Professional Documents

Culture Documents

PSA Technote

PSA Technote

Uploaded by

Angel RomeroOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PSA Technote

PSA Technote

Uploaded by

Angel RomeroCopyright:

Available Formats

PRESSURE SWING

ADSORPTION TECHNOLOGY

Many oxygen applications use cylinders, or

bulk oxygen in the form of liquid oxygen

(LOX) which must be delivered to the

place of use. However, a savings can

made by using an on-site generated oxygen

system. Oxygen made on-site may even be

more critical for remote applications, far

away from the source supply.

Enriched oxygen can be generated on-site

by several methods such as chemical,

TECHNICAL NOTE

electrolytic and cryogenic to name a few.

A cost effective and simple technology that

has been used since the 1950’s is Pressure

Swing Adsorption (PSA). By connecting an

OGSI oxygen generator to an existing air

supply, or a feed air system supplied by

OGSI, you can produce oxygen on

demand at considerable savings using

PSA Technology.

The air we breathe contains roughly 78%

nitrogen, 21% oxygen, .9% argon with the

balance being other gases. The oxygen is

separated from the air using PSA

Technology. The process centers around

molecular sieve called Zeolite. To complete the regeneration of the

first tank, a small amount of the oxygen

At high pressures the sieve adsorbs or is used to purge it. This process is

attracts nitrogen and at low pressures it completed over and over again until the

desorbs or releases nitrogen. The OGSI demand for oxygen is met. Under normal

Oxygen Generating Systems Intl.

generator consists of two tanks filled with operating conditions, which includes the

sieve. As high pressure air (about 72 psi) is use of clean, dry air for separation, the

introduced into the first tank, it passes sieve will last indefinitely.

• 716-564-5165

through the sieve and nitrogen is adsorbed.

The remaining oxygen and trace gases are Productivity of a PSA generator is

piped to a buffer or surge tank. dependent on the oxygen purity required.

A generator can produce significantly more

Just before the first tank becomes oxygen at 90% purity as it can at 95.4%,

completely saturated with nitrogen, feed air with a relatively small increase in feed air.

1-800-414-OGSI 6474

is redirected to the second tank which then By means of a PLC or some other micro

repeats the above process. An equalization processor based controller, it is practical

step is incorporated to optimize perfor- on larger generators for the user to change

mance. The first tank is then vented to the swing cycles. Purity and flow levels can

atmosphere which allows the nitrogen to be selected and optimized based on

desorb or release from the sieve. changing demand variables.

814 Wurlitzer Drive • North Tonawanda, New York 14120

1-800-414-OGSI(6474) • Phone 716/564-5165 • Fax 716/564-5173

www.ogsi.com A Division of Audubon Machinery Corporation www.ogsi.com

You might also like

- Aquamon SMARTPRO 8966 - PH Pipe & Wall Mount ManualDocument80 pagesAquamon SMARTPRO 8966 - PH Pipe & Wall Mount Manualkumar100% (6)

- MS - Fire Alarm SytemDocument11 pagesMS - Fire Alarm Sytemarun kurlanNo ratings yet

- NICE3000new 2019 Version PDFDocument366 pagesNICE3000new 2019 Version PDFAsdrubal Fredy GutierrezNo ratings yet

- Producing Nitrogen Via Pressure Swing Adsorption ArticleDocument5 pagesProducing Nitrogen Via Pressure Swing Adsorption Articledhlinva100% (1)

- Oxygen - Pressure Swing Adsorption PDFDocument4 pagesOxygen - Pressure Swing Adsorption PDFGustavo PalaciosNo ratings yet

- Specification No.: Ministry of Electricity Planning and Studies Office Baghdad - IraqDocument9 pagesSpecification No.: Ministry of Electricity Planning and Studies Office Baghdad - IraqAhmed JaNo ratings yet

- SOP For Quality Risk Management - Pharmaceutical GuidelinesDocument3 pagesSOP For Quality Risk Management - Pharmaceutical Guidelinessakib44586% (7)

- Nitrogen Intro in ReportDocument6 pagesNitrogen Intro in ReportlintasamimNo ratings yet

- Producing Nitrogen Via PSADocument5 pagesProducing Nitrogen Via PSAKaten MistryNo ratings yet

- Onsite Nitrogen Generation Via PSA TechnologyDocument4 pagesOnsite Nitrogen Generation Via PSA TechnologyAlexNo ratings yet

- Raj Calculation SheetDocument2 pagesRaj Calculation SheetRajdeepsinhNo ratings yet

- IEC 62443 - v1.0 - 202107Document54 pagesIEC 62443 - v1.0 - 202107Danila KireevNo ratings yet

- Emergency Alternative Mode of Oxygen Generation: Confidential 1Document30 pagesEmergency Alternative Mode of Oxygen Generation: Confidential 1Mendoud SofianeNo ratings yet

- 30 Years of PSA Technology For HydrogenDocument25 pages30 Years of PSA Technology For Hydrogengrpalem100% (4)

- N2 Membrane Vs PSADocument4 pagesN2 Membrane Vs PSAshiviitd02100% (2)

- The Energy Costs Associated With Nitrogen Specifications: Sustainable Manufacturing FeaturesDocument8 pagesThe Energy Costs Associated With Nitrogen Specifications: Sustainable Manufacturing FeaturesJaime Andres Pardo QuinteroNo ratings yet

- PSA Nitrogen GenerationDocument19 pagesPSA Nitrogen GenerationKaten Mistry100% (1)

- Oxygen Generation. by Vacuum Pressure Swing Adsorption. - tcm19-416454Document8 pagesOxygen Generation. by Vacuum Pressure Swing Adsorption. - tcm19-416454ChanJunKai100% (1)

- Practical Considerations For The Design of Adsorbent BedsDocument10 pagesPractical Considerations For The Design of Adsorbent BedsMariam AsgharNo ratings yet

- P Psa S G E P: Olybed Ystems FOR AS Xtraction and UrificationDocument2 pagesP Psa S G E P: Olybed Ystems FOR AS Xtraction and UrificationVivi OktaviantiNo ratings yet

- Oxygen Generator PresentationDocument121 pagesOxygen Generator PresentationWeuler CostaNo ratings yet

- Mep - Sox ScrubberDocument12 pagesMep - Sox Scrubbernacer zidiNo ratings yet

- Liquid Sample Introduction in ICP Spectrometry: A Practical GuideFrom EverandLiquid Sample Introduction in ICP Spectrometry: A Practical GuideRating: 4 out of 5 stars4/5 (6)

- N2 BlanketingDocument8 pagesN2 BlanketingRavi RanjanNo ratings yet

- Raj Oxygen Generation PlantDocument4 pagesRaj Oxygen Generation Plantsai kumar GoduguNo ratings yet

- OGV+ VPSA BrochureDocument18 pagesOGV+ VPSA Brochurenicolas.lelorrainNo ratings yet

- Oxair BrochureDocument12 pagesOxair BrochureVăn Tuấn NguyễnNo ratings yet

- Oxair Systems Presentation 2015Document29 pagesOxair Systems Presentation 2015Phillip GuerreroNo ratings yet

- LCMS Nitrogen White PaperDocument4 pagesLCMS Nitrogen White PaperMahesh CheNo ratings yet

- Industrial Oxygen: Its Generation and UseDocument12 pagesIndustrial Oxygen: Its Generation and UseJafar JilaniNo ratings yet

- OGV+ VSA - Oxygen GeneratorDocument18 pagesOGV+ VSA - Oxygen GeneratorAljamali AlhofashiNo ratings yet

- ProductionDocument35 pagesProductionVageeshNo ratings yet

- Technical Answers To Real World Problems: Cost Effective Oxygen Generation and StorageDocument10 pagesTechnical Answers To Real World Problems: Cost Effective Oxygen Generation and StorageRishavNo ratings yet

- Nitrogen Gas SystemDocument4 pagesNitrogen Gas Systemmilton1987No ratings yet

- 312 12 048 US Producing Nitrogen Via Pressure Swing AdsorptionDocument6 pages312 12 048 US Producing Nitrogen Via Pressure Swing AdsorptionRonak PanchalNo ratings yet

- Name SEM.: Year Roll No.: Subject: TOPIC:....... ............................................Document9 pagesName SEM.: Year Roll No.: Subject: TOPIC:....... ............................................U19CH014- VERMA APRAJITA SWATANTRAKUMAR SVNITNo ratings yet

- Medical Oxygen Generator FlyerDocument2 pagesMedical Oxygen Generator FlyertahatekriNo ratings yet

- PSA Oxygen Generator: FeaturesDocument2 pagesPSA Oxygen Generator: FeaturesMukesh DubeyNo ratings yet

- Pure O2 Activated SludgeDocument35 pagesPure O2 Activated SludgecyhdzNo ratings yet

- Air Separation Units (Asus) Simulation Using Aspen Hysys at Oxinor I of Air Liquid Chile S.A PlantDocument8 pagesAir Separation Units (Asus) Simulation Using Aspen Hysys at Oxinor I of Air Liquid Chile S.A PlantMohammad Yasser RamzanNo ratings yet

- Oxygen Concentrators For District Hospitals: Michael B Dobson, John Radcliffe Hospital, Oxford, UKDocument3 pagesOxygen Concentrators For District Hospitals: Michael B Dobson, John Radcliffe Hospital, Oxford, UKAwadhNo ratings yet

- schmidt2001Document11 pagesschmidt2001Sudkate BoonthawornNo ratings yet

- Xebec Hydrogen BrochureDocument24 pagesXebec Hydrogen BrochureJoshNo ratings yet

- Combustion in Control Fired Heaters Servomex Expert PaperDocument5 pagesCombustion in Control Fired Heaters Servomex Expert PaperOmar BouamoudNo ratings yet

- Conceptual Design For Oxygen Concentrator v0.1 PDFDocument8 pagesConceptual Design For Oxygen Concentrator v0.1 PDFMorego100% (1)

- Modern High Performance Ozone GeneratorsDocument7 pagesModern High Performance Ozone GeneratorsIAMANDU COSTANo ratings yet

- Tech Bulletin Comparing Oxygen Source OptionsDocument3 pagesTech Bulletin Comparing Oxygen Source OptionsRaydoon SadeqNo ratings yet

- Technical Specifications For Pressure Swing Adsorption (PSA) Oxygen PlantsDocument5 pagesTechnical Specifications For Pressure Swing Adsorption (PSA) Oxygen Plantszee khanNo ratings yet

- Oxygen Generation and Storage:: Pressure/Vacuum Swing Adsorption PlantDocument4 pagesOxygen Generation and Storage:: Pressure/Vacuum Swing Adsorption PlantHendri KurniawanNo ratings yet

- Emergency Alternative Mode of Oxygen Generation: Confidential 1Document37 pagesEmergency Alternative Mode of Oxygen Generation: Confidential 1Nipun Jain0% (1)

- Application of Nanosize Zeolite Molecular Sieves For Medical Oxygen ConcentrationDocument19 pagesApplication of Nanosize Zeolite Molecular Sieves For Medical Oxygen ConcentrationAla Ibrahim JalladNo ratings yet

- Group2 - 17BCM0026 - Cost Effective Oxygen Generation and StorageDocument5 pagesGroup2 - 17BCM0026 - Cost Effective Oxygen Generation and StorageRishavNo ratings yet

- Oxygen Concentrator: Unit B 13.3 Maintaining General Bedside Nursing Equipment 13.3.5 Maintain An Oxygen ConcentratorDocument12 pagesOxygen Concentrator: Unit B 13.3 Maintaining General Bedside Nursing Equipment 13.3.5 Maintain An Oxygen Concentratorزكريا دبوانNo ratings yet

- Use of Ozone and Oxygen in Advanced Wastewater Treatment and Costs.Document17 pagesUse of Ozone and Oxygen in Advanced Wastewater Treatment and Costs.OllafNo ratings yet

- Airsep PSA O2 Systems Brochure ML IND0035Document8 pagesAirsep PSA O2 Systems Brochure ML IND0035sgadkarNo ratings yet

- Sichuan Air SeparationDocument25 pagesSichuan Air SeparationFarshad Asgari0% (1)

- Basic Data On Biogas 2012Document8 pagesBasic Data On Biogas 2012Supriya ParteNo ratings yet

- Intro To ASUs Jan12Document1 pageIntro To ASUs Jan12Vilas Kunhikannan KunhikannanNo ratings yet

- Novel Design and Performance of A Medical Oxygen Concentrator Using A Rapid Pressure Swing Adsorption ConceptDocument6 pagesNovel Design and Performance of A Medical Oxygen Concentrator Using A Rapid Pressure Swing Adsorption ConceptRobert Solano MontoyaNo ratings yet

- Suspended Growth Biological TreatmentDocument21 pagesSuspended Growth Biological Treatmentsaiful islamNo ratings yet

- Portable Oxygen DeviceDocument70 pagesPortable Oxygen DevicemadhurNo ratings yet

- 1.2 Safety Warnings For Inert Gas (1778496)Document3 pages1.2 Safety Warnings For Inert Gas (1778496)MIGUEL ANGEL SOTELO HANCCONo ratings yet

- The Closed Circuit and The Low Flow SystemsDocument9 pagesThe Closed Circuit and The Low Flow SystemsHoward RompasNo ratings yet

- The Experimental Study of A New Pressure Equalization Step in The Pressure Swing Adsorption Cycle of A Portable Oxygen ConcentratorDocument10 pagesThe Experimental Study of A New Pressure Equalization Step in The Pressure Swing Adsorption Cycle of A Portable Oxygen Concentratorرنا حركاتيNo ratings yet

- Waste Water Treatment Waste Water Treatment: AerationDocument100 pagesWaste Water Treatment Waste Water Treatment: AerationAndré OliveiraNo ratings yet

- PrE7 Chapter 7 Business IntelligenceDocument12 pagesPrE7 Chapter 7 Business IntelligenceYeon kiminNo ratings yet

- Adobe Premiere Pro Manual - Jump Start 2023Document42 pagesAdobe Premiere Pro Manual - Jump Start 2023victor chandraNo ratings yet

- Engine Stands and SlingsDocument2 pagesEngine Stands and SlingsGenaire Limited100% (1)

- Musthaq Original 2023Document4 pagesMusthaq Original 2023Musthaq ahamedNo ratings yet

- RC Muscle Car ManualDocument8 pagesRC Muscle Car ManualBruntxoR cartónNo ratings yet

- Reducing The Braking Distance of An SQL Query Engine: Carey@almaden. Ibm. Corn Kossmann@db, Fmi - Uni-Passau - deDocument12 pagesReducing The Braking Distance of An SQL Query Engine: Carey@almaden. Ibm. Corn Kossmann@db, Fmi - Uni-Passau - dedavidrajhivcNo ratings yet

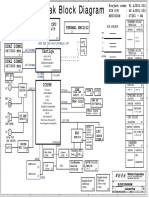

- Acer Aspire 5330 - 5730 Wistron Cathedral Peak RevSBDocument42 pagesAcer Aspire 5330 - 5730 Wistron Cathedral Peak RevSBRubén Pérez ArmasNo ratings yet

- 37-38 InsDocument8 pages37-38 InsPrashantNo ratings yet

- Guide To CPA Brake Resistors and Brake ChoppersDocument9 pagesGuide To CPA Brake Resistors and Brake ChoppersXonFaxonNo ratings yet

- 1110 SenguptaDocument18 pages1110 SenguptaAlisson PirolaNo ratings yet

- CNC Oxyacetylene Flame Cutting MachineDocument12 pagesCNC Oxyacetylene Flame Cutting MachineNaman JoharNo ratings yet

- PDF Eapp11 q1 Mod1 Reading and Writing Academic Texts Version 3 PDF DDDocument83 pagesPDF Eapp11 q1 Mod1 Reading and Writing Academic Texts Version 3 PDF DDJannah Mae Lauron DuranNo ratings yet

- Cs It 8 Sem Project DetailsDocument4 pagesCs It 8 Sem Project DetailsSandeep RaoNo ratings yet

- SOP For Storage of Temperature Sensitive Raw MaterialsDocument3 pagesSOP For Storage of Temperature Sensitive Raw MaterialsSolomonNo ratings yet

- HM-TRLR-D Series - EN - V1.1Document25 pagesHM-TRLR-D Series - EN - V1.1Oscar IsaiaNo ratings yet

- Datasheet Novasmoke Blue 784Document1 pageDatasheet Novasmoke Blue 784Jorge E. Arias VargasNo ratings yet

- Product Upgrading: General DescriptionDocument2 pagesProduct Upgrading: General DescriptionZEN MEDIANo ratings yet

- Farming Assistant Web Services AgricultorDocument9 pagesFarming Assistant Web Services AgricultorIJRASETPublicationsNo ratings yet

- UntitledDocument15 pagesUntitledSeda KandemirNo ratings yet

- Job Description: IT TECHNICIANDocument3 pagesJob Description: IT TECHNICIANteststudent UnknownNo ratings yet

- Rotating Equipment Snøhvit LNG Theory and Main Boosting TEP10Document35 pagesRotating Equipment Snøhvit LNG Theory and Main Boosting TEP10Jicheng PiaoNo ratings yet

- Tokyo Keiki - Radar Level GaugeDocument41 pagesTokyo Keiki - Radar Level GaugeFerry YusufNo ratings yet

- 1623853585875-Regd Vend 160621Document4 pages1623853585875-Regd Vend 160621Finmark Business groupNo ratings yet

- 03 CFD Geom and CFD Ace GuiDocument14 pages03 CFD Geom and CFD Ace GuiLovely JanNo ratings yet