Professional Documents

Culture Documents

Laser Gauge Instructions

Uploaded by

KnezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Laser Gauge Instructions

Uploaded by

KnezCopyright:

Available Formats

L-GAGE® LG Laser Gauging Sensors

Datasheet

• Self-contained Class 2 modulated visible laser gauging sensor needs no separate

controller

• Narrow effective beam is excellent for precision gauging applications such as

distance, height, or thickness measurement

• Resolution to better than 3 microns for LG5 Series models and better than 10

microns for LG10 Series models

• Banner’s unique scalable analog output automatically distributes the output signal

over the width of the programmed sensing window 1

• Analog and discrete (switched) outputs with independent window limits

• Analog output slope is either positive or negative, depending upon which window

limit is programmed first

• Fast, easy-to-use integrated push-button TEACH-mode programming; no

potentiometer adjustments – Remote TEACH function for security and

convenience

• Unique feature holds analog output value for 2 seconds upon loss of signal

• Modulated laser beam and narrow optical band-pass filter provide a high level of

ambient light immunity, including immunity from high-energy factory lighting

• Alarm output for signal saturation and overload of discrete output

• Output response is programmable for three speeds

• Supply voltage: 12 to 30 V dc

WARNING: Not To Be Used for Personnel Protection

Never use this device as a sensing device for personnel protection. Doing so could lead to serious injury or death.

This device does not include the self-checking redundant circuitry necessary to allow its use in personnel safety

applications. A sensor failure or malfunction can cause either an energized or de-energized sensor output

condition.

Models

Analog Current Output Analog Voltage Output

Sensing Distance Focal Point 2 Cable 3 Discrete Output

Models (4–20 mA) Models (0–10 V dc)

LG5A65PI LG5A65PU 2 m (6.5 ft) (8-wire)

PNP (Sourcing)

LG5A65PIQ LG5A65PUQ 70 mm (2.8 inches) Pigtail QD (8-pin Euro)

Beam size at 53 mm: 0.4 x 0.6 mm

LG5A65NI LG5A65NU (0.016 x 0.024 inches) 2 m (6.5 ft) (8-wire)

NPN (Sinking)

LG5A65NIQ LG5A65NUQ 45 to 60 mm (1.8 to Pigtail QD (8-pin Euro)

LG5B65PI LG5B65PU 2.4 inches) 2 m (6.5 ft) (8-wire)

PNP (Sourcing)

LG5B65PIQ LG5B65PUQ 53 mm (2.1 inches) Pigtail QD (8-pin Euro)

Beam size at 53 mm: 0.1 mm (0.004

LG5B65NI LG5B65NU inches) 2 m (6.5 ft) (8-wire)

NPN (Sinking)

LG5B65NIQ LG5B65NUQ Pigtail QD (8-pin Euro)

LG10A65PI LG10A65PU 2 m (6.5 ft) (8-wire)

PNP (Sourcing)

LG10A65PIQ LG10A65PUQ 180 mm (7.1 inches) Pigtail QD (8-pin Euro)

75 to 125 mm (2.9 to

4.9 inches) Beam size at 125 mm: 0.6 x 0.8 mm

LG10A65NI LG10A65NU (0.024 x 0.031 inches) 2 m (6.5 ft) (8-wire)

NPN (Sinking)

LG10A65NIQ LG10A65NUQ Pigtail QD (8-pin Euro)

1 Patent(s) issued or pending.

2 The focal point is the distance, measured from the sensor lens, at which the laser image is smallest.

3 To order the 9 m (30 ft) cable model, add suffix "W/30" to the cabled model number (LG5A65PI W/30).

Original Document 23 May 2017

59786 Rev. G

59786

L-GAGE® LG Laser Gauging Sensors

Overview

Banner’s Class 2 visible laser displacement sensor brings a sophisticated yet cost-effective solution to precision measurement

applications. L-GAGE Series sensors feature all-in-one design and require no separate controller.

The L-Gage Laser Gauging System operates in two modes: TEACH (or programming) and RUN. Near and far sensing window limits are set

quickly using simple push-button or remote signal TEACH-mode programming. One sensor can simultaneously provide both analog and

discrete (switched) outputs. Sensing window limits for each output may be independently programmed. The analog signal features

Banner’s unique scalable output (patent pending), which automatically distributes the output signal over the width of the programmed

sensing window.

The L-GAGE Laser Gauging Sensor boasts many additional features, including selectable response speed, self-diagnostics with alarm

output, comprehensive status indicator system, and unique output “hold” function in case of momentary signal loss in profiling

applications.

Optical Triangulation

The design of the L-GAGE Laser Gauging Sensor is based on optical triangulation. An PSD Receiver

Element

emitter transmits visible laser light through a lens, toward a target. The laser light

R

beam from the emitter bounces off the target, scattering some of its light through

another lens to the sensor’s PSD (position-sensitive device) receiver element. The Signal

target’s distance from the receiver determines the angle the light travels to the Conditioning Near Far

receiver element; this angle in turn determines where the received light will fall Circuitry Lenses Limit Limit

along the PSD receiver element. Target Movement

Microprocessor

The position of the light on the PSD receiver element is processed through analog

and digital electronics and analyzed by the microprocessor, which calculates the

appropriate output value. The analog output provides a variable signal that is Output

proportional to the target’s position within the user-programmed analog window Circuitry

limits. The discrete (switched) output energizes whenever the target is located Emitter

E

between the user-programmed discrete window limits. Analog and discrete window Circuitry

limits may be the same, or programmed independently. Laser

Emitter

Programmed

Sensing Window

Indicators

Signal LED. The Signal LED indicates the strength and condition of the sensor’s incoming signal.

Signal LED Status Indicates

OFF No signal is received, or the target is beyond the range limitations of the sensor (with some

tolerance beyond the recommended minimum and maximum sensing distance)

Flashing at 2 Hz Received signal is adequate for processing

Flashing at 10 Hz Received signal is in saturation (signal is too strong); alarm output energizes

ON Solid Received signal is within the nominal conditions for the sensor

Output LED. The Output LED lights when the discrete output is conducting.

Power ON/OFF LED. The Power ON/OFF LED indicates the operating status of the sensor.

Power ON/OFF LED Status Indicates

OFF Power is OFF

Flashing at 2 Hz Discrete or alarm output is overloaded

Flashing at 1 Hz Power ON, Laser is disabled

ON Solid Sensor is operating normally (power is ON, Laser enabled)

Power Up/Laser Enable. When powering up the sensor, the following should occur:

• All LEDs turn ON for 1 second

• Allow 1.25 second delay for Laser Enable at power up. (If sensor is already powered up, allow 0.25 second for Laser Enable.)

2 www.bannerengineering.com - Tel: +1-763-544-3164 P/N 59786 Rev. G

L-GAGE® LG Laser Gauging Sensors

Configuration Instructions

Sensor Programming

Program the sensor using either the sensor’s keypad or via remote

programming. Remote programming is also used to disable the

keypad for security, preventing unauthorized or accidental

Response Speed

programming adjustment on the production floor. Push Button

Response Speed

Indicators

Teach LED

Analog Output

Programming Push Button

Discrete (Switched) Output

Programming Push Button

Signal LED

Output LED

Power ON/OFF LED

Remote Programming

For remote programming, connect the sensor’s yellow wire to +5 to 30V dc, with a remote programming switch connected between

them. The impedance of the remote teach input is 18 kΩ minimum (65 kΩ minimum at 5V).

To program the sensor, follow the sequence of input pulses, button pushes, and “clicks” for programming on the sensor buttons. The

duration of each pulse (corresponding to a push button “click”), and the period between multiple pulses, are defined as: 0.04 seconds <

T < 0.8 seconds.

Analog Output Slope

The L-GAGE Laser Gauge may be programmed for either a positive or a negative output slope, based on which condition is taught first. If

the near limit is taught first, the slope will be positive; if the far limit is taught first, the slope will be negative. Banner’s unique scalable

analog output (patent pending) automatically distributes the output signal over the width of the programmed sensing window. Factory

analog output is 0 to 10V dc (LG..U models) or 4 to 20 mA (LG..I models).

Current Models Voltage Models

20 10

Analog Voltage Output (V dc)

Positive Positive

Slope Slope

Analog Output (mA)

0

4

Near Far

Near Far Window Window

Window Window Target Position

Target Position

Analog output as a function of target position

The L-GAGE also features a 2-second hold upon loss of the analog signal, which is useful for profiling and similar applications. In the

event of analog signal loss for longer than 2 seconds, the analog output goes to 0V dc (LG..U models) or 4 mA (LG..I models).

P/N 59786 Rev. G www.bannerengineering.com - Tel: +1-763-544-3164 3

L-GAGE® LG Laser Gauging Sensors

Teaching Analog Limits Using the Auto-Zero Feature (Analog Output)

For some analog applications, a sensing distance set point centered within a sensing window may be required. The TEACH procedure is

simple: teaching the same limit twice causes the sensor to program a window centered on the position taught. This window is 10 mm

wide (taught position ± 5 mm).

Teaching Fixed-Field Sensing Mode (Discrete Output)

Teaching the same limit twice creates a sensing window with the far limit at the teach distance and the near limit at the minimum

operating range of the sensor (approx. 42 mm for LG5 Series models, and approx. 60 mm for LG10 Series models).

Beam Dimensions (Typical)

Focal Point Distance Beam Width (X) Beam Height (Y)

LG5 Series

45 mm 0.3 mm 0.5 mm

53 mm (2.1 inches) 53 mm 0.1 mm 0.1 mm

Y 60 mm 0.3 mm 0.5 mm

45 mm 0.6 mm 0.9 mm

X 70 mm (2.8 inches) 53 mm 0.4 mm 0.6 mm

60 mm 0.3 mm 0.4 mm

LG10 Series

75 mm 1.1 mm 1.5 mm

180 mm (7.1 inches) 100 mm 0.8 mm 1.1 mm

125 mm 0.6 mm 0.8 mm

The focal point is the distance, measured from the sensor lens, at which the laser image is smallest.

Teaching Limits for Either Analog or Discrete Output

Either output may be programmed first. For the button or the remote wire, a button click or pulse is: 0.04 seconds ≤ T ≤ 0.8 seconds.

1. Enter programming mode.

Method Action Result

TEACH LED turns ON:

Red — Analog output

Push Button Push and hold the button for Analog or Discrete output for more than 2 seconds4

Green — Discrete output

Sensor is waiting for first limit

Remote Input No action required

2. Teach the first limit.

Method Action Result

TEACH LED flashes at 2 Hz

Push Button Position the target for the first limit and click the same button Sensor learns first limit and waits for second

limit

TEACH LED turns ON:

Red — Analog output

Position the target for the first limit. For the analog output, double-pulse the remote Green — Discrete output

Remote Input

line. For the discrete output, single-pulse the remote line. TEACH LED flashes at 2 Hz

Sensor learns first limit and waits for second

limit

4 Sensor returns to Run mode if the first TEACH condition is not registered within 120 seconds.

4 www.bannerengineering.com - Tel: +1-763-544-3164 P/N 59786 Rev. G

L-GAGE® LG Laser Gauging Sensors

3. Teach the second limit.

Method Action Result

Push Button Position the target for the second limit and click the same button TEACH LED goes OFF

Sensor learns second limit and returns

Remote Input Position the target for the second limit and single-pulse the remote line automatically to RUN mode

4. Repeat for the other output if a second output is desired.

Teaching Limits for Analog and Discrete Outputs Simultaneously

Both analog and discrete outputs will have identical limits. For the button or the remote wire, a button click or pulse is: 0.04 seconds ≤ T

≤ 0.8 seconds.

1. Enter programming mode.

Method Action Result

Push and hold either button for more than 2 seconds5 TEACH LED turns ON: Yellow

Push Button

Briefly click the other button Sensor is waiting for first limit

Remote Input No action required

2. Teach the first limit.

Method Action Result

TEACH LED flashes at 2 Hz, alternating Red and

Green

Push Button Position the target for the first limit and click either button

Sensor learns first limit and waits for second

limit

TEACH LED turns ON: Yellow

Sensor learns first limit and waits for second

Remote Input Position the target for the first limit and triple-pulse the remote line limit

TEACH LED flashes at 2 Hz, alternating Red and

Green

3. Teach the second limit.

Method Action Result

Push Button Position the target for the second limit and click either button TEACH LED goes OFF

Sensor learns second limit and returns

Remote Input Position the target for the second limit and single-pulse the remote line automatically to Run mode

Sensor Configuration

Response Speed. Use the Speed push button to toggle between the three response speed settings. The combination of indicator lights

(Fast and Slow) will tell you which of the three is selected:

Slow Fast Analog Output Frequency Response (–3 dB) Discrete Output Response Speed

ON OFF 4.5 Hz 100 milliseconds

ON ON 45 Hz 10 milliseconds

OFF ON 450 Hz 2 milliseconds

Push Button Lockout. Enables or disables the keypad to prevent accidental or unauthorized adjustment of the programming settings.

Procedure

Remote Wire (0.04 sec. < T < Result

Push Button 0.8 sec.)

Enable/Disable Push Buttons Not available via push button Four-pulse the remote line Push buttons are either enabled

or disabled, depending on

previous condition

5 Sensor returns to Run mode if first TEACH condition is not registered within 120 seconds.

P/N 59786 Rev. G www.bannerengineering.com - Tel: +1-763-544-3164 5

L-GAGE® LG Laser Gauging Sensors

Installation Notes

Some targets (those with a stepped plane facing the sensor, a boundary line, or rounded targets) pose specific problems for sensing

distances. The following two images illustrate sensor orientations for typical targets.

Recommended

Not Recommended

WARNING: Class 2 Safety Notes

Low-power lasers are by definition incapable of causing eye injury within the duration of the blink, or aversion

response of 0.25 seconds. They must also emit only visible wavelengths (400-700 nm). Therefore, an ocular hazard

can only exist if an individual overcomes their natural aversion to bright light and stares directly into the laser

beam. The device requirements for these lasers are to have a [hazard] label and to have an indicator light to

indicate laser emission.

The two operational safety rules are:

• Do not permit a person to stare at the laser from within the beam

• Do not point the laser at a person's eye at close range

6 www.bannerengineering.com - Tel: +1-763-544-3164 P/N 59786 Rev. G

L-GAGE® LG Laser Gauging Sensors

WARNING:

Beam Paths

The beam emitted by a class 2 laser product should be terminated

at the end of its useful path. Open laser beam paths should be

located above or below eye level where practical.

CAUTION: Do Not Disassemble for Repair

This device contains no user-serviceable components. Do not

RADIANT POWER 0.2 mW attempt to disassemble for repair. Use of controls or adjustments

9.8KHz 11-20% DUTY CYCLE or performance of procedures other than those specified herein

640 - 660 nm may result in hazardous radiation exposure. A defective unit must

Complies to 21CFR, Parts 1040.10 and be returned to the manufacturer.

1040.11 except for deviations pursuant to

Laser Notice 50, dated 7-26-01.

Wiring Diagrams

Wiring connections are functionally identical for either integral or QD cable.

NPN Models PNP Models Key

1 = White

2 2

+ + 2 = Brown

7

12–30 V dc

7

12–30 V dc 3 = Green

– – 4 = Yellow

1

+

4–20 mA 1 4–20 mA 5 = Gray

– or 0–10 V +

Discrete

– or 0–10 V 6 = Pink

5

Load 5

Discrete 7 = Blue

Load 8 = Shield

Alarm

6 Alarm

Load 6

Load

4 Remote + 5–30 V dc 4

Teach Remote + 5–30 V dc

3 Laser Teach

+ 5–30 V dc ON 3

Control Laser + 5–30 V dc ON

0 V dc OFF

8 Shield* Control 0 V dc OFF

8 Shield*

4 to 20 mA (LG..I models) or 0 to 10V dc (LG..U models)

*The bare shield wire is connected internally to the sensor housing and should be connected as follows:

1. If the sensor housing is mounted so that it is in continuity with both the machine frame and earth ground, connect the bare

wire (also) to earth ground.

2. If the sensor housing is mounted so that it is insulated from the machine frame, connect the bare wire to -V dc (together with

the blue wire).

3. If the sensor is mounted so that it is in continuity with the machine frame, but not with earth ground, do not connect the bare

wire (i.e. cut off the bare wire).

Conversion from Current to Voltage Output (LGxI Models Only)

bn + Typical Voltage Response

bu 12-30V dc Value of R Output Voltage

** – 250 Ω 1 to 5 V

R V 500 Ω 2 to 10 V

wh

**For best results, install a small amount of

capacitance (e.g., 0.1 μF) in parallel with the load resistor

P/N 59786 Rev. G www.bannerengineering.com - Tel: +1-763-544-3164 7

L-GAGE® LG Laser Gauging Sensors

Specifications

Supply Voltage Output Configurations

12 to 30 V dc (10% maximum ripple); 50 mA max at 24 V dc (exclusive of load) Discrete (switched) and alarm outputs: SPST solid-state switch; choose NPN

(current sinking) or PNP (current sourcing) models

Supply Protection Circuitry Analog current output (LG...I Models): 4 to 20 mA or 20 to 4 mA (current

Protected against reverse polarity and transient over voltages sourcing)

Sensing Range Analog voltage output (LG...U Models): 0 to 10 V dc or 10 to 0 V dc (voltage

sourcing)

LG5: 45 to 60 mm (1.77 to 2.36 inches)

LG10: 75 to 125 mm (2.95 to 4.92 inches) Output Ratings

Delay at Power-up Discrete (switched) and Alarm outputs: 100 mA maximum

1.25 seconds OFF-state leakage current: less than 5 microamps

Output saturation voltage - PNP outputs: less than 1.2 volts at 10 mA and less

Sensing Beam than 1.6 volts at 100 mA

650 nm visible red IEC and CDRH Class 2 laser; 0.20 mW radiant output power Output saturation voltage - NPN outputs: less than 200 millivolts at 10 mA and

less than 600 millivolts at 100 mA

Adjustments Analog output (LG...I Models): 1 kΩ max at 24 V dc, max load resistance = [(Vcc

Response speed: Push button toggles between Slow, Medium, and Fast (see - 4.5)/0.02]Ω

Output Response Time) Analog output (LG...U Models): 2.5 kΩ minimum load impedance

Window limits (analog or discrete): TEACH-mode programming of near and far

window limits (see programming procedure). Limits may also be taught Output Protection

remotely. Discrete and alarm outputs are protected against continuous overload and

Analog output slope: The first limit taught is assigned to the minimum analog short circuit

output. Analog Output (–3 dB) Response Time

Construction Fast: 450 Hz (1 millisecond average with 1 millisecond update rate)

Housing: Zinc alloy die-cast, plated and painted finish Medium: 45 Hz (10 millisecond average with 2 millisecond update rate)

Cover plate: aluminum with painted finish Slow: 4.5 Hz (100 millisecond average with 5 millisecond update rate)

Lens: acrylic Discrete Output Response Time

Connections Fast: 2.0 milliseconds ON and OFF

2 m (6.5 ft) or 9 m (30 ft) 7-conductor shielded PVC-jacketed attached cable, or Medium: 10 milliseconds ON and OFF

150 mm (6 in) 8-pin Euro-style pigtail quick-disconnect. Mating QD cables are Slow: 100 milliseconds ON and OFF

purchased separately.

Analog Resolution and Repeatability of Discrete Trip Point6(LG5) Analog Resolution and Repeatability of Discrete Trip Point6(LG10)

Fast: < 40 microns @ 50 mm Fast: < 150 microns @ 100 mm

Medium: < 12 microns @ 50 mm Medium: < 50 microns @ 100 mm

Slow: < 3 microns @ 50 mm Slow: < 10 microns @ 100 mm

Analog Linearity6 (LG5) Analog Linearity6 (LG10)

±60 microns (±0.002") over 45 to 60 mm sensing window ±200 microns (±0.008 inches) over 75 to 125 mm sensing window

±10 microns (±0.0003") over 49 to 51 mm sensing window ±20 microns (±0.0008 inches) over 95 to 100 mm sensing window

Minimum Window Size (Analog or Discrete) Hysteresis (Discrete Output)

LG5: 1.5 mm (0.06 inches) LG5: < 0.2 mm (0.008 inches)

LG10: 5 mm (0.2 inches) LG10: < 1.0 mm (0.04 inches)

Color Sensitivity (typical) Temperature Drift

LG5: < 75 microns (0.003 inches) for white to dark gray ceramic target LG5: ±7 microns/°C

LG10: < 100 microns (0.004 inches) for white to dark gray ceramic target LG10: ±25 microns/°C

Remote TEACH and Laser Control Input Impedance Laser Control

18 kΩ minimum (65 kΩ at 5V dc) To enable laser: Connect green wire to +5 to 30 V dc

To disable laser: Connect green wire to 0 to +2 V dc (or open connection)

Remote TEACH

250 millisecond delay upon enable/disable

To teach: Connect yellow wire to +5 to 30 V dc

To disable: Connect yellow wire to 0 to +2 V dc (or open connection)

6 Resolution and linearity specified @ 24 V dc, 22 °C, using a white ceramic test surface (see Application Notes)

8 www.bannerengineering.com - Tel: +1-763-544-3164 P/N 59786 Rev. G

L-GAGE® LG Laser Gauging Sensors

Application Notes Required Overcurrent Protection

For comparison, a white ceramic test surface has approximately 91% of the

reflectivity of a white Kodak test card with a matte finish. A dark gray ceramic WARNING: Electrical connections must be made

test surface has approximately 11% of the reflectivity of a white Kodak test by qualified personnel in accordance with local

card with a matte finish. (Allow 15-minute warm-up for maximum linearity.) and national electrical codes and regulations.

Operating Conditions Overcurrent protection is required to be provided by end product application

Temperature: –10 °C to 50 °C (14 °F to 122 °F) per the supplied table.

Maximum relative humidity: 90% at +50 °C, non-condensing Overcurrent protection may be provided with external fusing or via Current

Environmental rating Limiting, Class 2 Power Supply.

Supply wiring leads < 24 AWG shall not be spliced.

IP67, NEMA 6

For additional product support, go to www.bannerengineering.com.

Vibration and Mechanical Shock

Vibration: 60 Hz, 30 minutes, 3 axes Supply Wiring (AWG) Required Overcurrent Protection (Amps)

Shock: 30G for 11 milliseconds, half sine wave, 3 axes

20 5.0

Certifications

22 3.0

24 2.0

26 1.0

28 0.8

30 0.5

Resolution

The following charts illustrate the L-GAGE resolution with respect to speed (typical, using a white ceramic target).

LG5 Models LG10 Models

LG Models LG10 Models

225

45 Fast

200

40

Resolution (microns)

175

Resolution (microns)

35 150

30 125

25

Fast 100

75 Medium

20

50

15 25

10 0

Slow

Medium 75 95 105 115 125 135

5

Slow Distance (mm)

0

45 50 55 60 65

Distance (mm)

P/N 59786 Rev. G www.bannerengineering.com - Tel: +1-763-544-3164 9

L-GAGE® LG Laser Gauging Sensors

Dimensions

20.2 mm (0.80")

55.3 mm

(2.18")

45.5 mm

(1.79")

4.6 mm

(0.18") RA

Emitted Light

9.8K DIAN

Hz T P

Com 11-2 OW

1040 plie 64 0% ER 0.

.11 s to 21 0 - 66DUTY 2 mW

Laseexcept CFR 0 nm CYC

r N for , Par

otic devi ts 10

LE 23.9 mm

(0.94")

e 50 atio 40

, da ns .10

ted purs and

7-26 uant

-01. to

Received Light

19.1 mm

68.3 mm (0.75")

(2.69")

82.3 mm

Clearance for M4 (#8)

(3.24")

9.3 mm Screws (2 places)

(0.37")

Mounting hardware (M4) is included.

Accessories

Cordsets

8-Pin Threaded M12/Euro-Style Cordsets with Shield

Model Length Style Dimensions Pinout (Female)

2

3

MQDC-806 1.83 m (6 ft) 44 Typ. 1 4

7

5

6

8

Straight

M12 x 1

MQDC-815 4.57 m (15 ft) ø 14.5 1 = White 5 = Gray

2 = Brown 6 = Pink

MQDC-830 9.14 m (30 ft) 3 = Green 7 = Blue

4 = Yellow 8 = Shield

Brackets

SMBLG SMBLGA

• L-GAGE sensor mounting • L-GAGE adjustable bracket

bracket assembly

• 304 Stainless Steel • 304 Stainless Steel

10 www.bannerengineering.com - Tel: +1-763-544-3164 P/N 59786 Rev. G

L-GAGE® LG Laser Gauging Sensors

Banner Engineering Corp. Limited Warranty

Banner Engineering Corp. warrants its products to be free from defects in material and workmanship for one year following the date of shipment. Banner Engineering Corp. will repair or

replace, free of charge, any product of its manufacture which, at the time it is returned to the factory, is found to have been defective during the warranty period. This warranty does not cover

damage or liability for misuse, abuse, or the improper application or installation of the Banner product.

THIS LIMITED WARRANTY IS EXCLUSIVE AND IN LIEU OF ALL OTHER WARRANTIES WHETHER EXPRESS OR IMPLIED (INCLUDING, WITHOUT LIMITATION, ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE), AND WHETHER ARISING UNDER COURSE OF PERFORMANCE, COURSE OF DEALING OR TRADE USAGE.

This Warranty is exclusive and limited to repair or, at the discretion of Banner Engineering Corp., replacement. IN NO EVENT SHALL BANNER ENGINEERING CORP. BE LIABLE TO BUYER OR ANY

OTHER PERSON OR ENTITY FOR ANY EXTRA COSTS, EXPENSES, LOSSES, LOSS OF PROFITS, OR ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM ANY PRODUCT

DEFECT OR FROM THE USE OR INABILITY TO USE THE PRODUCT, WHETHER ARISING IN CONTRACT OR WARRANTY, STATUTE, TORT, STRICT LIABILITY, NEGLIGENCE, OR OTHERWISE.

Banner Engineering Corp. reserves the right to change, modify or improve the design of the product without assuming any obligations or liabilities relating to any product previously

manufactured by Banner Engineering Corp. Any misuse, abuse, or improper application or installation of this product or use of the product for personal protection applications when the

product is identified as not intended for such purposes will void the product warranty. Any modifications to this product without prior express approval by Banner Engineering Corp will void the

product warranties. All specifications published in this document are subject to change; Banner reserves the right to modify product specifications or update documentation at any time.

Specifications and product information in English supersede that which is provided in any other language. For the most recent version of any documentation, refer to:

www.bannerengineering.com.

© Banner Engineering Corp. All rights reserved

You might also like

- Beckman Coulter Chemistry Analyzer: Ise User GuideDocument84 pagesBeckman Coulter Chemistry Analyzer: Ise User GuidePhong Do100% (1)

- Masse MorseDocument1 pageMasse MorseDragan PilipovićNo ratings yet

- L-Gage LG Laser Gauging: DatasheDocument11 pagesL-Gage LG Laser Gauging: Datasheernesto floresNo ratings yet

- Sensor Banner NovoDocument7 pagesSensor Banner NovoDiego SouzaNo ratings yet

- Sensor Banner - BarreiraDocument4 pagesSensor Banner - BarreiraAdailton FreitasNo ratings yet

- Slo 30Document4 pagesSlo 30Jean RaminhoNo ratings yet

- Low-Power Single 2-Input Positive-AND GateDocument47 pagesLow-Power Single 2-Input Positive-AND Gateramidiab58No ratings yet

- Manual Sensor Proximity BannerDocument8 pagesManual Sensor Proximity BannersuryaNo ratings yet

- Datasheet KT5G-2P1111 1015993 enDocument8 pagesDatasheet KT5G-2P1111 1015993 enМилутин БошковићNo ratings yet

- Fotoceldas Laser LG10Document12 pagesFotoceldas Laser LG10Armando SotoNo ratings yet

- Chave SensaguardDocument3 pagesChave SensaguardpelebotiniNo ratings yet

- Sesnsor Laser Bannner LTEPUQDocument12 pagesSesnsor Laser Bannner LTEPUQDiego VolponiNo ratings yet

- Datasheet LG710 BTDocument2 pagesDatasheet LG710 BTEdwin Noe Ordoñez CespedesNo ratings yet

- Linear GageDocument40 pagesLinear GageSergio RivasNo ratings yet

- Installation Instructions 45LMS Laser Measurement Sensor: Important: Save These Instructions For Future UseDocument4 pagesInstallation Instructions 45LMS Laser Measurement Sensor: Important: Save These Instructions For Future UseDiauoliver RendersNo ratings yet

- Banner, LX Series Part-Sensing Light ScreenDocument4 pagesBanner, LX Series Part-Sensing Light Screenalejandro garciaNo ratings yet

- Tough: AccurateDocument44 pagesTough: AccurateRobNo ratings yet

- Keyence Sensor GT2 Datasheet - OptimizeDocument45 pagesKeyence Sensor GT2 Datasheet - Optimizeinigo.bretonNo ratings yet

- Opax330 50-Μv V, 0.25-Μv/°C, 35-Μa Cmos Operational Amplifiers Zero-Drift SeriesDocument51 pagesOpax330 50-Μv V, 0.25-Μv/°C, 35-Μa Cmos Operational Amplifiers Zero-Drift SeriesMyNameNo ratings yet

- LX Series Part-Sensing Light Screen: FeaturesDocument4 pagesLX Series Part-Sensing Light Screen: Featuresduonghieu8xNo ratings yet

- DF347D DF457D: GB Si Al BG HR MK Ro RS Rus UaDocument56 pagesDF347D DF457D: GB Si Al BG HR MK Ro RS Rus UaAdi MNo ratings yet

- Global Beam: Standard Sensors For AutomationDocument12 pagesGlobal Beam: Standard Sensors For AutomationfazalNo ratings yet

- Gapman Rev D-1Document4 pagesGapman Rev D-1bassam mahyoubNo ratings yet

- Datasheet KT5G-2N1111 1015981 enDocument8 pagesDatasheet KT5G-2N1111 1015981 enJL RNo ratings yet

- Digital SensorDocument44 pagesDigital SensorFrank OnermoNo ratings yet

- Sunx FX 11A Analog Fiber Sensors PDFDocument10 pagesSunx FX 11A Analog Fiber Sensors PDFNguyen LuongNo ratings yet

- Sales Presentation PipescanDocument24 pagesSales Presentation PipescanJesus E ContrerasNo ratings yet

- DS-00006 Rev8 P8864-SMD-B15 3D ToF Sensor Micro Module ENGDocument14 pagesDS-00006 Rev8 P8864-SMD-B15 3D ToF Sensor Micro Module ENGlanglanzhan129No ratings yet

- Banner Sensor ManualDocument8 pagesBanner Sensor ManualPumzile FaleniNo ratings yet

- Q10 Series: FeaturesDocument4 pagesQ10 Series: FeaturesAbdalla FarisNo ratings yet

- R58E Series Expert Registration Mark Sensors: DatasheetDocument11 pagesR58E Series Expert Registration Mark Sensors: DatasheetVikaas JainNo ratings yet

- Ficha Tecnica Sensor Banner QS18VP6LLPQ8Document7 pagesFicha Tecnica Sensor Banner QS18VP6LLPQ8Gustavo EgasNo ratings yet

- AS 4050.452 Crimping Machine L8Document3 pagesAS 4050.452 Crimping Machine L8LOI HONo ratings yet

- LM 78 L 05Document30 pagesLM 78 L 05Shakthi PriyaNo ratings yet

- Minilite IIDocument2 pagesMinilite IIariosuxNo ratings yet

- KT10WDocument9 pagesKT10WAldo Miranda LopezNo ratings yet

- Datasheet KT5W-2N1116 1018045 enDocument8 pagesDatasheet KT5W-2N1116 1018045 enAbu NaeemNo ratings yet

- GT2 Catalog PDFDocument32 pagesGT2 Catalog PDFone_blanche6175No ratings yet

- CL 1x8 Bidirectional SwitchDocument3 pagesCL 1x8 Bidirectional SwitchgattuvishNo ratings yet

- Flyer LPKF Microline 2000 Ci enDocument2 pagesFlyer LPKF Microline 2000 Ci ennothingtosayNo ratings yet

- Mslfp33: MSLFP33 X Ray DetectorDocument2 pagesMslfp33: MSLFP33 X Ray DetectorTAIWO ISHOLANo ratings yet

- Banner R GAGE Radar SensorsDocument4 pagesBanner R GAGE Radar SensorsMemik TylnNo ratings yet

- Wireless Level Alarm ProbeDocument3 pagesWireless Level Alarm ProbeAsep DarojatNo ratings yet

- Surface Roughness Tester SR-400TDocument4 pagesSurface Roughness Tester SR-400T周记伟No ratings yet

- Honeywell Is215t Data SheetDocument2 pagesHoneywell Is215t Data SheetAlarm Grid Home Security and Alarm MonitoringNo ratings yet

- Controlling Servo Motors Using RF Module Transmitter and Receiver With ArduinoDocument12 pagesControlling Servo Motors Using RF Module Transmitter and Receiver With ArduinoJemimah Aniel ClimacoNo ratings yet

- LX Series Part-Sensing Light Screen: DatasheetDocument6 pagesLX Series Part-Sensing Light Screen: DatasheetsazzadNo ratings yet

- RPG One 1.5 2.5Document2 pagesRPG One 1.5 2.5YJ JangNo ratings yet

- MOTOTRBO-R7 DataSheet ENG LCARDocument4 pagesMOTOTRBO-R7 DataSheet ENG LCARoskarfabianNo ratings yet

- LM Series MCU LCD Hour Meter Install Instr 50082092 3 enDocument9 pagesLM Series MCU LCD Hour Meter Install Instr 50082092 3 enandres solorzanoNo ratings yet

- Photocell Sensor DatasheetDocument7 pagesPhotocell Sensor DatasheetRiya RoyNo ratings yet

- Datasheet KT5W-2N1116D 1026540 enDocument8 pagesDatasheet KT5W-2N1116D 1026540 enBrahim RebaouiNo ratings yet

- World-Beam QS30 Diffuse-Mode Laser Sensor: DatasheetDocument12 pagesWorld-Beam QS30 Diffuse-Mode Laser Sensor: DatasheetrajeevvshishodiNo ratings yet

- WR10 RemoteDocument2 pagesWR10 Remoteed.survey.ncNo ratings yet

- GV-UBL2401 Series: 2MP H.264 WDR Pro IR Ultra Bullet IP CameraDocument5 pagesGV-UBL2401 Series: 2MP H.264 WDR Pro IR Ultra Bullet IP CameraenglishferNo ratings yet

- Lino L2P5G: Multi Line & Point Layout ToolDocument4 pagesLino L2P5G: Multi Line & Point Layout Toolbbutros_317684077No ratings yet

- 2012 Pel 7721Document2 pages2012 Pel 7721cfsturmanNo ratings yet

- Sound LocalizationDocument18 pagesSound LocalizationYasir JafriNo ratings yet

- Inductive Sensors Standard 3,4 Wire3Document20 pagesInductive Sensors Standard 3,4 Wire3Csaba VargaNo ratings yet

- Gated Intensified Relay OpticsDocument2 pagesGated Intensified Relay OpticsReimaNo ratings yet

- Banner SL-30 Series PDFDocument6 pagesBanner SL-30 Series PDFdirkz26No ratings yet

- Beginning Digital Electronics through ProjectsFrom EverandBeginning Digital Electronics through ProjectsRating: 5 out of 5 stars5/5 (1)

- ATV320 Installation Manual EN NVE41289 07Document166 pagesATV320 Installation Manual EN NVE41289 07KnezNo ratings yet

- Daikin Altherma High Temperature - ECPEN15-736 - Product Catalogues - EnglishDocument6 pagesDaikin Altherma High Temperature - ECPEN15-736 - Product Catalogues - EnglishKnezNo ratings yet

- The Trusted Force in Scooter Control: Installation ManualDocument80 pagesThe Trusted Force in Scooter Control: Installation ManualKnezNo ratings yet

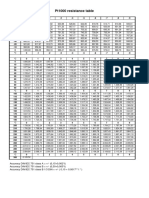

- PT 1000 enDocument1 pagePT 1000 enfatt27No ratings yet

- ICL 7106-7107 LED-LCD DisplayDocument16 pagesICL 7106-7107 LED-LCD DisplayKnezNo ratings yet

- Nightmare TalesDocument79 pagesNightmare TalesKnezNo ratings yet

- Hrxl-Maxsonar - WR Series: High Resolution, Precision, Ip67 Weather Resistant, Ultrasonic Range FinderDocument28 pagesHrxl-Maxsonar - WR Series: High Resolution, Precision, Ip67 Weather Resistant, Ultrasonic Range Finderavinashrai1No ratings yet

- MeasurIT OilSpy Extended Brochure 1003Document5 pagesMeasurIT OilSpy Extended Brochure 1003cwiejkowskaNo ratings yet

- Radar Water Level Sensor - Manualcs475Document40 pagesRadar Water Level Sensor - Manualcs475eftamargoNo ratings yet

- Pressure MeasurementDocument293 pagesPressure MeasurementGlen Lauren PerezNo ratings yet

- Beginner - S Guide To Ultrasonic LTDocument3 pagesBeginner - S Guide To Ultrasonic LTRahul ChandrawarNo ratings yet

- Float and Capacitance Level SensorDocument6 pagesFloat and Capacitance Level SensorJustin Paul CongeNo ratings yet

- Vegapuls 31: Two-Wire 4 20 mA/HART Radar Sensor For Continuous Level MeasurementDocument2 pagesVegapuls 31: Two-Wire 4 20 mA/HART Radar Sensor For Continuous Level MeasurementShrikant KambleNo ratings yet

- Liquid Level Controller - Water Level Controller - Level Controller - GIC IndiaDocument5 pagesLiquid Level Controller - Water Level Controller - Level Controller - GIC IndiaPrasadPurohitNo ratings yet

- Information Portable Gas Stations PDFDocument20 pagesInformation Portable Gas Stations PDFAsima NezirevicNo ratings yet

- Polydos 412A: Polymer Preparation SystemDocument32 pagesPolydos 412A: Polymer Preparation SystemreinpolyNo ratings yet

- Mechatronics Innovative Sensors and Telematics Systems ENG 2020Document24 pagesMechatronics Innovative Sensors and Telematics Systems ENG 2020AndreiNo ratings yet

- EN Specification Sheet VEGAPULS 31 Two Wire 4 20 Ma HARTDocument3 pagesEN Specification Sheet VEGAPULS 31 Two Wire 4 20 Ma HARTJose JohnNo ratings yet

- Winpact Winpact Fermentation and Cell Cultivation SystemDocument62 pagesWinpact Winpact Fermentation and Cell Cultivation SystemJokanoe LertNo ratings yet

- Product Information: Vegabar 51 Vegabar 52 Vegabar 53 Vegabar 54Document32 pagesProduct Information: Vegabar 51 Vegabar 52 Vegabar 53 Vegabar 54Javier CarrizoNo ratings yet

- Varec Automatic Tank GaugeDocument18 pagesVarec Automatic Tank GaugeNeilNo ratings yet

- Liquid Level Sensor UserManual PDFDocument3 pagesLiquid Level Sensor UserManual PDFRodrigo Ortolá InocentiNo ratings yet

- ENTIS BrochureDocument8 pagesENTIS BrochureMaribel CamachoNo ratings yet

- Data Sheet Rosemount Tank Gauging System en 104590Document46 pagesData Sheet Rosemount Tank Gauging System en 104590Alejandro LopezNo ratings yet

- PLC Exercises PDFDocument28 pagesPLC Exercises PDFzoulouweNo ratings yet

- FMR51Document110 pagesFMR51Shishir JhaNo ratings yet

- En002v1maintenance GuideDocument118 pagesEn002v1maintenance GuideAli HadiNo ratings yet

- Instrumentation For Process ControlDocument153 pagesInstrumentation For Process ControlAudrey Patrick KallaNo ratings yet

- DCU 1100 DatasheetDocument2 pagesDCU 1100 DatasheetAnthony FuNo ratings yet

- Flow Meter Slection GuideDocument8 pagesFlow Meter Slection GuidesushantNo ratings yet

- Cryogenics Handbook PDFDocument227 pagesCryogenics Handbook PDFmangyanNo ratings yet

- 998-20934418 Capabilities-BrochureDocument59 pages998-20934418 Capabilities-BrochureTeddy PahlewiNo ratings yet

- TC-Klinger Magnetic Level Gauge Principles and Application Rev 2CDocument57 pagesTC-Klinger Magnetic Level Gauge Principles and Application Rev 2CcherylteoooNo ratings yet

- Dynamelt S Series APS Adhesive Supply UnitDocument2 pagesDynamelt S Series APS Adhesive Supply UnitITWDynatecNo ratings yet

- Water Level SwitchDocument2 pagesWater Level Switchchandan GoswamiNo ratings yet