Professional Documents

Culture Documents

Base Plate Hinged - Moment On Anchors Adjusted 09-06-2021

Uploaded by

ahmed osmanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Base Plate Hinged - Moment On Anchors Adjusted 09-06-2021

Uploaded by

ahmed osmanCopyright:

Available Formats

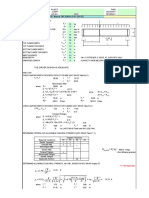

DESIGN OF BASE PLATE SUBJECTED TO AXIAL FORCE & SHEAR FORCE - REV 0

Project Tiltle : AAIB Bank BASE PLATE No. : R

Department :

Detail 73 82.40%

Building :

STRAINING ACTION

Comp. 0 tons

Ten. 10.9 tons

Qy 7 tons

Qx 0 tons

SECTION PROPERTIES

B.U.S.

STEEL GRADE ST. 52

H 500 mm

B 280 mm

Tw 6 mm

Tf 15 mm

distance between bolt and column web 54 mm

CONCRETE PROPERTIES

Fcu 250 Kg/cm2

Fbearing 74.44 Kg/cm2

Fbond 8.18 Kg/cm2

DESIGN OF ANCHOR BOLTS

NUMBER (N) DIAMETER (mm) STEEL GRADE OF ANCHOR BOLTS

4 24 HSB ( 8.8 )

Fyb = 6.4 t/cm2

Fub = 8 t/cm2

Bolt Area (A) = 4.52 cm2

Stress Area (As) = 3.53 cm2

Qeq = 7.00 tons

a= 0.25 for grades 4.8, 5.8 , 6.8, and 10.9 otherwise α=0.25

R sh.a = Qeq / N = 1.75 tons

R t.a = T / N = 2.73 tons

The bending moment in each rod equals the shear per rod times the half distance from the center of washer plate to the top of grout (Refer to AISC , design guide 1, page 43)

Applied moment on the anchor rod= 1.84 t.cm

tesile stress due to moment on anchor bolt = M/ S = M / (d3/6)

tesile stress due to moment on anchor bolt 1.16 t/cm2

Rma 4.08 tons

Rt, a total 6.81

R sh = 6.00 tons 15% Reduction in the Allowable Shear and Tension Stress

due to Fabrication Process

Rt = 7.92 tons

Tmin.= 10 mm wahser thickness

R Bearing = 9.98 tons SAFE check of bearing s 17.53%

Rcomb.=( Rsh.a / Rsh ) + ( Rt.a / Rt ) =

2 2 0.82 SAFE 82.40%

Min Lembedded = 480 mm

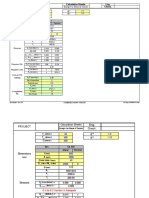

DESIGN OF BEARING PLATE

a (mm) b (mm) t (mm)

100 100 15

Lc net. = 3.8 cm

A net = 95.48 cm2

stress = 0.03 t/cm2

moment = 0.21 t.cm

t bearing plate = 7.0 mm SAFE

DIMENSIONS OF BASE PLATE

Hpl (mm) Bpl (mm) Tpl (mm) STIFFENER NO. (Nst) grout thickness

540 280 16 1 0

Fyb = 3.6 t/cm2

Fub = 5.2 t/cm2

CHECK BEARING STRESS ON CONCRETE

Fb = C/(HplXBpl) = 0.00 Kg/cm2 SAFE 0.00%

CHECK THICKNESS OF BASE PLATE DUE TO COMPRESSION FORCE

m =(Hpl-0.95XH)/2= 32.5 mm

n =(Bpl-0.85XB)/2= 28 mm

M1 bearing = 0.00 t.cm

treq. = 0.0 mm SAFE

CHECK THICKNESS OF BASE PLATE DUE TO TENSION FORCE

e= 70 mm

Tstiffener = 3.63 tons At = 112.2 cm2

Tflange =Tstiffener = 3.63 tons Af = 42 cm2

Ten. Force by Area = 4.08 tons

M2 = Tflange x e = 28.56 t.cm

treq. = 15 mm SAFE

Tbolt 2.725 tons

Mp= Tbolt* distance between bolt and web 14.715

effective width considering 45 degree distribution from bolt 228 mm

treq. = 12.222803681012 mm SAFE

CHECK WELD STEEL GRADE ST. 52 Fyb = 3.6

Fub = 5.2

S1= 6 mm

S2= 12 mm

Awy = 48 cm2

Awx = 120.96 cm2

CHECK SHEAR

qy = Qx/Awy--- (ton\cm2) = 0.15 SAFE 14.02%

qx = Qx/Awx--- (ton\cm2) = 0.00 SAFE 0.00%

qmax = --- (ton\cm2) = 1.04

CHECK NORMAL STRESS

fc. = 0.6C/Atotal ---(ton\cm2) = 0.00 SAFE 0.00%

ft. = T/Atotal ---(ton\cm2) = 0.06 SAFE 6.20%

fmax. = --- (ton\cm2) 1.04

CHECK EQ. STRESS

feq.=(fca2+3Xqy2)1/2---(t\cm2) = 0.26 SAFE 22.79%

F eq. max. ---(t\cm2) = 1.14

You might also like

- Base Plate Design - Rev-0Document8 pagesBase Plate Design - Rev-0KINGSUK PALNo ratings yet

- Properties and Specifications for Structural Steel Sections and ConnectionsDocument14 pagesProperties and Specifications for Structural Steel Sections and ConnectionsFunny & InformativeNo ratings yet

- Moment Connection - Beam SpliceDocument3 pagesMoment Connection - Beam SpliceSh MNNo ratings yet

- Standard Isolated Footing f1Document11 pagesStandard Isolated Footing f1Saajan bhathalNo ratings yet

- Wind Load Calculation NZS PDFDocument1 pageWind Load Calculation NZS PDFSantoshNo ratings yet

- Calculation of end plate beam connection designDocument1 pageCalculation of end plate beam connection designFortunata Citraningrum SukmonoNo ratings yet

- Bearing CheckDocument6 pagesBearing CheckdhanushkaNo ratings yet

- AnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTDocument3 pagesAnchorageWithCircularBasePlate-DÍAZ CORNEJO ROBERTRobert Díaz CornejoNo ratings yet

- Design of Base PlateDocument26 pagesDesign of Base Plateraghav abudhabiNo ratings yet

- Cranebeam v1 2 AramadaDocument1 pageCranebeam v1 2 AramadaronyNo ratings yet

- Cleat Angle ConnectionDocument38 pagesCleat Angle ConnectionMadhubalan AlagarNo ratings yet

- Buckling C ChannelDocument2 pagesBuckling C ChannelНемања КараклајићNo ratings yet

- Actual Base Plate Design V1 2 42 210Document6 pagesActual Base Plate Design V1 2 42 210Alphyl BalasabasNo ratings yet

- Beam dimensions and properties in metric and imperial unitsDocument5 pagesBeam dimensions and properties in metric and imperial unitsvinit soodNo ratings yet

- Hilti Bolt Connection-6 anchor-HSTDocument5 pagesHilti Bolt Connection-6 anchor-HSTTuấnThanhNo ratings yet

- Fin Plate-Beam To Beam Inside (AISC-LRFD)Document184 pagesFin Plate-Beam To Beam Inside (AISC-LRFD)AshishNo ratings yet

- Plate GirderDocument15 pagesPlate GirderPriodeep ChowdhuryNo ratings yet

- Pin Design AISCDocument3 pagesPin Design AISCFernando SimaNo ratings yet

- HDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Document8 pagesHDT & Atu Unit-Iocl Digboi 4580.09-VP1-30005-CV-3022 4580.09 0Mohammad Shadab AliNo ratings yet

- Concrete Corbel Design SummaryDocument14 pagesConcrete Corbel Design Summarynavneet3bawaNo ratings yet

- Stair Stringer DesignDocument2 pagesStair Stringer DesignTerry CheukNo ratings yet

- End Plate Moment Connection DesignDocument16 pagesEnd Plate Moment Connection DesignAbdul HameedNo ratings yet

- Fixed Normal 575Document8 pagesFixed Normal 575mohanNo ratings yet

- DG Consulting EngineersDocument8 pagesDG Consulting EngineersThakshayani SellavelNo ratings yet

- Project Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionDocument2 pagesProject Calculation Sheets Eng. Check.: Sec. 1 Shear TorsionmaheshbandhamNo ratings yet

- Pinned Base (I-Section) : Design CapacitiesDocument8 pagesPinned Base (I-Section) : Design CapacitiesAwais HameedNo ratings yet

- RPLC DEEP CONVERSION BRACING CONNECTION DESIGNDocument32 pagesRPLC DEEP CONVERSION BRACING CONNECTION DESIGNHeberth SanchezNo ratings yet

- 2.3.4 Design Parameters - Design Per AISC 360-05 and 360-10 (Unified)Document6 pages2.3.4 Design Parameters - Design Per AISC 360-05 and 360-10 (Unified)HamdiNo ratings yet

- 1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)Document49 pages1.01D21A Post perp-TYPE - II B1 (UC152x152X37) Tob2 (UC203X46)balaNo ratings yet

- Design of Brace Connection PlateDocument6 pagesDesign of Brace Connection PlateJonatas PrandiniNo ratings yet

- Gusset Plate Connection For TrussDocument8 pagesGusset Plate Connection For TrussYoukhanna ZayiaNo ratings yet

- Wind Load GTPOGTDocument2 pagesWind Load GTPOGTAnonymous 2CMPbqwBNo ratings yet

- Lug AngleDocument22 pagesLug AngleSnehalatha PNo ratings yet

- Fixed BaseDocument3 pagesFixed Basenoaman rehanNo ratings yet

- 16 Bolt Pattern Fixed Base Plate Design - For 4.6 Grade Anchor BoltsDocument30 pages16 Bolt Pattern Fixed Base Plate Design - For 4.6 Grade Anchor Boltsafzal samaNo ratings yet

- Base Plate DesignDocument1 pageBase Plate DesignShuvo ShahaNo ratings yet

- FND BoltDocument1 pageFND BoltArunkumar RackanNo ratings yet

- Bored Pile Design - Deep FoundationDocument5 pagesBored Pile Design - Deep FoundationALI ASGHARNo ratings yet

- Universal Beam and Column Properties SheetDocument11 pagesUniversal Beam and Column Properties SheetkalpanaadhiNo ratings yet

- C 0 - 85 F ' C B A T A F: Reference: ACI 318-05 Reinforced Concrete Beam Design DefinitionsDocument116 pagesC 0 - 85 F ' C B A T A F: Reference: ACI 318-05 Reinforced Concrete Beam Design DefinitionsIbrahim El SharNo ratings yet

- BP2Document3 pagesBP2insane88No ratings yet

- Beam To Column'S Flange Fixed Connection - Bcff-4: Design DataDocument6 pagesBeam To Column'S Flange Fixed Connection - Bcff-4: Design DataAchmad RifaiNo ratings yet

- 1.SHEAR (Or) MOMENT CONNE-GENERALDocument272 pages1.SHEAR (Or) MOMENT CONNE-GENERALbalaNo ratings yet

- Design of Fixed Base Connection (BP) : Reactions Input Material PropertiesDocument10 pagesDesign of Fixed Base Connection (BP) : Reactions Input Material PropertiesAnand.5No ratings yet

- Clamp Design 7F9BEDocument3 pagesClamp Design 7F9BECivil StructureNo ratings yet

- Corner Bracing Connection Capacity AnalysisDocument2 pagesCorner Bracing Connection Capacity AnalysisKaren Esther Acuña VelasquezNo ratings yet

- Base Plate & Anchor Bolt - BP1Document20 pagesBase Plate & Anchor Bolt - BP1munishant1No ratings yet

- 1th SectionDocument10 pages1th SectionfaridullahNo ratings yet

- Brace TR W6X25Document6 pagesBrace TR W6X25mihai_serban13No ratings yet

- Com ColumnDocument2 pagesCom ColumnHarjasa AdhiNo ratings yet

- 1.SP2 HEA160 SPLICE-A10%-S60%-M60% (End Plate) BoltedDocument120 pages1.SP2 HEA160 SPLICE-A10%-S60%-M60% (End Plate) BoltedbalaNo ratings yet

- PDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDocument29 pagesPDF Moment Connection Beam Column Is Amp Bs Section For Is800xls CompressDEVANG VIJAY SHINDENo ratings yet

- Analysis of Self-Supported Steel Chimney With The Effects of Geometrical ParametersDocument6 pagesAnalysis of Self-Supported Steel Chimney With The Effects of Geometrical Parametersvikram413No ratings yet

- Turkey temporary facility pedestal designDocument23 pagesTurkey temporary facility pedestal designMyunSu GooNo ratings yet

- RC Slab Crack Width Calculation According to ACI350-06 & ACI224R-01Document6 pagesRC Slab Crack Width Calculation According to ACI350-06 & ACI224R-01Sureshbabu NarayanasamyNo ratings yet

- Method of Superposition - Beam Deflection - Strength of Materials ReviewDocument7 pagesMethod of Superposition - Beam Deflection - Strength of Materials ReviewMatías FernándezNo ratings yet

- Pedestal DesignDocument11 pagesPedestal DesignNikhil TawadeNo ratings yet

- Body Flange .PVDB FlangeDocument1 pageBody Flange .PVDB FlangeAnonymous aBg51lbe18No ratings yet

- 1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12Document7 pages1-Way Solid Concrete Slab Design To Bs 81101997 Table 3.12bunheng lonNo ratings yet

- HSL 3 Heavy Duty AnchorDocument15 pagesHSL 3 Heavy Duty Anchorahmed osmanNo ratings yet

- Hiti Hit Re500 v3Document113 pagesHiti Hit Re500 v3ahmed osmanNo ratings yet

- HILTI HSL-GR Heavy Duty Anchor: Quality Management ApprovalsDocument7 pagesHILTI HSL-GR Heavy Duty Anchor: Quality Management Approvalsahmed osmanNo ratings yet

- Design of Composite Pipe Section - R - 0Document1 pageDesign of Composite Pipe Section - R - 0ahmed osmanNo ratings yet

- Performance of Extended End-Plate Bolted ConnectioDocument25 pagesPerformance of Extended End-Plate Bolted Connectioahmed osmanNo ratings yet

- Spring StiffnessDocument29 pagesSpring Stiffnessahmed osmanNo ratings yet

- A Design Guide For Footfall Induced Vibration of StructuresDocument84 pagesA Design Guide For Footfall Induced Vibration of StructuresJose Rzal67% (3)

- IJOPS-21-0058.R1 Proof HiDocument24 pagesIJOPS-21-0058.R1 Proof Hiahmed osmanNo ratings yet

- Grims Mo 2015Document38 pagesGrims Mo 2015ahmed osmanNo ratings yet

- En.1993.1.1.2005-Page 53Document1 pageEn.1993.1.1.2005-Page 53ahmed osmanNo ratings yet

- En.1993.1.8.2005-1-Page 46Document1 pageEn.1993.1.8.2005-1-Page 46ahmed osmanNo ratings yet

- Effect of COVID-19 On Global Supply ChainDocument4 pagesEffect of COVID-19 On Global Supply ChainInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Oracle Applications Invntory Training ManualDocument171 pagesOracle Applications Invntory Training ManualSivaNo ratings yet

- PCI Medical Catalog DOCS 500Document1 pagePCI Medical Catalog DOCS 500anghello buendiaNo ratings yet

- JPEG Standard: ISO/IEC JTC1/SC29/WG10Document31 pagesJPEG Standard: ISO/IEC JTC1/SC29/WG10bumerrNo ratings yet

- CHOOSING NAIA PaperDocument6 pagesCHOOSING NAIA PaperElyssa DaggettNo ratings yet

- Gen Eoli de D AlDocument7 pagesGen Eoli de D AlCarlos J Duran ForeNo ratings yet

- Kinematic Structure of Machine ToolsDocument23 pagesKinematic Structure of Machine ToolswagoheNo ratings yet

- Corrosion MonitoringDocument80 pagesCorrosion Monitoring이선엽86% (7)

- Laguna Kosmetik MC1 PlusDocument2 pagesLaguna Kosmetik MC1 PlusLaguna Karaoke TarakanNo ratings yet

- Major Report Wood LumberDocument45 pagesMajor Report Wood LumberTorreja JonjiNo ratings yet

- Untitled PresentationDocument14 pagesUntitled PresentationThe BeatableNo ratings yet

- Math in The Modern WorldDocument8 pagesMath in The Modern WorldMichael JoavanniNo ratings yet

- GSS5 Rising Main Condition Assessment and Risk Management ManualDocument2 pagesGSS5 Rising Main Condition Assessment and Risk Management ManualNickNo ratings yet

- Module 4 - Contemp World - BSA2Document7 pagesModule 4 - Contemp World - BSA2Marian AntipoloNo ratings yet

- BiologyDocument6 pagesBiologySuraj KumarNo ratings yet

- State of Maine DMR Motion To InterveneDocument147 pagesState of Maine DMR Motion To InterveneNEWS CENTER MaineNo ratings yet

- Geological Exploration Flowchart and SumDocument1 pageGeological Exploration Flowchart and SumKareemAmenNo ratings yet

- Electric Fields and Forces SolutionsDocument4 pagesElectric Fields and Forces Solutionsomar msmqNo ratings yet

- Anatomy of FirearmsDocument9 pagesAnatomy of Firearmswerdna67No ratings yet

- Katalog Promo PC200-8 Okt 2020Document6 pagesKatalog Promo PC200-8 Okt 2020ariy yuli styawanNo ratings yet

- VSTEP Writing Preparation PDFDocument39 pagesVSTEP Writing Preparation PDFNgân Hà Tô100% (1)

- The Validity of Beck Depression Inventory - Short Version in Depressed Patients Diagnosed According To ICD10Document11 pagesThe Validity of Beck Depression Inventory - Short Version in Depressed Patients Diagnosed According To ICD10sarhang talebaniNo ratings yet

- Guru Nanak Dev University, Amritsar: Notification No. B.Tech. (Mech. Engg.) (CBES) /-8th Semester/May-2019/1Document1 pageGuru Nanak Dev University, Amritsar: Notification No. B.Tech. (Mech. Engg.) (CBES) /-8th Semester/May-2019/1Nehal GuptaNo ratings yet

- Week - 5 (Deep Learning) Q. 1) Explain The Architecture of Feed Forward Neural Network or Multilayer Perceptron. (12 Marks)Document7 pagesWeek - 5 (Deep Learning) Q. 1) Explain The Architecture of Feed Forward Neural Network or Multilayer Perceptron. (12 Marks)Mrunal BhilareNo ratings yet

- Process TechnologyDocument31 pagesProcess TechnologyEugene MicarandayoNo ratings yet

- So You Think You Can Think Tools For Having Intelligent Conversations and Getting Along PDFDocument227 pagesSo You Think You Can Think Tools For Having Intelligent Conversations and Getting Along PDFChendikato PinasNo ratings yet

- Ut350 ConfigDocument21 pagesUt350 ConfigrenzomcuevaNo ratings yet

- Activity 3 GlobalizationDocument3 pagesActivity 3 GlobalizationLuis VillalobosNo ratings yet

- TD Tip Tinner PDFDocument2 pagesTD Tip Tinner PDFbehzadNo ratings yet

- Modern CV Template StyleDocument2 pagesModern CV Template StyleRedi Joel Córdova ArbietoNo ratings yet