Professional Documents

Culture Documents

Sistema de Arranque Kawasaki

Uploaded by

Willian Jose Navarro ZepedaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sistema de Arranque Kawasaki

Uploaded by

Willian Jose Navarro ZepedaCopyright:

Available Formats

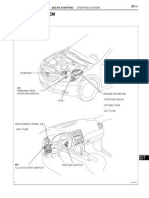

16-46 ELECTRICAL SYSTEM

Electric Starter System

Starter Motor Removal

CAUTION

Do not tap the starter motor shaft or body. Tapping

the shaft or body could damage the motor.

• Remove:

Fuel Tank (see Fuel Tank Removal in the Fuel System

(DFI) chapter)

Air Cleaner Housing (see Air Cleaner Housing Removal

in the Fuel System (DFI) chapter)

• Slide out the rubber cap [A].

• Remove the starter motor cable terminal nut [B].

• Remove the mounting bolts [C].

• Pull out the starter motor [D].

Starter Motor Installation

CAUTION

Do not tap the starter motor shaft or body. Tapping

the shaft or body could damage the motor.

• When installing the starter motor, clean the starter mo-

tor legs [A] and crankcase [B] where the starter motor is

grounded.

• Replace the O-ring [A] with a new one.

• Apply a non-permanent

Apply grease to the O-ring.

• the bolts and tighten the locking

bolts.

agent to the threads of

Torque - Starter Motor Mounting Bolts: 9.8 N·m (1.0 kgf·m,

87 in·lb)

• Install the starter motor cable [A] as shown.

About 20° [B]

Front [C]

• Tighten:

Torque - Starter Motor Cable Terminal Nut: 6.0 N·m (0.61

kgf·m, 53 in·lb)

• Slide back the rubber cap to the original position.

ELECTRICAL SYSTEM 16-47

Electric Starter System

Starter Motor Disassembly

• Remove the starter motor (see Starter Motor Removal).

• the both end starter

Take off the motor through bolts [A] and remove

covers [B].

• Pull out the armature [A] out of the yoke [B].

NOTE

○Do not remove the circlip [C] from the shaft.

• Remove the starter motor terminal locknut [A].

• Pull out the brushes from the brush holder [A].

• Brush Springs [B]

Remove:

Starter Motor Terminal [C]

Positive Brush Assembly [D]

Screw [E]

Negative Brush Assembly [F]

Brush Holder

Starter Motor Assembly

• Be sure that the stopper [A] is in position.

• Align the hole [B] of the brush holder [C] to the boss [D]

of the right-hand end cover [E].

16-48 ELECTRICAL SYSTEM

Electric Starter System

• Align the stoppers [A] of the negative brush assembly [B]

to the grooves [C] of the brush holder [D].

• Tighten the screw securely.

• Align the stoppers [A] of the positive brush assembly [B]

to the grooves [C] of the brush holder [D].

• Install the starter motor terminal.

• Replace the O-ring [A] with a new one.

• New O-ring

Install the following parts to the starter motor terminal [B].

Collar [C]

Washer [D]

Starter Motor Terminal Locknut [E]

○Install the collar so that stepped side faces outward.

•Tighten:

Torque - Starter Motor Terminal Locknut: 11 N·m (1.1

kgf·m, 97 in·lb)

• Install the brush springs [A] and insert the brushes [B].

• Apply thin coat of grease to the oil seal [A].

ELECTRICAL SYSTEM 16-49

Electric Starter System

• Replace the O-rings [A] with new ones.

• hollow sidearmature

Insert the [B] so that commutator side [C] faces

[D] of the yoke [E].

• Align the marks [A] to assembly the yoke and the end

covers [B].

• Replace the O-rings [A] with new ones.

• Tighten the through bolts [B].

Torque - Starter Motor Through Bolts: 5.0 N·m (0.51 kgf·m,

44 in·lb)

Brush Inspection

• Measure the length of each brush [A].

If any is worn down to the service limit, replace the brush

assembly.

Starter Motor Brush Length

Standard: 12 mm (0.47 in.)

Service Limit: 6.5 mm (0.26 in.)

Commutator Cleaning and Inspection

• Clean the metallic debris off the between commutator

segments [A].

NOTE

○Do not use emery or sand paper on the commutator.

• Check the commutator for damage or abnormal wear.

Replace the starter motor with a new one if there is any

damage or wear.

• Visually inspect the commutator segments for discol-

oration.

Replace the starter motor with a new one if discoloration

is noticed.

16-50 ELECTRICAL SYSTEM

Electric Starter System

Armature Inspection

• Using the × 1 Ω hand tester range, measure the resis-

tance between any two commutator segments [A].

Special Tool - Hand Tester: 57001-1394

If there is a high resistance or no reading (∞) between any

two segments, a winding is open and the starter motor

must be replaced.

• Using the highest hand tester range, measure the resis-

tance between the segments and the shaft [B].

If there is any reading at all, the armature has a short and

the starter motor must be replaced.

NOTE

○Even if the foregoing checks show the armature to be

good, it may be defective in some manner not readily

detectable with the hand tester. If all other starter motor

and starter motor circuit components check good, but

the starter motor still does not turn over or only turns

over weakly, replace the starter motor with a new one.

Brush Lead Inspection

• Using the × 1 Ω hand tester range, measure the resis-

tance as shown.

Terminal Bolt and Positive Brushes [A]

Right-hand End Cover and Negative Brushes [B]

Special Tool - Hand Tester: 57001-1394

If there is not close to zero ohms, the brush lead has an

open. Replace the brush assembly.

Right-hand End Cover Inspection

• Using the highest tester range, measure the resistance

as shown.

Terminal Bolt and Right-hand End Cover [A]

Terminal Bolt and Negative Brushes [B]

Special Tool - Hand Tester: 57001-1394

If there is any reading, the brush assy and/or terminal bolt

assy have a short. Replace the starter motor.

Starter Relay Inspection

• Remove:

Bolt [A]

Cover [B]

ELECTRICAL SYSTEM 16-51

Electric Starter System

• Disconnect:

Connector [A]

Starter Motor Cable [B]

Battery Positive (+) Cable [C]

• Remove the starter relay.

CAUTION

The battery positive (+) cable with the rubber cap is

connected directly to the battery positive (+) termi-

nal even when the ignition switch off, so take care

not to short the removed cable to chassis ground.

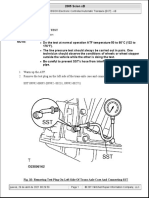

• Connect the hand tester [A] and 12 V battery [B] to the

starter relay [C] as shown.

Special Tool - Hand Tester: 57001-1394

If the relay does not work as specified, the relay is defec-

tive. Replace the relay.

Testing Relay

Tester Range: × 1 Ω range

Criteria: When battery is connected → 0 Ω

When battery is disconnected → ∞ Ω

16-52 ELECTRICAL SYSTEM

Electric Starter System

Electric Starter Circuit

1. Ignition Switch

2. Frame Ground

3. Water-proof Joint C

4. Starter Lockout Switch

5. Fuse Box

6. Ignition Fuse 10 A

7. Relay Box

8. Starter Circuit Relay

9. Main Fuse 30 A

10. Starter Relay

11. Starter Motor

12. Battery 12 V 10 Ah

13. Frame Ground

14. Sidestand Switch

15. Neutral Switch

16. Starter Button

17. Engine Stop Switch

You might also like

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Sistema de Carga de Kawasaki Er650Document10 pagesSistema de Carga de Kawasaki Er650Willian Jose Navarro ZepedaNo ratings yet

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Periodic Maintenance Procedures: Optional Part (P/No. 92005-3746) Is Available As A Gar-Den Hose AdapterDocument18 pagesPeriodic Maintenance Procedures: Optional Part (P/No. 92005-3746) Is Available As A Gar-Den Hose AdapterYamahauki SusukiNo ratings yet

- Removal of AlternatorDocument11 pagesRemoval of AlternatorvixentdNo ratings yet

- Chevelle Performance Projects: 1964-1972From EverandChevelle Performance Projects: 1964-1972Rating: 4.5 out of 5 stars4.5/5 (2)

- 13-8 Suspension: Front ForkDocument5 pages13-8 Suspension: Front ForkMIGUEL ANDRES MENDOZA MARTINEZNo ratings yet

- Boat Maintenance Companions: Electrics & Diesel Companions at SeaFrom EverandBoat Maintenance Companions: Electrics & Diesel Companions at SeaNo ratings yet

- Toyota Camry 2006-2011 2AZ-FE ChargingDocument21 pagesToyota Camry 2006-2011 2AZ-FE ChargingMichael MatthewsNo ratings yet

- Delco Radio Owner's Manual Model 633; Delcotron Generator InstallationFrom EverandDelco Radio Owner's Manual Model 633; Delcotron Generator InstallationNo ratings yet

- MINI Cooper, Cooper S, Clubman (R55, R56, R57) Service Manual: 2007-2013 - Excerpt: VANOS Units, Removing and Installing (N12, N16, N18 Engine)Document7 pagesMINI Cooper, Cooper S, Clubman (R55, R56, R57) Service Manual: 2007-2013 - Excerpt: VANOS Units, Removing and Installing (N12, N16, N18 Engine)Bentley Publishers88% (25)

- 1GR FE ChargingDocument15 pages1GR FE ChargingDemosthenes QuintanaNo ratings yet

- Engine Electrical SystemDocument14 pagesEngine Electrical SystemMatthew Robert QuinnNo ratings yet

- Starting System (2Az-Fe) : InspectionDocument40 pagesStarting System (2Az-Fe) : InspectionTung Nguyen100% (1)

- Alternator 130a.xmlDocument16 pagesAlternator 130a.xmlAnjaliNo ratings yet

- Charging System: PrecautionDocument17 pagesCharging System: PrecautionlogammicNo ratings yet

- 2GR FE ChargingDocument25 pages2GR FE Chargingmink4uNo ratings yet

- ChargingDocument17 pagesChargingSJElliNo ratings yet

- AlternatorDocument19 pagesAlternatorcpgmotorsNo ratings yet

- Preparatory Steps: Note: The Following Procedure Is Only To Be Used ForDocument9 pagesPreparatory Steps: Note: The Following Procedure Is Only To Be Used FordeedNo ratings yet

- 121-20 Battery, Starter, Alternator: Alternator, Removing and Installing (Turbo)Document1 page121-20 Battery, Starter, Alternator: Alternator, Removing and Installing (Turbo)Kevin HuangNo ratings yet

- Starting PDFDocument19 pagesStarting PDFAndrey GladyshevNo ratings yet

- 2AZ FE StartingDocument16 pages2AZ FE StartingLuks FernandezNo ratings yet

- Alternador y Bomba de VacioDocument9 pagesAlternador y Bomba de Vaciocarlos Gutierrez De La HozNo ratings yet

- K25 8Document17 pagesK25 8mushfiq66No ratings yet

- 7 BrakesDocument143 pages7 BrakesghettotalonNo ratings yet

- Motor3 Suzuki VL800Document20 pagesMotor3 Suzuki VL800Crisan SorinNo ratings yet

- QuickServe Online - (4021499) K19 Service ManualDocument10 pagesQuickServe Online - (4021499) K19 Service Manualengmohsen.ramadanhotmail.com100% (1)

- 7 +brakesDocument143 pages7 +brakesLuis Daniel RodriguezNo ratings yet

- 19 - Starting and Charging PDFDocument22 pages19 - Starting and Charging PDFJen-Yung ChangNo ratings yet

- Toyota 4EFE - Correa de Distribucion PDFDocument11 pagesToyota 4EFE - Correa de Distribucion PDFAlvaro Garcia100% (4)

- Acura ZDX V6-3.7L 2010-Timing Belt: Service and RepairDocument19 pagesAcura ZDX V6-3.7L 2010-Timing Belt: Service and RepairDaniel Alejandro Vázquez MárquezNo ratings yet

- Setting Obc KTA 19Document6 pagesSetting Obc KTA 19ariy yuli styawan100% (1)

- Yaesu G450Document12 pagesYaesu G450neosspn100% (1)

- Epicyclic Gear Train ApparatusDocument8 pagesEpicyclic Gear Train ApparatusGurmeet Mehma83% (6)

- Clutch Echo 2002Document17 pagesClutch Echo 2002Tomas DominguezNo ratings yet

- 9057803-Winding & Brushes ChangeDocument6 pages9057803-Winding & Brushes ChangeSergey MylnikovNo ratings yet

- Generator Starter ClutchDocument9 pagesGenerator Starter ClutchMar PopNo ratings yet

- Sicnronización de Motor Hyundai, Kia, G4LC PDFDocument18 pagesSicnronización de Motor Hyundai, Kia, G4LC PDFJorge Cedeno100% (3)

- Subject AreaDocument30 pagesSubject Areauri.cruz.zamoraNo ratings yet

- EC (STi) 02 Emission ControlDocument18 pagesEC (STi) 02 Emission ControlGustavo RivasNo ratings yet

- Overhaul: 1. Remove Repair Service Starter KitDocument6 pagesOverhaul: 1. Remove Repair Service Starter KitdiemnganNo ratings yet

- AUMA Valve ActuatorDocument14 pagesAUMA Valve ActuatorSellappan MuthusamyNo ratings yet

- Alignment of TwoDocument15 pagesAlignment of TwoquintanacalzadillasjaimeNo ratings yet

- Why Perform A Torsion TestDocument13 pagesWhy Perform A Torsion Testschoffil100% (1)

- Clutch Actuator & TCM AssemblyDocument13 pagesClutch Actuator & TCM AssemblyVinh XuânNo ratings yet

- Motor ProboxDocument12 pagesMotor ProboxrufuruNo ratings yet

- 841 - Pdfsam - SM PC300LC, HD-8 A90001, A87001 Up CEBM018701Document80 pages841 - Pdfsam - SM PC300LC, HD-8 A90001, A87001 Up CEBM018701jaime bolivarNo ratings yet

- Valves and Unit Injectors, AdjustmentDocument17 pagesValves and Unit Injectors, AdjustmentRolando Mancilla Flores91% (58)

- Inst Cylinder HeadDocument8 pagesInst Cylinder Headmanuel1357100% (1)

- Versys - 1000 (2014) - 37-40 PDFDocument4 pagesVersys - 1000 (2014) - 37-40 PDFPachu 99No ratings yet

- Đo kiểm MKĐDocument7 pagesĐo kiểm MKĐQuyền NguyễnNo ratings yet

- QuickServe Online - (3666003) C Series Troubleshooting and Repair Manual SETT VALVEDocument4 pagesQuickServe Online - (3666003) C Series Troubleshooting and Repair Manual SETT VALVEKrisman SimanjuntakNo ratings yet

- Starting SystemDocument23 pagesStarting SystemArgenis BriceñoNo ratings yet

- RB 25 HeadDocument9 pagesRB 25 HeadAlexander Dominguez0% (1)

- Testing Maintenance Troubleshooting ACBDocument16 pagesTesting Maintenance Troubleshooting ACB322399mk7086No ratings yet

- Toyota Celica l4 2.2l Dohc 5s Fe 1990Document16 pagesToyota Celica l4 2.2l Dohc 5s Fe 1990ORLANDO0301No ratings yet

- 1953 Lucas Dynamos E3L E3LM E3NDocument7 pages1953 Lucas Dynamos E3L E3LM E3NedelapolloNo ratings yet

- Timing Belt: Service and Repair Acura TL V6 3.2 2006Document16 pagesTiming Belt: Service and Repair Acura TL V6 3.2 2006Vicctor PiñaNo ratings yet

- Faja de Tiempo Mitsubishi Montero 1998Document6 pagesFaja de Tiempo Mitsubishi Montero 1998Willian Jose Navarro ZepedaNo ratings yet

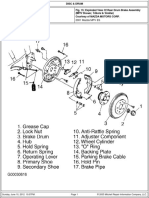

- Fig. 15 - Exploded View of RearDocument1 pageFig. 15 - Exploded View of RearWillian Jose Navarro ZepedaNo ratings yet

- Fig. 9 - Exploded View of FrontDocument1 pageFig. 9 - Exploded View of FrontWillian Jose Navarro ZepedaNo ratings yet

- Comprobación de MedicionesDocument1 pageComprobación de MedicionesWillian Jose Navarro ZepedaNo ratings yet

- Medicion Presion de Aceite Caja Automática SCION XBDocument2 pagesMedicion Presion de Aceite Caja Automática SCION XBWillian Jose Navarro ZepedaNo ratings yet

- Mecanismo de Cambio Mecánico de Velocidades 2Document4 pagesMecanismo de Cambio Mecánico de Velocidades 2Willian Jose Navarro ZepedaNo ratings yet

- Diagnostico y Overhaul A41 A40d Toyota TransmisionDocument66 pagesDiagnostico y Overhaul A41 A40d Toyota TransmisionWillian Jose Navarro ZepedaNo ratings yet

- Comprobación de MedicionesDocument1 pageComprobación de MedicionesWillian Jose Navarro ZepedaNo ratings yet

- CHAPTER 7: Benchmark Test ResultsDocument10 pagesCHAPTER 7: Benchmark Test Resultsnapoleon_velasc3617No ratings yet

- Catalog RAFI Components 2015Document663 pagesCatalog RAFI Components 2015Amd Mamd100% (1)

- Week1 QuizDocument7 pagesWeek1 QuizKrishna EelaNo ratings yet

- 4 - Ce133 - Strength Analysis of Beams According To Aci or NSCP Codes PDFDocument22 pages4 - Ce133 - Strength Analysis of Beams According To Aci or NSCP Codes PDFRalph PacilNo ratings yet

- 4.2 Beam Post-ProcessingDocument23 pages4.2 Beam Post-Processingjingyong123No ratings yet

- Metal Q Clip System Brochure PDFDocument5 pagesMetal Q Clip System Brochure PDFSunil Dinanath JoshiNo ratings yet

- API 510 Questions Amp Answers Closed Book 1 PDF FreeDocument12 pagesAPI 510 Questions Amp Answers Closed Book 1 PDF Freejakariya100% (2)

- Cross Platform Migration Using Transportable Tablespace 12c With Zero Downtime DBACLASS PDFDocument22 pagesCross Platform Migration Using Transportable Tablespace 12c With Zero Downtime DBACLASS PDFSiva KumarNo ratings yet

- CT Excel Skills Test Revised 12102015Document8 pagesCT Excel Skills Test Revised 12102015Soundarya Ramesh0% (1)

- Safety Stations G1902: Guardian EquipmentDocument2 pagesSafety Stations G1902: Guardian Equipmenteisenbarger5607No ratings yet

- Using Oracle Database Vault With Oracle Database 12c - D86597GC10 - 1080544 - USDocument3 pagesUsing Oracle Database Vault With Oracle Database 12c - D86597GC10 - 1080544 - USJinendraabhi0% (1)

- DIN - EN-571-1 Penetrent-TestingDocument18 pagesDIN - EN-571-1 Penetrent-TestingraldelgadomaNo ratings yet

- Waste TreatmentDocument8 pagesWaste TreatmentJournalNX - a Multidisciplinary Peer Reviewed JournalNo ratings yet

- Contoh Bangunan Tropis 3Document132 pagesContoh Bangunan Tropis 3Ahmad Aziz FuadiNo ratings yet

- Signaling in RE AreaDocument30 pagesSignaling in RE AreaVikas Srivastav93% (15)

- Montage Kit 4x4 FGDocument30 pagesMontage Kit 4x4 FGsousou0033No ratings yet

- Lecture-14 Sheet Metal Forming ProcessesDocument34 pagesLecture-14 Sheet Metal Forming ProcessesDida KhalingNo ratings yet

- Steel Structures - GeneralDocument16 pagesSteel Structures - Generalonur gunesNo ratings yet

- Nursing Informatics: Kozier & Erb: Concepts, Process & PracticeDocument13 pagesNursing Informatics: Kozier & Erb: Concepts, Process & Practiceanon-314986No ratings yet

- Rendering An Exterior Scene - V-Ray 2.0 For SketchUp - Chaos Group HelpDocument9 pagesRendering An Exterior Scene - V-Ray 2.0 For SketchUp - Chaos Group HelpRapha RachoNo ratings yet

- Rigging Guide 2008Document222 pagesRigging Guide 2008Alex1No ratings yet

- M04 - L01 - Student GuideDocument9 pagesM04 - L01 - Student GuideShreyasNo ratings yet

- HVAC Dampers Installation Method StatementDocument3 pagesHVAC Dampers Installation Method StatementDong VanraNo ratings yet

- 2N Lift1: Brief ManualDocument12 pages2N Lift1: Brief ManualMartijnMartensNo ratings yet

- Water Supply and Distribution SystemingDocument5 pagesWater Supply and Distribution SystemingMelissa GabayNo ratings yet

- Microwave JunctionsDocument20 pagesMicrowave JunctionsSaraswathi Asirvatham100% (2)

- The Chengdu Jian-20Document20 pagesThe Chengdu Jian-20Cat CrysisNo ratings yet

- EMM 3514 - Numerical MethodDocument33 pagesEMM 3514 - Numerical MethodAdhar GoodNo ratings yet

- JUMONG General (JMPS) Installation Manual - en - CMP200 - 20181129Document44 pagesJUMONG General (JMPS) Installation Manual - en - CMP200 - 20181129Juan Alberto RomeroNo ratings yet

- Foam-Water Spray Extinguishing System, Powerhouse Diesel EngDocument10 pagesFoam-Water Spray Extinguishing System, Powerhouse Diesel EngdheerajdorlikarNo ratings yet