Professional Documents

Culture Documents

Water Level Limiter 932

Uploaded by

Miraz RahmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Water Level Limiter 932

Uploaded by

Miraz RahmanCopyright:

Available Formats

Valves for heating installations

Water Level Limiter

932

Protection against insufficient water level in boilers

Field of application The water level limiter type 932 protects boilers in The water level limiter type 932 can also be used

heating installations against dry-heating resulting for any device, which operates with water level

from an insufficient water level. The installation dependent electric switches and requires a test

of such a device is highly recommended for safety possibility without lowering the water level.

reasons.

Design The water level limiter type 932 is designed with the system after cutting the burner off. When the

magnetic transmission of the float movement to a malfunction is eliminated, re-connect the system by

microswitch; it allows testing without lowering the means of the unlock key on the water level limiter.

water level. The electric switch unit is rotatable by Another type with a compacter construction form

360° and can be exchanged without draining the in- is available as special model 932.5.

stallation. The water level limiter type 932 isolates

Application technology 437

932 Water level limiter

Materials The nipple, the test sensor, the magnetic glide and copper parts in contact with water are nickel-

sleeve and the internal parts are made of a high plated. The sealing elements are made of heat and

quality low-lead brass alloy. The float is made of a ageing resistant elastomeric synthetic material.

heat and pressure resistant special glass and the The electric connection is made with a hardwired

switch unit body of synthetic material. All brass cable H 05 VV-F 4G 0.75 mm2, length 2.5 m.

Installation Screw the water level limiter type 932 in the pre- cable designation. After the installation, fill and

installed connection piece (DN 50) on the boiler. vent the system. Afterwards, vent the water level

When installing, imperatively ensure that the float limiter separately: loosen the gland packing on the

is not damaged. The electric connection has to test sensor until water comes out; then, re-tighten.

be made by an electrician in compliance with the To start up the installation, pull the test sensor

prescriptions of the local power supply company upwards to the stop; then, press the unlock key.

under consideration of the circuit diagram and the

Technical data Operating overpressure: max. 10 bar

Operating temperature: max. 120 °C

Service temperature: max. 70°C

Type of protection: IP 65

Microswitch: on-off switch, single pole

Mounting position: main axis vertical

Capacity: 10 (4) A / 250 Volt

Component approval: TÜV - HWB - 16-206

VDE-Nr.: 139223

Serial number: 0932...

Maintenance The device requires no regular maintenance. Howe- be exchanged separately. The switch unit can be

ver, it should be unlocked manually once per year exchanged without draining the installation.

in order to test functionality. All components can

438 Application technology

Valves for heating installations

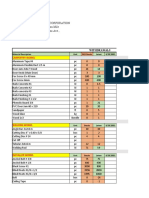

932.1 932.5

Nominal size DN 50

A G 2“

Dimensions in mm H (mm) 343

h (mm) 229

S (mm) 64 x 98

H 1 (mm) 247

h 1 (mm) 150

S 1 (mm) 64 x 98

Models: Type 932.1 standard construction form

Type 932.5 compact construction form

Application technology 439

932 Water level limiter

Components / Order numbers

1

Test sensor

0933.20.911

1

0932.50.904 (932.5)

2

Microswitch

0933.20.912

2

3

Switch unit

0932.50.900

0932.50.905 (932.5)

4 3

Complete float device

0932.50.901

0932.50.903 (932.5)

5

Glass float

0933.20.906

0932.50.906 (932.5) 4

6

Immersion sleeve with

screws

0932.50.906

440 Application technology

You might also like

- Water Level Limiter 933Document4 pagesWater Level Limiter 933Miraz RahmanNo ratings yet

- Ficha SprinkersDocument4 pagesFicha SprinkersMaestrycous KairosNo ratings yet

- Honeywell Sensing Temperature Sensors Line Guide 0 1109480Document12 pagesHoneywell Sensing Temperature Sensors Line Guide 0 1109480X'mix ĐreamerNo ratings yet

- Pressure and DP SwitchesDocument43 pagesPressure and DP Switchespin2wildstoneNo ratings yet

- EN VEGASWING 66 RelayDocument2 pagesEN VEGASWING 66 Relayfm429vm7x2No ratings yet

- Dow CorningDocument2 pagesDow Corningwardoyoclp75No ratings yet

- DB GB NK10Document4 pagesDB GB NK10cadhoaNo ratings yet

- Kat en DQ InchDocument14 pagesKat en DQ InchThariqNo ratings yet

- Siemens Ds 3se5122-0ce01 enDocument4 pagesSiemens Ds 3se5122-0ce01 enfadhlidzilNo ratings yet

- PRESOTATO S4320 TecsisDocument2 pagesPRESOTATO S4320 TecsisRolando Jara YoungNo ratings yet

- Barton 316c 318c DP Indicator SwitchDocument16 pagesBarton 316c 318c DP Indicator SwitchGeorge T. RogersNo ratings yet

- 2009 175 VG Schieflauf enDocument4 pages2009 175 VG Schieflauf enMarcelo Lima SouzaNo ratings yet

- Pressure Switch: 10 SeriesDocument8 pagesPressure Switch: 10 SeriesJavier CarrizoNo ratings yet

- Klima-Set Differential Pressure Switch For Air KS A2-7Document4 pagesKlima-Set Differential Pressure Switch For Air KS A2-7Edison SinchiguanoNo ratings yet

- WDG-1210 現址式氧氣分析儀Document4 pagesWDG-1210 現址式氧氣分析儀SeanKuoNo ratings yet

- Dwyer Series DM-1000Document1 pageDwyer Series DM-1000Marco Antonio Rivera DoteroNo ratings yet

- 5SL43257 Datasheet enDocument5 pages5SL43257 Datasheet enlianjosue1902No ratings yet

- HXE Water Cooled Magnetic Bearing Centrifugal ChillerDocument16 pagesHXE Water Cooled Magnetic Bearing Centrifugal ChillerĐặng Xuân ViệtNo ratings yet

- 5SY62047 Datasheet en PDFDocument3 pages5SY62047 Datasheet en PDFPrabhavathi RamasamyNo ratings yet

- Datasheet ThermistorDocument6 pagesDatasheet Thermistorkhoiru zadditNo ratings yet

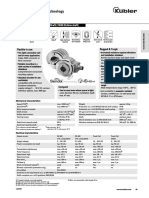

- Rotary Measuring Technology: Incremental EncodersDocument7 pagesRotary Measuring Technology: Incremental EncodersPassenger MedeamNo ratings yet

- 915nm 976nm 10W Fiber Coupled Module Oclaro-1416083626Document5 pages915nm 976nm 10W Fiber Coupled Module Oclaro-1416083626thuyNo ratings yet

- Wcvs-Prc001-En 042010Document19 pagesWcvs-Prc001-En 042010FadliNo ratings yet

- EATON pkz0-xhDocument3 pagesEATON pkz0-xhGILBERTO ANÍBAL BONILLA COSAMALÓNNo ratings yet

- 20283644D0698 LDocument8 pages20283644D0698 LBang OchimNo ratings yet

- Duratomic TP Brochure GT15-214 PDFDocument24 pagesDuratomic TP Brochure GT15-214 PDFDeysi CardenasNo ratings yet

- Eaton 281198 Dilm65 XMV en GBDocument2 pagesEaton 281198 Dilm65 XMV en GBwajdyzNo ratings yet

- Honeywell Limit Switch - GLCA01A2ADocument26 pagesHoneywell Limit Switch - GLCA01A2AAENo ratings yet

- PKI-C Cartridge Fire Dampers: Fire Resistance Class EI60S, EI90S and EI120SDocument7 pagesPKI-C Cartridge Fire Dampers: Fire Resistance Class EI60S, EI90S and EI120SKundzoNo ratings yet

- Sensor de Presion Bombas 321 2Document24 pagesSensor de Presion Bombas 321 2Natalia BeltránNo ratings yet

- Water Cooled Water ChillerDocument28 pagesWater Cooled Water ChillerHENRYNo ratings yet

- Thermal Management: DC Fans, Heat Sinks & Peltier DevicesDocument4 pagesThermal Management: DC Fans, Heat Sinks & Peltier DevicesvinidesoNo ratings yet

- Gulf Harmony Hvi April22 - 20220407195423Document2 pagesGulf Harmony Hvi April22 - 20220407195423AbhishekNo ratings yet

- ATKat 2004 eDocument103 pagesATKat 2004 eSaulius ŽilinskasNo ratings yet

- Metal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)Document4 pagesMetal Cored Wires BÖHLER HL 46 MC BÖHLER HL 51-FD (EN)lazaroccsNo ratings yet

- BN - TP 100257.2 en PDFDocument2 pagesBN - TP 100257.2 en PDFJosé Carlos Miguel BarriosNo ratings yet

- Simbologia e Identificacion de InstrumenDocument65 pagesSimbologia e Identificacion de InstrumenJuan LuisNo ratings yet

- 3NE33388 Datasheet enDocument4 pages3NE33388 Datasheet enluizNo ratings yet

- Pressure Switch Catalog Letest-91-109Document18 pagesPressure Switch Catalog Letest-91-109SUSOVAN BISWASNo ratings yet

- S753 E-32 6e2838105 TransformerDocument27 pagesS753 E-32 6e2838105 TransformerJosip ZohilNo ratings yet

- VITAULICDocument8 pagesVITAULICJoko SchumacherNo ratings yet

- en Vegaswing 63 Relay (DPDT)Document2 pagesen Vegaswing 63 Relay (DPDT)MaxiwendelNo ratings yet

- Kat en DQ CMDocument14 pagesKat en DQ CMThariqNo ratings yet

- Easidew Transmitters 97554 UK DatasheetDocument4 pagesEasidew Transmitters 97554 UK Datasheetrafik1995No ratings yet

- Apm Genesistd Rs 01 June 2018Document2 pagesApm Genesistd Rs 01 June 2018Nelson Calle ChoqueNo ratings yet

- Butterfly Valve DN250Document8 pagesButterfly Valve DN250Bakoelperkakas RagilKetujuhNo ratings yet

- Produktuebersicht EnglDocument12 pagesProduktuebersicht EnglAlkypperoeNo ratings yet

- ABB Control ValveDocument30 pagesABB Control ValveHafzi88% (8)

- Duct Master Ducting Ranges and AncillariesDocument34 pagesDuct Master Ducting Ranges and AncillariesCatalin StrugariuNo ratings yet

- 5SY43327 Datasheet enDocument6 pages5SY43327 Datasheet enLucas GiacomelliNo ratings yet

- Level CombinedDocument25 pagesLevel CombinedDANIEL LNo ratings yet

- 3NE13342 Datasheet enDocument4 pages3NE13342 Datasheet enWilber SánchezNo ratings yet

- 5SL Miniature Circuit Breakers - E10003-E38-9T-B2051-7600Document8 pages5SL Miniature Circuit Breakers - E10003-E38-9T-B2051-7600Ryan TorresNo ratings yet

- Partida 918 Topworx PDFDocument67 pagesPartida 918 Topworx PDFGustavo Adolfo Beltran MagañaNo ratings yet

- 5SL41047 Datasheet enDocument5 pages5SL41047 Datasheet enkavireeshgh_007No ratings yet

- Mechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsDocument8 pagesMechanical-T Bolted Branch Outlets: Carbon Steel Pipe - Hole Cut ProductsAritz BilbaoNo ratings yet

- 5SY42027 Datasheet enDocument4 pages5SY42027 Datasheet enLucas GiacomelliNo ratings yet

- Dms3106a22-14p CPDocument14 pagesDms3106a22-14p CPnishank srivastavaNo ratings yet

- 2017 175 VG Schieflauf EN KBDocument4 pages2017 175 VG Schieflauf EN KBK & TNo ratings yet

- Iec 62262 - 2002Document25 pagesIec 62262 - 2002Malik AzeemNo ratings yet

- Breadboard & Power SupplyDocument25 pagesBreadboard & Power SupplycyNo ratings yet

- Patch Cord FibraDocument2 pagesPatch Cord FibrajoquinNo ratings yet

- For Those Who Want To Win Tenders: An Interactive Comparison Between Danfoss AB-QM and New AB-QM 4.0Document1 pageFor Those Who Want To Win Tenders: An Interactive Comparison Between Danfoss AB-QM and New AB-QM 4.0DIOMER JERALDO BETETA CHUQUIYAURINo ratings yet

- Linear Heat Detection For Coal ConveryorsDocument6 pagesLinear Heat Detection For Coal ConveryorsPeter K PaulNo ratings yet

- Jib CranesDocument12 pagesJib CranesGloria RomicNo ratings yet

- TurbinesDocument21 pagesTurbinesAlyanna AngelesNo ratings yet

- E Instruments E1500 E4500 E6000 TrainingDocument19 pagesE Instruments E1500 E4500 E6000 TrainingRICARDO MAMANI GARCIANo ratings yet

- Daftar Barang Dan HargaDocument251 pagesDaftar Barang Dan HargaBondet parjanNo ratings yet

- Cognex Profile Plus PresentationDocument23 pagesCognex Profile Plus PresentationLuis ReynaNo ratings yet

- PH005 IO List PMS (R0) - 01.04.2016Document1 pagePH005 IO List PMS (R0) - 01.04.2016VirgilioNo ratings yet

- 2easy dmr11Document6 pages2easy dmr11kperenNo ratings yet

- Abarqgold Developer Corporation 2/F, Unit 3, Building 3, Masterson Mile Pueblo Business Park, Mastersons Ave., Cagayan de Oro CityDocument251 pagesAbarqgold Developer Corporation 2/F, Unit 3, Building 3, Masterson Mile Pueblo Business Park, Mastersons Ave., Cagayan de Oro CityBrille John ReyesNo ratings yet

- Fisa Tehnica - Panou Fotovoltaic 375 W MonocristalinDocument2 pagesFisa Tehnica - Panou Fotovoltaic 375 W MonocristalinAlexandru PielmusNo ratings yet

- Brochure Analog System enDocument2 pagesBrochure Analog System enEverardo Bracamontes DíazNo ratings yet

- APC UPS BackUp 850/1100Document1 pageAPC UPS BackUp 850/1100GRHarisNo ratings yet

- Caterpillar Cat 329E L Excavator (Prefix ZCD) Service Repair Manual (ZCD00001 and Up)Document29 pagesCaterpillar Cat 329E L Excavator (Prefix ZCD) Service Repair Manual (ZCD00001 and Up)kfm8seuudu0% (1)

- SUMSEM-2021-22 - MEE2003 - ETH - VL2021220701593 - Reference - Material - II - 19-08-2022 - Air ConditioningDocument15 pagesSUMSEM-2021-22 - MEE2003 - ETH - VL2021220701593 - Reference - Material - II - 19-08-2022 - Air ConditioningNikhil SaraswathNo ratings yet

- Unitron Forensic MicroscopeDocument2 pagesUnitron Forensic Microscopefaycalsalmi24No ratings yet

- Edid041611 (FTKC25-71QVM4)Document188 pagesEdid041611 (FTKC25-71QVM4)yoga pNo ratings yet

- KDE13SS3 Spare Parts ListDocument36 pagesKDE13SS3 Spare Parts ListyajairaNo ratings yet

- Building For Future LTD.: Project:JhumkolotaDocument2 pagesBuilding For Future LTD.: Project:JhumkolotahelalNo ratings yet

- Installation ManualDocument130 pagesInstallation ManualChristiaan NijkampNo ratings yet

- Pricelist Implant Ortopedi Pt. Hanif Putra Perkasa Harga User No Nama Produk Satuan Total Harga 1 Cortical Screw 3.5mmDocument6 pagesPricelist Implant Ortopedi Pt. Hanif Putra Perkasa Harga User No Nama Produk Satuan Total Harga 1 Cortical Screw 3.5mmasriNo ratings yet

- Technical Manual MKTHDocument30 pagesTechnical Manual MKTHahmed abdoh0% (1)

- CAMERADocument15 pagesCAMERALakshit Mittal100% (1)

- Instruction VCC 466430 9Document23 pagesInstruction VCC 466430 9jazzugeoNo ratings yet

- CB Lcs-150E.1 Level Control System: Features and BenefitsDocument3 pagesCB Lcs-150E.1 Level Control System: Features and Benefitsfauzi endraNo ratings yet

- 692 Pressure SensorDocument5 pages692 Pressure SensorSyed Waheed Ul HasanNo ratings yet

- BU1-DC2 - DC Voltage Relay: Fig. 1: Front PlateDocument4 pagesBU1-DC2 - DC Voltage Relay: Fig. 1: Front PlateLászló MártonNo ratings yet