Professional Documents

Culture Documents

ME1

ME1

Uploaded by

Marlatif Sakandal0 ratings0% found this document useful (0 votes)

14 views1 pageOriginal Title

ME1.

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views1 pageME1

ME1

Uploaded by

Marlatif SakandalCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 1

Jw fraction passing the 0.07Smm (No.200) sieve shall not be greater than 0.66 (two thirds of the

fuvction passing the 0.425(No. 40 )sieve.

Wi filler, in additi 1 to that naturally present, is necessary to meet the grading requirements or

satisfactory bondit.s, it shall be uniformly blended with the base course material on the road or in a

pug mill unless otherwise specified! or approved. Filler shall be taken from approved sources, shall

tw free from hard lumps and shall not be contain more than 15 percent material retained on the

4 1Smm(N0.4) sieve.

Limit: (AASHTO T89)

‘The fraction passing the 0.425mm (N2.40) sieve shal aliquid limit not greater than 25

Mustic limit: (AASHTO 790)

The fraction passing the 0.42Smm (No.40) sieve shall have a plasticity index (PI) not greater than 6,

ABRASION TEST

SIGNIFICANCE:

This test evaluates the structural sirength of coarse aggregate. It gives an indication of quality as

determined by resistance to impact and wear. The results do not automatically permit valid

‘vomparisons to be made between sources distinctly different in origin, composition, or structure.

WPARATUS:

1, Los Angeles Machine

2. Standard sieves with pan & cover

3. Abrasive charges

4. pans

5. balance é& weights

PROCEDURE:

‘The test sample shall consist of clean aggregates which has been oven-dried to constant

weight/mass at 105°C and shall conform to one of the following table:

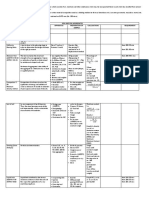

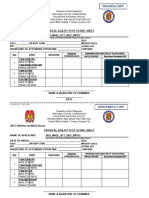

SIEVE SIZE GiRADING AND WEIGHT OF TEST SAMPLE, g

Passing | Retained on [A B c dD [E FG

7mm 6mm ——‘|- ~ = ~ 1250 [-

6mm | 50mm - - I- = ~ 1250 <

50mm 35mm [7 - - 5000 | 5000 | -

375mm 25mm [- [5000 |

25mm 19mm. . 5000

n 12.5mm 1250 | 1250 ra

am | 9.3mm 2

9.5mm

63mn 475mm |

475mm | 236mm

You might also like

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ME REVIEWER ECI Part 5-9Document17 pagesME REVIEWER ECI Part 5-9Marlatif SakandalNo ratings yet

- 2019 Exam With ExplanationDocument100 pages2019 Exam With ExplanationMarlatif SakandalNo ratings yet

- SOILDocument4 pagesSOILMarlatif SakandalNo ratings yet

- Img 4038Document1 pageImg 4038Marlatif SakandalNo ratings yet

- MQC Training ExamDocument24 pagesMQC Training ExamMarlatif SakandalNo ratings yet

- Img 3881Document1 pageImg 3881Marlatif SakandalNo ratings yet

- Img 4049Document1 pageImg 4049Marlatif SakandalNo ratings yet

- Rep 0722 Marlat Sakand Mpwgov cpb4Document2 pagesRep 0722 Marlat Sakand Mpwgov cpb4Marlatif SakandalNo ratings yet

- SummaryDO and Circ - TechDefnDocument2 pagesSummaryDO and Circ - TechDefnMarlatif SakandalNo ratings yet

- Const. MatlsDocument3 pagesConst. MatlsMarlatif SakandalNo ratings yet

- Stress and Coping Self TestDocument3 pagesStress and Coping Self TestMarlatif SakandalNo ratings yet

- ME Relationships and Responsibilities PROBLEMSDocument2 pagesME Relationships and Responsibilities PROBLEMSMarlatif SakandalNo ratings yet

- PCCPDocument3 pagesPCCPMarlatif SakandalNo ratings yet

- Mat Ls Testing Tech For ReviewDocument107 pagesMat Ls Testing Tech For ReviewMarlatif SakandalNo ratings yet

- 1final WatchersDocument4 pages1final WatchersMarlatif SakandalNo ratings yet

- Me 2Document1 pageMe 2Marlatif SakandalNo ratings yet

- SOILSDocument5 pagesSOILSMarlatif SakandalNo ratings yet

- CEMENTDocument4 pagesCEMENTMarlatif SakandalNo ratings yet

- Dokumen - Tips - Materials Engineer Mcdot John Shi PHD Pe Materials Engineer Mcdot ArizonaDocument47 pagesDokumen - Tips - Materials Engineer Mcdot John Shi PHD Pe Materials Engineer Mcdot ArizonaMarlatif SakandalNo ratings yet

- Dokumen - Tips - Reviewer Materials Engineer AccreditationDocument67 pagesDokumen - Tips - Reviewer Materials Engineer AccreditationMarlatif SakandalNo ratings yet

- ContractDocument10 pagesContractMarlatif SakandalNo ratings yet

- RTC Agu.Document1 pageRTC Agu.Marlatif SakandalNo ratings yet

- Pa Tag Lity FormDocument3 pagesPa Tag Lity FormMarlatif SakandalNo ratings yet

- Rep Marlat A Mfbmgov Pap2 2ndreportDocument1 pageRep Marlat A Mfbmgov Pap2 2ndreportMarlatif SakandalNo ratings yet

- Vtsa-Information SheetDocument1 pageVtsa-Information SheetMarlatif SakandalNo ratings yet

- Marlatif Albang SakandalDocument4 pagesMarlatif Albang SakandalMarlatif SakandalNo ratings yet

- Materials Reviewer PDFDocument25 pagesMaterials Reviewer PDFMarlatif SakandalNo ratings yet

- ME Reviewer 2 600 Problems ME Reviewer 2 600 ProblemsDocument39 pagesME Reviewer 2 600 Problems ME Reviewer 2 600 ProblemsMarlatif SakandalNo ratings yet

- Dokumen - Tips - DPWH Materials Engineering Exam Reviewer For Item 300 With Notes From A MaterialsDocument76 pagesDokumen - Tips - DPWH Materials Engineering Exam Reviewer For Item 300 With Notes From A MaterialsMarlatif SakandalNo ratings yet

- BANGSAMORO Job PortalDocument1 pageBANGSAMORO Job PortalMarlatif SakandalNo ratings yet