Professional Documents

Culture Documents

Blasting Permit STB-HSE-P-01

Uploaded by

Istaqrar Mehdi BaqriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Blasting Permit STB-HSE-P-01

Uploaded by

Istaqrar Mehdi BaqriCopyright:

Available Formats

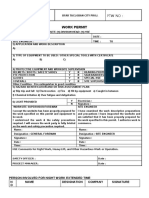

BLASTING PERMIT

Project Name: Exact Location:

Contractor Name: Blaster Name:

Date & Time of issue:

Name of Permit Issuer:

Name of Permittee:

Permit No. & Validity:

Sl. Description Observation Remark, if any

No. (Y/N/NA)

01 a. No. of holes

b. Amount of Charge per hole

c. Name of Explosive Used

d. Firing Pattern & Sequence (Sketch on Page-3)

e. No. of misfire if any

02 Has the permission for blasting operation taken from authority?

03 Is ID card & license available with blaster?

04 Is safety induction training provided to all workers & blaster?

05 Is competent supervisor & EHSO available at work location?

06 Does toolbox for safety precaution conducted & record available?

07 Is relevant PPEs used by workers & blaster?

08 Is the driller provided with helmet, apron, safety glass, gum boot

& ear plug?

09 Is “No Unauthorized Operation” implemented and displayed?

10 Are weather conditions considered for blasting (such as rain/

thunderstorm/ wind)?

11 Are warning posters & red flags displayed?

12 Is the danger zone cordoned off to control unauthorised person?

13 Is the nearby area vacated from traffic, trespassers, cattle, etc.?

14 Is the drilling equipment inspected before use & fit for use?

15 Is there any electrical/telecom/gas line in close vicinity of blasting?

16 Are the bored holes cleared off all debris before insertion of

explosives?

17 Has the vehicle carrying explosives is approve and licensed?

18 Are the explosives & cartridges of correct size?

19 Are the excessive cartridges removed from location before

blasting?

20 Are the filled holes covered with 5mm Steel sheet & Sandbags?

21 Are all workers leaving the “blasting zone” after loading?

22 Is there a proper system of siren & hooter to evacuate /prevent

trespassers from blasting zone?

23 Have the circuit been checked for continuity before blasting by

blaster?

24 Are electric blasting caps/ safety blasting cap available?

25 Are safety fuse and detonating cord delay connectors available?

26 Has position of all holes to be drilled marked out with white paint?

27 Is blasting material inventory maintained?

28 Are wooden tamping tools with no exposed metal parts except

STB-HSE-P-01 Page 1 of 3 Rev.: 00, Dated: 26.08.2022

BLASTING PERMIT

non-sparking metal connectors for jointed poles used?

29 Are sand, earth, clay or other suitable non-combustible stemming

material used to confine the explosives in the bore hole?

30 Is welding/cutting of metal done inside the tunnel at the time of

loading?

31 Is firing circuit kept completely insulated from the ground or

other conductors, such as bare wires, rails, pipes etc.

32 have shot firer valid license, Safety inducted & medically fit?

33 Have explosives transported and stored along with other

materials?

34 Have explosives, detonating fuse & detonators kept in separate

wooden boxes at least 2m away.

35 Have the documents such as method statement, HIRA, permit is

approved and available during the activity?

36 Are 30 minutes interval between drilling & placement of primed

cartridges in the drill holes maintained?

37 Has visually inspection of the explosives done before use?

38 Are explosives being used damaged?

39 Have all connection checked before blasting?

40 Is there safe place for shot firer at least 30m away from blasting

area while firing?

41 Whether any misfire detected?

If yes, give the details (Action Taken)

42 Are we ensuring charged holes attended till the completion of

blasting operation?

43 Has bore holes thoroughly cleaned before a cartridge is inserted?

44 Wooden tamping rods (not pointed, but cylindrical throughout

shall be used in charging the holes.

Note: All person shall be evacuated from danger zone and warning siren shall be blown before the starting of

blast.

The precautions and safe conditions mentioned above have been verified. So, blasting operation may be

performed.

Name and Designation of Issuing Authority:

Signature:

I have checked the above points of this permit and found conditions are suitable and safe to undertake the blast.

Name and Designation of Permittee:

Signature:

Post Blasting Activities

STB-HSE-P-01 Page 2 of 3 Rev.: 00, Dated: 26.08.2022

BLASTING PERMIT

01 Has the blaster returned to blasting site after firing within the 5

minutes after blast?

02 Have the shot holes examined after blasting in case of electric shot

firing?

03 Are any person approaching the blasting site within 5 minutes in

case of misfire?

04 Are there any counting system to know about the no of misfire?

05 Is there any mechanism to ensue no person allowed to approach

the blasting site within the 30 minutes.

06 Are all holes carefully inspected for residual undetonated

explosives after firing the shots?

07 Are any mechanism to ensue new hole 60 cm away from the old

bore.

* After verification of all safety measure, “All Clear Siren” must be blown to resume the work.

** Permit must be closed for blast.

Permittee Issuing Authority Name of EHSO

Signature Signature Signature

Date & Time Date & Time Date & Time

Firing Pattern:

STB-HSE-P-01 Page 3 of 3 Rev.: 00, Dated: 26.08.2022

You might also like

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&AFrom EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&ANo ratings yet

- Safety - Form-SAF019-HotWorkPermitDocument5 pagesSafety - Form-SAF019-HotWorkPermitEdwin MofokengNo ratings yet

- Drilling Blasting Safety ChecklistDocument3 pagesDrilling Blasting Safety ChecklistPankaj JagtapNo ratings yet

- Permit-to-Work For Blasting OperationDocument1 pagePermit-to-Work For Blasting Operationsrinu degalaNo ratings yet

- Safety - Walk - Down - Checklist-Issue - 2-Rev - .0 - UMSQEMRDDocument3 pagesSafety - Walk - Down - Checklist-Issue - 2-Rev - .0 - UMSQEMRDShalu vargheseNo ratings yet

- Checklist For Welding & CuttingDocument1 pageChecklist For Welding & CuttingBTL EPC LTDNo ratings yet

- PTW - BlastingDocument4 pagesPTW - BlastingJaya Prakash100% (1)

- Pre-Spud Checklist C-1Document2 pagesPre-Spud Checklist C-1Ericson OlaloNo ratings yet

- Permit For Blasting Operation A. To Be Filled Up by The Person Taking The PermitDocument3 pagesPermit For Blasting Operation A. To Be Filled Up by The Person Taking The PermitDinesh BadheNo ratings yet

- HSE Hot Work PermitDocument3 pagesHSE Hot Work PermitCSD shakthiNo ratings yet

- Hot Work ChecklistDocument1 pageHot Work ChecklistloganathanNo ratings yet

- Daily Inspection ChecklistDocument1 pageDaily Inspection ChecklistprabhuNo ratings yet

- K007-OHSE Daily Inspn CHK ListDocument1 pageK007-OHSE Daily Inspn CHK ListKarthik KarthikNo ratings yet

- WPR... Converted 65questionsDocument8 pagesWPR... Converted 65questionsMohamed rasheedNo ratings yet

- Blasting Work PermitDocument2 pagesBlasting Work PermitHariharan MuthukrishananNo ratings yet

- Excavation Work PermitDocument1 pageExcavation Work Permitsadafnoor997No ratings yet

- HCC F 085 17 004, R 01, 1 OF 2 - Balasting PermitDocument1 pageHCC F 085 17 004, R 01, 1 OF 2 - Balasting PermitAshwin JadhavNo ratings yet

- Excavation ChecklistDocument5 pagesExcavation ChecklistBassam HSENo ratings yet

- SWP CHECKLISTS - Welding Cutting and HeatingDocument3 pagesSWP CHECKLISTS - Welding Cutting and HeatingSrinivas Dumpala HSE100% (1)

- HSE Contractors Predictive Metrics Compliance ChecklistDocument25 pagesHSE Contractors Predictive Metrics Compliance Checklistzubair khanNo ratings yet

- Safety Audit ListDocument4 pagesSafety Audit ListBHARAT TALPADANo ratings yet

- Abrasive Blasting Inspection ChecklistDocument1 pageAbrasive Blasting Inspection ChecklistRísês Ãfröz67% (3)

- SPI HSE FR 01 Foundation ChecklistDocument1 pageSPI HSE FR 01 Foundation ChecklistChandan KumarNo ratings yet

- 1 HotworkDocument1 page1 Hotworkchariot1729No ratings yet

- P-HSE-25 HOT WORKS Safety PermitDocument1 pageP-HSE-25 HOT WORKS Safety PermitgilNo ratings yet

- Blasting AwarenessDocument74 pagesBlasting AwarenessSaurav ChhabraNo ratings yet

- FRM-2530-03 Daily Site Inspection Checkllist Ver - 00Document4 pagesFRM-2530-03 Daily Site Inspection Checkllist Ver - 00Ali KaziNo ratings yet

- S-0508-CSC Contractor Safety ChecklistDocument1 pageS-0508-CSC Contractor Safety Checklist김순혁No ratings yet

- FRM-OHS-HOT - WORK - PERMIT - Permit & GuidelinesDocument2 pagesFRM-OHS-HOT - WORK - PERMIT - Permit & Guidelinespunitg_2No ratings yet

- Checklist For ARC Welding MachineDocument2 pagesChecklist For ARC Welding Machineelbba ninloNo ratings yet

- Hot Work PermitDocument1 pageHot Work PermitAMG Co.No ratings yet

- Excavation Checklist: Name of Contractor: Date: Location: Activities: Checked By: Project NameDocument1 pageExcavation Checklist: Name of Contractor: Date: Location: Activities: Checked By: Project NameRahul Kumar100% (1)

- Welding Machine ChecklistDocument1 pageWelding Machine ChecklistBiswaranjan SahooNo ratings yet

- Hot Work PermitDocument2 pagesHot Work PermitSiddharthNo ratings yet

- Housekeeping Inspection Checklist for Naval Base ReconstructionDocument2 pagesHousekeeping Inspection Checklist for Naval Base Reconstructionprabu lingamNo ratings yet

- Pre Pouring Inspection ChecklistDocument2 pagesPre Pouring Inspection Checklistvarunstuff75% (4)

- HCC F 085 17 004, R 01, 2 OF 2 - Balasting PermitDocument1 pageHCC F 085 17 004, R 01, 2 OF 2 - Balasting PermitAshwin JadhavNo ratings yet

- C01.Daily Inspection Checklist For Safety Mesures at SiteDocument1 pageC01.Daily Inspection Checklist For Safety Mesures at SiteSRR OHSENo ratings yet

- R 14 Height Work Permit FormatDocument2 pagesR 14 Height Work Permit FormatPRIYESH . K. PRIYANNo ratings yet

- A Cold WorkDocument1 pageA Cold WorkUmesh AryaNo ratings yet

- Excavation Permit FormDocument2 pagesExcavation Permit FormazozinlcNo ratings yet

- ESH Hotworks Compliance ChecklistDocument1 pageESH Hotworks Compliance ChecklistRichard BaileyNo ratings yet

- All ChecklistDocument31 pagesAll Checklistsunil KumarSwainNo ratings yet

- Safe Work PermitDocument33 pagesSafe Work PermitkishpatNo ratings yet

- Work PermitDocument2 pagesWork PermitJames TripoliNo ratings yet

- Drilling Inspection Form 3160-10Document3 pagesDrilling Inspection Form 3160-10vitali_curteanuNo ratings yet

- PGF-001 Blast Guard ProcedureDocument6 pagesPGF-001 Blast Guard ProcedureBenito Lionel ZoboNo ratings yet

- Wrapping Coating ProcedureDocument5 pagesWrapping Coating Procedureshantanu kumar100% (1)

- Work Permit - Hot WorkDocument2 pagesWork Permit - Hot WorkNibha100% (1)

- HSE Inspection Checklist: 1 Safety PromotionDocument4 pagesHSE Inspection Checklist: 1 Safety PromotionRanjan PrNo ratings yet

- Safe Work Permit 1Document33 pagesSafe Work Permit 1harish14586No ratings yet

- Ohs-Pr-09-10-F05 (A) Explosive Power Tool & Cartridge Issuing RegisterDocument2 pagesOhs-Pr-09-10-F05 (A) Explosive Power Tool & Cartridge Issuing RegisterSiddiqui100% (1)

- Excavation Work Checklist: Saline Water Desalination Plant On The West CoastDocument2 pagesExcavation Work Checklist: Saline Water Desalination Plant On The West CoastBRC HSE Dept.No ratings yet

- Excavation Safety ChecklistDocument2 pagesExcavation Safety Checklistsindarth raveendrakrishnanNo ratings yet

- PSU Kitchen Safety ChecklistDocument2 pagesPSU Kitchen Safety ChecklistDhaval DobariyaNo ratings yet

- Concreting Safety Checklist: Oh & S Management SystemDocument2 pagesConcreting Safety Checklist: Oh & S Management Systemmunna yadavNo ratings yet

- Excavation Work PermitDocument2 pagesExcavation Work Permitmuhammad.younisNo ratings yet

- OLD BGAS Grade-1 - Revision Questions - 2007Document11 pagesOLD BGAS Grade-1 - Revision Questions - 2007Alex joseph alexNo ratings yet

- Safe Work PermitsDocument35 pagesSafe Work PermitsSourav JaiswalNo ratings yet

- 21st Century Literature Quarter 2 Week 7Document5 pages21st Century Literature Quarter 2 Week 7SHERRY MAE MINGONo ratings yet

- MCAS Forces and Equilibrium PracticeDocument51 pagesMCAS Forces and Equilibrium PracticeSyd MalaxosNo ratings yet

- Mccsemi: 8050 SS-C 8050 SS-DDocument2 pagesMccsemi: 8050 SS-C 8050 SS-DLeonardo IñiguezNo ratings yet

- Knowledge (2) Comprehension (3) Application (4) Analysis (5) Synthesis (6) EvaluationDocument5 pagesKnowledge (2) Comprehension (3) Application (4) Analysis (5) Synthesis (6) EvaluationxtinNo ratings yet

- Methanol from Syngas Plant DesignDocument13 pagesMethanol from Syngas Plant DesignKhalidMadaniNo ratings yet

- PTR 326 Theoretical Lecture 1Document14 pagesPTR 326 Theoretical Lecture 1muhammedariwanNo ratings yet

- Sta. Cruz South Central ES Project Proposal: Name of OfficeDocument2 pagesSta. Cruz South Central ES Project Proposal: Name of OfficeLea Joy Mendiguarin-Dela Cruz100% (2)

- Chapter OneDocument36 pagesChapter Onepretoria agreement21No ratings yet

- MCMC Methods For Multi-Response Generalized LinearDocument22 pagesMCMC Methods For Multi-Response Generalized LinearkyotopinheiroNo ratings yet

- LS - 0 - 2 - 1 - 02384346aa856-Essay Writing For SSC T-3 (English) PDFDocument47 pagesLS - 0 - 2 - 1 - 02384346aa856-Essay Writing For SSC T-3 (English) PDFBHARATH S RNo ratings yet

- VsamDocument24 pagesVsamRodrigoNo ratings yet

- Industrial Radiography Image Forming Techniques English 4Document114 pagesIndustrial Radiography Image Forming Techniques English 4Narasimha Murthy InampudiNo ratings yet

- Application of CFD To Debottleneck Production SepaDocument14 pagesApplication of CFD To Debottleneck Production SepaFernando AmoresNo ratings yet

- Clarke 1973 Loss of InnocenceDocument13 pagesClarke 1973 Loss of InnocencePaula TralmaNo ratings yet

- Asia Pacific Chemicals 181302Document52 pagesAsia Pacific Chemicals 181302sealaishaniNo ratings yet

- Master of Arts (Education) /post Graduate Diploma in Educational Management and Administration (Maedu/Pgdema) Term-End Examination June, 2020Document7 pagesMaster of Arts (Education) /post Graduate Diploma in Educational Management and Administration (Maedu/Pgdema) Term-End Examination June, 2020Shreyashi Santra MitraNo ratings yet

- 1 A Simulation Based Model For The BerthDocument9 pages1 A Simulation Based Model For The Berthmonu_vitsNo ratings yet

- Chap3-2e SO2 Absorption ExampleDocument8 pagesChap3-2e SO2 Absorption Exampledarkelf_riderNo ratings yet

- Why Am I Getting Temperature Divergence in AMG SolverDocument7 pagesWhy Am I Getting Temperature Divergence in AMG SolverSulaimanNo ratings yet

- Ideas For Income Generating Projects PDFDocument29 pagesIdeas For Income Generating Projects PDFheart AquinoNo ratings yet

- Nouveau Document TexteDocument6 pagesNouveau Document Texteamal mallouliNo ratings yet

- How To Avoid PlagiarismDocument2 pagesHow To Avoid PlagiarismShiny Deva PriyaNo ratings yet

- Build Pulse Oximeter InstructionsDocument3 pagesBuild Pulse Oximeter InstructionsPrabhuDevNo ratings yet

- Case Study of Haleeb FoodDocument18 pagesCase Study of Haleeb Foodjazi_4u86% (22)

- Oil and Gas FieldDocument5 pagesOil and Gas FieldMuhammad SyafiieNo ratings yet

- Blogger TemplateDocument15 pagesBlogger TemplateSteffi Jasmyn BelderolNo ratings yet

- Remote Access Portal User GuideDocument3 pagesRemote Access Portal User GuidezeljavaNo ratings yet

- Solar Bloc DatasheetDocument2 pagesSolar Bloc DatasheetandresNo ratings yet

- Calculating production costs and selling pricesDocument2 pagesCalculating production costs and selling pricesMitch BelmonteNo ratings yet

- Estatement 2020022506Document1 pageEstatement 2020022506ALL IN ONE. BOOLIWOOd SONGNo ratings yet