Professional Documents

Culture Documents

Fang 08 PTL

Uploaded by

Thái Trần DanhOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fang 08 PTL

Uploaded by

Thái Trần DanhCopyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/224326781

A Distributed Bragg Reflector Silicon Evanescent Laser

Article in IEEE Photonics Technology Letters · November 2008

DOI: 10.1109/LPT.2008.2003382 · Source: IEEE Xplore

CITATIONS READS

109 580

7 authors, including:

Alexander Fang Brian Koch

Aurrion Inc. Aurrion Inc.

110 PUBLICATIONS 6,901 CITATIONS 52 PUBLICATIONS 1,579 CITATIONS

SEE PROFILE SEE PROFILE

Di Liang John Edward Bowers

HP Inc. University of California, Santa Barbara

208 PUBLICATIONS 5,046 CITATIONS 1,986 PUBLICATIONS 50,668 CITATIONS

SEE PROFILE SEE PROFILE

Some of the authors of this publication are also working on these related projects:

Monolithic integration of IIIV photonics devices on Si substrates View project

Low power switches View project

All content following this page was uploaded by Alexander Fang on 06 June 2014.

The user has requested enhancement of the downloaded file.

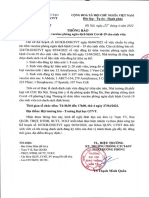

IEEE PHOTONICS TECHNOLOGY LETTERS, VOL. 20, NO. 20, OCTOBER 15, 2008 1667

A Distributed Bragg Reflector Silicon

Evanescent Laser

Alexander W. Fang, Student Member, IEEE, Brian R. Koch, Student Member, IEEE, Richard Jones, Member, IEEE,

Erica Lively, Di Liang, Member, IEEE, Ying-Hao Kuo, and John E. Bowers, Fellow, IEEE

Abstract—We report a distributed Bragg reflector silicon

evanescent laser operating continuous wave at 1596 nm. The

lasing threshold and maximum output power are 65 mA and

11 mW, respectively. The device generates open eye-diagrams

under direct modulation at data rates up to 4 Gb/s.

Index Terms—Hybrid integration, semiconductor lasers,

silicon-on-insulator technology.

I. INTRODUCTION

YBRID integration is currently being investigated as a

H method of creating electrically pumped laser sources

for silicon photonic integration. This new interest is due to

promising developments in the transfer of thin crystalline III–V

films to silicon through benzocyclobutene (BCB)-based wafer

bonding, direct wafer bonding, and low temperature oxygen

plasma-assisted wafer bonding [1]–[3]. These approaches have

led to the demonstration of electrically pumped micro-disk

and Fabry–Pérot (FP) III–V membrane lasers coupled to sil-

icon waveguides [3], [4] and FP and racetrack hybrid silicon

evanescent lasers [5]. These devices allow for the use of elec-

trically pumped III–V gain regions while enabling scalable

manufacturing through alignment-free bonding that is absent

in conventional gold bump bond die attachment of III–V active Fig. 1. (a) Passive silicon rib and (b) hybrid silicon evanescent waveguide cross

section. (c) Microscope image of a hybrid to passive taper. (d) DBR-SEL top-

devices. Hybrid silicon evanescent lasers (SELs) utilize both view topographical structure.

III–V regions and silicon waveguide regions within the device,

allowing for processing in the silicon region to define the cavity

along with lasing properties. (DBR) lasers occupy a different design space where longer cav-

Earlier this year, we demonstrated a distributed feedback ities can be employed to reduce the device thermal impedance

(DFB) SEL [6]. A surface corrugated grating was formed at and increase output powers. We demonstrate here a DBR-SEL

the bonded interface of the silicon waveguide and III–V active where passive silicon gratings are placed on both sides of the

region bisecting the optical mode, leading to a high grating active region in order to form a wavelength selective cavity. The

strength, , of 240 cm . While high grating strength lasers are 600- m-long asymmetric cavity allows for 96% of its 11.5-mW

advantageous for short and low threshold DFBs, their maximum output power to exit one side of the device. We also present test

output power is limited due to their small mode volume. In results of direct digital modulation at 2.5 and 4 Gb/s.

addition, their short device length also leads to higher thermal

impedance. On the other hand, distributed Bragg reflector II. DEVICE STRUCTURE

The DBR-SEL is fabricated on the hybrid silicon evanescent

Manuscript received June 23, 2008; revised July 14, 2008. First published waveguide platform as described in [5]. Fig. 1(a) and (b) shows

August 19, 2008; current version published September 26, 2008. This work was

supported in part by a grant from Intel Corporation, in part by the Defense Ad- the waveguide cross section of the passive silicon waveguide

vanced Research Projects Agency under Program DARPA/MTO DODN, and in and the hybrid silicon evanescent waveguide regions, respec-

part by ARL under Awards W911NF-05-1-0175 and W911NF-04-9-0001. tively. The silicon waveguide has a width, height, and rib etch

A. W. Fang, E. Lively, D. Liang, Y.-H. Kuo, and J. E. Bowers are with the

Department of Electrical and Computer Engineering, University of California,

depth of 2, 0.7, and 0.5 m, respectively. This results in silicon

Santa Barbara, CA 93106 USA (e-mail: awfang@ece.ucsb.edu). and quantum well confinement factors of 66% and 4.4% in the

B. R. Koch and R. Jones are with the Photonics Technology Laboratory, Intel hybrid region.

Corporation, Santa Clara, CA 95054 USA.

Color versions of some of the figures in this letter are available online at http://

The device topography [Fig. 1(d)] consists of two passive

ieeexplore.ieee.org. Bragg reflector mirrors placed 600 m apart to form an optical

Digital Object Identifier 10.1109/LPT.2008.2003382 cavity. The back and front mirror lengths are 300 and 100 m.

1041-1135/$25.00 © 2008 IEEE

1668 IEEE PHOTONICS TECHNOLOGY LETTERS, VOL. 20, NO. 20, OCTOBER 15, 2008

Fig. 2. DBR-SEL L–I–V curve for various temperatures measured out of the

front mirror.

The surface corrugated gratings are formed during silicon

processing prior to wafer bonding through e-beam lithography.

SU-8 is used to clad the gratings since they have a low index of

2.11 while providing a low capacitance dielectric barrier for the Fig. 3. Optical spectrum of the DBR-SEL driven at 200 mA.

device contacts. The gratings have an etch depth and duty cycle

of 25 nm and 75%, respectively, leading to a grating strength, ,

of 80 cm . The grating was measured on grating test struc-

tures by measuring the transmission spectra stop band extinc-

tion ratio for grating lengths , of 50, 100, and 300 m. The

power reflectivity of the gratings can be calculated using the

following expression [7]:

resulting in power reflectivities of 97% and 44% for the back

and front mirrors, respectively.

A 440- m-long silicon evanescent gain region and two

80- m-long tapers [Fig. 1(c)] are placed inside the cavity.

The tapers provide an adiabatic transition between the passive

silicon regions and the silicon evanescent waveguide regions

by varying the width of the upper III–V layers along the length

of the taper, reducing the reflection, and allowing for low loss Fig. 4. Fiber coupled L–I curve and spectrum versus current at a stage temper-

coupling ( 1.2 dB) between these two regions [5]. The tapers ature of 18 C.

are electrically driven in parallel with the gain region in order

to minimize absorption.

Fig. 3 with a lasing peak at 1597.5 nm when driven at 200 mA.

III. EXPERIMENTAL RESULTS The device has a free spectral range (FSR) of 0.47 nm, which

The continuous wave laser output power is measured with corresponds to a group index of 3.86 based on the sum of the

an integrating sphere at the front mirror of the laser. The front physical cavity length and mirror penetration depths of 61 and

mirror output power–current–voltage (L–I–V) characteristic is 42 m. The sidemode suppression ratio is 50 dB.

shown in Fig. 2. The device has a lasing threshold of 65 mA, Fig. 4 shows the lasing spectrum as a function of drive current

a maximum front mirror output power of 11 mW, leading to a along with the corresponding L–I curve. Note that the output

differential efficiency of 15%. The taper transmission loss can power in this case is fiber coupled, which is 5 dB lower than

have a significant impact on the threshold current and therefore the total output power measured earlier in Fig. 2. It can be seen

it affects many important laser characteristics such as wall plug that as the device heats with larger current injection, the lasing

efficiency and resonance frequency. If we use our estimations mode moves to longer wavelengths due to the thermooptic ef-

of the material and laser properties, calculations show that the fect in the cavity. When the mode moves far enough from the

taper loss of 1.2 dB increases the threshold current by a factor of reflection peak, a longitudinal mode hop to another mode oc-

2 due to the accumulated loss through four taper transitions in curs. The mode hopping appears to be chaotic between stable

one round trip through the cavity. We estimate that a reduction in mode positions and the reason for the exact hopping pattern we

the single pass taper losses to 0.5 dB would reduce this factor to observed is unknown at this time.

1.2. The laser operates up to a stage temperature of 45 C. The We measured the modulation characteristics of the device by

kinks in the LI are from mode hopping and will be discussed using a bias-T to drive the laser simultaneously with a dc bias

later. The device has a lasing turn-on voltage of 2.6 V and a current and an radio frequency (RF) signal while measuring the

series resistance of 11.5 . The lasing spectrum is shown in electrooptic (EO) response on a photodetector. Fig. 5 shows the

FANG et al.: DISTRIBUTED BRAGG REFLECTOR SILICON EVANESCENT LASER 1669

Fig. 7. Extinction ratio versus dc bias for 2.5-Gb/s modulation under different

operating conditions.

Fig. 5. Photodetected frequency response of the DFB-SEL for three different

bias currents with a stage temperature of 18 C and (inset) plot of resonance

frequency versus the square root of current above threshold.

105 mA occurs due to a mode hop (Fig. 4). The modulation

characteristics change significantly on either side of the hop,

indicated by the need for a higher RF power to maintain the

same ER. We believe this change is related to the detuning from

the reflectivity peak [8], which changes signs before and after

mode hops.

Fig. 6. Eye diagrams of a directly modulated DBR-SEL at (a) 2.5 Gb/s and IV. CONCLUSION

(b) 4 Gb/s.

We demonstrated a DBF laser on the hybrid silicon evanes-

cent platform operating at 1596 nm with a sidemode suppres-

sion ratio of 50 dB. The laser operates continuous wave with

photodetected EO response of the laser combined with all con-

a lasing threshold of 65 mA and maximum output power of

nected components under small signal modulation ( 10 dBm).

11 mW at 15 C. The laser generated open eye diagrams with

S11 measurements indicate that the electrical contact geometry

extinction ratios of 8.7 and 5.5 dB for data rates of 2.5 and

is not limiting the performance of the device, so reflected power

4 Gb/s, respectively. These output characteristics are compa-

has not been factored out of these curves. A 2-pF device ca-

rable to commercially available lasers. We believe this device

pacitance was extracted from the S11 measurement, resulting

is an attractive option for a directly modulated laser to be inte-

in an RC limited bandwidth of 7 GHz. Fig. 5 (inset) shows the

grated with silicon electronics and arrayed waveguide gratings

resonance frequency versus the square root of dc drive current

in order to create low cost, scalable, silicon wavelength divi-

above threshold, which has a roughly linear dependence as ex-

sion-multiplexed transmitters.

pected. Under higher modulation powers the resonance peak be-

comes significantly dampened. The 3-dB electrical bandwidth

at 105 mA is 2.5 GHz. ACKNOWLEDGMENT

We directly modulated the laser biased at 105-mA dc current The authors would like to thank J. Shah, M. Haney,

with a 2.5 Gb/s, 2 1 PRBS electrical signal with 20 mW of M. Paniccia, H. Park, and H.-W. Chen for insightful discussions.

RF power. The resulting eye diagram is shown in Fig. 6(a). The

extinction ratio is 8.7 dB and the fiber coupled output power is

0.7 mW when cooled to 18 C. Although the output power REFERENCES

and modulation bandwidth increases at higher dc currents, the [1] D. Pasquariello and K. Hjort, “Plasma-assisted InP-to-Si low temper-

peak-to-peak (P-P) current swing corresponds to a lower P-P ature wafer bonding,” IEEE J. Sel. Topics Quantum Electron., vol. 8,

no. 1, pp. 118–131, Jan. 2002.

output power swing at higher current biases (Fig. 2). This leads [2] Q. Tong, Q. Ga, G. Hudson, G. Fountain, and P. Enquist, “Low temper-

to lower extinction ratios at higher current biases unless larger ature InP/Si wafer bonding,” Appl. Phys. Lett., vol. 84, p. 732, 2004.

RF modulation powers are used. For example, Fig. 6(b) shows [3] J. Van Campenhout et al., “Electrically pumped InP-based microdisk

lasers integrated with a nanophotonic silicon-on insulator waveguide

an eye diagram at 4 Gb/s that can be obtained with a dc bias circuit,” Opt. Express, vol. 15, no. 11, pp. 6744–6749.

of 135 mA and an RF power of 39 mW. However, in this case [4] G. Roelkens, D. Van Thourhout, R. Baets, R. Nötzel, and M. Smit,

the extinction ratio (ER) is closer to 5.5 dB. Improving the laser “Laser emission and photodetection in an InP/InGaAsP layer integrated

on and coupled to a silicon-on-insulator waveguide circuit,” Opt. Ex-

design to decrease the threshold current and increase the differ- press, vol. 14, pp. 8154–8159, 2006.

ential gain is expected to significantly improve the modulation [5] H. Park et al., “Photonic integration on hybrid silicon evanescent device

bandwidth in future devices. platform,” Advances Opt. Technol., p. 682978, 2008.

[6] A. W. Fang, E. Lively, Y.-H. Kuo, D. Liang, and J. E. Bowers, “A

Fig. 7 shows characteristics of the eye diagrams under distributed feedback silicon evanescent laser,” Opt. Express, vol. 16,

different operating conditions. Depending on network require- pp. 4413–4419, 2008.

ments, different operating points could be chosen to minimize [7] M. Bass, Handbook of Optics IV. New York: McGraw-Hill, 2001, p.

power dissipation. The differences between uncooled operation 9.4.

[8] U. Feiste, “Optimization of modulation bandwidth in DBR lasers with

and operation at 18 C result from differences in the output detuned Bragg reflectors,” IEEE J. Quantum Electron., vol. 34, no. 12,

power for a given dc bias. The discontinuity in the data near pp. 2371–2379, Dec. 1998.

View publication stats

You might also like

- Exploiting CMOS Manufacturing To Reduce Tuning Requirements For Resonant Optical DevicesDocument14 pagesExploiting CMOS Manufacturing To Reduce Tuning Requirements For Resonant Optical DevicesRamón José Pérez MenéndezNo ratings yet

- Signal-To-Noise Ratio Measurement and Radiation DaDocument6 pagesSignal-To-Noise Ratio Measurement and Radiation DaNgôn NguyễnNo ratings yet

- Micro Characterization and Degradation Mechanism of Liquid Silicone Rubber Used For External InsulationDocument10 pagesMicro Characterization and Degradation Mechanism of Liquid Silicone Rubber Used For External InsulationKurtusNo ratings yet

- Modelling MITDocument6 pagesModelling MITChandra ShettyNo ratings yet

- Design and Development of Wilkinson Power Divider For Wifi ApplicationDocument7 pagesDesign and Development of Wilkinson Power Divider For Wifi ApplicationAditya MishraNo ratings yet

- Antenna Array Elements For Ka-Band Satellite Communication On The MoveDocument6 pagesAntenna Array Elements For Ka-Band Satellite Communication On The MovelongNo ratings yet

- Compact Optical Switches and Modulators Based On DDocument13 pagesCompact Optical Switches and Modulators Based On DJorge GuerreroNo ratings yet

- SiC Si SBD FRD UFRD ComparativeDocument7 pagesSiC Si SBD FRD UFRD ComparativefgjNo ratings yet

- 4 668989 PDFDocument10 pages4 668989 PDFFadi AlsaoorNo ratings yet

- Towards An Optical FPGA - Programmable Silicon Photonic CircuitsDocument19 pagesTowards An Optical FPGA - Programmable Silicon Photonic CircuitsMurat Yasar ERTASNo ratings yet

- Oc Nov 2014 Solns JntukDocument62 pagesOc Nov 2014 Solns JntukrppvchNo ratings yet

- 15 - 2010 - Optics Letters - Efficient Light Coupling Between Dielectric Slot Waveguide and Plasmonic Slot WaveguideDocument4 pages15 - 2010 - Optics Letters - Efficient Light Coupling Between Dielectric Slot Waveguide and Plasmonic Slot WaveguideRami WahshehNo ratings yet

- A Bandpass Filter Design Using Half-Wavelength SteDocument4 pagesA Bandpass Filter Design Using Half-Wavelength SteyyryNo ratings yet

- Review LiNbO3 ModulatorsDocument15 pagesReview LiNbO3 Modulatorsmarcochiarini191067No ratings yet

- Performance Study of Optical ModulatorDocument10 pagesPerformance Study of Optical ModulatorAbu SalmanNo ratings yet

- Fabrication of A Laser-Based Microstructure For Particle AccelerationDocument3 pagesFabrication of A Laser-Based Microstructure For Particle AccelerationParticle Beam Physics LabNo ratings yet

- Quantum Dot Photonic Crystal Light SourcesDocument15 pagesQuantum Dot Photonic Crystal Light SourcesCalvin MonneNo ratings yet

- Lattice Filter: Design, Fabrication, and Characterization For Photonic Integrated CircuitsDocument23 pagesLattice Filter: Design, Fabrication, and Characterization For Photonic Integrated CircuitsTiewsoh LikyntiNo ratings yet

- Sciencedirect: Fabrication and Characterization of Optical Devices On Lithium Niobate On Insulator ChipsDocument4 pagesSciencedirect: Fabrication and Characterization of Optical Devices On Lithium Niobate On Insulator ChipskaiomichiruNo ratings yet

- Laser Printing and Femtosecond Laser Structuring of Electrode Materials For The Manufacturing of 3D Lithium-Ion Micro-BatteriesDocument6 pagesLaser Printing and Femtosecond Laser Structuring of Electrode Materials For The Manufacturing of 3D Lithium-Ion Micro-Batterieskhue tranNo ratings yet

- Communication Systems Lab SolvedDocument63 pagesCommunication Systems Lab SolvedChristy PollyNo ratings yet

- Jisheng 2020 IOP Conf. Ser. Earth Environ. Sci. 431 012003Document9 pagesJisheng 2020 IOP Conf. Ser. Earth Environ. Sci. 431 012003elcarmoNo ratings yet

- Ieps 1Document10 pagesIeps 1Sundaravathanan ChellappanNo ratings yet

- Carl WeimanDocument20 pagesCarl WeimanTushar GuptaNo ratings yet

- KamalRahim05 Microstrip Dipole AntennaDocument5 pagesKamalRahim05 Microstrip Dipole AntennaMark NguyenNo ratings yet

- LaserDocument7 pagesLaserSreenath R NairNo ratings yet

- Development of An Amplified Variable Shaped Long PDocument4 pagesDevelopment of An Amplified Variable Shaped Long PIbrahim AbdelfattahNo ratings yet

- Optical Phase Modulators For MHZ and GHZ Modulation in Silicon-On-Insulator (Soi)Document10 pagesOptical Phase Modulators For MHZ and GHZ Modulation in Silicon-On-Insulator (Soi)Azie BasirNo ratings yet

- Antenna Design EquationsDocument9 pagesAntenna Design EquationsSreeja SujithNo ratings yet

- Guard Rings Pramana Aug 2005Document14 pagesGuard Rings Pramana Aug 2005Vishal SrivastavaNo ratings yet

- Using Diode Lasers For Atomic Physics WiemanDocument20 pagesUsing Diode Lasers For Atomic Physics WiemanMario Ricardo Montero HurtadoNo ratings yet

- On PD-SOIDocument27 pagesOn PD-SOIpramodagarwal_nitrklNo ratings yet

- Wide Band Gap SemiconductorsDocument45 pagesWide Band Gap SemiconductorspawaniitkgpNo ratings yet

- Flashover Performance of Ice-Covered Post Insulators With Booster Sheds Using Experiments and Partial Arc ModelingDocument8 pagesFlashover Performance of Ice-Covered Post Insulators With Booster Sheds Using Experiments and Partial Arc ModelingDavid GutierrezNo ratings yet

- 3PL SiOC-ErDocument6 pages3PL SiOC-ErMagui Ros MonNo ratings yet

- Influence of Interconnection Concepts For IBC Solar Cell Performance by SimulationDocument9 pagesInfluence of Interconnection Concepts For IBC Solar Cell Performance by SimulationloydtarrosaNo ratings yet

- A High Return Loss of Microwave Bandpass Filter Using Superconducting Electrospun YBCO NanostructuresDocument14 pagesA High Return Loss of Microwave Bandpass Filter Using Superconducting Electrospun YBCO NanostructuresyyryNo ratings yet

- 1 s2.0 S0026271421003899 MainDocument7 pages1 s2.0 S0026271421003899 MainSaqib Ali KhanNo ratings yet

- Microstrip Inductor Design and ImplementationDocument5 pagesMicrostrip Inductor Design and Implementationp.mallikarjunaNo ratings yet

- Irjet V4i8364 PDFDocument2 pagesIrjet V4i8364 PDFNixon IsraelNo ratings yet

- Fabrication of Arbitraily Narrow Vertical Dielectric Slots in Silicon WaveguidesDocument4 pagesFabrication of Arbitraily Narrow Vertical Dielectric Slots in Silicon Waveguidesjames byersNo ratings yet

- Ofcli 2Document5 pagesOfcli 2ALINo ratings yet

- Fulltext01 PDFDocument74 pagesFulltext01 PDFKawsar MobinNo ratings yet

- Rectangular Microstrip Patch Antenna With EBG Structure: December 2012Document7 pagesRectangular Microstrip Patch Antenna With EBG Structure: December 2012Mylavarapu SriprithamNo ratings yet

- Progress in High Performance DI-BSCCO WireDocument10 pagesProgress in High Performance DI-BSCCO Wirehariyati lubisNo ratings yet

- Ultralow Loss Single Layer Submicron Silicon waveguide-CROSSINGDocument10 pagesUltralow Loss Single Layer Submicron Silicon waveguide-CROSSINGjohn xuNo ratings yet

- Losses in Optical FiberDocument30 pagesLosses in Optical FiberMarcus FNo ratings yet

- High-Performance Macromodel of The Quarter-Wavelength Solidly Mounted ResonatorDocument5 pagesHigh-Performance Macromodel of The Quarter-Wavelength Solidly Mounted ResonatorVinita ChoudharyNo ratings yet

- E3sconf Icbte2019 01035Document4 pagesE3sconf Icbte2019 01035saravanan jNo ratings yet

- Bulk Acoustic Wave ResonatorsDocument4 pagesBulk Acoustic Wave Resonatorsscr1beNo ratings yet

- Module 6 7 Electrical Wiring Design2Document8 pagesModule 6 7 Electrical Wiring Design2moonbin sarangNo ratings yet

- 11 - 2014 - FIO - Ultra-Compact Integrated Nanoplasmonic Air-Gap CouplerDocument2 pages11 - 2014 - FIO - Ultra-Compact Integrated Nanoplasmonic Air-Gap CouplerRami WahshehNo ratings yet

- Low-Loss Silicon Integrated Aluminum Nitride PhotoDocument20 pagesLow-Loss Silicon Integrated Aluminum Nitride PhotoEunso ShinNo ratings yet

- Miniaturized Microstrip Wilkinson Power Divider With Harmonic SuppressionDocument3 pagesMiniaturized Microstrip Wilkinson Power Divider With Harmonic Suppressionmakarandkulkarni1No ratings yet

- 21 - 2009 - HONET - Silicon Microring Vertical CouplerDocument4 pages21 - 2009 - HONET - Silicon Microring Vertical CouplerRami WahshehNo ratings yet

- Micro Electret Power GeneratorDocument5 pagesMicro Electret Power GeneratorOmkar DashNo ratings yet

- 2018ParametricStudyofModifiedU shapedSplitRingDocument6 pages2018ParametricStudyofModifiedU shapedSplitRingAkhilkumar Singh RathoreNo ratings yet

- Fabrication of Vacuum Tube Arrays With A Sub-Micron Dimension Using Anodic Aluminum Oxide Nano-TemplatesDocument6 pagesFabrication of Vacuum Tube Arrays With A Sub-Micron Dimension Using Anodic Aluminum Oxide Nano-TemplatesyahyaNo ratings yet

- Nghia 2016Document6 pagesNghia 2016Thái Trần DanhNo ratings yet

- SPK Task 1Document4 pagesSPK Task 1Thái Trần DanhNo ratings yet

- Applications of Image Processing For Grading Agriculture ProductsDocument9 pagesApplications of Image Processing For Grading Agriculture ProductsThái Trần DanhNo ratings yet

- Medium Access Control Design For all-IP and Ad Hoc Wireless NetwoDocument138 pagesMedium Access Control Design For all-IP and Ad Hoc Wireless NetwoThái Trần DanhNo ratings yet

- JLT2012Document12 pagesJLT2012Thái Trần DanhNo ratings yet

- A Photodiode-Based, Low-Cost Telemetric-Lidar For The Continuous Monitoring of Urban Particulate MatterDocument17 pagesA Photodiode-Based, Low-Cost Telemetric-Lidar For The Continuous Monitoring of Urban Particulate MatterThái Trần DanhNo ratings yet

- Distributed Bragg Reflector LasersDocument16 pagesDistributed Bragg Reflector LasersThái Trần DanhNo ratings yet

- Open The Way To Future Networks - A Viewpoint FramDocument13 pagesOpen The Way To Future Networks - A Viewpoint FramThái Trần DanhNo ratings yet

- Open The Way To Future Networks - A Viewpoint FramDocument13 pagesOpen The Way To Future Networks - A Viewpoint FramThái Trần DanhNo ratings yet

- Fullpaper ICSE2008Document6 pagesFullpaper ICSE2008Thái Trần DanhNo ratings yet

- Maca-P A Mac Protocol To Improve Parallelism in MuDocument16 pagesMaca-P A Mac Protocol To Improve Parallelism in MuThái Trần DanhNo ratings yet

- Writing Tools I Use: Tool 1Document7 pagesWriting Tools I Use: Tool 1Thái Trần DanhNo ratings yet

- Laterally Coupled DBR Laser Emitting atDocument3 pagesLaterally Coupled DBR Laser Emitting atThái Trần DanhNo ratings yet

- Digital Wavelength-Selected DBR LaserDocument15 pagesDigital Wavelength-Selected DBR LaserThái Trần DanhNo ratings yet

- Lịch tiêm vaccine Covid19Document25 pagesLịch tiêm vaccine Covid19Thái Trần DanhNo ratings yet

- Interviewing Skill Development v3.0Document27 pagesInterviewing Skill Development v3.0Thái Trần DanhNo ratings yet

- An Improved Time-Based One Time Password Authentication Framework For Electronic PaymentsDocument9 pagesAn Improved Time-Based One Time Password Authentication Framework For Electronic PaymentsThái Trần DanhNo ratings yet

- Smith Chart From Black Magic DesignDocument1 pageSmith Chart From Black Magic DesignkgrhoadsNo ratings yet

- O Using A Foreign Key: @onetooneDocument2 pagesO Using A Foreign Key: @onetooneThái Trần DanhNo ratings yet

- History LasersDocument8 pagesHistory LasersVivek SuranaNo ratings yet

- đề 22-23 (bt ở nhà)Document6 pagesđề 22-23 (bt ở nhà)Nguyễn Tuấn VũNo ratings yet

- LASERDocument30 pagesLASERanilm130484meNo ratings yet

- UltravioletDocument17 pagesUltravioletDhanmeet KaurNo ratings yet

- Assign 4175Document8 pagesAssign 4175Md pacificNo ratings yet

- Afbr S50MV85G DS104 D4Document18 pagesAfbr S50MV85G DS104 D4niroshan047No ratings yet

- Nova User Manual 0Document92 pagesNova User Manual 0Alin ANo ratings yet

- Argonne's Advanced Photon Source/Laser Applications Lab - EC&G Mound's Laser & Photonics CenterDocument70 pagesArgonne's Advanced Photon Source/Laser Applications Lab - EC&G Mound's Laser & Photonics CenterSofiane MelkiNo ratings yet

- Laser Gauge InstructionsDocument11 pagesLaser Gauge InstructionsKnezNo ratings yet

- 2012 FEIYUE Light Price ListDocument17 pages2012 FEIYUE Light Price ListEduardo te SanchezNo ratings yet

- An Overview of DWDMDocument19 pagesAn Overview of DWDMArindamDuttaChoudhury100% (15)

- Electro-Culture of PlantsDocument11 pagesElectro-Culture of PlantsAC5CHNo ratings yet

- Laser Cooling Luis Orozco PDFDocument31 pagesLaser Cooling Luis Orozco PDFEduardo Latorre LópezNo ratings yet

- Application of Modern Physics in ElectronicsDocument12 pagesApplication of Modern Physics in ElectronicsFurkan Erdoğan100% (1)

- Mir MoscowDocument69 pagesMir MoscowRitankar Ghosh100% (1)

- 数字硬件简卡英文Document11 pages数字硬件简卡英文johanes kharismaNo ratings yet

- G.C LoataDocument228 pagesG.C LoataAkhil RoutNo ratings yet

- Civilug PDFDocument272 pagesCivilug PDF90302 49233No ratings yet

- Turbine AlignmentDocument1 pageTurbine AlignmentGuru Raja Ragavendran NagarajanNo ratings yet

- Grandway Fhs2q01f Light SourceDocument2 pagesGrandway Fhs2q01f Light SourceCarbon Nano TubeNo ratings yet

- Yawei CKY Laser Machines Catalog CFFP CFFC CFFTDocument9 pagesYawei CKY Laser Machines Catalog CFFP CFFC CFFTdavidferrerNo ratings yet

- Laser HardeningDocument3 pagesLaser HardeningsaiNo ratings yet

- Laser - 2nd BPT - 1st ClassDocument20 pagesLaser - 2nd BPT - 1st Classamitesh_mpthNo ratings yet

- Konica Drypro832 Install (0921YF220A)Document230 pagesKonica Drypro832 Install (0921YF220A)Omar Stalin Lucio Ron67% (3)

- Finger NailDocument17 pagesFinger NailEfe Osato83% (6)

- Optoelectronic Devices SyllabusDocument1 pageOptoelectronic Devices SyllabusRAJESHNo ratings yet

- E3NC Series: Smart Laser SensorDocument14 pagesE3NC Series: Smart Laser SensorGita Indra HariesdaNo ratings yet

- Laser Beam Machining Definition Working Process Principle Advantages Disadvantages Application NotesDocument4 pagesLaser Beam Machining Definition Working Process Principle Advantages Disadvantages Application NotesMD Al-AminNo ratings yet

- ParticleDocument31 pagesParticlejustmenobleskNo ratings yet

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeFrom EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeRating: 5 out of 5 stars5/5 (8)

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesFrom EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesRating: 5 out of 5 stars5/5 (1)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionFrom EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionRating: 4.5 out of 5 stars4.5/5 (543)

- Complete Electronics Self-Teaching Guide with ProjectsFrom EverandComplete Electronics Self-Teaching Guide with ProjectsRating: 3 out of 5 stars3/5 (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialFrom EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialRating: 3.5 out of 5 stars3.5/5 (3)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersFrom Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersRating: 5 out of 5 stars5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsFrom EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsRating: 3.5 out of 5 stars3.5/5 (2)

- C++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingFrom EverandC++ Programming Language: Simple, Short, and Straightforward Way of Learning C++ ProgrammingRating: 4 out of 5 stars4/5 (1)

- Teach Yourself Electricity and Electronics, 6th EditionFrom EverandTeach Yourself Electricity and Electronics, 6th EditionRating: 3.5 out of 5 stars3.5/5 (15)

- Collection of Raspberry Pi ProjectsFrom EverandCollection of Raspberry Pi ProjectsRating: 5 out of 5 stars5/5 (1)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)From EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Rating: 4.5 out of 5 stars4.5/5 (2)

- Current Interruption Transients CalculationFrom EverandCurrent Interruption Transients CalculationRating: 4 out of 5 stars4/5 (1)

- ARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)From EverandARDUINO CODE: Mastering Arduino Programming for Embedded Systems (2024 Guide)No ratings yet

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesFrom EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesRating: 5 out of 5 stars5/5 (1)

- Understanding Automotive Electronics: An Engineering PerspectiveFrom EverandUnderstanding Automotive Electronics: An Engineering PerspectiveRating: 3.5 out of 5 stars3.5/5 (16)

- Open Radio Access Network (O-RAN) Systems Architecture and DesignFrom EverandOpen Radio Access Network (O-RAN) Systems Architecture and DesignNo ratings yet

- The Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026From EverandThe Fast Track to Your Technician Class Ham Radio License: For Exams July 1, 2022 - June 30, 2026Rating: 5 out of 5 stars5/5 (1)

- Build Your Own Electric Vehicle, Third EditionFrom EverandBuild Your Own Electric Vehicle, Third EditionRating: 4.5 out of 5 stars4.5/5 (3)

- Practical Electronics for Inventors, Fourth EditionFrom EverandPractical Electronics for Inventors, Fourth EditionRating: 4 out of 5 stars4/5 (3)

- Practical Troubleshooting of Electrical Equipment and Control CircuitsFrom EverandPractical Troubleshooting of Electrical Equipment and Control CircuitsRating: 4 out of 5 stars4/5 (5)