ROHM SEMICONDUCTOR SENSORSHLD1-EVK-101 DECIMAL ANGLE

X .1 30

DATE: 2016-03-24 PROJECT NUMBER: REV. XX .03 MACH FINISH

XXX .010

JOB#: NUMBER 01

ART FILM - SILK_TOP

ART FILM - SMASK_TOP

COMPANY NAME:

SOLDERMASK UNLESS OTHERWISE

SPECIFIED DIMENSIONS

PRIMARY-SIDE ROHM SEMICONDUCTOR USA ARE IN INCHES

DESIGNER: PTEC PROJECT NAME:

TOLERANCES

CHECKER: ROHM SEMICONDUCTOR SENSORSHLD1-EVK-101 DECIMAL ANGLE

X .1 30

DATE: 2016-03-24 PROJECT NUMBER: REV. XX .03 MACH FINISH

XXX .010

JOB#: NUMBER 01

ART FILM - SMASK_TOP

ART FILM - SMASK_BOTTOM

JOB#: NUMBER 01 XXX .010

XX .03 MACH FINISH

DATE: 2016-03-24 PROJECT NUMBER: REV. X .1 30

CHECKER: ROHM SEMICONDUCTOR SENSORSHLD1-EVK-101 DECIMAL ANGLE

TOLERANCES

DESIGNER: PTEC

PROJECT NAME:

ARE IN INCHES

SECONDARY-SIDE ROHM SEMICONDUCTOR USA SPECIFIED DIMENSIONS

UNLESS OTHERWISE

SOLDERMASK COMPANY NAME:

ART FILM - SMASK_BOTTOM

ART FILM - PASTE_TOP

COMPANY NAME:

PASTEMASK UNLESS OTHERWISE

SPECIFIED DIMENSIONS

PRIMARY-SIDE ROHM SEMICONDUCTOR USA ARE IN INCHES

DESIGNER: PTEC PROJECT NAME:

TOLERANCES

CHECKER: ROHM SEMICONDUCTOR SENSORSHLD1-EVK-101 DECIMAL ANGLE

X .1 30

DATE: 2016-03-24 PROJECT NUMBER: REV. XX .03 MACH FINISH

XXX .010

JOB#: NUMBER 01

ART FILM - PASTE_TOP

ART FILM - ASSY_TOP

4 3 2

REVISIONS

REV DESCRIPTION DATE APPROVED

D D

H3

R11

R12

R13

R14

R15

R16

R39

R17

R33

R18

R10

R19

R20

R21

R22

R23

R24

R25

R26

R9

R8

C30

C24

U13

C25

C31

U16

C1

C2

C5

R1

U1 U4

U2 C3

C21

R41

U8

C

U11 H1

C11

R42

C19

R34

C10

C12

C36

U18 C38

C17

C22

C35

C

R46 R43 C8

C7

U19

U17 U5 U6 U7 C9

C37

R45 C34 R37

C32 R40

C6

R44 C33

D1

C23

C26

C28

C27

C29

R36

U12 R35

U14 R38 U15

R27

R28

R29

R30

R31

H2

ASSEMBLY

PRIMARY-SIDE

B

B

A A

COMPANY NAME:

UNLESS OTHERWISE

ASSEMBLY TOP SPECIFIED DIMENSIONS

ROHM SEMICONDUCTOR USA ARE IN INCHES

DESIGNER: PTEC PROJECT NAME:

TOLERANCES

CHECKER: INITIAL SENSORSHLD1-EVK-101 DECIMAL ANGLE

X .1 30

DATE: 2016-03-24 ASSEMBLY NUMBER: REV. SHEET: XX .03 MACH FINISH

XXX .010

JOB#: NUMBER 01 1 OF 2

4 3 2

ART FILM - ASSY_TOP

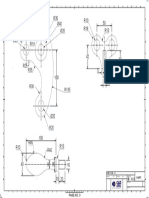

ART FILM - FAB

4 3 2

LAYER STACKING DETAIL REVISIONS

Copper Copper Dielectric REV DESCRIPTION DATE APPROVED

Layer Material

Weight Thickness Thickness

Layer # Type (Oz) (Mils) Type - Ply (Mils)

Plating 1.35 NOTES:

1 SIG 0.5 0.65 1. Specifications.

A. Fabricate IAW IPC600, latest revision.

D 2 0.5 0.65

Prepreg 58.00

B. Producibility study - It is the respondsibility of the supplier

D

SIG

Plating

to conduct a thorough review of the artwork and media for

1.35

manufacturability in the supplier's process compliance to all

Total Overal Thickness: 62.00+/-10% Mils

applicable specifications. Customer must be advised in

Material Ordering Info (used in lieu of Fasttrak data)

writing (in advance of manufacturing) of any changes, revisions,or

Panel Size ______

corrections made or recommendations to ensure conformance to

Number Up ______

standards, and of any specifications that cannot be met.

Number of Parts Due ______

Prepregs Construction Added? ______

D. This drawing is to be used in conjunction with the provided

gerber and drill data when applicable.

Material Ply Specified ______

Material Type (ie Nelco-29, 370 HR, ...) E. All notes are "Unless Otherwise Specified."

FR4

2. Material

A. FR4.

B. Color to be opaque.

2.800

3. Soldermask

Solder mask both sides with (green color) liquid

photoimageable soldermask, 003 max. thickness.

Soldermask over bare copper.

Soldermask is allowed in via holes.

4. Drilling

A. All hole diameters are finished sizes.

B. All hole to be +/- .003 from true position unless otherwise specified.

2.200

C. All hole diameters to be +/- .003 unless otherwise specified. C

C D. An NC drill file has been supplied - see drill table.

5. Finish

A. Plate thru with copper .0010 min to .002 max. thickness drill size

dimension apply after plating.

B. Use gold immersion over nickel.

C. Finished boards shall not have nicks,

scratches, voids, exposed copper, poor plating, all misdrilled holes.

6. Silkscreen

FAB NOTE

A. Silkscreen using white non-conductive epoxy or equivalent (both sides).

B. No silkscreen allowed on exposed lands.

C. Silkscreen must be a minimum of 3mm away form fiducial marks.

D. Minimum clearance between silkscreen legend and vias, pads, or holes

to be .005.

E. Silkscreen is allowed in via holes.

DRILL CHART: TOP to BOTTOM 7. Electrical Test

ALL UNITS ARE IN MILS A. All boards shall be 100% electrically tested for opens/short at 10 volts.

FIGURE SIZE TOLERANCE PLATED QTY MIL-SPEC boards to be tested at 40 volts.

B. Apply test stamp in non-legend area on solder side of PCB.

12.0 +3.0/-10.0 PLATED 264 C. Test is required on both sides of the board. B

B 40.0 +3.0/-3.0 PLATED 54

8. Cleanliness

125.0 +3.0/-3.0 PLATED 4 A. Boards shall be free of fiber glass dust or any other foreign material.

B. Finished boards must conform to 0.01 MG/IN max NAcL ionic contamination

as meaxured by the omega meter 600SMD.

9. Packaging

There shall be a max of 25 units per package, individually wrapped,

and shipped in cardboard cratons with sufficient surrounding

material to prevend shipping damage.

10. Bow and Twist

Bow and twist to be .007 IN/IN or .090 max according to IPC-A-600D.

11. Inspection

A.Automatic optical inspection of all layers required.

B.The impedance should be controlled by stackup layer.

12. Inside corners should be rounded-off

13. Changes to board geometries and apertures are not

A allowed unless they are approved by customer.

A

14. Rounding is allowed on 90 degree corners with the size of

standard routing bit.

COMPANY NAME:

UNLESS OTHERWISE

FAB DRAWING SPECIFIED DIMENSIONS

ROHM SEMICONDUCTOR USA ARE IN INCHES

DESIGNER: PTEC PROJECT NAME:

TOLERANCES

CHECKER: INITIAL SENSORSHLD1-EVK-101 DECIMAL ANGLE

X .1 30

DATE: 2016-03-24 FAB NUMBER: REV. SHEET: XX .03 MACH FINISH

XXX .010

JOB#: NUMBER 01 1 OF 2

4 3 2

ART FILM - FAB

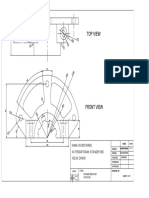

ART FILM - PANEL

4 3 2

REVISIONS

REV DESCRIPTION DATE APPROVED

D D

2.800

2.200

C

C

B

B

A A

COMPANY NAME:

UNLESS OTHERWISE

PANEL DRAWING SPECIFIED DIMENSIONS

ROHM SEMICONDUCTOR USA ARE IN INCHES

DESIGNER: PTEC PROJECT NAME:

TOLERANCES

CHECKER: INITIAL SENSORSHLD1-EVK-101 DECIMAL ANGLE

X .1 30

DATE: 2016-03-24 FAB NUMBER: REV. SHEET: XX .03 MACH FINISH

XXX .010

JOB#: NUMBER 01 2 OF 2

4 3 2

ART FILM - PANEL

ART FILM - ASSY_BOTTOM

2 3 4

JOB#: 01 2 OF 2 XXX .010

XX .03 MACH FINISH

DATE: 2016-03-24 REV. SHEET: X .1 30

DECIMAL ANGLE

CHECKER: INITIAL SENSORSHLD1-EVK-101

TOLERANCES

DESIGNER: PTEC

PROJECT NAME:

ARE IN INCHES

SECONDARY-SIDE ROHM SEMICONDUCTOR USA SPECIFIED DIMENSIONS

UNLESS OTHERWISE

ASSEMBLY

COMPANY NAME:

A A

B

B

SECONDARY-SIDE

ASSEMBLY

H5 H4

C

C

H7

H6

H8

D D

APPROVED DATE DESCRIPTION REV

REVISIONS

2 3 4

ART FILM - ASSY_BOTTOM

ART FILM - SILK_BOTTOM

JOB#: NUMBER 01 XXX .010

XX .03 MACH FINISH

DATE: 2016-03-24 PROJECT NUMBER: REV. X .1 30

CHECKER: ROHM SEMICONDUCTOR SENSORSHLD1-EVK-101 DECIMAL ANGLE

TOLERANCES

DESIGNER: PTEC

PROJECT NAME:

ARE IN INCHES

SECONDARY-SIDE ROHM SEMICONDUCTOR USA SPECIFIED DIMENSIONS

UNLESS OTHERWISE

SILKSCREEN COMPANY NAME:

4 6 8

H5 H4

5

H6 8 H7 10

3

H8

ART FILM - SILK_BOTTOM

You might also like

- Tonepad BigmuffDocument2 pagesTonepad BigmuffMarceloMeirellesNo ratings yet

- Tonepad BigmuffDocument2 pagesTonepad BigmuffTiarles MadeiraNo ratings yet

- Gran Mango 3.1416: Resistors Capacitors Potentiometers Parts List (Stock Big Muff)Document2 pagesGran Mango 3.1416: Resistors Capacitors Potentiometers Parts List (Stock Big Muff)Serhii KarpenkoNo ratings yet

- Tonepad BigmuffDocument2 pagesTonepad BigmuffBAMFNo ratings yet

- Tonepad BigmuffDocument2 pagesTonepad BigmuffArley GomesNo ratings yet

- Gran Mango 3.1416: Resistors Capacitors Potentiometers Parts List (Stock Big Muff)Document2 pagesGran Mango 3.1416: Resistors Capacitors Potentiometers Parts List (Stock Big Muff)Léon GomesNo ratings yet

- Gran Mango 3.1416: Resistors Capacitors Potentiometers Parts List (Stock Big Muff)Document2 pagesGran Mango 3.1416: Resistors Capacitors Potentiometers Parts List (Stock Big Muff)CraigNo ratings yet

- Hour Minute SEC: 24HR Digital Clock - PDSPRJDocument1 pageHour Minute SEC: 24HR Digital Clock - PDSPRJTaufiqulhadiNo ratings yet

- PCB Tester V103Document1 pagePCB Tester V103AlejoNo ratings yet

- Schematics Led ControlDocument1 pageSchematics Led Controlkbartl100% (1)

- Page No. 2: Drawn: Date: Checked: DateDocument1 pagePage No. 2: Drawn: Date: Checked: Dateadmam jonesNo ratings yet

- LED circuit with DIP switches and 74HC574 chipsDocument1 pageLED circuit with DIP switches and 74HC574 chips29Nyoman Danu Tri DamartaNo ratings yet

- UcD-XLiteFB Ver.3 - SchematicDocument2 pagesUcD-XLiteFB Ver.3 - Schematichoirus solehNo ratings yet

- UcD-XLiteFB Ver.3a - PCB and Schematic Discrete Class D AmplifierDocument5 pagesUcD-XLiteFB Ver.3a - PCB and Schematic Discrete Class D AmplifierRainPlay100% (4)

- STR c4 Menggunakan b2Document2 pagesSTR c4 Menggunakan b2Rana HardinNo ratings yet

- Neod2K Ultimate V.1: - C:/Users/Minipc/Desktop/Class D/D2Kneo/D2Kneo Ultimate V.1.AscDocument2 pagesNeod2K Ultimate V.1: - C:/Users/Minipc/Desktop/Class D/D2Kneo/D2Kneo Ultimate V.1.AscDanang PrasetiyoNo ratings yet

- Allen Heath Zed-10fx SMDocument63 pagesAllen Heath Zed-10fx SMIojan AndreiNo ratings yet

- 815 Power Amp Input&driver StageDocument1 page815 Power Amp Input&driver StageJeff DeckerNo ratings yet

- Voltcraft p9-2 SCHDocument1 pageVoltcraft p9-2 SCHkandi abdNo ratings yet

- Voltcraft p9-2 SCH PDFDocument1 pageVoltcraft p9-2 SCH PDFkandi abdNo ratings yet

- 3Document1 page3admam jonesNo ratings yet

- Premier Magnetics Inc.: 100watt PFC Universal Off-Line Switching MagneticsDocument2 pagesPremier Magnetics Inc.: 100watt PFC Universal Off-Line Switching Magneticsanon_316469432No ratings yet

- Autodesk Training Center VietnamDocument1 pageAutodesk Training Center VietnamThành TrầnNo ratings yet

- Top View: Nama: Duventhiren No Pendaftaran: 01Dkm20F1065 Kelas: Dkm1BDocument1 pageTop View: Nama: Duventhiren No Pendaftaran: 01Dkm20F1065 Kelas: Dkm1BDuventhirenNo ratings yet

- D1KPro Schematic Ver.5Document1 pageD1KPro Schematic Ver.5pcbskunNo ratings yet

- PIC18F Board ConstructionDocument15 pagesPIC18F Board ConstructionDamith Buddhika Sri WimalarathnaNo ratings yet

- Specificatii 12733Document2 pagesSpecificatii 12733serafini36No ratings yet

- 2311091733_UMW-Youtai-Semiconductor-Co---Ltd--78L05_C347258Document12 pages2311091733_UMW-Youtai-Semiconductor-Co---Ltd--78L05_C347258Andres GvNo ratings yet

- 65Document1 page65MostafaElrakhawyNo ratings yet

- 4Document1 page4MostafaElrakhawyNo ratings yet

- 3Document1 page3MostafaElrakhawyNo ratings yet

- Superreg PCBGBDocument1 pageSuperreg PCBGBknight of awesomeNo ratings yet

- GPS 450aa 101aDocument3 pagesGPS 450aa 101aBogdan DorofteyNo ratings yet

- GPS 450aa 101aDocument3 pagesGPS 450aa 101aАндрей НемченкоNo ratings yet

- An SEO-Optimized Title for an Electronics Circuit DiagramDocument3 pagesAn SEO-Optimized Title for an Electronics Circuit DiagramtsromailNo ratings yet

- Stereo Hi Fi Preamplifier: R1 R2 RL8Document1 pageStereo Hi Fi Preamplifier: R1 R2 RL8Rey TiburonNo ratings yet

- Rear Wiring Harness LHDocument2 pagesRear Wiring Harness LHLinas PaskocimasNo ratings yet

- CF BallisticsDocument4 pagesCF BallisticsDC6driverNo ratings yet

- A Shahib Al Banna Muhammad Fajar Rahmadani Muhammad Yoga Firdaus Muhammad Nurhidayat Politeknik Negeri Banjarmasin 2019 Teknik ElektronikaDocument1 pageA Shahib Al Banna Muhammad Fajar Rahmadani Muhammad Yoga Firdaus Muhammad Nurhidayat Politeknik Negeri Banjarmasin 2019 Teknik ElektronikaMuhammad Nur HidayatNo ratings yet

- D2KFB - Fullbridge V.2Document1 pageD2KFB - Fullbridge V.2esfri-arNo ratings yet

- D2KFB - Fullbridge v.2Document1 pageD2KFB - Fullbridge v.2amdono vitonNo ratings yet

- D2KFB - Fullbridge V.2Document1 pageD2KFB - Fullbridge V.2Zamfir VanguNo ratings yet

- D2KFB - Fullbridge V.2Document1 pageD2KFB - Fullbridge V.2Đoàn Minh CươngNo ratings yet

- D2KFB - Fullbridge v.2Document1 pageD2KFB - Fullbridge v.2Đoàn Minh CươngNo ratings yet

- D2KFB - Fullbridge v.2Document1 pageD2KFB - Fullbridge v.2BerbieNo ratings yet

- D2KFB - Fullbridge V.2Document1 pageD2KFB - Fullbridge V.2Gianmarco ScarabelloNo ratings yet

- D1KPro - UcD Version ver1Document1 pageD1KPro - UcD Version ver1VismayNo ratings yet

- V1-ESQUEMA ELECTRONICO CERRADURADocument1 pageV1-ESQUEMA ELECTRONICO CERRADURARoberto NogueraNo ratings yet

- Drawing3 ModelDocument1 pageDrawing3 Modeldibyendum013No ratings yet

- Insulators Catalogue 2015Document31 pagesInsulators Catalogue 2015Weber HahnNo ratings yet

- Panasonic Rx-d29 SchematicDocument17 pagesPanasonic Rx-d29 SchematicRoshan de Silva100% (1)

- IT2307: Microcontrollers and Industrial Automation: Assignment No.: 02Document2 pagesIT2307: Microcontrollers and Industrial Automation: Assignment No.: 02dinuNo ratings yet

- HOOK2 CadDocument1 pageHOOK2 CadMohammed SultanNo ratings yet

- McBennett VCF - R27 RevDocument1 pageMcBennett VCF - R27 RevAdrianoEngelNo ratings yet

- GPS 500ab ADocument3 pagesGPS 500ab ALaurMateiNo ratings yet

- GPS 500ab ADocument3 pagesGPS 500ab AJerzy LisowskiNo ratings yet

- daihatsu-sirion-model-m300-series-service-manual-no9890-wiper-washerDocument23 pagesdaihatsu-sirion-model-m300-series-service-manual-no9890-wiper-washerMarx RedzNo ratings yet

- T4 Base Wiring From May 1999 OnDocument23 pagesT4 Base Wiring From May 1999 OnOHW SERNo ratings yet

- Final Solid Geometry SbaDocument1 pageFinal Solid Geometry Sbajifihet931No ratings yet

- Black on the Block: The Politics of Race and Class in the CityFrom EverandBlack on the Block: The Politics of Race and Class in the CityRating: 3.5 out of 5 stars3.5/5 (10)

- INTERNET STANDARDSDocument18 pagesINTERNET STANDARDSDawn HaneyNo ratings yet

- 19 12 2023 BDA EngDocument1 page19 12 2023 BDA EngkishorNo ratings yet

- Easypact EZC630H circuit breaker specsDocument6 pagesEasypact EZC630H circuit breaker specsAnirudh VNNo ratings yet

- Trifecta Verde en Resplandor Villas Floor Plans BrochureDocument45 pagesTrifecta Verde en Resplandor Villas Floor Plans BrochureAnirudh VNNo ratings yet

- EasyPact EZC - EZC400H3400NDocument6 pagesEasyPact EZC - EZC400H3400NAnirudh VNNo ratings yet

- Panel Builder - Pricelist - W.E.F. 1st Aug V1 2022Document308 pagesPanel Builder - Pricelist - W.E.F. 1st Aug V1 2022Anirudh VNNo ratings yet

- EasyPact EZC - EZC400N4400NDocument6 pagesEasyPact EZC - EZC400N4400NAnirudh VNNo ratings yet

- TEC Charges UpdatedDocument1 pageTEC Charges UpdatedAnirudh VNNo ratings yet

- Concorde - Luxepolis Brochure UpdatedDocument29 pagesConcorde - Luxepolis Brochure UpdatedAnirudh VNNo ratings yet

- Samwha Power Capacitor CatalogueDocument68 pagesSamwha Power Capacitor CatalogueAnirudh VNNo ratings yet

- Samwha Capacitor - Heavy Electric (Power & Power Electronics)Document51 pagesSamwha Capacitor - Heavy Electric (Power & Power Electronics)Anirudh VNNo ratings yet

- LMV34x Rail-to-Rail Output CMOS Operational Amplifiers With ShutdownDocument34 pagesLMV34x Rail-to-Rail Output CMOS Operational Amplifiers With ShutdownAnirudh VNNo ratings yet

- Flexi Cap Fund Scheme FlyerDocument4 pagesFlexi Cap Fund Scheme FlyerAnirudh VNNo ratings yet

- Inside Out or Outside In. Meeting With Couples. Hugh JenkinsDocument24 pagesInside Out or Outside In. Meeting With Couples. Hugh JenkinsRita1976No ratings yet

- Emerging Foodborne Enteric Bacterial Pathogens: A ReviewDocument11 pagesEmerging Foodborne Enteric Bacterial Pathogens: A ReviewAngelica Alejandra De La Torre AnayaNo ratings yet

- Mesfin A. Agri. Econ. - 2005Document129 pagesMesfin A. Agri. Econ. - 2005Rafez JoneNo ratings yet

- Esign IPS: Reducing Switching Losses in Portable DC/DC ConvertersDocument2 pagesEsign IPS: Reducing Switching Losses in Portable DC/DC ConvertersAbhishek SinghNo ratings yet

- Chery Amulet 1,6 Engine Service ManualDocument76 pagesChery Amulet 1,6 Engine Service ManualG x HxhNo ratings yet

- Population Ecology: Aecc-I +3 1 YearDocument32 pagesPopulation Ecology: Aecc-I +3 1 YearAnita kumari SahuNo ratings yet

- Mcimt NDT Kids at 1Document12 pagesMcimt NDT Kids at 1api-485106673No ratings yet

- Winged Scapula Caused by Dorsal Scapular.21Document4 pagesWinged Scapula Caused by Dorsal Scapular.21emilio9fernandez9gatNo ratings yet

- STC Bec Wir Plu D 0209 01 PDFDocument10 pagesSTC Bec Wir Plu D 0209 01 PDFAdel MorsyNo ratings yet

- Science Activity Sheet Quarter 4 - MELC 2 Week 2: Uses of WaterDocument13 pagesScience Activity Sheet Quarter 4 - MELC 2 Week 2: Uses of WaterShareinne TeamkNo ratings yet

- Case 1Document25 pagesCase 1hamshiniNo ratings yet

- Paragenesis of OlivineDocument18 pagesParagenesis of OlivineSyed Zaman100% (2)

- Administrative Case ResolutionDocument2 pagesAdministrative Case ResolutionEunice Osam RamirezNo ratings yet

- Pensions Reforms at NSSFDocument4 pagesPensions Reforms at NSSFcliffmogere2348No ratings yet

- Round-The-clock Acid Control of Rabeprazole On Acid Related DisorderDocument8 pagesRound-The-clock Acid Control of Rabeprazole On Acid Related DisorderRabeprazole SodiumNo ratings yet

- Market ReseachDocument3 pagesMarket ReseachSam Cy PuyalesNo ratings yet

- Chemistry Units 8 12Document29 pagesChemistry Units 8 12reg speckNo ratings yet

- The Dilemma of The Neighborhood BoardDocument2 pagesThe Dilemma of The Neighborhood BoardRosaNo ratings yet

- Conveying Water Distribution SEODocument90 pagesConveying Water Distribution SEOmichelghanemNo ratings yet

- Music and Therapy Bun2Document17 pagesMusic and Therapy Bun2PanteaAlisaNo ratings yet

- Paper 1Document8 pagesPaper 1Santhoshi Sadhanaa SankarNo ratings yet

- Top 50 Most Delicious Taco Reci - Julie HatfieldDocument267 pagesTop 50 Most Delicious Taco Reci - Julie HatfieldMazhar Aslam100% (2)

- ป 6Document43 pagesป 6MoLo Kanyarat ChenpitaksombatNo ratings yet

- Derivatives and Risk ManagementDocument17 pagesDerivatives and Risk ManagementDeepak guptaNo ratings yet

- Department of The Navy Core Values CharterDocument1 pageDepartment of The Navy Core Values CharterShaun JohnsonNo ratings yet

- UM16000 Flame Detector Installation Guide EnglishDocument12 pagesUM16000 Flame Detector Installation Guide Englishmohamed.rescoNo ratings yet

- PackageCare Maintenance ChecklistDocument1 pagePackageCare Maintenance ChecklistBùi ViệtNo ratings yet

- The Role of Technology in AgricultureDocument35 pagesThe Role of Technology in AgricultureDivyesh ThumarNo ratings yet

- GRADES 1 To 12 Daily Lesson LogDocument5 pagesGRADES 1 To 12 Daily Lesson LogFlordeliza Manaois RamosNo ratings yet

- IRC Girl Shine Part 4 DigitalDocument124 pagesIRC Girl Shine Part 4 DigitalMónica SalesNo ratings yet