Professional Documents

Culture Documents

Translate Jurnal

Uploaded by

Kevin KurniawanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Translate Jurnal

Uploaded by

Kevin KurniawanCopyright:

Available Formats

ISSN: 2456-9909 (Online)

International Journal of Research in AYUSH and

Pharmaceutical Sciences

Research Article

FORMULATION AND EVALUATION OF PARACETAMOL SUSPENSION BY USING

NATURAL SUSPENDING AGENT EXTRACTED FROM BANANA PEELS

M. Sai Vishnu*, A. Lakshmana Rao, M. Yamini, M. Rajya Lakshmi, M. Meenakshi Prasanna,

N. Uma Mounika

Department of Pharmaceutics, V. V. Institute of Pharmaceutical Sciences, Gudlavalleru, Andhra Pradesh.

Keywords: Musa ABSTRACT

paradisica, paracetamol, The present work was aimed to formulate and evaluate a new, cheap and effective

swelling index, natural suspending agent that can be used as an effective alternative for

phytochemical testing, traditional suspending agent. The study procedure involved extraction of

sedimentation volume. suspending agent from the Musa paradisica (Banana) fruit peels, determination of

swelling index, phytochemical testing, Micromeritic properties of mucilage like

Bulk density, Tapped density, Carr’s index, Hausner’s ratio, Angle of repose,

Calibration of paracetamol, preparation of paracetamol suspensions and

evaluated for pH determination, determination of sedimentation volume,

redispersibility, determination of flow rate, measurement of viscosity, effect of

temperature, drug content, particle size determination and In-vitro dissolution

studies. The study showed that the extraction of suspending agent from banana

fruit peels. The swelling index was found to be 40%. The photochemical test

showed contains carbohydrates. As the concentration of suspending agent

increases therefore viscosity of suspension increases which ultimately reduces

the sedimentation of suspension.

INTRODUCTION

Taste is one of the most important that spontaneously from colloidal dispersions with

parameters governing patient compliance. water because of an affinity between the dispersed

Undesirable taste is one of several important particles and the dispersion medium.[2] They help in

formulation problems that are encountered with lowering the sedimentation rate of particles in

certain drugs. Oral administration of bitter drugs suspension.[3,4]

with an acceptable degree of palatability is a key Rationale of suspending agent selection

issue for health care providers, especially for Mucilage of Musa paradisica can be used as

paediatric patients. Several oral pharmaceuticals, Binding agent, Suspending agent, Thickening agent,

numerous food and beverage products, and bulking Humidifying agent, Disintegrating agent,

agents have unpleasant, bitter tasting components. Gelling agent and Release controlling properties in

So, any pharmaceutical formulation with a pleasing medicines. In the present study, attempts shall be

taste would definitely be preferred over a made to utilize dried powder of banana peel

competitor's product and would translate into mucilage as suspending agent.

better compliance and therapeutic value for the

Aim: The present work was aimed to formulate and

patient and more business and profits for the

evaluation of paracetamol suspension by using a

company. The desire of improved palatability in

new, cheap and effective natural suspending agent

these products has prompted the development of

from Musa paradisica (Banana) fruit peels.

numerous formulations with improved perfor-

mance and acceptability.[1] Suspending agents also Objective: The main objective of this extraction of

called thickening agents are used to stabilize suspending agent from a Banana fruit peels.

suspensions are hydrophilic colloid i.e substances Formulation development was done by using this

IJRAPS | January 2018 | Vol 2 | Issue 1 199

IJRAPS, 2018:2(1):199-208

suspending agent in order to optimize the natural dish was discarded and the weight increase of the

suspending agent of banana peel mucilage. isolated mucilage was determined. [7]

MATERIALS AND METHODS Swelling Index % (SI) = (W2 – W1/W2) x 100

Materials W1= Weight of compact at time ‘0’

Paracetamol were obtained from Yarrow W2= Weight of compact t at time ‘t’

Chem Products, Mumbai. Banana fruits were 2. Phytochemical Screening of Mucilage

purchased from local market. Glycerin, Propyl Preliminary tests were performed to

paraben, Methyl paraben, Sodium saccharine, confirm the nature of mucilage obtained. The

sodium metabisulphate and Peppermint oil were chemical tests that were conducted are: Molisch’s

obtained from Darwin Formulations Pvt. Ltd., test, Ninhydrin test, Wagner’s test, Ruthenium red

Vijayawada. Amaranth was obtained from Finar test, Iodine test, Shinoda test, Keller-Killaini test

Limited, Vijayawada. All other solvents used were of and Ferric chloride test. [7]

analytical grade.

3. Micromeritic Properties of Mucilage

Extraction of suspending agent from Musa

a & b: Bulk density and Tapped density:[8, 9]

paradisica (Ripe Fruit Peels)

Loose bulk density and Tapped bulk density was

Initially ripe fruit peels of Musa paradisica calculated by the following formula

were crushed and reduced in size using mill. The

𝑩𝒖𝒍𝒌 𝒅𝒆𝒏𝒔𝒊𝒕𝒚

crushed peels were soaked in 1% sodium 𝑴𝒂𝒔𝒔 𝒐𝒇 𝒑𝒐𝒘𝒅𝒆𝒓

metabisulphite solution for 12 hrs and boiled in =

water bath to prepare slurry. Further slurry was 𝑩𝒖𝒍𝒌 𝒗𝒐𝒍𝒖𝒎𝒆 𝒐𝒇 𝒕𝒉𝒆 𝒑𝒐𝒘𝒅𝒆𝒓

cooled and allows settling down unwanted material.

Upper portion was collected and concentrated in 𝑻𝒂𝒑𝒑𝒆𝒅 𝒅𝒆𝒏𝒔𝒊𝒕𝒚

water bath and after cooling acetone was added in 𝑴𝒂𝒔𝒔 𝒐𝒇 𝒑𝒐𝒘𝒅𝒆𝒓

=

it with continuous stirring. The precipitate was 𝑻𝒂𝒑𝒑𝒆𝒅 𝒗𝒐𝒍𝒖𝒎𝒆 𝒐𝒇 𝒕𝒉𝒆 𝒑𝒐𝒘𝒅𝒆𝒓

collected and dried at room temperature for 24 hrs.

The air dried material further subjected to size c. Carr’s Compressibility Index

reduction and passed through sieve no. 60 and % Carr’s Index can be calculated by using the

stored in desiccators for further evaluation. following formula

Evaluation of extracted powder 𝑪𝒂𝒓𝒓′ 𝒔 𝒊𝒏𝒅𝒆𝒙 %

1. Determination of Swelling Index 𝑻𝒂𝒑𝒑𝒆𝒅 𝒅𝒆𝒏𝒔𝒊𝒕𝒚 − 𝑩𝒖𝒍𝒌 𝒅𝒆𝒏𝒔𝒊𝒕𝒚

= 𝒙 𝟏𝟎𝟎

2. Phytochemical Screening of Mucilage 𝑻𝒂𝒑𝒑𝒆𝒅 𝒅𝒆𝒏𝒔𝒊𝒕𝒚

3. Micromeritic Properties of Mucilage d. Hausner’s ratio

a. Bulk density Hausner ratio is an indirect index of ease of

b. Tapped density measuring the powder flow. It is calculated by the

c. Carr’s Compressibility Index following formula

d. Hausner’s ratio 𝑻𝒂𝒑𝒑𝒆𝒅 𝒅𝒆𝒏𝒔𝒊𝒕𝒚

𝑯𝒂𝒖𝒔𝒏𝒆𝒓′ 𝒔 𝒓𝒂𝒕𝒊𝒐 =

e. Angle of repose 𝑩𝒖𝒍𝒌 𝒅𝒆𝒏𝒔𝒊𝒕𝒚

1. Determination of Swelling Index e. Angle of repose

500 mg of isolated mucilage was taken in a Petri Angle of repose (θ) can be calculated from the

dish and then 10 ml of distilled water was added following formula

𝒉 𝒉

and the mixture was shaken and allowed to stand 𝑻𝒂𝒏Ɵ = 𝒓 (or) Ɵ = 𝒕𝒂𝒏-1 𝒓

for 1 hour. After 1 hour the remaining water in Petri H = height of pile and r = radius of the base of pile

Table 1: Physical characterization of the extracted powder

S. No. Angle of repose Carr’s index Hausner's ratio Flow property

1. 25-30 5-12 1.00-1.11 Free flowing

2. 30-35 12-16 1.12-1.18 Good

3. 35-40 18-21 1.19-1.25 Fair

4. 40-55 23-35 1.35-1.45 Poor

5. 55-65 33-38 1.46-1.59 Very poor

6. >65 >40 >1.60 Extremely poor

Website: http://ijraps.in 200

M. Sai Vishnu et al. Formulation and Evaluation of Paracetamol Suspension by using Natural Suspending Agent

Extracted from Banana Peels

Estimation of Paracetamol ml were transferred to 10 ml volumetric flask,

Determination of λmax of Paracetamol in volume was adjusted with pH 5.8 phosphate buffer,

Phosphate buffer pH 5.8 which gave a concentration of 2, 4, 6, 8 and 10

Stock solution: Standard stock solution was µg/ml of the final standard. A standard curve was

prepared by dissolving 100 mg drug in pH 5.8 and plotted by taking absorbance of secondary stock

make up with pH 5.8 to get concentration of 100 solutions in UV double beam spectrophotometer at

µg/ml. 257nm.

Method development: From the above stock Formulation development

solution, 1 ml was transferred into a 10 ml Design: F1, F2, F3, F4, F5and F6were designed to

volumetric flask and volume was adjusted to 10 ml optimize the ratios of paracetamol and banana peel

that corresponded to 100 µg/ml solution. From that mucilage and to study the effect of mucilage in

solution different aliquots of 0.2, 0.4, 0.6, 0.8 and 1 ratios.

Chemicals used in formulation:

Table 2: List of chemicals used in study and their manufacturers

S. No. Chemicals Manufacturer Purpose

1 Paracetamol Yarrow chem products, Mumbai API

2 Banana peel mucilage Isolated product Suspending agent

Protect API from natural

3 Glycerin Darwin, Vijayawada

suspending agent

4 Propyl paraben Darwin, Vijayawada preservative

5 Methyl paraben Darwin, Vijayawada preservative

6 Sodium saccharine Darwin, Vijayawada Sweetening agent

7 Peppermint oil Darwin, Vijayawada Flavoring agent

8 Amaranth Finar, Vijayawada Coloring agent

9 Purified water Institutional supply Solvent

API- Active Pharmaceutical Ingredient

Equipments used in formulation

Table 3: List of instruments used in study and their manufacturers

S. No. Equipment Manufacturer

1 Electronic balance Shimadzu, Mumbai.

2 Mechanical sieve shaker Darwin, Vijayawada

3 Tap density tester Delta, Vijayawada

4 Dissolution apparatus USP2 Lab India DS 8000, Mumbai

5 Hot air oven KEMI, Ernakulam, Kerala

6 U.Vspectrophotometer Shimadzu, Mumbai.

7 PH meter Darwin, Vijayawada

8 Ostwald viscometer Darwin, Vijayawada

9 Brookfield's viscometer Asian Scientific Instruments, Hyderabad

10 Microscope Magnus Analytics, New Delhi

Formulation of suspension

Formulation of suspension was prepared as per formula given in Table 4. Extracted banana peel

powder was taken in mortar to which methyl and propyl paraben were added and triturated for some time

along with water to make paste. In beaker paracetamol was mixed well with glycerin. This mixture was

further added to the above paste and triturated for 20 min. Then colouring agent i.e. Amaranth and

IJRAPS | January 2018 | Vol 2 | Issue 1 201

IJRAPS, 2018:2(1):199-208

flavouring agent i.e. Peppermint oil were added mixed well in suspension. Volume made up with water up to

50 ml and further homogenized of suspension.

Optimization of formulation ingredients in preparation

Table 4: Optimization of formulation ingredients

S. No. Ingredients F1 F2 F3 F4 F5 F6

1. Paracetamol (g) 2.5 2.5 2.5 2.5 2.5 2.5

3. Banana peel mucilage (g) 0.25 0.5 1 2 3 4

4. Glycerin (ml) 5 5 5 5 5 5

5. Propyl paraben (g) 0.1 0.1 0.1 0.1 0.1 0.1

6. Methyl paraben (g) 0.15 0.15 0.15 0.15 0.15 0.15

7. Sodium saccharine (g) 0.05 0.05 0.05 0.05 0.05 0.05

8. Peppermint oil (ml) 1 1 1 1 1 1

9. Amaranth (g) 0.01 0.01 0.01 0.01 0.01 0.01

10. Purified water (m1) 50 50 50 50 50 50

Characterization of formulated suspensions: 9] [8, Where, (Vu) floc is ultimate sedimentation

i. pH determination of suspension volume in flocculated suspension and (Vu) defloc is

The pH of all developed formulations was ultimate sedimentation volume in deflocculated

measured using digital pH meter. suspension.

ii. Sedimentation volume (Vu) floc

𝐹=

Sedimentation volume is determined by following (Vu) defloc

equation, vii. Drug content

Hu 5 ml of suspension (250mg/ml) was accurately

𝐹= measured and transferred into 100 ml volumetric

Ho

Where, Hu is ultimate or final height of sediment as flask. And volume made up with PH 5.8. Further

suspension settles, Ho is original height of from above suspension 1 ml was withdrawn and

suspension. added to 10 ml flask, volume made with PH 5.8.

iii. Redispersibility Absorbance was measured using UV-Visible double

beam spectrophotometer at λ max 257 nm. Drug

Fixed volume of each suspension (50 ml) was kept

content was calculated by comparing the

in calibrated tubes which were stored at room

absorbance with standard curve.

temperature for various time intervals (1, 5, 10, 15,

20, 30, 45 days). At regular interval one tube was viii. Particle size measurement

removed and shaken vigorously to redistribute the Particle size determination is carried out by optical

sediment and the presence of deposit if any was microscopy method using motic microscope.

recorded. Suspension was spread on slide & observed under

iv. Flow rate (F) microscope. Diameters of 50 particles were

measured.

The time taken for 10ml sample of suspension to

flow through a 10ml pipette was determined and ix. In-vitro dissolution studies

the flow rate calculated using the following Dissolution study of formulated suspensions was

equation: carried out in USP type II dissolution test apparatus

Volume of pipette (ml) in 500 ml of water for 30 min (37 ± 0.5oC and

𝐹= 25rpm). USP type II dissolution test apparatus

Flow time (sec)

although mainly designed for tablets and capsules,

v. Determination of viscosity this apparatus has also been used by several

The viscosity of suspension samples was investigators to study the dissolution behaviour of

determined using the Brookfield viscometer at 100 suspensions.

rpm. All determinations were carried out in at least 5 ml suspension was introduced carefully into the

triplicates and results obtained were expressed as bottom of the apparatus. 5 ml aliquots were

the mean values. withdrawn at interval of 5 min for analysis and

vi. Degree of flocculation replenished by equivalent amount of blank. The

Degree of flocculation (β) was determined using aliquots were filtered through Whatman filter

following equation. paper and further analyzed at respective

Website: http://ijraps.in 202

M. Sai Vishnu et al. Formulation and Evaluation of Paracetamol Suspension by using Natural Suspending Agent

Extracted from Banana Peels

wavelength by double beam UV visible The graph is plotted percentage log% cumulative

spectrophotometer. [10] drug unreleased v/s time

To study the drug release kinetics, the data RESULTS AND DISSCUSSION

obtained from in vitro drug release studies were Evaluation of extracted powder

plotted in various kinetic models such as a first 1. Determination of swelling index

order equation.

Result: Swelling index of banana peel mucilage was

x. First order kinetics: To study the first order found to be 40% at end of 1hrs.

release kinetics the release data was fitted into the

Discussion: Result shows that the swelling index

following equation.

was found to be increased with time. Swelling index

DQ/dt = K1Q was increased, because weight gain by mucilage

Where Q is amount of drug unreleased was proportional to rate of hydration. The direct

K1 is first order release rate constant relationship was observed between swelling index

t is release time and mucilage concentration. As the mucilage

concentration increases swelling index increases.

2. Phytochemical screening of mucilage

Table 5: Phytochemical screening of mucilage

S. No. Identification test Name of the test Observation

1. Test for carbohydrates Molisch’s test Positive

2. Test for proteins Ninhydrin test Negative

3. Test for alkaloids Wagner’s test Negative

4. Test for mucilage Ruthenium red test Positive

5. Test for starch Iodine test Negative

6. Test for flavonoids Shinoda test Negative

7. Test for glycosides Keller Killani test Negative

8. Test for tannins Ferric chloride test Negative

Discussion

Phytochemical test carries out on banana peel mucilage confirmed the absence of alkaloids,

glycosides, starch and tannins. Treatment of mucilage with ruthenium red showed red coloration confirms

the obtained product as mucilage. A violet ring was formed at the junction of two liquids on reaction with

Molisch’s reagent indicates presence of carbohydrates. The results are shown in Table 5.

3. Micromeritic properties of mucilage

Table 6: Micromeritic properties of mucilage

S. No. Parameters Valve

1. Bulk density 0.75g\ml

2. Tapped density 0.80g\ml

3. Hausner’s ratio 1.06

4. Carr’s compressibility index 6.25

5. Angle of repose 29

Discussion: Values of Carr’s compressibility index showed that mucilage powder has excellent flow

properties. Values of Angle of repose and Hausner’s ratio showed that mucilage powder has good flow

properties. The flow properties results are shown in Table 6.

Standard curve of Paracetamol

Table 7: Series of concentrations and their absorbance

Concentration (µg/ml) Absorbance

0 0

2 0.163

4 0.308

6 0.464

IJRAPS | January 2018 | Vol 2 | Issue 1 203

IJRAPS, 2018:2(1):199-208

8 0.597

10 0.755

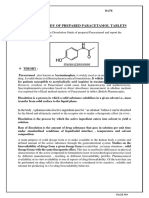

Fig. 1: Calibration curve of Paracetamol

Discussion: It has been inferred that API shows linearity in concentration range of 2-10µg/ml. the

regression coefficient of calibration curve was found to be 0.999. The linearity results were shown in Table.

7 and calibration curve were shown in Fig. 1.

Evaluation of formulated suspensions

i. pH

Table 8: pH values data for F1, F2, F3, F4, F5 and F6

Formulation F1 F2 F3 F4 F5 F6

pH 7.01 7.1 7.15 7.19 7.29 7.24

Fig. 2: Comparative profiles of pH values of all formulations

Discussion: pH of all formulation was found to be in the range of 7.01 to 7.29. All the pH values are within

the limits. The pH values were shown in Table. 8 and Comparative profiles of pH of all batches were shown

in Fig. 2.

Website: http://ijraps.in 204

M. Sai Vishnu et al. Formulation and Evaluation of Paracetamol Suspension by using Natural Suspending Agent

Extracted from Banana Peels

ii. Sedimentation volume

Table 9: Sedimentation volume values for F1, F2, F3, F4, F5 and F6

S. No. Time (Days) F1 F2 F3 F4 F5 F6

1. 0 0 0 0 0 0 0

2. 1 0.44 0.65 0.7 0.75 0.8 0.99

3. 2 0.40 0.54 0.67 0.7 0.76 0.95

4. 3 0.35 0.5 0.6 0.65 0.72 0.89

5. 4 0.30 0.4 0.54 0.64 0.66 0.82

6. 5 0.25 0.36 0.49 0.56 0.62 0.78

7. 10 0.20 0.35 0.42 0.51 0.54 0.72

8. 20 0.15 0.34 0.36 0.48 0.49 1.67

9. 30 0.126 0.32 0.35 0.45 0.45 0.62

10. 45 0.10 0.3 0.34 0.39 0.4 0.60

Fig. 3: Comparative profiles of sedimentation volume of all formulations

Discussions: sedimentation volumes were found to be decreased at the end of 5 days. Batch F6, was found

to be stable and dispersed at the end of 45 days. The dispersed particle were sediment at faster rate in

suspension containing lower concentration of suspending agent compared to containing higher amount. The

sedimentation volume values were shown in Table 9 and Comparative profiles of sedimentation volume of

all batches were shown in Fig. 3.

Evaluation of suspensions like particle size, degree of flocculation, flow rate, redispersibility, drug

content and viscosity:

Table 10: Evaluation of suspensions for F1, F2, F3, F4, F5 and F6

Particle Degree of Drug content

Formula Flow Rate Redispersibility Viscosity

size (µm) flocculation (%)

F1 68.2 2.57 0.50 5 96.09 1.18

F2 71.2 2.99 0.30 6 97.8 1.93

F3 65.8 3.10 0.12 8 95.96 3.28

F4 66.5 3.31 0.08 9 98.36 4.48

IJRAPS | January 2018 | Vol 2 | Issue 1 205

IJRAPS, 2018:2(1):199-208

F5 64.5 3.55 0.067 10 97.97 5.94

F6 67.2 4.01 0.046 11 99.12 7.10

iii. Particle size (µm): Particle size of 50 particles of all formulated suspensions was determined and valves

are reported. Which is acceptable and within limits. The particle size values were shown in Table 10.

iv. Degree of flocculation: Degree of flocculation was determined for all formulation suspensions using

different concentration of banana peel mucilage. The values of degree of flocculation for all formulated

suspension have been shown in above Table were found to be increased at higher concentration of

suspending agent, due to higher viscosity of suspension at higher concentration which ultimately reduces

the sedimentation of suspension. The degree of flocculation values were shown in Table 10.

v. Flow rate: Flow rate was found to be decreased as concentration of suspending agent and viscosity of

suspension increased found in the range of 0.5 to 0.046. The flow rate values were shown in Table 10.

vi. Redispersibility: Since the suspension sediment on storage it must be readily dispersible so as to ensure

a more uniform dosage administration of medicament after shaking. All the suspension was found to be

easily redispersible after maximum 11 shakings after 45 days. Redispersibility was found to be faster for

suspension with lower amount of suspending agent comparing to higher concentration. The redispersibility

values were shown in Table 10.

vii. Drug content (%): Drug content for all batches was found to be in the range of 95.96 to 99.12%. The

drug content values were shown in Table 10.

viii. Viscosity (poise): Viscosity was found to be increased as concentration of suspending agent increased.

It found in the range of 1.18 to 7.10. The viscosity values were shown in Table 10.

ix. In-vitro Dissolution:

Table 11: Dissolution data for F1, F2, F3, F4, F5 and F6

S. No. Time (mins) F1 F2 F3 F4 F5 F6

1. 0 0 0 0 0 0 0

2. 5 60 58 58 56 58 58

3. 10 65 60 60 65 68 68

4. 15 66 68 68 73 78 76

5. 20 70 76 68 78 86 84

6. 25 82 86 80 80 90 92

7. 30 90 90 92 92 98 99

Fig. 4: Comparative dissolution profiles for F1, F2, F3, F4, F5 and F6

Website: http://ijraps.in 206

M. Sai Vishnu et al. Formulation and Evaluation of Paracetamol Suspension by using Natural Suspending Agent

Extracted from Banana Peels

Discussion: Results shows that all formulations drug release was almost 90 to 99% at the end of 30 min. For

most of the batches, the release kinetics of Paracetamol suspensions appeared to follow first order release

kinetics. The dissolution values were shown in Table. 11 and Comparative profiles of dissolution values of all

batches were shown in Fig. 4.

x. First order kinetics for dissolution profiles

Table 12: Regression co-efficient (R2) values for F1, F2, F3, F4, F5 and F6

Formulation F1 F2 F3 F4 F5 F6

R2 Valve 0.90 0.94 0.86 0.91 0.90 0.963

Fig. 5: First order kinetics for dissolution profiles

Discussion: Regression co-efficient values were Pharmaceutical Sciences, Gudlavalleru for their

closer to unity in case of first order hence, release is encouragement towards the success of the work.

apparently first order. As clearly indicated the

release of the drug followed first order release

kinetics and regression value indicates fair of

REFERENCES

linearity in the data. This shows that the release is

dependent on the concentration of drug. The first 1. Sohi H, Sultana Y and Khar RK. Taste masking

order values were shown in Table 12 and technologies in oral pharmaceuticals. Drug

Comparative profiles of first order values of all Development Industrial pharmacy. 2004; 30(5):

batches were shown in Fig. 5. 429-448.

CONCLUSION 2. Subramanyam CVS. “Suspensions” Text Book of

Physical Pharamaceutics. Second edition. India;

We can conclude that this formulation

Publisher Vallabh Prakashan; 2011; 374-387.

development was used to optimize the natural

suspending agent of banana peel mucilage. The 3. Ansel C, Allen LV, and Popovich NG. “Disperse

result generated in this study showed that all the systems” Pharmaceutical Dosage Forms & Drug

evaluation values within the limits and were Delivery Systems. Eighth edition. Philadelphia;

optimized formulation according to the Lippincott Williams and Wilkins; 2005; 387-

sedimentation volume. As the concentration of 389, 398.

suspending agent increases viscosity of suspension 4. Martin A. “Coarse dispersion” Physical

increases this ultimately reduces the sedimentation Pharmacy. Fourth edition. Philadelphia;

volume of suspension. Lippincott Williams and Wilkins; 2001; 479-

ACKNOWLEDEMENTS 481.

The authors are thankful to Yarrow Chem 5. Sameer JN, Sachin SM, Sachin SS and Piyush MK.

Products, Mumbai for providing a Paracetamol and Formulation and evaluation of ciprofloxacin

the authors are also thankful to V. V. Institute of suspension using natural suspending agent.

IJRAPS | January 2018 | Vol 2 | Issue 1 207

IJRAPS, 2018:2(1):199-208

International Journal of Pharma Sciences and Industrial Pharmacy. Third edition. Varghese

Research. 2014; 3(5): 63-70 Publishing House; Mumbai; 1987; 67–71.

6. Rajendra J, Sanjay JD, Ram Kumar Sahu and 9. Lieberman HA, Lachman L, Joseph BS and Kanig

Jagdish Singh. Formulation development and JL. Preformulation. In: The Theory and Practice

evaluation of suspension of Gatifloxacin using of Industrial Pharmacy. Third edition. Varghese

suspending agent. Pharmacologyonline. 2011; Publishing House; Mumbai; 1987; 183–184.

2: 1161-1170. 10. Strum JD, Colaizzi JL, Goehl JL, Jaffe JM, Pitlick

7. Khandelwal KR. Practical Pharmacognosy, WH, Shah VP and Poust RI. Bioavailalivity of

Techniques and Experiments. 9th edition. Nirali sulfonamide suspensions I: Dissolution profiles

prakashan; 2002; 149-156. of sulfamethizole using paddle method. Journal

8. Libermann HA, Lachmann L, Joseph BS and of Pharmaceutical Sciences. 1978, 6(7): 1399-

Kanig JL. Compression and consolidation of 1402.

powdered solids. In: The Theory and Practice of

Cite this article as: *Address for correspondence

M. Sai Vishnu, A. Lakshmana Rao, M. Yamini, M. Rajya Lakshmi, M. Mr. M. Sai Vishnu

Meenakshi Prasanna, N. Uma Mounika. Formulation and Evaluation Assistant Professor

of Paracetamol Suspension by using Natural Suspending Agent V. V. Institute of Pharmaceutical

Extracted from Banana Peels. International Journal of Research in Sciences, Gudlavalleru, Andhra

AYUSH and Pharmaceutical Sciences, 2018;2(1):199-208. Pradesh.

Source of support: Nil, Conflict of interest: None Declared Email: saivishnu13@gmail.com

Phone: 7396565240

Website: http://ijraps.in 208

You might also like

- Fts Cair Suspensi 2Document10 pagesFts Cair Suspensi 2Raodatul IstiharohNo ratings yet

- Formulation Development and Evaluation of Medicated Jelly With Cuminum Cyminum Extract and Its Comparative Study Using Different Jelling AgentsDocument7 pagesFormulation Development and Evaluation of Medicated Jelly With Cuminum Cyminum Extract and Its Comparative Study Using Different Jelling AgentsBaru Chandrasekhar RaoNo ratings yet

- 31713-Article Text-147150-1-10-20190103Document4 pages31713-Article Text-147150-1-10-20190103DrBipin DevaniNo ratings yet

- Materials and MethodsDocument11 pagesMaterials and MethodsVaibhav KaleNo ratings yet

- Materials and MethodsDocument11 pagesMaterials and MethodsVaibhav KaleNo ratings yet

- Banana peel mucilage pharmaceutical excipientDocument10 pagesBanana peel mucilage pharmaceutical excipientDinda MaulidyaNo ratings yet

- Development and in Vitro-In Vivo Evaluation of Gastro Retentive Drug Delivery of Nizatidine Using Natural and Semi - Synthetic PolymersDocument17 pagesDevelopment and in Vitro-In Vivo Evaluation of Gastro Retentive Drug Delivery of Nizatidine Using Natural and Semi - Synthetic PolymersShyamlaNo ratings yet

- Journal of Drug Delivery and Therapeutics: Role of Naturally Isolated Pear Starch On The Bioavailability of FamotidineDocument6 pagesJournal of Drug Delivery and Therapeutics: Role of Naturally Isolated Pear Starch On The Bioavailability of FamotidineyunitaknNo ratings yet

- Extraction of Polysaccharide Polymer From Dioscorea Trifida and Evaluation As A Tablet BinderDocument6 pagesExtraction of Polysaccharide Polymer From Dioscorea Trifida and Evaluation As A Tablet BinderMurali Krishna ReddyNo ratings yet

- Novel Formulation and Evaluation Herbal Based Lotion For The Antimicrobial and Antifungal PropertiesDocument9 pagesNovel Formulation and Evaluation Herbal Based Lotion For The Antimicrobial and Antifungal PropertiesMr.S. p.royNo ratings yet

- Formulasi Dan Evaluasi Fisik Granul Effervescent Sari Buah Naga Hylocereus UndatusDocument4 pagesFormulasi Dan Evaluasi Fisik Granul Effervescent Sari Buah Naga Hylocereus UndatusDjogker C-mpalNo ratings yet

- Bharath 2012 EXTRACTION OF POLYSACCHARIDE POLYMER FROM DIOSCOREA TRIFIDA AND EVALUATION AS A TABLET BINDER PDFDocument6 pagesBharath 2012 EXTRACTION OF POLYSACCHARIDE POLYMER FROM DIOSCOREA TRIFIDA AND EVALUATION AS A TABLET BINDER PDFfortuna_dNo ratings yet

- ACTRA-2018-034Document11 pagesACTRA-2018-034EnggerianiNo ratings yet

- (574 580) V9N12PTDocument7 pages(574 580) V9N12PTjeane wattimenaNo ratings yet

- Formulation and Evaluation of Solid Dispersion Containing ParacetamolDocument5 pagesFormulation and Evaluation of Solid Dispersion Containing Paracetamolindah marhaniNo ratings yet

- ArticleDocument9 pagesArticleArjumand DurraniNo ratings yet

- 1481 D0752025 PDFDocument6 pages1481 D0752025 PDFANo ratings yet

- Article Wjpps 1472640171Document11 pagesArticle Wjpps 1472640171DrBipin DevaniNo ratings yet

- Effect of Guar Gum On Dissolution and Sustained Release of Metronidazole Effervescent TabletsDocument20 pagesEffect of Guar Gum On Dissolution and Sustained Release of Metronidazole Effervescent Tabletsnosheen shabbirNo ratings yet

- Stabilization of Microcapsules Suspensions Containing Sage ExtractDocument10 pagesStabilization of Microcapsules Suspensions Containing Sage ExtractAzka TralalaNo ratings yet

- Herbal shampoo formulation and evaluationDocument8 pagesHerbal shampoo formulation and evaluationgisella hapsariNo ratings yet

- Anti Sebum Efficacy of Guava Toner: A Split Face, Randomized, Single Blind Placebo Controlled StudyDocument5 pagesAnti Sebum Efficacy of Guava Toner: A Split Face, Randomized, Single Blind Placebo Controlled StudyVITA OKTAVIYANTI PUTRI 2018No ratings yet

- 18 3 2 - p.155 160Document6 pages18 3 2 - p.155 160Bình MinhNo ratings yet

- Transdermal Permeation of Salicylic Acid Using Mucinated Honey FormulationsDocument4 pagesTransdermal Permeation of Salicylic Acid Using Mucinated Honey FormulationsAndrianna NastasyaNo ratings yet

- ijcpa2013002Document3 pagesijcpa2013002AHMED MOHAMMED MAHMOUD MUSTAFANo ratings yet

- 20.Md Musharraf Ali and V.saikishoreDocument9 pages20.Md Musharraf Ali and V.saikishoreBaru Chandrasekhar RaoNo ratings yet

- Formulation of Herbal Face Wash Using Luffa ExtractDocument6 pagesFormulation of Herbal Face Wash Using Luffa ExtractSuci PurwaningsihNo ratings yet

- Formulation and Evaluation of Fast Dissolving Tablets of Paracetamol Using Oats PowderDocument6 pagesFormulation and Evaluation of Fast Dissolving Tablets of Paracetamol Using Oats PowderinventionjournalsNo ratings yet

- Diclofenac Suspension For Redispersibility StudyDocument6 pagesDiclofenac Suspension For Redispersibility Studysunieljagtap1982No ratings yet

- Cucumber MucilageDocument18 pagesCucumber Mucilagesaicharan88417No ratings yet

- Preparation of Sea Cucumber Holothuria Scabra PowdDocument5 pagesPreparation of Sea Cucumber Holothuria Scabra PowdShane LiewNo ratings yet

- Hibiscus sabdariffa Mucilage Fast Dissolving Nebivolol TabletsDocument7 pagesHibiscus sabdariffa Mucilage Fast Dissolving Nebivolol TabletstiaraNo ratings yet

- Isolation and Evaluation of Binding Property of Sago Starch in Paracetamol TabletDocument7 pagesIsolation and Evaluation of Binding Property of Sago Starch in Paracetamol TabletGusti Ketut KusumaNo ratings yet

- FullText UmeshDocument3 pagesFullText UmeshUmesh GilhotraNo ratings yet

- Studies On Cohesiveness of Isolated Starch From The Seeds of Cajanas CajanDocument5 pagesStudies On Cohesiveness of Isolated Starch From The Seeds of Cajanas CajanAnnalakshmi ChatterjeeNo ratings yet

- Ijrpb 1 (4) 14 Page 549-553Document5 pagesIjrpb 1 (4) 14 Page 549-553dini hanifaNo ratings yet

- Ormulation and Evaluation of Ointment Containing Sunflower WaxDocument6 pagesOrmulation and Evaluation of Ointment Containing Sunflower WaxXuân ThảoNo ratings yet

- Article WJPR 1564557129Document14 pagesArticle WJPR 1564557129DILLADILLANo ratings yet

- Antioxidant Capacity and Phenolics of Spray Dried Arenga Pinnata Juice PowderDocument5 pagesAntioxidant Capacity and Phenolics of Spray Dried Arenga Pinnata Juice PowderSupawinee KointhaNo ratings yet

- Formulation and Evaluation of Herbal Lipstick From Broccoli Flower Extract and Analytical Bioactive Characterization and QuantificationDocument8 pagesFormulation and Evaluation of Herbal Lipstick From Broccoli Flower Extract and Analytical Bioactive Characterization and QuantificationInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Preparation and Development of Diclofenac Loaded Aloevera Gel Nanoparticles For Transdermal Drug Delivery SystemsDocument4 pagesPreparation and Development of Diclofenac Loaded Aloevera Gel Nanoparticles For Transdermal Drug Delivery SystemsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- WJPPS PDFDocument12 pagesWJPPS PDFwaelNo ratings yet

- 04 IJPBA 2084 23 RevisedDocument13 pages04 IJPBA 2084 23 RevisedBRNSS Publication Hub InfoNo ratings yet

- Formulation and Evaluation of Diclofenac Sodium Matrix Tablets Using Abelmoschus Esculentusmucilage As A PolymerDocument6 pagesFormulation and Evaluation of Diclofenac Sodium Matrix Tablets Using Abelmoschus Esculentusmucilage As A Polymerpbs4yvxjndNo ratings yet

- Formulation and Characterization of Papaya Leaf GelDocument6 pagesFormulation and Characterization of Papaya Leaf GelTutorial BEMNo ratings yet

- 9 To 11 FinalDocument19 pages9 To 11 FinalSusmita GhoshNo ratings yet

- Rada 2018Document10 pagesRada 2018AdewaleNo ratings yet

- Comparative Evaluation of Flow of Pharmaceutical Powders and Granules of Triphala ChurnaDocument7 pagesComparative Evaluation of Flow of Pharmaceutical Powders and Granules of Triphala ChurnaEditor IJTSRDNo ratings yet

- 16067-Article Text-53544-1-10-20161124Document10 pages16067-Article Text-53544-1-10-20161124St NurhayatiNo ratings yet

- Amytriptilin FormulationDocument7 pagesAmytriptilin FormulationWahyu RedfieldNo ratings yet

- Bisoprolol Fumarate Optizorb Dispersible Tablet PDFDocument16 pagesBisoprolol Fumarate Optizorb Dispersible Tablet PDFmailtorubal2573No ratings yet

- Formulation and In-Vitro Characterization of Risperidone Nanosuspensions For The Enhancement of Drug Release RateDocument16 pagesFormulation and In-Vitro Characterization of Risperidone Nanosuspensions For The Enhancement of Drug Release RateSiva PrasadNo ratings yet

- 2045 6063 1 PB PDFDocument5 pages2045 6063 1 PB PDFPradeep ShivaNo ratings yet

- 6 Bananapowderpototostarchasdisintegrant IJPPSDocument5 pages6 Bananapowderpototostarchasdisintegrant IJPPSAdda 07No ratings yet

- Gemcitabine Dry Powder Formulation DevelopmentDocument16 pagesGemcitabine Dry Powder Formulation DevelopmentFIRMAN MUHARAMNo ratings yet

- Thesis Proposal Saccharum SpontaneumDocument6 pagesThesis Proposal Saccharum SpontaneumApril Mergelle LapuzNo ratings yet

- Bionanosuspensions 1 PDFDocument8 pagesBionanosuspensions 1 PDFtemp1 sNo ratings yet

- Evaluation of The Suspending Property of Khaya Snegalensis Gum in Co-Trimoxazole SuspensionsDocument6 pagesEvaluation of The Suspending Property of Khaya Snegalensis Gum in Co-Trimoxazole SuspensionsridwanridwanNo ratings yet

- 12 - Chapter 4Document38 pages12 - Chapter 4Tayyab TahirNo ratings yet

- Practical Handbook of Pharmaceutical Chemistry for M.PharmFrom EverandPractical Handbook of Pharmaceutical Chemistry for M.PharmNo ratings yet

- Porous Dust Fences in SotckyardsDocument7 pagesPorous Dust Fences in SotckyardsDiego DiazNo ratings yet

- Incompressible Non-Newtonian Fluid Flows PDFDocument27 pagesIncompressible Non-Newtonian Fluid Flows PDFSang TranNo ratings yet

- Colloidal Materials: Part IVDocument21 pagesColloidal Materials: Part IVUday Prakash SahuNo ratings yet

- Kronospan Romania PUZ3 Mobiltherm - RoDocument8 pagesKronospan Romania PUZ3 Mobiltherm - RogtrudhNo ratings yet

- HVM 472 Englisch 72Document4 pagesHVM 472 Englisch 72Kwabena AbrantieNo ratings yet

- Navier-Stokes Equations and Approximations ExplainedDocument16 pagesNavier-Stokes Equations and Approximations ExplainedRider RakulNo ratings yet

- PseudoP.xls Computes Real Gas PseudopressuresDocument199 pagesPseudoP.xls Computes Real Gas PseudopressuresKalou BoniNo ratings yet

- Validation of Linear and Weakly Nonlinear Seakeeping CodesDocument17 pagesValidation of Linear and Weakly Nonlinear Seakeeping Codespraveench1888No ratings yet

- ZhengM - Thesis - Complete - Edition - Final Final Format Approved LW 8-8-14Document81 pagesZhengM - Thesis - Complete - Edition - Final Final Format Approved LW 8-8-14Dinda Dwi SeptianiNo ratings yet

- CPI SeparatorDocument77 pagesCPI SeparatorVidyasen100% (1)

- NASA Technical Memorandum Provides Coefficients for Calculating Thermophysical PropertiesDocument94 pagesNASA Technical Memorandum Provides Coefficients for Calculating Thermophysical PropertiesFélix Gallo CruzNo ratings yet

- IBP1432 - 12 Influence of Co2 On PVT Properties of An Oil Crude at High PressureDocument8 pagesIBP1432 - 12 Influence of Co2 On PVT Properties of An Oil Crude at High PressureMarcelo Varejão CasarinNo ratings yet

- Servotherm Oils for Heat Transfer ApplicationsDocument1 pageServotherm Oils for Heat Transfer Applicationssofiane aliNo ratings yet

- Inertial Effects On Flow and Transport in Heterogeneous Porous MediaDocument5 pagesInertial Effects On Flow and Transport in Heterogeneous Porous MediaOscar A. LuévanoNo ratings yet

- Puma HD Drive Train 10W 30 40 50 TDSDocument2 pagesPuma HD Drive Train 10W 30 40 50 TDSHakim AmmorNo ratings yet

- Assignment 2 - ViscosityDocument7 pagesAssignment 2 - ViscosityluluNo ratings yet

- D 56 - 00Document6 pagesD 56 - 00Tria HikmaNo ratings yet

- NETZSCH Compliant API-01 18 PDFDocument12 pagesNETZSCH Compliant API-01 18 PDFTeslah MartineNo ratings yet

- GR Screw PumpsDocument36 pagesGR Screw PumpsBernardo Orozco LariosNo ratings yet

- Model Question-1 of Hydraulics For DAE-IIDocument6 pagesModel Question-1 of Hydraulics For DAE-IISougata DasNo ratings yet

- Contrabalance Walvoil CC10ADocument3 pagesContrabalance Walvoil CC10AMatias Oñate ArriagadaNo ratings yet

- SPE-177914-MS Successful Chemical Water Shut-Off Treatment in An Omani Field Heavy-Oil WellDocument19 pagesSPE-177914-MS Successful Chemical Water Shut-Off Treatment in An Omani Field Heavy-Oil Wellnia setya budiningtyasNo ratings yet

- Fobas Bunker Sample ResultDocument6 pagesFobas Bunker Sample ResultRiskyMaulanaNo ratings yet

- GenChem2 Q3 Module1B Properties-Of-Liquids v4Document12 pagesGenChem2 Q3 Module1B Properties-Of-Liquids v4Ana Leah BacusNo ratings yet

- TB Hydrocolloids FNFN201009Document9 pagesTB Hydrocolloids FNFN201009Yomo OuyaneNo ratings yet

- Titanus EpDocument1 pageTitanus EpTAREK HAMADNo ratings yet

- AGP:CP/336 FAO Spec for Acephate Water Soluble PowderDocument15 pagesAGP:CP/336 FAO Spec for Acephate Water Soluble PowderNadeem MirzaNo ratings yet

- Introduction To Graduate Fluid Mechanics: Charles R. (Chuck) SmithDocument655 pagesIntroduction To Graduate Fluid Mechanics: Charles R. (Chuck) SmithSupriya kumariNo ratings yet

- Early Age Properties of Self-Compacting Concrete - Effects of Fine Aggregate and Limestone Filler - ThesisDocument206 pagesEarly Age Properties of Self-Compacting Concrete - Effects of Fine Aggregate and Limestone Filler - ThesisyoussefNo ratings yet