Professional Documents

Culture Documents

Layout of Different Power Plants

Uploaded by

SHAIK NOOR AHAMED0 ratings0% found this document useful (0 votes)

35 views17 pagesOriginal Title

3. Layout of Different Power Plants

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

35 views17 pagesLayout of Different Power Plants

Uploaded by

SHAIK NOOR AHAMEDCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 17

Power Plant

• A power plant may be defined as a machine or assembly of

equipment that generates and delivers a flow of mechanical or

electrical energy.

• The main equipment for the generation of electric power is

generator. When coupling it to a prime mover runs the

generator, the electricity is generated.

• The type of prime mover determines the type of power plants.

The major power plants are,

• 1. Steam power plant

• 2. Diesel power plant

• 3. Gas turbine power plant

• 4. Nuclear power plant

• 5. Hydro electric power plant

THERMAL POWER PLANT

• A THERMAL POWER PLANT convert heat into

electric energy.

– Steam Power Plant, Diesel Power Plant, Gas Turbine

Power Plant and Nuclear Power Plants are called

THERMAL POWER PLANT.

• Steam is the most common working fluid used in

steam/Thermal power plant

STEAM POWER PLANT LAYOUT:

1. A furnace to burn the fuel.

2. Steam generator or boiler containing water. Heat generated

in the furnace is utilized to convert water in steam.

3. Main power unit such as an engine or turbine to use the

heat energy of steam and perform work.

4. Piping system to convey steam and water.

• “A steam power plant using steam as working substance

works basically on Rankine cycle. Steam is generated in a

boiler, expanded in the prime mover and condensed in the

condenser and fed into the boiler again “

STEAM POWER PLANT LAYOUT:

Layout of thermal plant can be easily understood by

dividing the plant components into four circuits.

• Coal and ash circuit.

• Air and gas circuit.

• Feed water and steam circuit.

• Cooling water circuit

STEAM POWER PLANT LAYOUT:

• The different types of systems and components used in

steam power plant are as follows:

• (i) High pressure boiler

• (ii) Prime mover

• (iii) Condensers and cooling towers

• (iv) Coal handling system

• (v) Ash and dust handling system

• (vi) Draught system

• (vii) Feed water purification plant

• (viii) Pumping system

• (ix) Air preheater, economizer, super heater, feed heaters

MHD POWER PLANT LAYOUT:

• The MHD generation or, also known as magneto

hydrodynamic power generation is a direct energy conversion

system which converts the heat energy directly into electrical

energy, without any intermediate mechanical energy

conversion

• Principle of MHD Power generation:

– The principal of MHD power generation is very simple and is

based on Faraday’s law of electromagnetic induction, which

states that when a conductor and a magnetic field moves

relative to each other, then voltage is induced in the conductor,

which results in flow of current across the terminals.

MHD Cycles and Working Fluids

The MHD cycles can be of two types, namely

• Open Cycle MHD.

• Closed Cycle MHD.

Open MHD System:

• In open cycle MHD system, atmospheric air at very high

temperature and pressure is passed through the strong

magnetic field.

• Coal is first processed and burnet in the combustor at a high

temperature of about 2700oC and pressure about 12 ATP

with pre-heated air from the plasma.

• Then a seeding material such as potassium carbonate is

injected to the plasma to increase the electrical

conductivity.

• The resulting mixture having an electrical conductivity of

about 10 Siemens/m is expanded through a nozzle, so as to

have a high velocity and then passed through the magnetic

field of MHD generator.

Open Cycle MHD

Open MHD System:

• During the expansion of the gas at high

temperature, the positive and negative ions move

to the electrodes and thus constitute an electric

current.

• The gas is then made to exhaust through the

generator. Since the same air cannot be reused

again hence it forms an open cycle and thus is

named as open cycle MHD.

Closed MHD System:

• The fuel, coal (or natural gas ) is burnt to produce hot

gas.

• The hot gas is then seeded with a small amount of an

ionized alkali metal (cesium or potassium) to increase

the electrical conductivity of the gas

• The gas expands through the rocket like generator

surrounded by powerful magnet. During the motion

of the gas positive and negative ions move to the

electrodes and constitute an electric current

Closed MHD System:

• The rejected gas passes through an air heater for

preheating the inlet air.

• The seed material is recovered for successive use.

• The nitrogen and sulphur are removed (for

pollution control) and the gases are discharged to

the atmosphere

You might also like

- Thermal Power PlantsDocument24 pagesThermal Power Plantslakshmigsr6610100% (1)

- Captive Power PlantDocument30 pagesCaptive Power PlantDeepakGawasNo ratings yet

- Thermal Power PlantDocument24 pagesThermal Power PlantRon 61No ratings yet

- Summer Training Experience at NTPC Dadri Power PlantDocument33 pagesSummer Training Experience at NTPC Dadri Power PlantSubodh DuhanNo ratings yet

- Department of Oral Medicine and Radiology MCQ 1Document14 pagesDepartment of Oral Medicine and Radiology MCQ 1Gokul RavichandranNo ratings yet

- Construction and Working of Thermal Power PlantDocument5 pagesConstruction and Working of Thermal Power PlantdibyenindusNo ratings yet

- NDT Non-Destructive TestingDocument65 pagesNDT Non-Destructive TestingAnanthakrishnan V100% (1)

- Introduction To Power Plants and BoilersDocument47 pagesIntroduction To Power Plants and Boilersl8o8r8d8s8i8v8No ratings yet

- Scientists' Accounts of Particle Physics HistoryDocument28 pagesScientists' Accounts of Particle Physics HistorybprtxrcqilmqsvsdhrNo ratings yet

- 17.THERMAL POWER PLANT PPT 1Document25 pages17.THERMAL POWER PLANT PPT 1Amit kumar Gupta100% (6)

- Thermal Power PlantDocument35 pagesThermal Power PlantAngelaa DassNo ratings yet

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningFrom EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningRating: 5 out of 5 stars5/5 (2)

- Thermal Power PlantDocument33 pagesThermal Power Plantnavdeep kaurNo ratings yet

- Introduction and Thermal Power PlantDocument27 pagesIntroduction and Thermal Power PlantKshitij AggarwalNo ratings yet

- EEE Notes Unit 3 Conventional Energy Resources PDFDocument8 pagesEEE Notes Unit 3 Conventional Energy Resources PDFAyush NandurkarNo ratings yet

- Power System ComponentsDocument17 pagesPower System ComponentsbobidmrNo ratings yet

- Me Lab 3Document27 pagesMe Lab 3Jerome Vega AndesNo ratings yet

- Basic Civil and Mechanical Engineering: Unit IIIDocument83 pagesBasic Civil and Mechanical Engineering: Unit IIIvelavansuNo ratings yet

- Thermal Power Plants-FinalDocument61 pagesThermal Power Plants-FinalBhavya ShrivastwaNo ratings yet

- Thermal Power PlantDocument73 pagesThermal Power PlantRitwik JaiswalNo ratings yet

- Ppe - Unit 1 - Lecture 1Document96 pagesPpe - Unit 1 - Lecture 1teja souryaNo ratings yet

- TurbineDocument18 pagesTurbineumarNo ratings yet

- Overview of Thermal Power Plant & Brief DiscussionDocument35 pagesOverview of Thermal Power Plant & Brief DiscussionSayan HazraNo ratings yet

- Importance of Electrical Energy GenerationDocument65 pagesImportance of Electrical Energy GenerationtawqeerNo ratings yet

- BCM NotesDocument13 pagesBCM NotesMurugesan JeevaNo ratings yet

- Mechanical Engineering: Steam Power Plant BasicsDocument9 pagesMechanical Engineering: Steam Power Plant BasicsMukesh ChoudharyNo ratings yet

- Presentation On Thermal Power Station: Presented ByDocument24 pagesPresentation On Thermal Power Station: Presented Bykritika negiNo ratings yet

- Chapter 52 Wind PPDocument48 pagesChapter 52 Wind PPmatusala abhaNo ratings yet

- Water HarvestingDocument44 pagesWater HarvestingTanmay KhuranaNo ratings yet

- Unit 3 Power Plant EngineeringDocument49 pagesUnit 3 Power Plant EngineeringNaren NathanNo ratings yet

- National Capital Power Station N.T.P.C: Presented by KshitijDocument25 pagesNational Capital Power Station N.T.P.C: Presented by KshitijHarshit MittalNo ratings yet

- Industrial Training PresentationDocument25 pagesIndustrial Training PresentationHarshit MittalNo ratings yet

- Unit 1: Power Plants: For Internal Circulation OnlyDocument5 pagesUnit 1: Power Plants: For Internal Circulation OnlyRahul munthaNo ratings yet

- Coal Power Generation Process in a Typical Coal Fired Power PlantDocument31 pagesCoal Power Generation Process in a Typical Coal Fired Power PlantbjswamyNo ratings yet

- Industrial Training Report: Report On "Generation of Thermal Power" AT NTPC DadriDocument19 pagesIndustrial Training Report: Report On "Generation of Thermal Power" AT NTPC DadriayushNo ratings yet

- Thermal Power Plant Layout & ComponentsDocument31 pagesThermal Power Plant Layout & ComponentsfefwerewNo ratings yet

- Thermal Power Plant: Shubham Thakur 13BME8149 5MEL3 Mechanical EngineeringDocument34 pagesThermal Power Plant: Shubham Thakur 13BME8149 5MEL3 Mechanical EngineeringMos MohNo ratings yet

- Report On "Generation of Thermal Power" AT NTPC DadriDocument17 pagesReport On "Generation of Thermal Power" AT NTPC DadriVaibhav RaoNo ratings yet

- DVC Mejia ReportDocument37 pagesDVC Mejia ReportRahul RoyNo ratings yet

- BCM Unit 3Document85 pagesBCM Unit 3Keerthi k.cNo ratings yet

- Report On "Generation of Thermal Power" AT NTPC Dadri: BY-Rishabh Awasthi EEE-4 Year 1509121041Document19 pagesReport On "Generation of Thermal Power" AT NTPC Dadri: BY-Rishabh Awasthi EEE-4 Year 1509121041Rishabh AwasthiNo ratings yet

- Steam Power PlantDocument56 pagesSteam Power PlantصصNo ratings yet

- Solar Thermal Power PlantDocument34 pagesSolar Thermal Power PlantKripa DevanNo ratings yet

- Introduction to Power Engineering Units and EfficiencyDocument32 pagesIntroduction to Power Engineering Units and EfficiencyMuhammad abdur rehmanNo ratings yet

- Basic Civil and Mechanical EngineeringDocument28 pagesBasic Civil and Mechanical EngineeringRAJARAMNo ratings yet

- PPT4 Coal FiredDocument31 pagesPPT4 Coal FiredWinston LibangaNo ratings yet

- Thermal Power PlantDocument29 pagesThermal Power PlantSiri VenniNo ratings yet

- MHD and Wave Energy SystemsDocument35 pagesMHD and Wave Energy SystemsTinu Paul JepinNo ratings yet

- Report On "Generation of Thermal Power" - NTPC Dadri: Submited By-Vishal Kumar Gaur Eee 4 YearDocument19 pagesReport On "Generation of Thermal Power" - NTPC Dadri: Submited By-Vishal Kumar Gaur Eee 4 YearVîsħ GåürNo ratings yet

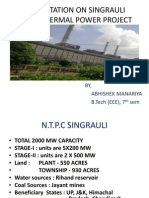

- Presentation On Singrauli Super Thermal Power ProjectDocument17 pagesPresentation On Singrauli Super Thermal Power ProjectAbhishek ManariyaNo ratings yet

- Electrical Power Generation - Lecture 8Document51 pagesElectrical Power Generation - Lecture 8dp05No ratings yet

- Magneto Hydrodynamic Power GenerationDocument67 pagesMagneto Hydrodynamic Power GenerationVinay PrakashNo ratings yet

- Magneto Hydro Dynamic GeneratorDocument19 pagesMagneto Hydro Dynamic GeneratorKarthik ViratNo ratings yet

- Presentation on vocational training at NTPC Unchahar power plantDocument24 pagesPresentation on vocational training at NTPC Unchahar power plantRoshan KumarNo ratings yet

- Chapter 1 Steam GenerationDocument18 pagesChapter 1 Steam GenerationfaranimohamedNo ratings yet

- Thermal Power PPT 1274193706 Phpapp02Document31 pagesThermal Power PPT 1274193706 Phpapp02riteshbohareNo ratings yet

- Thermal Power PlantDocument42 pagesThermal Power PlantAravind C.KNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- “Foundations to Flight: Mastering Physics from Curiosity to Confidence: Cipher 4”: “Foundations to Flight: Mastering Physics from Curiosity to Confidence, #4From Everand“Foundations to Flight: Mastering Physics from Curiosity to Confidence: Cipher 4”: “Foundations to Flight: Mastering Physics from Curiosity to Confidence, #4No ratings yet

- B.tech R09 Mech Engg SyllabusDocument167 pagesB.tech R09 Mech Engg SyllabusSHAIK NOOR AHAMEDNo ratings yet

- Combined Cycle Power PlantDocument4 pagesCombined Cycle Power PlantSHAIK NOOR AHAMEDNo ratings yet

- Economics of Power PlantDocument16 pagesEconomics of Power PlantSHAIK NOOR AHAMEDNo ratings yet

- Development of Power in IndiaDocument3 pagesDevelopment of Power in IndiaSHAIK NOOR AHAMEDNo ratings yet

- Introduction To PPEDocument10 pagesIntroduction To PPESHAIK NOOR AHAMEDNo ratings yet

- Atomic Structure Neet Class 12Document4 pagesAtomic Structure Neet Class 12ICSE HubNo ratings yet

- DPP-1 QuantizationDocument1 pageDPP-1 QuantizationVikasNo ratings yet

- Exploring The Quantum World: Quantum Computing Devices - Principles, Designs, and AnalysisDocument2 pagesExploring The Quantum World: Quantum Computing Devices - Principles, Designs, and Analysissepot24093No ratings yet

- Monolayer SNC As Anode Material For Na Ion BatteriesDocument7 pagesMonolayer SNC As Anode Material For Na Ion BatteriesVu TuanNo ratings yet

- Tutorial 2 Gausss LawDocument2 pagesTutorial 2 Gausss LawAFIQ DANISH AZRUL MIZAMNo ratings yet

- Avogadro's Number English PresentationDocument15 pagesAvogadro's Number English Presentationikram bellatrecheNo ratings yet

- M.Sc. Part 1 Sem 2 (Wef 2021-22)Document22 pagesM.Sc. Part 1 Sem 2 (Wef 2021-22)Shifa ChaudhariNo ratings yet

- The Growth Fission Gas Bubbles in Irradiated Uranium DioxideDocument16 pagesThe Growth Fission Gas Bubbles in Irradiated Uranium DioxideGwanyun JeongNo ratings yet

- General Physics 1 Quarter 1Document5 pagesGeneral Physics 1 Quarter 1Ennyliejor YusayNo ratings yet

- معايرة حمض متعددDocument12 pagesمعايرة حمض متعددMôhãmëđ KämäłÿNo ratings yet

- Genchem Module The ATOMDocument19 pagesGenchem Module The ATOMKimberly AllejosNo ratings yet

- LAS No. 5 Ancient Greek's Idea On The AtomDocument2 pagesLAS No. 5 Ancient Greek's Idea On The AtomWarren OlemberioNo ratings yet

- Chemistry 3719 Old ExamsDocument300 pagesChemistry 3719 Old ExamsHY-11 Đỗ Quốc TiệpNo ratings yet

- 5245 20UPES01 BCA B SC 31 03 2021 FNDocument7 pages5245 20UPES01 BCA B SC 31 03 2021 FNDr GopinathNo ratings yet

- Important Points About Introduction of Analytical ChemistryDocument9 pagesImportant Points About Introduction of Analytical ChemistryMohammed AlherbawiNo ratings yet

- Science: Quarter 2, Wk.2-M2Document29 pagesScience: Quarter 2, Wk.2-M2Sir Miguel MalvarNo ratings yet

- Cambridge International General Certificate of Secondary EducationDocument16 pagesCambridge International General Certificate of Secondary Educationzainab tamerNo ratings yet

- Physics Value Based Questions Chapter 11 Dual Nature of Radiation and Matter PDFDocument39 pagesPhysics Value Based Questions Chapter 11 Dual Nature of Radiation and Matter PDFMohammad HuzaifaNo ratings yet

- J. Scheffel, P. Brunsell - Fusion PhysicsDocument208 pagesJ. Scheffel, P. Brunsell - Fusion PhysicsMário NY AmaroNo ratings yet

- Physics HHW (Investigatory Project)Document2 pagesPhysics HHW (Investigatory Project)MaanNo ratings yet

- Game Changer 1.0 - General Organic Chemistry - 7 DecDocument92 pagesGame Changer 1.0 - General Organic Chemistry - 7 DecFURIAS FACTYNo ratings yet

- G8 Science Q3 Adm Module For PrintingDocument36 pagesG8 Science Q3 Adm Module For PrintingJenn ElardeNo ratings yet

- Chemistry: DPP - Daily Practice ProblemsDocument7 pagesChemistry: DPP - Daily Practice ProblemsAdityaNo ratings yet

- Josa 42 3 200Document4 pagesJosa 42 3 200jan dildoNo ratings yet

- A-Level Physics Question and Answers 20 20/2021Document148 pagesA-Level Physics Question and Answers 20 20/2021FireFrostNo ratings yet

- UNITIIIStereochemistryIsomerismGeometricalIsomerism BP401T PHARMACEUTICALORGANICCHEMISTRYIII B.pharmIVSem GITAMDeemedtobeUniversityDocument48 pagesUNITIIIStereochemistryIsomerismGeometricalIsomerism BP401T PHARMACEUTICALORGANICCHEMISTRYIII B.pharmIVSem GITAMDeemedtobeUniversityNIKITA KUMARINo ratings yet

- FY - Nuclear MCQDocument10 pagesFY - Nuclear MCQNeelam KapoorNo ratings yet