Professional Documents

Culture Documents

Contract specifications centrifugal pump

Uploaded by

Diego RuanoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Contract specifications centrifugal pump

Uploaded by

Diego RuanoCopyright:

Available Formats

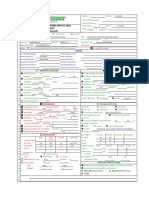

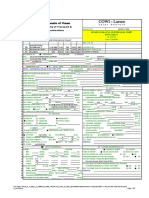

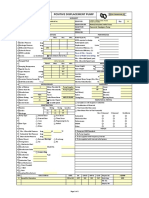

CONTRACT ENERPET ITEM NO.

TAG. AP53734 A / AP53734B

SPECIFICATION No. IN TERMS OF SR4142

DOCUMENT No. 0

REVISION NO. 0 DATE "Mayo 2013

CENTRIFUGAL PUMP DATA SHEET PAGE 1 OF 2 BY

1 APPLICABLE TO: PROPOSALS PURCHASE AS BUILT

2 FOR ECOPETROL UNIT

3 SITE ACACIAS, ESTACION ACACIAS SERVICE CENTRIFUGAL PUMPS

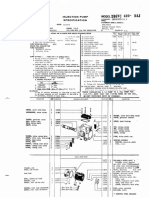

4 NO. REQ PUMP SIZE TYPE Centrifugal Horizontal

5 MANUFACTURER

6 MODEL SERIAL NO. 4172 / 4171

6 NOTE: INFORMATION BELOW TO BE COMPLETED: BY PURCHASER BY MANUFACTURER BY MANUFACTURER OR PURCHASER

7 NUMBER MOTOR DRIVEN N/A NUMBER TURBINE DRIVEN N/A GEARBOX ITEM NUMBER. N/A

8 MOTOR ITEM NUMBER. N/A TURBINE ITEM NUMBER. N/A GEARBOX PROVIDED BY N/A

9 MOTOR PROVIDED BY Pump Mnf. TURBINE PROVIDED BY N/A GEARBOX MOUNTED BY N/A

10 MOTOR MOUNTED BY Pump Mnf. TURBINE MOUNTED BY N/A

11 OPERATING CONDITIONS PERFORMANCE

12 Rated Max. Normal Min. Performance Curve No. GLM-15 Speed (rpm) 3600

13 Capacity (gpm) 60 70 60 50

14 Suction Pressure (psig) 10 20 10 5 Measured at Capacity Rated Max. Normal Min.

15 Discharge Pressure (psig) 55 80 55 40 NPSH Req'd (ft.)

16 Differential Pressure (psi) 45 Total Differential Head @ Rated Impeller (ft.)

17 Differential Head (ft.) 173,25 Max. Differential Head @ Rated Impeller (ft.)

18 Hydraulic Power (hp) 6,00 Minimum Continuos Flow

19 At Designated Capacity Normal Min Thermal (gpm) Stable (gpm)

20 Operating Time (hr./yr.) Allowable Operating Region To (gpm)

21 NPSH Available (ft.) 6,5 Best Efficiency Point for Rated Impeller (gpm)

22 System Design Suction Specific Speed

23 Stand Alone Operation One operating / One spare Impeller Diameter Rated Max. Min. (In.)

24 Series Operation with Item Number Pump Rated Power (bhp) Efficiency (%)

25 Suction Pressure Min./Max. 5,0 / 20 (psig) Maximum Power @ Rated Impeller (bhp)

26 Service Centrifugal, Nafta Rotation (Viewed from Coupling End) CW CCW

27 Continuous Intermittent (Starts/Day)

28 System Control Method Case Pressure Rating

29 Speed Flow Level Temperature Max. Allowable Working Pressure (psig)

30 Pressure Pipe Friction Resistence Only @ (°F)

31 PUMPED FLUID Hydrostatic Test Pressure (psig)

32 Pumped Fluid Gasoline Drain SITE CONDITIONS

33 Location Indoor Outdoor

34 Rated Max. Normal Min. Altitude 1575 (ft.)

35 Pumping Temperature (°F) Note 8 110 120 100 90 Range of Ambient Temperature Min./Max. 105 / 100 (°F)

36 Specific Gravity 0,6 65 60 0,58 Electrical Classification CL. 1 Div 2

37 Vapor Pressure (psia) 13 16 13 12 Non Hazardous

38 Viscocity (cP) 0,22 25 0,22 0,21 UTILITY CONDITIONS

39 Specific Heat (BTU/Lbmole.°F) 45 Electricity VOLTAGE PHASE HERTZ

40 Initial boiling point (°F) @ (psia) Drivers 460 VAC 3 60

41 Liquid Hazardous Flammable Heating N/A N/A N/A

42 Other Control 24 VDC 1 0

43 Shutdown 24 VDC 1 0

44 System Voltage DIP 80% Other

45 Corrosion/Erosion Caused By Steam MAX. PRESS. MAX. TEMP. MIN. PRESS. MIN. TEMP.

46 % Solid Max. Particle Size (in.) Drivers

47 MOTOR Heating

48 Manufacturer WEG Cooling Water Source NOT AVAILABLE

49 Horsepower Rating 7,5 (hp) Speed 3600 (rpm) Supply Temp. (°F) Max.. Return Temp. (°F)

50 Drive HP Selected or Max. S.G. & Max. Visc. (cp) Normal Pressure (psig) Design Pressure (psig)

51 Frame Enclosure TEFC Min. Rtn. Pressure (psig) Max. Allow. Drop P. (psi)

52 Horizontal Vertical Service Factor 1,15 Choride Concentration: (ppm)

53 Volts/Phase/Hertz 460 / 3 / 60 Instrument Air: Max./Min. Pressure: 150 / 100 (psig)

54 Type

55 Minimum Starting Voltage REMARKS.

56 Insulation class F Temperature Rise (°F)

57 Full Load Amps

51 Locked Rotor Amps

52 Starting Method Direct

53 Lube

54 Bearings (Type / Number):

55 Radial /

56 Thrust /

57 Vertical Thrust Capacity

58 Up (LBS) Down (LBS)

59

Centrifugal-Booster Data Sheet

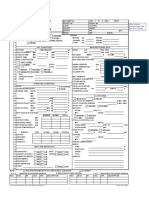

CONTRACT ENERPET ITEM NO.

TAG. AP53734 A / AP53734B

SPECIFICATION No. IN TERMS OF SR4142

DOCUMENT No. 0

REVISION NO. 0 DATE "Mayo 2013

CENTRIFUGAL PUMP DATA SHEET PAGE 2 OF 2 BY

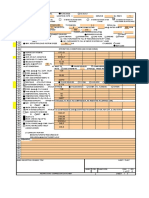

60 MECHANICAL DATA COUPLING BETWEEN PUMP AND DRIVER

61 Impeller Type Manufacturer

62 Closed Open Type DIRECT COUPLING

63 Semi-Open Other Size

64 Casing Mounting Model

65 Foot Centerline Spacer Length (in.)

66 Vertical Inline Close-Coupled Coupling Guard type

67 Bearings Manufacturer's Standard

68 Bearings Manufacturer SKF Base plate Mounted

69 Radial Bearing Type ball bearing No. 6305zz/6306zz Non-Spark Coupling Guard Required

70 Thrust Bearing Type No. Remarks

71 Bearings Isolators

72 Shaft Stiffness Ratio (L3/D4)

73 Lubrication

74 Flood Pure Mist Shielded (Grease) BASEPLATE

75 Grease Purge Mist Sealed (Grease) Remarks Grounded

76 Constant Level Oiler Required Centerline of pump to stilt bottom (in.)

77 Housing Vent Required Vertical Pump Case Support Bracket

78 Magnetic Drain Plug in Housing Required Design PIP Standard RESP002

79 Oil Cooler Required Manufacturer Standard

80 Seal Spray Guard Required Remarks

81 Oil Viscosity ISO Grade

82 Other

83 Nozzle Connections

84 PAINT AND SHIPMENT PREPARATION

85 SIZE (IN) FLANGE FACING Pump Baseplate

86 RATING (LBS) Manufacturer's Standard Manufacturer's Standard

87 Suction 2" 150# Oring Other Other

88 Discharge 1 1/2" 150# Oring Shipment

89 Aux. Case Connection Drain Required Domestic Export Export Boxing Required

90 Size (in.) Number of Months of Storage

91 Threaded welded and Flanged Weights

92 Pump (lbs) Baseplate (lbs)

93 MATERIALS Driver (lbs) Total (lbs)

94

95 Material Class Code INSPECTION AND TESTING

96 Casing GRAY IRON Final Inspection Required Days Notification Required

97 Impeller BRASS

98 Cover Test Non-Withnessed Withnessed Certificate

99 Shaft STEEL SAE 4140 Hydrostatic

100 Shaft Sleeve STEEL SAE 4140 Performance

101 Base Plate NPSHR

102 Casing Gasket TUNGTEN CARBIDE Vibration

103 Impeller Gasket Other

104 Casing Fasteners ASI 416 Dismantle and Inspect After Test

105 Bearing Housing GRAY IRON Casting Repair Procedure Approval Rquired

106 Bearing Housing Adapter Material Certificate Required

107 Bearing Housing End Seals Casing Cover Impeller Shaft

108 Coupling Guard GRAY IRON Other Bearings, O´rings, Fixed and move track insert

109 Mechanical Seal Gland Inspection Required for Connection Welds

110 Mechanical Seal Gland Fasteners Manufacturer's Standard Visual Inspection

111 Inspection Required for Castings

112 REMARKS. Is the responsibility of the vendor providing the construction Manufacturer's Standard Visual Inspection

113 materials of the pump suitable for handling fluid to be pumped Other

114

115 MANUFACTURER DOCUMENTATION REQUIREMENTS

116

117 For Vendor Data Requirements Refer to:

118

119 REMARKS:

120

121

122

123

124

Centrifugal-Booster Data Sheet

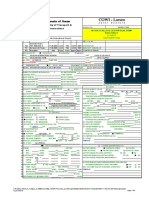

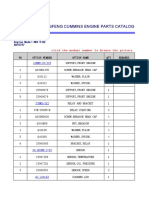

JOB NO. 0 ITEM NO. 0

PURCHASE ORDER No.

SPECIFICATION No. IN TERMS OF SR4142

DOCUMENT No. 0

REVISION NO. 0 DATE "Mayo 2013

CENTRIFUGAL PUMP DATA SHEET PAGE 3 OF 4 BY

125 MECHANICAL SEAL BARRIER/BUFFER FLUSH SYSTEM

126 Supplied By Pump Manufacturer Purchaser

127 Mounted By Pump Manufacturer Purchaser Barrier Flush Plan

128 Seal Classification Code Barrier Flush Liquid

129 Manufacturer Temperature Min./Max. / (°F)

130 Model Specific Gravity

131 Manufacturer Code Specific Heat (BTU/Lb.°F)

132 Seal Type Cartridge Component Vapor Pressure (psia) @ (°F)

133 Seal design Single Dual Dry Gas Pressure Required Min./Max. / (psig)

134 Pressurized Unpressurized MAWP of Secondary Seal System (psig)

135 Seal Chamber Taper Bore Cylindrical bore Temperature Required Min./Max. / (°F)

136 Seal Chamber size Oversized Standard Secondary Seal Flush Piping Tubing Pipe

137 Material 316SS Carbon steel

138 Pumping Ring Required Other

139 Throat Bushing Required Materials Piping/Tubing Size (in.)

140 REMARKS. Piping Assembly

141 Threaded Unions Flanged

142 Tube Type Fittings Socket Welded

143 REMARKS.

144 SEAL GLAND

145 Taps Required Quench Flush Drain

146 Other

147 Throttle Bushing Materials

148

149 SEAL FLUSHING SEAL SYSTEM INSTRUMENTATION

150

151 Primary Flush Plan No. Plan 11 Primary Seals Gauges Switches

152 External Flush Liquid Flow

153 Supply Temperature Min./Max. / (°F) Temperature

154 Specific Gravity Pressure

155 Specific Heat (BTU/Lb.°F) Secondary Seals

156 Vapor Pressure (psia) @ (°F) Flow

157 Flow Rate Required Min./Max. / (gpm) Pressure

158 Pressure Required Min./Max. / (psig) Level

159 Temperature Required Min./Max. / (°F)

160 REMARKS.

161 Primary Seal Flush Piping

162 Tubing Pipe Other

163 Material 316SS Carbon steel

164 Other

165 Piping/Tubing Size (in.)

166 Piping Assembly COOLING OR HEATING PIPING PLANS

167 Threaded Unions Flanged

168 Tube Type Fittings Socket Welded Piping Plan no.

169 REMARKS. Name of Fluid

170 Inlet Temperature (°F)

171 Outlet Temperature (°F)

172 Rated Flow (gpm)

173 Supply Pressure (psig)

174 Max. Allowable ΔP (psi)

175 SPARE PARTS

176 Start-Up Normal Maintenace Galvanized Pipe SS Tubing

177 Speciy Sight Flow indicator

178 Outlet Shut-Off Valve

179

180 REMARKS.

181

182

183

184

185

186 REMARKS.

187

188

189

190

191

192

193

194

195

196

197

198

199

200

201

Centrifugal-Booster Data Sheet

JOB NO. 0 ITEM NO. 0

PURCHASE ORDER No.

SPECIFICATION No. IN TERMS OF SR4142

DOCUMENT No. 0

REVISION NO. 0 DATE "Mayo 2013

CENTRIFUGAL PUMP DATA SHEET PAGE 4 OF 4 BY

202 GENERAL REMARKS

203

204 Note 1. SELLER shall complete and fill out data sheet information as required.

205 Note 2. SELLER shall mount each pump complete with its driver, and accessories on a skid for installation by the BUYER

206 as a complete unit.

207 Note 3. The pump selected for testing shall be the first pump completed unless otherwise mutually agreed by SELLER and BUYER.

208 Note 4. SELLER shall select materials in accordance with pumped fluid and ASME B73.1 standard.

209 Note 5. Pumps will be Electrical Motor driven and packaged by the pumps SELLER.

210

211

212

213

214

215

216

217

218

219

220

221

222

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

247

248

249

250

251

252

Centrifugal-Booster Data Sheet

You might also like

- Asme b31 3 2022Document23 pagesAsme b31 3 2022Surendra Tholchuri50% (22)

- API 675 Pump DatasheetDocument2 pagesAPI 675 Pump DatasheetArun CPNo ratings yet

- Centrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si UnitsDocument15 pagesCentrifugal Pump API 610 10TH EDITION / ISO 13709 Process Data Sheet Si Unitsf09aiNo ratings yet

- Pompa KSB Type RPH 100-230, PT Multi Trading Pratama - TBBM BatulicinDocument124 pagesPompa KSB Type RPH 100-230, PT Multi Trading Pratama - TBBM Batulicinmuh_akbar2451No ratings yet

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

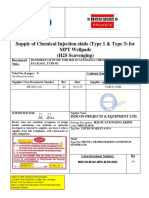

- Supply Chemical Injection SkidsDocument4 pagesSupply Chemical Injection Skidsbmanojkumar16No ratings yet

- Know and Understand Centrifugal PumpsFrom EverandKnow and Understand Centrifugal PumpsL. BachusRating: 4 out of 5 stars4/5 (1)

- 30001-Technical Specification Sheet (Datasheet)Document6 pages30001-Technical Specification Sheet (Datasheet)ali valatabar100% (1)

- SEO-OPTIMIZED TITLEDocument5 pagesSEO-OPTIMIZED TITLEaltipatlarNo ratings yet

- Veco Engineering Ltd. Equipment Data Sheet: Positive Displacement PumpDocument3 pagesVeco Engineering Ltd. Equipment Data Sheet: Positive Displacement PumpChike NwachukwuNo ratings yet

- BFP - Part 1Document1 pageBFP - Part 1nejatihosseinNo ratings yet

- SA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02Document5 pagesSA-980-P-11443 - API 685 Offloading Pump Landside PZ - Vert02altipatlarNo ratings yet

- Hoja de Datos de BombaDocument5 pagesHoja de Datos de Bombaluis zambranoNo ratings yet

- SEO-Optimized Title for API 685 Centrifugal Pump Data SheetDocument5 pagesSEO-Optimized Title for API 685 Centrifugal Pump Data SheetaltipatlarNo ratings yet

- General: Centrifugal Pump Data SheetDocument3 pagesGeneral: Centrifugal Pump Data Sheetfaraujodff10No ratings yet

- Data Sheet Multiphase Pump BornermanDocument5 pagesData Sheet Multiphase Pump BornermanUmar Ijaz KhanNo ratings yet

- SEO-OPTIMIZED TITLEDocument3 pagesSEO-OPTIMIZED TITLEwado11No ratings yet

- Datasheet Rev 1Document7 pagesDatasheet Rev 1Tauasi TauasisNo ratings yet

- Gerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinDocument4 pagesGerencia de Proyectos de Refinacion Y Petroquimica Departamento de Ingeniería - PinGerencia Rigar Colombia SASNo ratings yet

- UntitledDocument5 pagesUntitledJuan Bautista Rojas VillegasNo ratings yet

- SA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02Document5 pagesSA-980-P-11448 - API 685 Tank Transfer Pump PZ - Vert02altipatlarNo ratings yet

- Reciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneralDocument10 pagesReciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneraltxagusNo ratings yet

- Veco Engineering Ltd. Equipment Data Sheet: Centrifugal FanDocument9 pagesVeco Engineering Ltd. Equipment Data Sheet: Centrifugal Fanwado11No ratings yet

- Sulphuric Acid Dosing Pump Motor ManualDocument28 pagesSulphuric Acid Dosing Pump Motor ManualmohammedsfNo ratings yet

- bb2 Pump-DatasheetDocument14 pagesbb2 Pump-DatasheetMojtabaNo ratings yet

- Po#141802tpeDocument7 pagesPo#141802tpeocanhthuNo ratings yet

- 141022.TGT-HWL-G-H05-DS-7109 Pump Datasheet - Rev 0 - AttachedDocument4 pages141022.TGT-HWL-G-H05-DS-7109 Pump Datasheet - Rev 0 - AttachedocanhthuNo ratings yet

- Data Book P-8A01 FinalDocument129 pagesData Book P-8A01 FinalRUBEN ACOSTANo ratings yet

- Data SheetDocument1 pageData SheetStephen BeasleyNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur DieselDocument7 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur DieselBilel MahjoubNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueDocument6 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueBilel MahjoubNo ratings yet

- Methanol Storage Facility Project: No. Dok.: - Revision No.Document1 pageMethanol Storage Facility Project: No. Dok.: - Revision No.Adhya RazanNo ratings yet

- 14960-000-ME-DAS-003 Data Sheet For Sump PumpsDocument8 pages14960-000-ME-DAS-003 Data Sheet For Sump PumpsAshish TIwariNo ratings yet

- DatasheetDocument71 pagesDatasheetRhadityo Shakti BudimanNo ratings yet

- (API 674-2nd) Reciprocating PumpDocument6 pages(API 674-2nd) Reciprocating PumpadistiNo ratings yet

- LNG booster pump datasheet for Indonesian LNG terminalDocument7 pagesLNG booster pump datasheet for Indonesian LNG terminalsswahyudiNo ratings yet

- VP-PP4-MP-255-PK-1401-0431 - Rev.0 - Vendor Document For H2so4 Dosing PumpDocument10 pagesVP-PP4-MP-255-PK-1401-0431 - Rev.0 - Vendor Document For H2so4 Dosing PumpMinh PhamNo ratings yet

- Contract: API 610 Vertical Centrifugal Pump DataDocument7 pagesContract: API 610 Vertical Centrifugal Pump DataNAHASALI11No ratings yet

- G. Pumps and DriversDocument14 pagesG. Pumps and DriversJithinNo ratings yet

- Data Sheet P-0560 - Hot Oil Drain Tank Sump PumpDocument2 pagesData Sheet P-0560 - Hot Oil Drain Tank Sump Pumpcygnus marine panamaNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- Data Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary UnitsDocument10 pagesData Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1No ratings yet

- Notes Information Below To Be Completed: by Manufacturer or PurchaserDocument5 pagesNotes Information Below To Be Completed: by Manufacturer or Purchaserrajindo1No ratings yet

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNo ratings yet

- Manual Del Vendedor2Document12 pagesManual Del Vendedor2Carolina EnriquezNo ratings yet

- Cam 200-390-110kwDocument4 pagesCam 200-390-110kwbocahjeblogNo ratings yet

- 18CO5009-10-It2-D03-2 Pump Datasheet Format)Document10 pages18CO5009-10-It2-D03-2 Pump Datasheet Format)Gerencia Rigar Colombia SASNo ratings yet

- Separated water pump data sheetDocument1 pageSeparated water pump data sheetSara KhanNo ratings yet

- DSA Scrubber Pump DatasheetDocument10 pagesDSA Scrubber Pump DatasheetNavNo ratings yet

- API 610 Data Sheet 1 PDFDocument6 pagesAPI 610 Data Sheet 1 PDFSuresh Kumar MittapalliNo ratings yet

- Modeldbgvc 429-3: Injection Pump Specification DBGVC429-1 J 5Document2 pagesModeldbgvc 429-3: Injection Pump Specification DBGVC429-1 J 5johnny sabinNo ratings yet

- VP-PP4-MP-255-PK-1401-0430 - REV.0 - VENDOR DOCUMENT FOR NaOH DOSING PUMPDocument10 pagesVP-PP4-MP-255-PK-1401-0430 - REV.0 - VENDOR DOCUMENT FOR NaOH DOSING PUMPMinh PhamNo ratings yet

- Technical Bid Tabulation: Vendor Description SpecificationDocument8 pagesTechnical Bid Tabulation: Vendor Description SpecificationGunturMudaAliAkbarNo ratings yet

- S-1504 Pump Data Sheet 3 PhaseDocument1 pageS-1504 Pump Data Sheet 3 PhaseHoonNo ratings yet

- Recipro Compressor SpecsDocument5 pagesRecipro Compressor SpecsHisham ElsayedNo ratings yet

- Positive Displacement Pump DatasheetDocument2 pagesPositive Displacement Pump Datasheetanon_884425478No ratings yet

- (API 610-10th) Centrifugal Pump - SI Units PDFDocument2 pages(API 610-10th) Centrifugal Pump - SI Units PDFParaschiv AlexandruNo ratings yet

- (API 610-10th) Centrifugal Pump - SI UnitsDocument2 pages(API 610-10th) Centrifugal Pump - SI UnitsParaschiv AlexandruNo ratings yet

- Sok0929245 PDFDocument17 pagesSok0929245 PDFLeonardo Basante HerreraNo ratings yet

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesFrom EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNo ratings yet

- Data Sheet Coupling (By Harol - Rojas@indequipos - Com)Document6 pagesData Sheet Coupling (By Harol - Rojas@indequipos - Com)Diego RuanoNo ratings yet

- Data Sheet Turbina Medidora de GasDocument2 pagesData Sheet Turbina Medidora de GasDiego RuanoNo ratings yet

- Data Sheet PSVDocument12 pagesData Sheet PSVDiego RuanoNo ratings yet

- Ball Valve FCTDocument16 pagesBall Valve FCTAnggi SujiwoNo ratings yet

- Data SHEET SEPARADOR 3Document1 pageData SHEET SEPARADOR 3Diego RuanoNo ratings yet

- Uniform Mechanical Code - 2009 Chapter 17Document22 pagesUniform Mechanical Code - 2009 Chapter 17memosplumbingNo ratings yet

- Vee-Ball Designs V150, V200 and V300 Noise AttenuatorDocument6 pagesVee-Ball Designs V150, V200 and V300 Noise AttenuatorDatt NguyenNo ratings yet

- Eaton Busway Non Segregated Phase Bus Duct Design Guide Ca017003enDocument26 pagesEaton Busway Non Segregated Phase Bus Duct Design Guide Ca017003enUmerNo ratings yet

- Valve PDFDocument20 pagesValve PDFRamalingam Prabhakaran100% (1)

- Guide 2 3e 13939Document37 pagesGuide 2 3e 13939Hany El samadyNo ratings yet

- Bedienungs-Und Wartungsanleitung: Operating and Maintenance InstructionsDocument17 pagesBedienungs-Und Wartungsanleitung: Operating and Maintenance Instructionsuuur35No ratings yet

- Indian Standard Specification for Reels and Drums for Bare ConductorsDocument5 pagesIndian Standard Specification for Reels and Drums for Bare ConductorsPratapNo ratings yet

- ISO-Standard Plug Valve Sealing OptionsDocument6 pagesISO-Standard Plug Valve Sealing OptionsThássio MartinsNo ratings yet

- Consolidated-Relief Valve CatalogueDocument89 pagesConsolidated-Relief Valve CatalogueAshvin ParmarNo ratings yet

- Water Works RTADocument15 pagesWater Works RTAalfaza3No ratings yet

- EFAFLU Transformer Pumps and FansDocument32 pagesEFAFLU Transformer Pumps and FansTomas PinheiroNo ratings yet

- GPT Isolation Gasket Installation Instructions: RTJ & RF OkDocument2 pagesGPT Isolation Gasket Installation Instructions: RTJ & RF OkmansurudinNo ratings yet

- Swing Check Valves PN 16Document2 pagesSwing Check Valves PN 16Mohamed RaafatNo ratings yet

- Rrvb-Svx01a-En - Rupture GuardDocument26 pagesRrvb-Svx01a-En - Rupture GuardEmerson PenaforteNo ratings yet

- 4B3.9G2 So10737Document72 pages4B3.9G2 So10737Alexis SanchezNo ratings yet

- 4.5 Optek BrochureDocument28 pages4.5 Optek BrochureRizal AfyudinNo ratings yet

- Stainless steel steam trap connectorsDocument2 pagesStainless steel steam trap connectorspandahiuNo ratings yet

- GESTRA FlowserveDocument44 pagesGESTRA FlowserveBalaita DorelNo ratings yet

- Vertical Pumps 50hzDocument36 pagesVertical Pumps 50hznaleengtNo ratings yet

- TB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)Document20 pagesTB3 - 117 Engine Maintenance Manual: (EMM Book1 TOC) (Chapter 72 TOC)robinyNo ratings yet

- Válvula de Cheque - Forbes Marshall Modelo FMDCVDocument2 pagesVálvula de Cheque - Forbes Marshall Modelo FMDCVDennis MendozaNo ratings yet

- Valero Blinding Guideline Provides Safety ProceduresDocument13 pagesValero Blinding Guideline Provides Safety ProcedureskishorsinghNo ratings yet

- Hydro TestDocument12 pagesHydro TestEndika Alfan100% (2)

- Gate Valve STD SpecificationsDocument1 pageGate Valve STD SpecificationsMunishTrichyNo ratings yet

- Final DR P0089 VSFMDocument49 pagesFinal DR P0089 VSFMFILIN VLADIMIRNo ratings yet

- Cast Iron Flange DimensionsDocument1 pageCast Iron Flange DimensionsBudiman SaragihNo ratings yet

- GSW NG01017640 GEN MP4033 00002 001 Piping Material SpecificationDocument114 pagesGSW NG01017640 GEN MP4033 00002 001 Piping Material SpecificationJustice NnamdiNo ratings yet

- Info On HDPE PipesDocument49 pagesInfo On HDPE PipesH.V. Patil100% (1)