Professional Documents

Culture Documents

TMACAM-131a - T5 Calibration (Series 300)

Uploaded by

ashwiniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TMACAM-131a - T5 Calibration (Series 300)

Uploaded by

ashwiniCopyright:

Available Formats

Trans Maldivian Airways

Continuing Airworthiness Management Organization T5 Calibration

Data Record Sheet

(Series 300)

Aircraft 8Q- _____ Position LH RH Date _____ - _____ - 20___

Task Card __________ - _____ Reason ECTM Callout Engine Change Unschedule

Effectivity DHC-6 Series 300 aircraft and components fitted thereof

References Latest revision of the PSM 1-63-2 Chapter 77-20-00

Equipment

T5 Tester

Required

Step WORK STEPS TECH SIGN ENG STAMP

CAUTION: EXERCISE CARE WHEN REMOVING OR INSTALLING ENGINE T5

HARNESS TERMINAL BOLTS/NUTS. HOLD THE STATIONARY PART WITH A

SUITABLE WRENCH. EXCESSIVE PRESSURE ON LUGS COULD RESULT IN

DAMAGE TO INSULATION.

1 Disconnect T5 airframe harness wires and trim thermocouple wires from engine.

Using a T5 tester, check insulation resistance and loop resistance at engine T5 harness

and trim stick. Record values below:

Description Resistance Reference

Insulation

not less than 50,000 Ω

(terminals to ground)

Resistance

between 0.58 and 0.74 Ω

(between terminals)

2

Description Part Number/Resistance

Trim Thermocouple PN

Trim Thermocouple Resistance

Trim Thermocouple Insulation Resistance

3 Reconnect removed T5 indicating system wires at engine T5 harness terminals.

Connect T5 tester in place of aircraft indicator and check resistance of the system

4

circuit.

Connect T5 tester in place of aircraft indicator and check resistance of system circuit. If

the resistance is not within range, go to Step 5a. Else, skip Step 5a and go to Step 6.

5 Description Resistance Acceptable Range

System Resistance 25.00 + 0.07 or – 0.00 Ω

If resistance is greater/less than required, carry out Steps in 5a. Record corrected

5a figures in the table provided in 5a. v. Strike out this part if the resistance of system

circuit is within the tolerance.

i. Clean cannon plugs J11/J12 in the nose compartment

ii. Clean J24/J25 in the engine firewall

TMACAM-131a Page 1 of 2 Form Rev: I1R0, 18/10/2017

Trans Maldivian Airways

Continuing Airworthiness Management Organization T5 Calibration

Data Record Sheet

(Series 300)

Step WORK STEPS TECH SIGN ENG STAMP

5a iii. Inspect trimspool for condition and security

iv. Inspect TB24/TB25 chromel terminals for condition and security.

v. Record (corrected) values below after carrying out steps in 5a i. to iv. (inclusive):

Description Resistance Reference

System Resistance 25.00 + 0.07 or – 0.00 Ω

Connect test lead to aircraft indicator. Ensure the tester internal resistance is 25 Ω.

Record the details of the T5 indicator below:

6 Part Number Serial Number

Check aircraft indicator at the following temperatures:

Indicator Indicator

Temperature Temperature

Reading Reading

°C °C

°C °C

100 ± 30 725 ± 2

200 ± 30 750 ± 3

300 ± 30 800 +30/-10

7

400 ± 30 850 +30/-10

500 ± 30 900 ± 30

600 ± 10 950 ± 30

650 ± 5 1000 ± 30

700 ± 2 1100 ± 30

Reject indicator if unable to obtain acceptable readings. Record PN and SN of the

8

replacement indicator in the Corrective Action field of the Task Card.

TMACAM-131a Page 2 of 2 Form Rev: I1R0, 18/10/2017

You might also like

- Ha04 - 3mva Unit Auxailry Transformer Unit#10Document5 pagesHa04 - 3mva Unit Auxailry Transformer Unit#10Asgher khkattakNo ratings yet

- SG1524Document9 pagesSG1524Med Habib AitNo ratings yet

- Phase SequenceDocument3 pagesPhase SequenceWail AskarNo ratings yet

- Cupiagua CPF: Contactor Starter - Fused Switch Function Test CertificateDocument1 pageCupiagua CPF: Contactor Starter - Fused Switch Function Test CertificateKhaled FatnassiNo ratings yet

- Operator's Manual: Series 300 Automatic Transfer Switches D Design, 30 Through 230 Amp. SizesDocument20 pagesOperator's Manual: Series 300 Automatic Transfer Switches D Design, 30 Through 230 Amp. SizesEdward SchenkNo ratings yet

- LM741 Operational Amplifier: General DescriptionDocument9 pagesLM741 Operational Amplifier: General DescriptionKasNo ratings yet

- TR-MARK III - 250V Option (TRO-250) : Instruction ManualDocument7 pagesTR-MARK III - 250V Option (TRO-250) : Instruction ManualMuhammad KashifNo ratings yet

- Simirel: Monitors, Interfaces, RelaysDocument32 pagesSimirel: Monitors, Interfaces, RelaysRomel Toledo CalvopiñaNo ratings yet

- Ha05 - Bus CouplerDocument5 pagesHa05 - Bus CouplerAsgher khkattakNo ratings yet

- ASCO 300 Series Auto Transfer SwitchDocument19 pagesASCO 300 Series Auto Transfer SwitchWarren WoolseyNo ratings yet

- Zelio Control RM4TR32 Document-1561572 PDFDocument8 pagesZelio Control RM4TR32 Document-1561572 PDFGustavo SchermanNo ratings yet

- RM35TF30Document4 pagesRM35TF30J raymond FNo ratings yet

- TL7700A Series: Supply Voltage SupervisorsDocument7 pagesTL7700A Series: Supply Voltage SupervisorsLucaDirafNo ratings yet

- Type TA Class 10: Thermal Overload RelaysDocument18 pagesType TA Class 10: Thermal Overload RelaysAli ArslanNo ratings yet

- SG1524 PWM ReguladorDocument6 pagesSG1524 PWM ReguladoralvaroNo ratings yet

- Relee Electronice SIEMENSDocument32 pagesRelee Electronice SIEMENSciocioi iancuNo ratings yet

- Asco ABT 300 30 To 230amp OperatorDocument19 pagesAsco ABT 300 30 To 230amp OperatorGuilherme ChiminelliNo ratings yet

- ICL8069 - Low Voltage Reference - Intersil CorporationDocument6 pagesICL8069 - Low Voltage Reference - Intersil Corporationwlen2012No ratings yet

- STV9379F: Vertical Deflection BoosterDocument5 pagesSTV9379F: Vertical Deflection BoosterCarlos RamirezNo ratings yet

- Operator's Manual: Series 300 Automatic Transfer Switches D Design 30 Through 200 AmpsDocument18 pagesOperator's Manual: Series 300 Automatic Transfer Switches D Design 30 Through 200 AmpsCanaril VictóriaNo ratings yet

- SGS Thomson DB3-DB4-DC34 Diode Data SheetDocument5 pagesSGS Thomson DB3-DB4-DC34 Diode Data SheethoahlukeNo ratings yet

- Datasheet ET1100Document10 pagesDatasheet ET1100Manal FeghaliNo ratings yet

- Product Compatibility: Model 3095MVDocument4 pagesProduct Compatibility: Model 3095MVKARIMNo ratings yet

- Z 0409 MFDocument6 pagesZ 0409 MFYadira RodriguezNo ratings yet

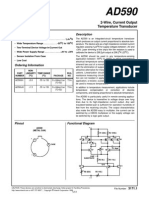

- AD590Document11 pagesAD590Timmy Neil SixxNo ratings yet

- Ntcle100 88101Document18 pagesNtcle100 88101Edwin Alfredo Lopez AguirreNo ratings yet

- Operator's Manual: An Experienced Licensed Electrician Must Install The ATSDocument19 pagesOperator's Manual: An Experienced Licensed Electrician Must Install The ATSEslam SalamonyNo ratings yet

- Data SheetDocument6 pagesData SheetCarlos Andres Cerón PugaNo ratings yet

- Packaging Code: GRM31BR73A222KW01 - (1206, X7R:EIA, 2200pF, DC1000V) Reference SheetDocument26 pagesPackaging Code: GRM31BR73A222KW01 - (1206, X7R:EIA, 2200pF, DC1000V) Reference Sheetakshay rajNo ratings yet

- Conzerv 6438Document10 pagesConzerv 6438Pur WantoNo ratings yet

- Em6438 6436 Dual Quick Start GuideDocument10 pagesEm6438 6436 Dual Quick Start GuideReji KurianNo ratings yet

- TMP 35 GDocument16 pagesTMP 35 GWeslley FariaNo ratings yet

- Air Circuit BreakerDocument13 pagesAir Circuit BreakercjtagayloNo ratings yet

- Fast Recovery Rectifier Diode: ApplicationsDocument3 pagesFast Recovery Rectifier Diode: ApplicationsMiloud ChouguiNo ratings yet

- Sbaa 275Document42 pagesSbaa 275Salman AlparisiNo ratings yet

- A Basic Guide To RTD Measurements: Application ReportDocument42 pagesA Basic Guide To RTD Measurements: Application ReportSyfNo ratings yet

- MMBD1701/A / 1703/A / 1704/A / 1705/A: Small Signal DiodesDocument4 pagesMMBD1701/A / 1703/A / 1704/A / 1705/A: Small Signal DiodesJavier VelasquezNo ratings yet

- Rele Termico ZEVDocument42 pagesRele Termico ZEVdaroltecNo ratings yet

- Ver5 Ver6 OLE16-0044-04 CLU056 15kh LM-80 ReportDocument23 pagesVer5 Ver6 OLE16-0044-04 CLU056 15kh LM-80 Reporttata kaisserliNo ratings yet

- Ha01-Incomer Unit#10Document7 pagesHa01-Incomer Unit#10Asgher khkattakNo ratings yet

- Esm - 4410 ManualDocument28 pagesEsm - 4410 ManualFabricio Farel CardenasNo ratings yet

- Fuzhou Tianyu Electric Co., LTD.: KYN31-12 Armored Metal-Enclosed Switch CabinetDocument26 pagesFuzhou Tianyu Electric Co., LTD.: KYN31-12 Armored Metal-Enclosed Switch CabinetRusman LumbantoruanNo ratings yet

- 6lb+r-Red 670Document15 pages6lb+r-Red 670Mohamed AwadNo ratings yet

- LM555 Timer: Features DescriptionDocument21 pagesLM555 Timer: Features DescriptionJaviMadridNo ratings yet

- Non Dir. O/C Relay-7SR1102-1NA87-1CA0-ZDocument4 pagesNon Dir. O/C Relay-7SR1102-1NA87-1CA0-ZAnonymous dH3DIEtzNo ratings yet

- A3910 DatasheetDocument7 pagesA3910 DatasheetLêĐìnhDanhNo ratings yet

- Schneider Zelio Control RM4TR32-356472Document8 pagesSchneider Zelio Control RM4TR32-356472TERASAT SANo ratings yet

- STAMFORD Industrial Ratings Book 2Document64 pagesSTAMFORD Industrial Ratings Book 2Murali SubramaniNo ratings yet

- CTO 1050 230 Current TransformerDocument3 pagesCTO 1050 230 Current Transformersagar ramaniNo ratings yet

- 3030 2sin1 (CRI80) - LEMWS36X - Family DatasheetDocument30 pages3030 2sin1 (CRI80) - LEMWS36X - Family DatasheetGiancarloRichardRivadeneyraMirandaNo ratings yet

- Calibration Procedure For Tpi Model 275 Digital Amp Meter - Tb-9-6625-2400-24Document17 pagesCalibration Procedure For Tpi Model 275 Digital Amp Meter - Tb-9-6625-2400-24luroguitaNo ratings yet

- Ideal Industries, Inc. Technical Manual Models: 61-773 61-775Document11 pagesIdeal Industries, Inc. Technical Manual Models: 61-773 61-775Alexandre LiraNo ratings yet

- RM4TR32 Schneider Electric Datasheet 10978291Document7 pagesRM4TR32 Schneider Electric Datasheet 10978291carlosvillamar1234No ratings yet

- Procedimiento de Calibracion de Los TT1000A PDFDocument9 pagesProcedimiento de Calibracion de Los TT1000A PDFjose gutierrezNo ratings yet

- Zelio Control RM4TA32 PDFDocument7 pagesZelio Control RM4TA32 PDFariessukmawanNo ratings yet

- Packaging Code: GRT32EC81C476KE13 - (1210, X6S:EIA, 47uf, DC16V) Reference SheetDocument30 pagesPackaging Code: GRT32EC81C476KE13 - (1210, X6S:EIA, 47uf, DC16V) Reference Sheetfebry alwan putraNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Introduction to Power System ProtectionFrom EverandIntroduction to Power System ProtectionRating: 5 out of 5 stars5/5 (1)

- Re-KYC - CleanedDocument4 pagesRe-KYC - CleanedashwiniNo ratings yet

- AMOTM21-001 - Discrepancies While Completing Maintenance Docu...Document1 pageAMOTM21-001 - Discrepancies While Completing Maintenance Docu...ashwiniNo ratings yet

- Acceptable Deferred Defects Report - 13-Feb-2021Document1 pageAcceptable Deferred Defects Report - 13-Feb-2021ashwiniNo ratings yet

- Trans Maldivian Airways PVT LTD: Task CardDocument1 pageTrans Maldivian Airways PVT LTD: Task CardashwiniNo ratings yet

- ADS-B SystemDocument7 pagesADS-B SystemashwiniNo ratings yet

- Trans Maldivian Airways PVT LTD: Task CardDocument1 pageTrans Maldivian Airways PVT LTD: Task CardashwiniNo ratings yet

- 2020-09-30 MCAR-13B - Issue 1.00Document43 pages2020-09-30 MCAR-13B - Issue 1.00ashwiniNo ratings yet

- 2020-09-30 MCAR-19 Transition Rules - Issue 1.00Document61 pages2020-09-30 MCAR-19 Transition Rules - Issue 1.00ashwiniNo ratings yet

- TMAAMO-083 - List of Logbook Assessors - Rev 01 - 2022 Jan 20Document1 pageTMAAMO-083 - List of Logbook Assessors - Rev 01 - 2022 Jan 20ashwiniNo ratings yet

- Trans Maldivian Airways PVT LTD: Task CardDocument1 pageTrans Maldivian Airways PVT LTD: Task CardashwiniNo ratings yet

- Trans Maldivian Airways PVT LTD: Task CardDocument1 pageTrans Maldivian Airways PVT LTD: Task CardashwiniNo ratings yet

- Bendix King KN 62ADocument62 pagesBendix King KN 62AashwiniNo ratings yet

- TMA MOE App 1 - Capability List - Iss 3 Am 4 - 17 Sep 2022Document23 pagesTMA MOE App 1 - Capability List - Iss 3 Am 4 - 17 Sep 2022ashwiniNo ratings yet

- TB ShootDocument169 pagesTB Shootashwini100% (1)

- I 08 AML FORM 19 2021 UpdatedDocument6 pagesI 08 AML FORM 19 2021 UpdatedashwiniNo ratings yet

- Ref of Task CardDocument1 pageRef of Task CardashwiniNo ratings yet

- Skandi SingaporeDocument9 pagesSkandi SingaporeTrie MardiantoNo ratings yet

- Reading Explorer 2 PDFDocument4 pagesReading Explorer 2 PDFWilmerVelez83% (12)

- Effects: of V-22 Blade Modifications On Whirl Flutter and LoadsDocument15 pagesEffects: of V-22 Blade Modifications On Whirl Flutter and LoadsbernymirNo ratings yet

- A320 Ceo SpecificationDocument4 pagesA320 Ceo SpecificationlifefullpassionNo ratings yet

- ROTORCRAFT AEROMECHANICS 0. FrontmatterDocument6 pagesROTORCRAFT AEROMECHANICS 0. FrontmatterQuang Tuan BuiNo ratings yet

- Satellite Attitude and Orbital Dynamics Simulator: NtroductionDocument5 pagesSatellite Attitude and Orbital Dynamics Simulator: NtroductionJ.Y.No ratings yet

- Satellite IsolationDocument11 pagesSatellite Isolationmajid shahzadNo ratings yet

- Info Eduard - June 2021Document97 pagesInfo Eduard - June 2021Marcello AssunçãoNo ratings yet

- 38 TOCPA Paris March 2018 - Embraer - Fixing Airplanes Twice As Fast With CCPMDocument16 pages38 TOCPA Paris March 2018 - Embraer - Fixing Airplanes Twice As Fast With CCPMJelena FedurkoNo ratings yet

- Applied Aerodynamics BookDocument213 pagesApplied Aerodynamics BookYasser NogoudNo ratings yet

- Task 5 Tell The StoryDocument40 pagesTask 5 Tell The StoryVicente LozanoNo ratings yet

- RT4000 Single AntennaDocument2 pagesRT4000 Single AntennabaruaeeeNo ratings yet

- Air Data Attitude Heading Reference System: FeaturesDocument2 pagesAir Data Attitude Heading Reference System: FeaturesIventNo ratings yet

- ICAO Frequency Management ManualDocument19 pagesICAO Frequency Management ManualelgauchoandresNo ratings yet

- G950 NXi Beech1900DDocument4 pagesG950 NXi Beech1900Dmchinks theaNo ratings yet

- Performance Improvement of FD FanDocument2 pagesPerformance Improvement of FD FanVIBHAVNo ratings yet

- Thakur Institute of Aviation TechnologyDocument10 pagesThakur Institute of Aviation TechnologyAshwini ChaurasiaNo ratings yet

- GOW - A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - 12-15-38-613-001-A - Fill The Potable Water Tank System (Aircraft Electrical Power Available)Document6 pagesGOW - A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - 12-15-38-613-001-A - Fill The Potable Water Tank System (Aircraft Electrical Power Available)nazia0% (1)

- Adaptive Missile Guidance Using GpsDocument9 pagesAdaptive Missile Guidance Using GpsAvinash MishraNo ratings yet

- TUM Mechanical EngineeringDocument41 pagesTUM Mechanical EngineeringJuan Carlos Pinzon OchoaNo ratings yet

- Bearing - Replacement - Guide - NSK 2015 PDFDocument428 pagesBearing - Replacement - Guide - NSK 2015 PDFLeroyNo ratings yet

- AKD20503 - 6a Autotrottle SystemDocument28 pagesAKD20503 - 6a Autotrottle SystemAtiqah Nabilah RazaliNo ratings yet

- SMS v-1Document321 pagesSMS v-1Muhammad RazaNo ratings yet

- Check My TripDocument3 pagesCheck My TripjiranaNo ratings yet

- John M. Seddon - EL Goldsmith - Intake Aerodynamics 1 (1999, Blackwell Science LTD)Document473 pagesJohn M. Seddon - EL Goldsmith - Intake Aerodynamics 1 (1999, Blackwell Science LTD)MNS KNo ratings yet

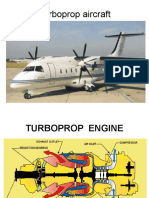

- Turboprop PropDocument46 pagesTurboprop PropJohan100% (2)

- Reach Datasheet V2020.2Document2 pagesReach Datasheet V2020.2Akshay DolasNo ratings yet

- Friction Welding: Schillings Tsang, EG&G Rocky FlatsDocument3 pagesFriction Welding: Schillings Tsang, EG&G Rocky FlatsDarryl007No ratings yet

- Solar Portable GPS Tracker (JT600) - China Gps Tracker, Solar GPS, Solar Gps Tracker in GPSDocument2 pagesSolar Portable GPS Tracker (JT600) - China Gps Tracker, Solar GPS, Solar Gps Tracker in GPSCecilia GrunauerNo ratings yet

- Conic Word ProblemsDocument4 pagesConic Word ProblemsAubrey Love LabardaNo ratings yet