Professional Documents

Culture Documents

141022.TGT-HWL-G-H05-DS-7109 Pump Datasheet - Rev 0 - Attached

Uploaded by

ocanhthuOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

141022.TGT-HWL-G-H05-DS-7109 Pump Datasheet - Rev 0 - Attached

Uploaded by

ocanhthuCopyright:

Available Formats

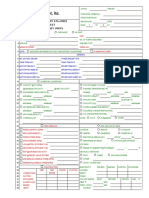

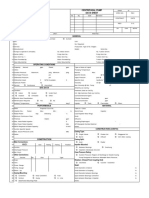

TGT FIELD DEVELOPMENT PROJECT

TITLE DOCUMENT NUMBER REV DATE PAGE

PUMP DATASHEET TGT-HWL-G-H05-DS-7109 0 7-Jul-14 3 of 13

REVISION CONTROL SHEET

Latest Rev. Date Issued Prepared Reviewed Approved Comments

A 20-Jun-14 PTA PVT LAV

B 20-Jun-14 PTA PVT LAV

C 7-Jul-14 PTA PVT LAV

0 1-Sep-14 PTA PVT LAV

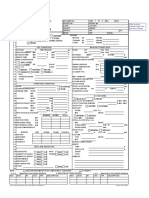

TGT FIELD DEVELOPMENT PROJECT

TITLE DOCUMENT NUMBER REV DATE PAGE

PUMP DATASHEET TGT-HWL-G-H05-DS-7109 0 1-Sep-14 4 of 13

1 APPLICABLE TO: ● PROPOSAL ● PURCHASE ○ AS BUILT

2 FOR HOANG LONG JOINT OPERATING COMPANY UNIT CHEMICAL INJECTION PACKAGE

3 SITE VIET NAM NO. OF PUMPS REQUIRED ONE (1) x 100%

4 SERVICE CHEMICAL DOSING SIZE AND TYPE PL149T18M238/EN.9.C5.LD.VV2.Z

5 MANUFACTURER MILTON ROY EUROPE SERIAL NO. NOTE 3

6

7 NOTE: ○ INDICATES INFORMATION TO BE COMPLETED BY PURCHASER □ BY MANUFACTURER

8 GENERAL

9 NO. MOTORS DRIVEN 1 B OTHER DRIVER TYPE N/A

10 PUMP ITEM NO'S H05-49-P-001A PUMP ITEM NO'S N/A

11 MOTOR ITEM NO'S H05-49-PM-002A DRIVER ITEM NO'S N/A GEAR ITEM NO'S N/A

12 MOTOR PROVIDED BY MRE B DRIVER PROVIDED BY N/A GEAR PROVIDED BY N/A

13 MOTOR MOUNTED BY MRE DRIVER MOUNTED BY N/A GEAR MOUNTED BY N/A

14 MOTOR DATA SHEET NO. INCLUDED DRIVER DATA SHEET NO. N/A GEAR DATASHEET NO. N/A

15

16 ● OPERATING CONDITIONS ● LIQUID

17 ● CAPACITY @ PUMPING TEMPERATURE (LPH): ● TYPE OR NAME OF LIQUID POUR POINT DEPRESSANT

18 MAXIMUM 71.0 MINIMUM RATED ● PUMPING TEMPERATURE (°C):

19 ● DISCHARGE PRESSURE (barg): NORMAL AMB MAX 35.5 MIN 17.4

20 MAXIMUM 40 MINIMUM 20 ● SPECIFIC GRAVITY 0.9 @ 50 deg C MAXIMUM MINIMUM

21 ● SUCTION PRESSURE (barg): ○ SPECIFIC HEAT Cp (kJ/kg.oC)

22 MAXIMUM ATM MINIMUM ● VISCOSITY (cP) 80 @ 50 deg C MINIMUM 200 @ 50 deg C MAXIMUM

23 ● DIFFERENTIAL PRESSURE (bar) ○ CORROSIVE/EROSIVE AGENTS

24 MAXIMUM 40 MINIMUM 20 ○ CHLORIDE CONCENTRATION (PPM)

25 ■ NPSH AVAILABLE (m) 13.333 ○ H S CONCENTRATION (PPM)

2

26 WITHOUT ACCELERATION HEAD 4.767 ACTUAL - LIQUID ● TOXIC ● FLAMMABLE ○ OTHER

27 ● TURNDOWN RATIO 10 : 1

28

29 ■ PERFORMANCE ● SITE AND UTILITY DATA

30 ■ NUMBER OF FEEDS 1 RATED CAPACITY (LPH) 102 LOCATION ○ INDOOR ● OUTDOOR

31 ■ NPSH REQUIRED (m) 10.305 ○ HEATED ● UNHEATED ● UNDER ROOF

32 ■ kw RATED 2.981 AT RELIEF SETTING 238 Barg ● ELECT. AREA CLASS T3 GROUP II A DIV ZONE 2

33 ■ PLUNGER SPEED (strokes/min) 151 DESIGN MAX 180 ○ WINTERIZATION REQD ● TROPICALIZATION REQD

34 ■ DIAMETER (mm) 18 LENGTH OF STROKE (mm) 50 SITE DATA

35 PUMP HEAD: 1 ● RANGE OF AMBIENT TEMPS:MIN/MAX 17.4 / 35.5 °C

36 MAXIMUM PRESSURE (barg) 350 UNUSUAL CONDITIONS MARINE - OFFSHORE

37 ■ HYDRO TEST PRESSURE (barg) 357 ○ DUST ○ INDOOR ● OUTDOOR

38 ■ MAX DISCH PRESS. W/ JOB DRIVER (barg) 238 ○ OTHER

39 ■ MAX KW BASIS GEAR STRENGTH 5.5

40 ● UTILITY CONDITIONS

41 ■ CONSTRUCTION ELECTRICITY DRIVERS HEATING CONTROL SHUTDOWN

42 SIZE ANSI FACING POSITION VOLTAGE 400 110 110

43 CONNECTIONS RATING HERTZ 50 50 50

44 SUCTION 1/2" NPTM N/A BOTTOM PHASE 3 1 1

45 DISCHARGE 1/2" NPTM N/A TOP COOLING WATER INLET RETURN DESIGN MAX Δ

46 FLUSH TEMP °C NA MAX

47 PRESS. (barg) NA MIN

48 LIQUID END ○ JACKET REQ'D SOURCE

49 TYPE ○ DIAPHRAGM ● PLUNGER UTILITY AIR NORMAL MIN

50 ■ DIAPHRAGM DIA (MM) 162 NO REQ. 02 PRESSURE (barg) N/A N/A

51

52 ■ VALVES/FEED SUCTION DISCHARGE APPLICABLE SPECIFICATIONS:

53 TYPE BALL BALL ● API 675 POSITIVE DISPLACEMENT PUMPS - CONTROLLED VOLUME

54 NUMBER 02 02 ● GOVERNING SPECIFICATION (IF DIFFERENT) GEN-M-XXX-SP-0003

55

56 REMARKS 1. Each pumps set shall consist of a PPD pump head (H05-49-P-001A) & Demilsifier pump head (H05-49-P-002A) with a common electric motor

57 (Tag No: H05-49-PM-002A) B

58 2. Protective coating and painting shall comply with COMPANY's specification or equivalent with COMPANY's prior approval.

59 3. Serial No. for each pump shall be provided later.

60

61

62

63

64

65

TGT FIELD DEVELOPMENT PROJECT

TITLE DOCUMENT NUMBER REV DATE PAGE

PUMP DATASHEET TGT-HWL-G-H05-DS-7109 0 1-Sep-14 5 of 13

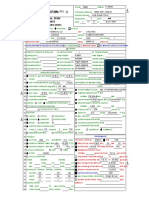

1 ■ MATERIALS CONTROLS

2 LIQUID END 316L SS TYPE: SIGNAL:

3 CONTOUR PLATE 316L SS ● MANUAL ● REMOTE ○ PNEUMATIC

4 HYDRAULIC DIAPHRAGM 316L SS ○ AUTOMATIC ○ LOCAL ○ ELECTRONIC

5 PROCESS DIAPHRAGM 316L SS STROKE CONTROL: ECC ELECTRONIC ACTUATOR

6 PLUNGER CS ATEX CE II/D T5 220V / 1 PH / 50 Hz - IP 55

7 LANTERN RING N/A MINIMUM MAXIMUM

8 PACKING GLAND N/A ELECTRONIC (mA): SERVO METER

9 PACKING N/A MINIMUM 4 mA MAXIMUM 20 mA

10

11 VALVE 316L SS OTHER PURCHASE REQUIREMENTS

12 VALVE SEAT SS17-4PH NAMEPLATE UNITS ○ U.S. CUSTOMARY ● SI

13 VALVE GUIDE 316L SS ● VENDOR FURNISHED PROCESS PIPING

14 VALVE BODY 316L SS

15 VALVE GASKET N/A ● VENDOR REVIEW PIPING DRAWINGS

16 FRAME CI ● VENDOR FURNISHED PULSATION SUPPRESSION DEVICES

17 SPECIAL MATERIAL TESTS (2.13.1.3) ● VENDOR FURNISHED RELIEF VALVE

18 ○ INTERNAL ● EXTERNAL

19 ○ LOW AMBIENT TEMPERATURE MATERIALS TESTS (2.13.5) ● RELIEF VALVE SETTING (barg) 238

20 ○ VENDOR FURNISHED BACK-PRESSURE VALVE

21 QA INSPECTION AND TEST

● DOUBLE CHECK VALVES REQUIRED

22 ● COMPLIANCE WITH INSPECTORS CHECK LIST ○ OIL-FILLED PRESSURE GAUGES REQUIRED

23 ● CERTIFICATION OF MATERIALS EN10204 3.1 ○ VENDOR FURNISHED CONTROL PANEL

24 ● FINAL ASSEMBLY CLEARANCES ○ BASEPLATE PREPARED FOR EPOXY GROUT

25 ● SURFACE AND SUBSURFACE EXAMINATIONS ● PROVIDE TECHNICAL DATA MANUAL

26 ○ RADIOGRAPHY AS PER SPECS. & API

27 ○ ULTRASONIC AS PER SPECS. & API

28 ○ MAGNETIC PARTICLE N/A PREPARATION FOR SHIPMENT

29 ○ LIQUID PENETRANT N/A ○ DOMESTIC ○ EXPORT ● EXPORT BOXING

30 ● OUTDOOR STORAGE MORE THAN 6 MONTHS

31 ● CLEANLINESS PRIOR TO FINAL ASSEMBLY WEIGHTS (kg)

32 ● HARDNESS OF PARTS, WELDS & HEAT AFFECTED ZONESNACE MR 0175 ■ PUMP 255 ■ GEAR INCLUDED

33 ● FURNISH PROCEDURES FOR OPTIONAL TESTS ■ BASE INCLUDED ■ DRIVER N/A

34

35 TESTS REQ'D WIT OBS DRIVERS

36 HYDROSTATIC ● ● ○ NOTE: REFER TO MOTOR DETAILS UNDER DEMULSIFIER PUMP DATASHEET.

37 STEADY STATE ACCURACY ● ○ ○

38 REPEATABILITY ● ○ ○

39 LINEARITY ● ○ ○

40 FAT ● ● ○

41

42 LUBRICATION FLUID

43 □ CRANKCASE ISO 220 □ INTERMEDIATE

44 □ HYDRAULIC FLUID SHELL TELLUS 32S

45 ACCESSORIES

46 ● PUMP CONTROLLER / STROKE REDUCER

47 ■ MANUFACTURER MILTON ROY EUROPE

48 ● INTEGRAL ○ SEPARATE `

49 □ MODEL WORM GEAR

50 □ RATIO 9.66 : 1

51 ○ BASEPLATE UNDER SOLE BASEPLATE FOR DUPLEX

52 ○ COUPLING

53 □ COUPLING MANUFACTURER MP FILTRI

54 □ TYPE FLEXIBLE

55

56

57

58

59

60

61

62

63

64

65

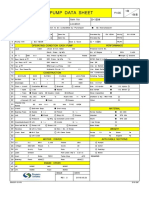

TGT FIELD DEVELOPMENT PROJECT

TITLE DOCUMENT NUMBER REV DATE PAGE

PUMP DATASHEET TGT-HWL-G-H05-DS-7109 0 1-Sep-14 6 of 13

1 APPLICABLE TO: ● PROPOSAL ● PURCHASE ○ AS BUILT

2 FOR HOANG LONG JOINT OPERATING COMPANY UNIT CHEMICAL INJECTION PACKAGE

3 SITE VIET NAM NO. OF PUMPS REQUIRED ONE (1) x 100%

4 SERVICE CHEMICAL DOSING SIZE AND TYPE PL96R18M238/EN.C5.LD.VV2.Z

5 MANUFACTURER MILTON ROY EUROPE SERIAL NO. NOTE 3

6

7 NOTE: ○ INDICATES INFORMATION TO BE COMPLETED BY PURCHASER □ BY MANUFACTURER

8 GENERAL

B

9 NO. MOTORS DRIVEN 1 OTHER DRIVER TYPE N/A

10 PUMP ITEM NO'S H05-49-P-002A PUMP ITEM NO'S N/A

11 MOTOR ITEM NO'S H05-49-PM-002A DRIVER ITEM NO'S N/A GEAR ITEM NO'S N/A

12 MOTOR PROVIDED BY MRE B DRIVER PROVIDED BY N/A GEAR PROVIDED BY N/A

13 MOTOR MOUNTED BY MRE DRIVER MOUNTED BY N/A GEAR MOUNTED BY N/A

14 MOTOR DATA SHEET NO. INCLUDED DRIVER DATA SHEET NO. N/A GEAR DATASHEET NO. N/A

15

16 ● OPERATING CONDITIONS ● LIQUID

17 ● CAPACITY @ PUMPING TEMPERATURE (LPH): ● TYPE OR NAME OF LIQUID DEMULSIFIER

18 MAXIMUM 50.0 MINIMUM RATED ● PUMPING TEMPERATURE (°C):

19 ● DISCHARGE PRESSURE (barg): NORMAL AMB MAX 35.5 MIN 17.4

20 MAXIMUM 40 MINIMUM 20 ● SPECIFIC GRAVITY 0.99 @ 16 deg C MAXIMUM 0.92 @ 16 deg C MINIMUM

21 ● SUCTION PRESSURE (barg): ○ SPECIFIC HEAT Cp (kJ/kg.oC)

22 MAXIMUM ATM MINIMUM ● VISCOSITY (cP) MINIMUM 20 @ 38 deg C MAXIMUM

23 ● DIFFERENTIAL PRESSURE (bar) ○ CORROSIVE/EROSIVE AGENTS

24 MAXIMUM 40 MINIMUM 20 ○ CHLORIDE CONCENTRATION (PPM)

25 ■ NPSH AVAILABLE (m) 12.334 ○ H S CONCENTRATION (PPM)

2

26 WITHOUT ACCELERATION HEAD 10.409 ACTUAL - LIQUID ● TOXIC ● FLAMMABLE ○ OTHER

27 ● TURNDOWN RATIO 10 : 1

28

29 ■ PERFORMANCE ● SITE AND UTILITY DATA

30 ■ NUMBER OF FEEDS 1 RATED CAPACITY (LPH) 66 LOCATION ○ INDOOR ● OUTDOOR

31 ■ NPSH REQUIRED (m) 1.925 ○ HEATED ● UNHEATED ● UNDER ROOF

32 ■ kw RATED 2.009 AT RELIEF SETTING 238 Barg ● ELECT. AREA CLASS T3 GROUP II A DIV ZONE 2

33 ■ PLUNGER SPEED (strokes/min) 97 DESIGN MAX 180 ○ WINTERIZATION REQD ● TROPICALIZATION REQD

34 ■ DIAMETER (mm) 18 LENGTH OF STROKE (mm) 50 SITE DATA

35 PUMP HEAD: 1 ● RANGE OF AMBIENT TEMPS:MIN/MAX 17.4 / 35.5 °C

36 MAXIMUM PRESSURE (barg) 350 UNUSUAL CONDITIONS MARINE - OFFSHORE

37 ■ HYDRO TEST PRESSURE (barg) 357 ○ DUST ○ INDOOR ● OUTDOOR

38 ■ MAX DISCH PRESS. W/ JOB DRIVER (barg) 238 ○ OTHER

39 ■ MAX KW BASIS GEAR STRENGTH 5.5

40 ● UTILITY CONDITIONS

41 ■ CONSTRUCTION ELECTRICITY DRIVERS HEATING CONTROL SHUTDOWN

42 SIZE ANSI FACING POSITION VOLTAGE 400 110 110

43 CONNECTIONS RATING HERTZ 50 50 50

44 SUCTION 1/2" NPTM N/A BOTTOM PHASE 3 1 1

45 DISCHARGE 1/2" NPTM N/A TOP COOLING WATER INLET RETURN DESIGN MAX Δ

46 FLUSH TEMP °C NA MAX

47 PRESS. (barg) NA MIN

48 LIQUID END ○ JACKET REQ'D SOURCE

49 TYPE ○ DIAPHRAGM ● PLUNGER UTILITY AIR NORMAL MIN

50 ■ DIAPHRAGM DIA (MM) 162 NO REQ. 02 PRESSURE (barg) N/A N/A

51

52 ■ VALVES/FEED SUCTION DISCHARGE APPLICABLE SPECIFICATIONS:

53 TYPE BALL BALL ● API 675 POSITIVE DISPLACEMENT PUMPS - CONTROLLED VOLUME

54 NUMBER 02 02 ● GOVERNING SPECIFICATION (IF DIFFERENT) GEN-M-XXX-SP-0003

55

56 REMARKS 1. Each pumps set shall consist of a PPD pump head (H05-49-P-001A) & Demilsifier pump head (H05-49-P-002A) with a common electric motor

57 (Tag No: H05-49-PM-002A) B

58 2. Protective coating and painting shall comply with COMPANY's specification or equivalent with COMPANY's prior approval.

59 3. Serial No. for each pump shall be provided later.

60

61

62

63

64

65

You might also like

- Po#141802tpeDocument7 pagesPo#141802tpeocanhthuNo ratings yet

- Data Sheet Multiphase Pump BornermanDocument5 pagesData Sheet Multiphase Pump BornermanUmar Ijaz KhanNo ratings yet

- Turbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionFrom EverandTurbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionRating: 5 out of 5 stars5/5 (4)

- API 675 Pump DatasheetDocument2 pagesAPI 675 Pump DatasheetArun CPNo ratings yet

- Loadsheet Demin Water Pump PU-1202 ABDocument13 pagesLoadsheet Demin Water Pump PU-1202 ABGunturMudaAliAkbarNo ratings yet

- Pompa KSB Type RPH 100-230, PT Multi Trading Pratama - TBBM BatulicinDocument124 pagesPompa KSB Type RPH 100-230, PT Multi Trading Pratama - TBBM Batulicinmuh_akbar2451No ratings yet

- Sulphuric Acid Dosing Pump Motor ManualDocument28 pagesSulphuric Acid Dosing Pump Motor ManualmohammedsfNo ratings yet

- Datasheet Rev 1Document7 pagesDatasheet Rev 1Tauasi TauasisNo ratings yet

- Data Sheet Pompa HydrantDocument3 pagesData Sheet Pompa HydrantAnonymous 6S9tcbhNo ratings yet

- Rotary Pump - Customary UnitsDocument2 pagesRotary Pump - Customary UnitsVicky ANo ratings yet

- Centrifugal-Booster Data SheetDocument4 pagesCentrifugal-Booster Data SheetDiego RuanoNo ratings yet

- Hoja de Datos de BombaDocument5 pagesHoja de Datos de Bombaluis zambranoNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- BFP - Part 1Document1 pageBFP - Part 1nejatihosseinNo ratings yet

- Technical Bid Tabulation: Vendor Description SpecificationDocument8 pagesTechnical Bid Tabulation: Vendor Description SpecificationGunturMudaAliAkbarNo ratings yet

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

- Reciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneralDocument10 pagesReciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneraltxagusNo ratings yet

- Gas Compressor Package DatasheetDocument69 pagesGas Compressor Package Datasheetjohn100% (2)

- LNG Booster Pump DatasheetDocument7 pagesLNG Booster Pump DatasheetsswahyudiNo ratings yet

- AgitatorDocument3 pagesAgitatorMarcelo PerettiNo ratings yet

- (GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Document3 pages(GPM) (GPM) (PSIG) (ºF) (PSIG) (PSIA) (PSI) S. G. (FT) (PSIA) (CP) CP (BTU/Lb ºF)Said ArjonaNo ratings yet

- Rotary Pump Data SheetDocument6 pagesRotary Pump Data SheetCarlos GomezNo ratings yet

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet U.S. Customary UnitsDocument4 pagesBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet U.S. Customary UnitsLipika GayenNo ratings yet

- SA-980-P-11449 - API 685 Submerged Pump PZ - Vert02Document5 pagesSA-980-P-11449 - API 685 Submerged Pump PZ - Vert02altipatlarNo ratings yet

- SA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02Document5 pagesSA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02altipatlarNo ratings yet

- API 610 Data Sheet 1 PDFDocument6 pagesAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliNo ratings yet

- 18CO5009-10-It2-D03-2 Pump Datasheet Format)Document10 pages18CO5009-10-It2-D03-2 Pump Datasheet Format)Gerencia Rigar Colombia SASNo ratings yet

- DatasheetDocument71 pagesDatasheetRhadityo Shakti BudimanNo ratings yet

- Solvent Recovery Bottoms Pumps (09P007A/B) : Data SheetDocument6 pagesSolvent Recovery Bottoms Pumps (09P007A/B) : Data SheetAthiphap SrisupareerathNo ratings yet

- (API 674-2nd) Reciprocating PumpDocument6 pages(API 674-2nd) Reciprocating PumpadistiNo ratings yet

- 14960-000-ME-DAS-003 Data Sheet For Sump PumpsDocument8 pages14960-000-ME-DAS-003 Data Sheet For Sump PumpsAshish TIwariNo ratings yet

- Sick Tanker Unloading PumpDocument3 pagesSick Tanker Unloading PumpSumantrra ChattopadhyayNo ratings yet

- 4936 Im Ap 02 10005Document7 pages4936 Im Ap 02 10005mauroalexandreandreNo ratings yet

- Data Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary UnitsDocument10 pagesData Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1No ratings yet

- Notes Information Below To Be Completed: by Manufacturer or PurchaserDocument5 pagesNotes Information Below To Be Completed: by Manufacturer or Purchaserrajindo1No ratings yet

- Controlled Volume Pump (Api 675-2Nd) Data Sheet U.S. Customary UnitsDocument3 pagesControlled Volume Pump (Api 675-2Nd) Data Sheet U.S. Customary UnitshamedNo ratings yet

- S-1504 Pump Data Sheet 3 PhaseDocument1 pageS-1504 Pump Data Sheet 3 PhaseHoonNo ratings yet

- UntitledDocument5 pagesUntitledJuan Bautista Rojas VillegasNo ratings yet

- Master Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)Document5 pagesMaster Planning of Utility Compound and Preliminary Engineering Design (30% Design Level) (30% Design Level)bubbles82No ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur DieselDocument7 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur DieselBilel MahjoubNo ratings yet

- Veco Engineering Ltd. Equipment Data Sheet: Positive Displacement PumpDocument3 pagesVeco Engineering Ltd. Equipment Data Sheet: Positive Displacement PumpChike NwachukwuNo ratings yet

- Api 674 Pump Data SheetDocument5 pagesApi 674 Pump Data Sheetroronoa_zorro11No ratings yet

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Document5 pagesSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNo ratings yet

- CDPL-EEL-SNM-PUMP-DS-0001 - Mainline Pump Data Sheet 4PD-47939 - R1Document7 pagesCDPL-EEL-SNM-PUMP-DS-0001 - Mainline Pump Data Sheet 4PD-47939 - R1Amit KumarNo ratings yet

- Gerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinDocument4 pagesGerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinGerencia Rigar Colombia SASNo ratings yet

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Document7 pagesData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaNo ratings yet

- VP-PP4-MP-255-PK-1401-0430 - REV.0 - VENDOR DOCUMENT FOR NaOH DOSING PUMPDocument10 pagesVP-PP4-MP-255-PK-1401-0430 - REV.0 - VENDOR DOCUMENT FOR NaOH DOSING PUMPMinh PhamNo ratings yet

- bb2 Pump-DatasheetDocument14 pagesbb2 Pump-DatasheetMojtabaNo ratings yet

- Datasheet For Pressure Controller - IfbDocument17 pagesDatasheet For Pressure Controller - Ifbfathan fathullahNo ratings yet

- 30001-Technical Specification Sheet (Datasheet)Document6 pages30001-Technical Specification Sheet (Datasheet)ali valatabar100% (1)

- General: Centrifugal Pump Data SheetDocument3 pagesGeneral: Centrifugal Pump Data Sheetfaraujodff10No ratings yet

- 2061-MIX-001 Rev1Document2 pages2061-MIX-001 Rev1Emmanuel Ber SNo ratings yet

- Lavalin Bomba SumergibleDocument3 pagesLavalin Bomba SumergibleEyffer Cabrera PalominoNo ratings yet

- Methanol Storage Facility Project: No. Dok.: - Revision No.Document1 pageMethanol Storage Facility Project: No. Dok.: - Revision No.Adhya RazanNo ratings yet

- DH01 M E 0007 - Mechanical Datashet For TankDocument4 pagesDH01 M E 0007 - Mechanical Datashet For TankDuy NamNo ratings yet

- BLG-SNT-M-INST-DSH-001-A4 Rev. 0 (Mechanical Datasheet) PDFDocument6 pagesBLG-SNT-M-INST-DSH-001-A4 Rev. 0 (Mechanical Datasheet) PDFEdy AlamNo ratings yet

- Comp 10 6 X 7 Phe7 Ba2Document2 pagesComp 10 6 X 7 Phe7 Ba2Ravi KantNo ratings yet

- Level Switch - Rev0Document8 pagesLevel Switch - Rev0ocanhthuNo ratings yet

- (ThTC3) BKT-001-TS-ME4-DS-09 - 1 - DATASHEET FOR FM-200 FIRE-EXTINGUISHING SYSTEMDocument3 pages(ThTC3) BKT-001-TS-ME4-DS-09 - 1 - DATASHEET FOR FM-200 FIRE-EXTINGUISHING SYSTEMocanhthuNo ratings yet

- Control Valves - Rev00Document12 pagesControl Valves - Rev00ocanhthuNo ratings yet

- Level Gauge - Rev0Document6 pagesLevel Gauge - Rev0ocanhthuNo ratings yet

- (Thtc3) BKT 001 Ts Me4 SP 07 - 2 - Specification For FM 200 Fire Extinguishing SystemDocument21 pages(Thtc3) BKT 001 Ts Me4 SP 07 - 2 - Specification For FM 200 Fire Extinguishing SystemocanhthuNo ratings yet

- Q 280416 IBSS CommentsDocument4 pagesQ 280416 IBSS CommentsocanhthuNo ratings yet

- (Thtc3) BKT 001 Ts Tx4 Pid 05 - 0 - FM 200 Fire Extinguishing System P and I DiagramDocument2 pages(Thtc3) BKT 001 Ts Tx4 Pid 05 - 0 - FM 200 Fire Extinguishing System P and I DiagramocanhthuNo ratings yet

- Po - 96508941 OdDocument6 pagesPo - 96508941 OdocanhthuNo ratings yet

- (Thtc3) BKT 001 Gen Az7 SP 01 - 0 - Technical Specification For PaintingDocument37 pages(Thtc3) BKT 001 Gen Az7 SP 01 - 0 - Technical Specification For PaintingocanhthuNo ratings yet

- PHS-9F4D24-01-14 - Alpha ECCDocument1 pagePHS-9F4D24-01-14 - Alpha ECCocanhthuNo ratings yet

- 829-13 ALTM - SSI - Packing ListDocument5 pages829-13 ALTM - SSI - Packing ListocanhthuNo ratings yet

- Filter Element DrawingsDocument11 pagesFilter Element DrawingsocanhthuNo ratings yet

- Leaflet - S 201 - 2015 - EnglishDocument1 pageLeaflet - S 201 - 2015 - EnglishocanhthuNo ratings yet

- Im 0012 S201 Englsih V3 7Document8 pagesIm 0012 S201 Englsih V3 7ocanhthuNo ratings yet

- 141014.datasheet For PSV-1323Document2 pages141014.datasheet For PSV-1323ocanhthuNo ratings yet

- 2 Cert of OriginDocument1 page2 Cert of OriginocanhthuNo ratings yet

- GasAlertMicroClip XT - Datasheet (6642 1 EN)Document2 pagesGasAlertMicroClip XT - Datasheet (6642 1 EN)ocanhthuNo ratings yet

- Narayana... Iit Jee PaperDocument26 pagesNarayana... Iit Jee PaperAbhishek KumarNo ratings yet

- Thermodynamics Fundamental PrinciplesDocument444 pagesThermodynamics Fundamental PrinciplesWilliam Charly Calderon Rosales100% (2)

- ActuatorsDocument9 pagesActuatorsAvinash BaldiNo ratings yet

- Light-Reflection and RefractionDocument41 pagesLight-Reflection and Refractionapi-268345960No ratings yet

- Vacuum Technology (Part I) (A. Roth) (October 1972) (Israel Atomic Energy Commission)Document610 pagesVacuum Technology (Part I) (A. Roth) (October 1972) (Israel Atomic Energy Commission)Prashant Thankey100% (1)

- Manual de Partes Finisher InternoDocument41 pagesManual de Partes Finisher InternoAlex RendonNo ratings yet

- CHP 15-2 Wave Characteristics PDFDocument8 pagesCHP 15-2 Wave Characteristics PDFLakshyaNo ratings yet

- Cooling Tower Data Sheet REV-00Document12 pagesCooling Tower Data Sheet REV-00Anonymous ZnuMEWN1No ratings yet

- Physics Details SolutionDocument15 pagesPhysics Details SolutionkolodoloNo ratings yet

- Dynamometers 161011144109Document28 pagesDynamometers 161011144109Mr.S UpenderNo ratings yet

- Agission ADU451802 Datasheet PDFDocument1 pageAgission ADU451802 Datasheet PDFGiang Nguyễn TrườngNo ratings yet

- Flow Regimes On Sieve Trays For Gas Liquid ContactingDocument196 pagesFlow Regimes On Sieve Trays For Gas Liquid ContactingGrant FirthNo ratings yet

- Firas PPS AdhesionDocument23 pagesFiras PPS AdhesionYamili ChávezNo ratings yet

- BMS I-O ListDocument5 pagesBMS I-O ListCulve YonNo ratings yet

- Wei Huang Dissertation PDFDocument156 pagesWei Huang Dissertation PDFLinh NguyenNo ratings yet

- Chapter 6 Slab DesignDocument18 pagesChapter 6 Slab DesignZAX100% (1)

- NADCA-High Temp DieDocument12 pagesNADCA-High Temp DiejalilemadiNo ratings yet

- A Pipe Is Gradually Tapering in SizeDocument2 pagesA Pipe Is Gradually Tapering in SizeRez AdolfoNo ratings yet

- Steel Design 1Document26 pagesSteel Design 1Gracielle NebresNo ratings yet

- Integrity of Structural Steel After Exposure To Fire PDFDocument13 pagesIntegrity of Structural Steel After Exposure To Fire PDFSevrinNo ratings yet

- DARBY - Chemical Engineering Fluid Mechanics 3edition PDFDocument578 pagesDARBY - Chemical Engineering Fluid Mechanics 3edition PDFMiguel Zuniga100% (2)

- Question BankDocument7 pagesQuestion BankmunirajNo ratings yet

- Design A Safe, In-Compliance Relief ValveDocument5 pagesDesign A Safe, In-Compliance Relief Valvehans nijmeijerNo ratings yet

- HT Lecture 13 ConvectionSolvedProblemsDocument17 pagesHT Lecture 13 ConvectionSolvedProblemsJulio Cesar Castañeda MancipeNo ratings yet

- Ps2 GeoDocument9 pagesPs2 GeoRio Fae BautistaNo ratings yet

- Model Calculation of Heat Balance of Wood PyrolysiDocument10 pagesModel Calculation of Heat Balance of Wood PyrolysiqwerNo ratings yet

- Heat Mass TransferDocument221 pagesHeat Mass Transferjeas grejoyNo ratings yet

- Gas Dynamics 3rd Edition John Solutions ManualDocument35 pagesGas Dynamics 3rd Edition John Solutions Manualamandawrightrwfdcombka100% (22)

- Design Speculations: M-25 Mix Design (By Mass) For Ips-5 (Shastri Nagar), MeerutDocument3 pagesDesign Speculations: M-25 Mix Design (By Mass) For Ips-5 (Shastri Nagar), MeerutMuneer HaiderNo ratings yet

- Blue Moon Approach To Rare Events: Molecular Simulation September 2004Document9 pagesBlue Moon Approach To Rare Events: Molecular Simulation September 2004Della KhoirunnisaNo ratings yet