Professional Documents

Culture Documents

Recipro Compressor Specs

Uploaded by

Hisham Elsayed0 ratings0% found this document useful (0 votes)

52 views5 pagesThis document contains specifications for a reciprocating compressor including:

- Manufacturer and model details

- Operating conditions such as gas analysis, site location, and part load operation

- Performance parameters including capacity, power requirements, speeds, and pressures

- Certifications and classifications needed for electrical safety and hazardous area compliance

Original Description:

Original Title

Hojas_API_SI

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document contains specifications for a reciprocating compressor including:

- Manufacturer and model details

- Operating conditions such as gas analysis, site location, and part load operation

- Performance parameters including capacity, power requirements, speeds, and pressures

- Certifications and classifications needed for electrical safety and hazardous area compliance

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

52 views5 pagesRecipro Compressor Specs

Uploaded by

Hisham ElsayedThis document contains specifications for a reciprocating compressor including:

- Manufacturer and model details

- Operating conditions such as gas analysis, site location, and part load operation

- Performance parameters including capacity, power requirements, speeds, and pressures

- Certifications and classifications needed for electrical safety and hazardous area compliance

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

1 APPLICABLE TO: PROPOSAL PURCHASE AS BUILT

2 ITEM LOCATION / SITE X SERVICE No. REQ'D 1

3 NOTE

INFORMATION TO BE BY MANUFACTURER WITH BY MANUACTURER AFTER BY MANUFACTURER OR

4 COMPLETED BY PURCHASER PROPOSAL ORDER PURCHASER AS APPLICABLE

5

6 MANUFACTURER ABC COMPRESSORS TYPE MODEL (...) SERIAL No.

7 COMPR. THROWS: TOTAL No. 2 No. W/ CYLS. 4 NOM.FRAME.RATING kW @ RATED RPM OF 600 RPM

8 MAX/MIN ALLOWABLE SPEED 660 / 370 RPM

9 DRIVE MANUFACT. POWER (KW) / RATED SPEED (RPM) /

10 DRIVE SYSTEM: DIRECT COUPLED GEARED COUPLED V-BELT

11 TYPE OF DRIVER: IND. MOTOR SYN. MOTOR STEAM TURB. GAS TURB. ENGINE OTHER

12 NO NEGATIVE TOLERANCE APPLIES: YES: PURCHASER TO FILL IN "REQUIRED CAPACITY" LINES.

13 (NNT) NO: PURCHASER TO FILL IN "MFGR.'S RATED CAP." LINES

14 MAX. ACCEPTABLE AVG PISTON SPEED 4,4 m/s CYLINDERS LUBE

15 NON LUBE

16

OPERATING CONDITIONS (EACH MACHINE)

17

18 SERVICE OR ITEM No. OPC-01

19 STAGE 2

20 NOR. OR ALT. CONDITION NOR/ALT

21 CERTIFIED PT. CHECK ONE X

22 MOLECULAR WEIGHT 62,63

23 Cp/Cv (K) @ 65ºC OR 50 ºC 1,10

24 INLET CONDITIONS AT INLET TO PULSE DEVICES COMPRESSOR CYLINDER FLANGES

25 NOTE SIDE STREAM TO STAGE(S), THESE INLET PRESSURES ARE FIXED

26 PRES. (bara) @ PUL. SUPP. INLET 1,06

27 PRES. (bara) @ CYL. FLANGE

28 TEMPERATURE (ºC) 50,00

29 REF. SIDE STREAM TEMPS. ºC

30 COMPRESSIBILITY (Zs) 0,9719

31 INTERSTAGE AT OUTLET FROM PULSE DEVICES PIPING COOLERS SEPARATORS OTHER

32 DP BETWEEN STAGES, % / (bar) 0.2 %

33 DISCHARGE CONDITIONS: AT OUTLET FROM PULSE DEVICE COMP. CYL. FLANGES OTHER

34 PRES. (bara) @ CYL FLANGE 7,38

35 PRES. (barg) @ PUL. SUPP. OUTLET

36 TEMPERATURE, ADIABATIC, ºC 83

37 TEMPERATURE, PREDICTED ºC 79

38 COMPRESsIBILITY (Z2) OR (ZAVG) 0,8877

39 * REQUIRED CAPACITY, RATED FOR PROCESS, AT INLET TO COMPRESSOR, NO NEGATIVE TOLERANCE (-0%)

40 kg/h CAPACITY SPECIFIED

41 IS WET DRY

42 Nm3/h (760 mm Hg & 0ºC)

43 MGFR.'S RATED CAPACITY AT INLET TO COMPRESSOR) & kW @ CERTIFIED TOLERANCE OF +3% FOR CAP. & +3% FOR Kw

44 kg/h CAPACITY SPECIFIED

7095,97

45 IS WET DRY

46 3

INLET m /h 2783,89

47 Nm3/h (760 mm Hg & 0 ºC) 2460,00

48 POWER/STAGE, Kw 95,8\93,4

49 TOTAL POWER,Kw @ COMP. SHAFT 240,5

50 TOTAL KW INCLUDIG V-BELT

245,4

51 & GEAR LOSSES

52

53 (*) CAPACITY FOR NNT

54 MANUFACTURER'S=REQUIRED÷0.97

55 REQUIRED=MANUFACTURER'S x 0.97

56 REMARKS

57

58

59

60

61

62

63

64

ANNEX DESCRIPTION / DRAWING TITLE: CLIENT / PLANT

ANNEX SPEC. PLANE CODE: PAGE REV.

1 of 5 0

RECIPROCATING COMPRESSORS DATA SHEET SHEET 1 5

1 GAS ANALYSIS AT OPERATING CONDITIONS

REMARKS

2 MOLE% (BY VOLUME) ONLY

3 SERVICE / ITEM No.

4 STAGE

5 NORMAL OR ALT.

6 MW

7 AIR 28.966

8 OXIGEN O2 32.000

9 NITROGEN N2 28.016

10 WATER VAPOR H2O 18.016 0,000

11 CARBON MONOXIDE CO 28.010

12 CARBON DIOXIDE CO2 44.010

13 HYDRO. SULFIDE H2S 34.076

14 HYDROGEN H2 2.016

15 METHANE CH4 16.042 0,110

16 ETHYLENE C2H4 28.052

17 ETHANE C2H6 30.068 1,350

18 PROPYLENE C3H6 42.078

19 PROPANE C3H8 44.094 14,250

20 I-BUTANE C4H10 58.120 9,910

21 n-BUTANE C4H10 58.120 25,010

22 I-PENTANE C5H12 72.146

APPLICABLE SPECIFICATIONS

23 n-PENTANE C5H12 72.146 49,370

24 HEXANE PLUS

25 AMMONIA NH3 17.031

26 HYDRO. CHLORIDE HCl 36.461 REPSOL YPF ED-B-04.00-01

27 CHLORINE Cl2 70.914 API 618 5th EDITION

28 CHLORIDES-TRACES NACE MR-0175

29 1-BUTENE 56,11

30

31

32 CALCULATED MOL WT. 62,63

33 Cp/Cv (K) @ 65° O 50 ºC 1,10

34

35 NOTE: IF WATER VAPOR AND / OR CHLORIDES ARE PRESENT, EVEN IN

36 MINUTE TRACES, IN THE GAS BEING COMPRESSED, IT MUST BE

37 INCLUDED ABOVE.

38

SITE / LOCATION CONDITIONS

39

40

41 ELEVATION m BAROMETER (bara) AMBIENT TEMPS: MAX ºC MIN ºC

42

43 MIN DESING METAL TEMP ºC (6.15.8.1) RELATIVE HUMIDITY: MAX % MIN %

44

45 COMPRESSOR LOCATION INDOOR HEATED UNHEATED AT GRADE LEVEL ELEVATED m

46 OUTDOOR NO ROOF UNDER ROOF PARTIAL SIDES PLATFORM

47 OFF-SHORE WEATHER PROTECTION REQ. TROPICALIZATION REQ.

48 WINTERIZATION REQUIRED

49

50 UNUSUAL CONDITIONS CORROSIVES DUST FUMES OTHER:

51

52 ELECTRICAL CASSIFICATIONS

53 MAIN UNIT CLASS ZONE GROUP TEMP. CLASS

54 (COMPRESSOR AND ATEX (94/9/EC) GROUP CATEG. TEMP. CLASS

55 DRIVER) NON-HAZARDOUS

56 CONSOLE CLASS ZONE GROUP TEMP. CLASS

57 (LUBRICATION AND ATEX (94/9/EC) GROUP CATEG. TEMP. CLASS

58 COOLING WATER) NON-HAZARDOUS

59 LOCAL PANEL CLASS ZONE GROUP TEMP. CLASS

60 ATEX (94/9/EC) GROUP CATEG. TEMP. CLASS

61 NON-HAZARDOUS

62 REMARKS:

63

64

ANNEX DESCRIPTION / DRAWING TITLE: CLIENT / PLANT

ANNEX SPEC. PLANE CODE: PAGE REV.

2 of 5 0

RECIPROCATING COMPRESSORS DATA SHEET SHEET 2 OF 5

1

PART LOAD OPERATING CONDITIONS

2

3 BY: MANUFACT. CAPACITY CONTROL PURCHASERS BY-PASS BOTH OTHER

4 CAPACITY FOR: PART LOAD CONDITIONS START-UP ONLY BOTH

5 CONTROL WITH: AUTO LOADING DELAY INTERLOCK (3.6.2.2) AUTO IMMEDIATE UNLOADING

6 USING: FIXED VOLUME POCK SUCTION VALVE UNLOADERS: FINGER PLUG OTHER

7 ACTION DIRECT (AIR-TO-UNLOAD) REVERSE (AIR-TO-LOAD / FAIL SAFE)

8 NUMBER OF STEPS: ONE THREE FIVE OTHER:

9 RAIN COVER REQUIRED OVER UNLOADERS

10 ALL UNLOADING STEPS BASIS MANUFACTURERS CAPACITY SHOWN ON PAGE 1.

11 INLET AND DISCHARGE PRESSURE ARE AT CYLINDER FLANGES PULSATION SUPPRESSOR FANGES

12

13 SERVICE OR ITEM No. OPC-01

14 STAGE 1 2

15 NORMAL OR ALT. CONDITION NOR/ALT NOR/ALT

16 PERCENT CAPACITY

17 FLOW, kg/h dry 7095,97 7095,97

3

18 Nm h/h (760 mm Hg & 0°C) dry 2460,00 2460,00

19 POCKETS / VALVES OPERATION *

20 CLEARANCE ADDED % 0,00 0,00

21 TYPE UNLOADERS, PUG / FINGER FINGER FINGER

22 INLET TEMPERATURE, ºC 50 45

23 INLET PRESSURE, bar-A 1,05 2,55

24 DISCHARGE PRESSURE, bar-A 2,56 7,38

25 DISCHARGE TEMP., ADIABATIC, ºC 76 83

26 DISCHARGE TEMP., PREDICTED, ºC 73 79

27 VOLUMETRIC EFF., %HE / %CE 85,3 85,2 76,4 75,7

28 CALC. GAS ROD LOAD, kN, C** 23,83 34,40

29 CALC. GAS ROD LOAD, kN, T** 23,51 32,85

30 COMB. ROD LOAD, KN C (GAS & INERTIA) 23,88 32,81

31 COMB. ROD LOAD, KN T (GAS & INERTIA) 19,28 28,63

32 ROD REV., DEGREES MIN @ X-HD PIN *** 173,08 176,41

33 BkW/STAGE 95,8 93,4

34 TOTAL kW @ COMPRESSOR SHAFT 240,54

35 TOTAL kW INCL. V-BELT & GEAR LOSSES 245,35

36

*SHOW OPERTATION WITH THE FOLLOWINGS SYMBOLS:

37

38 SUCTION VALVE(S) UNLOADED = S

39 HEAD END = HE OR

40 OR PLUS FIXED POCKET OPEN = F

41 CRANK END = CE OR

42 VARIABLE POCKET OPEN = V

43

EXAMPLE: HE-F / CE-S = HEAD END FIXED POCKET OPEN / CRANK END SUCTION VALVE(S) UNLOADED

44

45 ** C = COMPRESSION T = TENSION ***X - HD = CROSSHEAD

46

47 MINUMUM PRESSURE REQUIRED TO OPERATE CYLINDER UNLOADING DEVICES 6 (barg)

48

49 CYLINDER UNLOADING MEDIUM: AIR NITROGEN OTHER

50

51 PRESSURE AVAILABLE FOR CYLINDER UNLOADING DEVICES, MAX / MIN 6 / 6 (barg)

52

53 REMARKS:

54

55

56

57

58

59

60

61

62

63

64

ANNEX DESCRIPTION / DRAWING TITLE: CLIENT / PLANT

ANNEX SPEC. PLANE CODE: PAGE REV.

3 of 5 0

RECIPROCATING COMPRESSORS DATA SHEET SHEET 3 OF 5

1

CYCINDER DATA AT FULL LOAD CONDITION

2

3

SERVICE ITEM No. OPC-01

4

5 STAGE 1 2

6 INLET PRESSURE (bar A) @ CYLINDER 1,06 2,55

7 DISCHARGE PRESSURE (bar A) FLANGES 2,56 7,38

8 CYLINDERS PER STAGE 2 2

9 SINGLE OR DOUBLE ACTING (SA OR DA) DA DA

10 BORE, mm 450,00 300,00

11 STROKE, mm 200,00 200,00

12 RPM: RATED / MAX. ALLOW 432 / 660

13 PISTON SPEED, m/s RATED / MAX. ALLOW 2,88 / 4,40

14 CYLINDER LINER, YES / NO NO NO

15 LINER NOMINAL THICKNESS, mm

16 PISTON DISPLACEMENT, m3/h 3275,68 1444,55

17 CYLINDER DESING CLEARANCE, % AVERAGE 0,06 0,10

18 VOLUMENTRIC EFFICIENCY, % AVERAGE 0,85 0,76

19 VALVES, INLET / DISCHARGE, QUANTITY PER CYLINDER n / n n / n / / / /

20 TYPE OF VALVES PLATE PLATE

21 VALVE LIFT, INLET / DISCHARGE, mm 1.4 / 1.4 1.4 / 1.4 / / / /

22 VALVE VELOCITY, API 4TH EDITION, m/s

23 SUCTION VALVE(S) 25,78 17,18

24 DISCHARGE VALVE(S) 25,46 16,71

25 ROD DIAMETER, mm 50,00 50,00

26 MAX ALLOW. COMBINED ROD LOADING, kN, C* 120,0 120,0

27 MAX ALLOW. COMBINED ROD LOADING, kN, T* 120,0 120,0

28 CALCULATED GAS ROD LOAD, kN, C* 23,8 34,4

29 CALCULATED GAS ROD LOAD, kN, T* 23,5 32,8

30 COMBINED ROD LOAD (GAS+INERTIA), kN, C* 23,9 32,8

31 COMBINED ROD LOAD (GAS+INERTIA), kN, T* 19,3 28,6

32 ROD VER., DEGREES MIN @ X-HD PIN** 173,08 176,41

33 RECIP WT. (PISTON, ROD, S-HD & NUTS), KG 106,2 95,8

33 MAX ALLOW. WORKING PRESSURE, (bar G)

35 MAX ALLOW. WORKING TEMPERATURE, ºC

36 HYDROSTATIC TEST PRESSURE, (bar G)

37 HELIUM TEST PRESSURE, (bar G)

38 INLET FLANGE SIZE / RATING / / / / / /

39 FACING

40 DISCHARGE FLANGE SIZE / RATING / / / / / /

41 FACING

42 DISCHARGE RELIEF VALVE SETTING BASED ON DATA FOR INLET PRESSURES GIVEN ABOVE:

43 RECOMMENDED SETING, (bar G)

44 GAS ROD LOAD,KN, T*

45 GAS ROD LOAD,KN, C*

46 COMBINED ROD LOAD, kN, T*

47 COMBINED ROD LOAD, kN, C*

48 ROD REVERSAL, DEGREE MIN. @ S-HD PINN**

49 NOTE: CALCULATED AT INLET PRESSURES GIVEN ABOVE &

50 RECOMMENDED PSV SETING

51 SETTLE-OUT GAS PRESSURE (bar G)

52 (DATA REQUIRED FOR STARTING)

53 *C = COMPRESSION *T = TENSION

54 REMARKS:

55

56

57

58

59

60

61

62

63

64

ANNEX DESCRIPTION / DRAWING TITLE: CLIENT / PLANT

ANNEX SPEC. PLANE CODE: PAGE REV.

4 of 5 0

RECIPROCATING COMPRESSORS DATA SHEET SHEET 4 OF 5

1

CONSTRUCTION FEATURES

2

3 SERVICE ITEM No.

4 STAGE 1 2

5 CYLINDER SIZE (BORE DIA), mm 450 300

6 ROD RUN-OUT;

7 (NORMAL COLD VERTICAL, per appendix C)

8

MATERIALS OF CONSTRUCTION

9

10 CYLINDER(S) CI/DI CI/DI

11 CYLINDER LINER(S) NONE/YES NONE/YES

12 PISTON(S) ALUM/SS ALUM/SS

13 PISTON RINGS PTFE PTFE

14 WEAR BANDS REQUIRED PTFE PTFE

15 PISTON ROD(S): MATERIAL/YIELD; N/mm2 SS SS / / / /

16 THREAD ROOT STRESS @ MACRL * @X-HD END

17 PISTON ROD HARDENESS, BASE MATERIAL, Rc 53 53

18 PISTON ROD COATING REQUIRED NONE NONE

19 COATING HARDNESS, Rc

20 VALVE SEATS / SEAT PLATE SS SS

21 VALVE SEAT MIN HARDNESS, Rc

22 VALVE GUARDS (STOPS) SS SS

23 VALVE DISCS SS SS

24 VALVE SPRINGS SS SS

25 ROD PRESSURE PACKING RINGS PTFE PTFE

26 ROD PRESSURES PACKING CASE SS SS

27 ROD PRESSURE PACKING SPRINGS SS SS

28 SEAL / BUFFER PACKING, DISTANCE PIECE PTFE PTFE

29 SEAL / BUFFER PACKING, INTERMEDIATE

30 WIPER PACKING RINGS BRONZE BRONZE

31 MAIN JOURNAL BEARING, CRANKSHAFT TRIMETAL TRIMETAL

32 CONNECTING ROD BEARING, CRANKPIN TRIMETAL TRIMETAL

33 CONNECTING ROD BUSHING, X-HD END BRONZE BRONZE

34 CROSSHEAD (X-HD) PIN BUSHING

35 CROSSHEAD PIN Mn STEEL Mn STEEL

36 CROSSHEAD DI DI

37 CROSSHEAD SHOES

38 CYLINDER INDICATOR VALVES (X)

39 INDICATOR CONNECTIONS ABOVE 345 BAR

40 FLUOROCARBON SPRAYED CYLINDER (X)

41 INSTRUMENTATION IN COLD SIDE (X)

42 CONTACT W/ PROCESS GAS HOT SIDE ( X)

43 (*) MACRL - MAXIMUM ALLOWABLE COMBINED ROD LOAD

44 USE (X) IN APPROPRIATE COLUMN WHERE APPLICABLE

45

46 COMPRESSOR CYLINDER ROD PACKING DISTANCE PIECES: TYPE A TYPE B

47 FULL FLOATING PACKING (See Fig. G-3) TYPE C TYPE D

48 VENTED TO: FLARE @ barG ATMOSPH. COVERS: SOLID METAL SCREEN LOUVERED

49 SUCTION PRESSURE @ barG CYLINDER COMPARTEMENT: VENTED TO barG

50 FORCED LUBRICATED NON LUBE TFE (outboard distance piece) PURGED AT barG

51 WATER COOLED, STAGE(S) GPM REQ'D. PRESSURIZED TO barG

52 OIL COOLED, STAGE(S) GPM REQ'D. WITH FELIEF VALVE

53 WATER FILTER PROV. FUT. WATER/OIL COOL'G FRAME COMPARTMENT: VENTED TO barG

54 VENT/BUFFER GAS SEAL PACKING ARR. (REF. APP. I, FIG I-1) (outboard distance piece) PURGED AT barG

55 CONSTANT OR VARIABLE DISPOSAL SYSTEM PRESSURIZED TO barG

56 BUFFER GAS PRESSURE, barG WITH FELIEF VALVE

57 SPLASH GUARDS FOR WIPER PACKING DISTANCE PIECE MAWP (Min) barG

58 REMARKS:

59

60

61

62

63

64

ANNEX DESCRIPTION / DRAWING TITLE: CLIENT / PLANT

ANNEX SPEC. PLANE CODE: PAGE REV.

5of 5 0

RECIPROCATING COMPRESSORS DATA SHEET SHEET 5 OF 5

You might also like

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- 22-DS-R-002 Rev 0 API 616 Turbine Data SheetDocument13 pages22-DS-R-002 Rev 0 API 616 Turbine Data SheetChike NwachukwuNo ratings yet

- Centrifugal Compressor Specification Sheet: Operating ConditionsDocument6 pagesCentrifugal Compressor Specification Sheet: Operating ConditionsIsmail SayyedNo ratings yet

- API 675 Pump DatasheetDocument2 pagesAPI 675 Pump DatasheetArun CPNo ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueDocument6 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueBilel MahjoubNo ratings yet

- 02 190 0012 MK 062Document9 pages02 190 0012 MK 062phuchau nguyenNo ratings yet

- Data Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary UnitsDocument10 pagesData Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1No ratings yet

- API 673 3rd Ed Data SheetsDocument27 pagesAPI 673 3rd Ed Data Sheetsjuan ninaNo ratings yet

- BFP - Part 1Document1 pageBFP - Part 1nejatihosseinNo ratings yet

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Document7 pagesData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaNo ratings yet

- Specification Datasheet For Instrument Air Compressor PackageDocument5 pagesSpecification Datasheet For Instrument Air Compressor PackageBarata RendengNo ratings yet

- Data Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Document7 pagesData Sheet For Tank-To-tank Transfer Pump (Rev.a) - Returned (P-1501)Panisa BanimaNo ratings yet

- Api 617Document14 pagesApi 617ecsuperal100% (1)

- Data Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary UnitsDocument10 pagesData Sheet No. Ds-P-5983 Rev. 1: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1No ratings yet

- Data Sheet Multiphase Pump BornermanDocument5 pagesData Sheet Multiphase Pump BornermanUmar Ijaz KhanNo ratings yet

- bb2 Pump-DatasheetDocument14 pagesbb2 Pump-DatasheetMojtabaNo ratings yet

- Brown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsDocument12 pagesBrown & Root, Inc.: Centrifugal Compressor Data Sheet (Api 617-6Th) U.S. Customary UnitsPebriyantoNo ratings yet

- Sulphuric Acid Dosing Pump Motor ManualDocument28 pagesSulphuric Acid Dosing Pump Motor ManualmohammedsfNo ratings yet

- Centrifugal Pump Datasheet Api 610 11Th Edition: US CustomaryDocument1 pageCentrifugal Pump Datasheet Api 610 11Th Edition: US CustomaryAthiphap Srisupareerath100% (1)

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Mechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraDocument5 pagesMechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraAhmad RifaiNo ratings yet

- Contract: API 610 Vertical Centrifugal Pump DataDocument7 pagesContract: API 610 Vertical Centrifugal Pump DataNAHASALI11No ratings yet

- 3-4 HD - Api - 617 PDFDocument8 pages3-4 HD - Api - 617 PDFkagasaw023No ratings yet

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur DieselDocument7 pagesFeuilles Des Données de Nouveau Groupe de Pompage Moteur DieselBilel MahjoubNo ratings yet

- vs1 DatasheetDocument22 pagesvs1 DatasheetMojtabaNo ratings yet

- Data Motor & Pump-1Document29 pagesData Motor & Pump-1naspauzanNo ratings yet

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNo ratings yet

- Hoja API Vs4 001Document9 pagesHoja API Vs4 001brujula24No ratings yet

- Data Sheet No. Ds-P-5107 Rev. 2: 6590-10 6590-10D1-J310-03 J-RE-PUMP-610-P 2 12-Jul-00 1 6 KMG / BeyDocument8 pagesData Sheet No. Ds-P-5107 Rev. 2: 6590-10 6590-10D1-J310-03 J-RE-PUMP-610-P 2 12-Jul-00 1 6 KMG / Beyrajindo1No ratings yet

- TECNICAS REUNIDAS PROPERTY AND CONFIDENTIALITY NOTICEDocument8 pagesTECNICAS REUNIDAS PROPERTY AND CONFIDENTIALITY NOTICEAlonso1593No ratings yet

- 3p531-Api 617-C505u-Re C505 - LPCDocument8 pages3p531-Api 617-C505u-Re C505 - LPCYusri FakhrizalNo ratings yet

- Compressor Data Sheet Provides Gas Composition and Operating ConditionsDocument7 pagesCompressor Data Sheet Provides Gas Composition and Operating ConditionsYusri FakhrizalNo ratings yet

- SEVERN GLOCON CONTROL VALVE SPECIFICATION SHEETDocument6 pagesSEVERN GLOCON CONTROL VALVE SPECIFICATION SHEETAmit Surti0% (1)

- Severn Glocon Lot2Document5 pagesSevern Glocon Lot2Amit SurtiNo ratings yet

- API 610 10th Edition (Iso 13709) Pump DatasheetDocument3 pagesAPI 610 10th Edition (Iso 13709) Pump DatasheetMuhammad Azka50% (4)

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 pagesData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisNo ratings yet

- CWC Mec DTS P001abcdDocument8 pagesCWC Mec DTS P001abcdAlonso1593No ratings yet

- Centrifugal Pump Data SheetDocument20 pagesCentrifugal Pump Data SheetMojtabaNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Ac0041402 Pb1i3 MD17006Document5 pagesAc0041402 Pb1i3 MD17006Jhonny Rafael Blanco CauraNo ratings yet

- Veco Engineering Ltd. Equipment Data Sheet: Centrifugal FanDocument9 pagesVeco Engineering Ltd. Equipment Data Sheet: Centrifugal Fanwado11No ratings yet

- Process Data Sheet For Fired HeaterDocument8 pagesProcess Data Sheet For Fired HeaterBangkiyak LanangNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Document17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- Centrifugal Pump Process Data Sheet (API 610 10th. Ed.) : In-Tank Vertical, Submerged MotorDocument2 pagesCentrifugal Pump Process Data Sheet (API 610 10th. Ed.) : In-Tank Vertical, Submerged MotorJuan José Grajeda AguayoNo ratings yet

- CENTRIFUGAL PUMP CALCULATION SUMMARYDocument2 pagesCENTRIFUGAL PUMP CALCULATION SUMMARYTheodoros AtheridisNo ratings yet

- Api 618 4th Ed Si DatasheetsDocument17 pagesApi 618 4th Ed Si Datasheetshmshawki100% (5)

- Api 610 Datasheet PDF FreeDocument7 pagesApi 610 Datasheet PDF FreeRisyda PutriNo ratings yet

- Brown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsDocument15 pagesBrown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsLipika GayenNo ratings yet

- Atlas Copco India LTD.: Gas Process ApplicationDocument4 pagesAtlas Copco India LTD.: Gas Process ApplicationAmit SurtiNo ratings yet

- Offsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectDocument5 pagesOffsites Engineering Works For The Erbil Refinery 40,000 B/D Expansion ProjectSardar PerdawoodNo ratings yet

- EGPM-10-DAS-MOV-01 - Datasheet For MOV ActuatorDocument7 pagesEGPM-10-DAS-MOV-01 - Datasheet For MOV Actuatordrkongala100% (1)

- General: CRUDE OIL / Liquid 313.9 / 313.9Document1 pageGeneral: CRUDE OIL / Liquid 313.9 / 313.9amirNo ratings yet

- NHT Heater API DatasheetDocument9 pagesNHT Heater API DatasheetAravind AravindNo ratings yet

- 5691 CPP Me DS 0001 0 PDFDocument17 pages5691 CPP Me DS 0001 0 PDFĐiệnBiênNhâmNo ratings yet

- Hoja de Datos de BombaDocument5 pagesHoja de Datos de Bombaluis zambranoNo ratings yet

- Operation Procedure: 1 P.B.MohapatraDocument8 pagesOperation Procedure: 1 P.B.MohapatraSanjay SharmaNo ratings yet

- Analysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantFrom EverandAnalysis of Engineering Cycles: Power, Refrigerating and Gas Liquefaction PlantNo ratings yet

- Gold 8 GM, 10 GMDocument2 pagesGold 8 GM, 10 GMHisham ElsayedNo ratings yet

- Siemens Terms & ConditionsDocument11 pagesSiemens Terms & ConditionsHisham ElsayedNo ratings yet

- ProfileDocument1 pageProfileHisham ElsayedNo ratings yet

- Norpetco Cost SheetDocument2 pagesNorpetco Cost SheetHisham ElsayedNo ratings yet

- Siemens safety rulesDocument12 pagesSiemens safety rulesHisham ElsayedNo ratings yet

- Field Service Rates 2018: Onshore Services - DRDocument1 pageField Service Rates 2018: Onshore Services - DRHisham ElsayedNo ratings yet

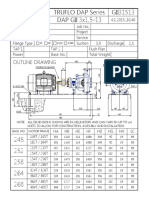

- DAP GII 3x1.5 13Document1 pageDAP GII 3x1.5 13Hisham ElsayedNo ratings yet

- Process Pump Technical OfferDocument53 pagesProcess Pump Technical OfferHisham ElsayedNo ratings yet

- Process Pump Technical OfferDocument53 pagesProcess Pump Technical OfferHisham ElsayedNo ratings yet

- Technical OfferDocument50 pagesTechnical OfferHisham ElsayedNo ratings yet

- Gas Compressor Technical ReportDocument12 pagesGas Compressor Technical ReportHisham ElsayedNo ratings yet

- Petrosnan Schdule 1 AugDocument1 pagePetrosnan Schdule 1 AugHisham ElsayedNo ratings yet

- DAP GII 3x1.5 13Document1 pageDAP GII 3x1.5 13Hisham ElsayedNo ratings yet

- ProfileDocument1 pageProfileHisham ElsayedNo ratings yet

- Hydrotech Pump Proposal SummaryDocument50 pagesHydrotech Pump Proposal SummaryHisham ElsayedNo ratings yet

- Gas Compressor Technical ReportDocument12 pagesGas Compressor Technical ReportHisham ElsayedNo ratings yet

- AMAPETCO ClarificationsDocument7 pagesAMAPETCO ClarificationsHisham ElsayedNo ratings yet

- Petrosnan Schdule 1 AugDocument1 pagePetrosnan Schdule 1 AugHisham ElsayedNo ratings yet

- 2802LE Starter-Fuel Gas Piping SN-85981Document1 page2802LE Starter-Fuel Gas Piping SN-85981Hisham ElsayedNo ratings yet

- Document For 30&% Advance LGDocument35 pagesDocument For 30&% Advance LGHisham ElsayedNo ratings yet

- Cooper spare parts sales quoteDocument5 pagesCooper spare parts sales quoteHisham ElsayedNo ratings yet

- JP CombiChem GBDocument8 pagesJP CombiChem GBBala MuruganNo ratings yet

- ABB Drives For Water and Wastewater: ACQ580, 0.75 To 500 KWDocument52 pagesABB Drives For Water and Wastewater: ACQ580, 0.75 To 500 KWElvis QuispeNo ratings yet

- Optimize pump performance up to 390 RPMDocument2 pagesOptimize pump performance up to 390 RPMHamada AbdelgawadNo ratings yet

- Drives For Water and Wastewater: 0.75 To 500 KWDocument2 pagesDrives For Water and Wastewater: 0.75 To 500 KWHisham ElsayedNo ratings yet

- Pump and VFD QuotaionDocument1 pagePump and VFD QuotaionHisham ElsayedNo ratings yet

- TDIOilGasCatalog PDFDocument31 pagesTDIOilGasCatalog PDFakamalapuri388No ratings yet

- JP MCH MCHZ MCV SB GBDocument8 pagesJP MCH MCHZ MCV SB GBHisham ElsayedNo ratings yet

- MCH (S) (W) : Instruction ManualDocument113 pagesMCH (S) (W) : Instruction ManualHisham ElsayedNo ratings yet

- 1011-2011 TRAINING MANUAL Deutz Engine 999 0512Document141 pages1011-2011 TRAINING MANUAL Deutz Engine 999 0512Anangtri Wahyudi97% (29)

- Clutches, Brakes and Planed Stages PDFDocument6 pagesClutches, Brakes and Planed Stages PDFCEVegaONo ratings yet

- GEET Fuel Processor Plans: WARNING: This Information Is Clasified As EXPERIMENTAL!Document10 pagesGEET Fuel Processor Plans: WARNING: This Information Is Clasified As EXPERIMENTAL!John BlackNo ratings yet

- Cams and FollowersDocument27 pagesCams and FollowersMaruthiNo ratings yet

- Design MethodologyDocument7 pagesDesign MethodologyRaviJoshiNo ratings yet

- RX Screw CataloguesDocument2 pagesRX Screw CataloguesPuppala Laxmana PrasadNo ratings yet

- Mini Split Air Conditioner 36,000 Btu/hr: Owner'S ManualDocument27 pagesMini Split Air Conditioner 36,000 Btu/hr: Owner'S ManualKyaw MyoNo ratings yet

- dSPACE ASM Product Information 2018-01 English PDFDocument40 pagesdSPACE ASM Product Information 2018-01 English PDFkkkprotNo ratings yet

- 2017 Audi A6 s6 71914Document280 pages2017 Audi A6 s6 71914Paulo MenezesNo ratings yet

- Protective System ANSI NumbersDocument3 pagesProtective System ANSI Numbersumarnair1105No ratings yet

- Nec430 150-148Document2 pagesNec430 150-148Jonathan VillorenteNo ratings yet

- Production Time: Operator Name-Dharmendra GuptaDocument16 pagesProduction Time: Operator Name-Dharmendra GuptaProduction HeicoNo ratings yet

- Kioti Daedong DK4520-EU, DK5020-EU, DK6020-EU Tractors Service Manual WM201231Document19 pagesKioti Daedong DK4520-EU, DK5020-EU, DK6020-EU Tractors Service Manual WM201231LisakolyNo ratings yet

- Screw Compressor DataDocument6 pagesScrew Compressor Datamochamad iwanNo ratings yet

- SF - ELE - Lago de Guadalupe - Arrancador VEDocument20 pagesSF - ELE - Lago de Guadalupe - Arrancador VERODOLFO MARTINEZNo ratings yet

- Designing a 100-Ton Overhead CraneDocument44 pagesDesigning a 100-Ton Overhead CraneEyob AdNo ratings yet

- Hoja de Datos Cummins MotorDocument7 pagesHoja de Datos Cummins Motorelperrote3No ratings yet

- Fuel System PDFDocument809 pagesFuel System PDFDiogenes CardosoNo ratings yet

- Odel 4Hp18Q: Vehicle Model Model YearDocument5 pagesOdel 4Hp18Q: Vehicle Model Model YearFernando BasNo ratings yet

- Agri-Fab, Craftsman Front Mount DethatcherDocument12 pagesAgri-Fab, Craftsman Front Mount DethatcherKevins Small Engine and Tractor ServiceNo ratings yet

- Intro To AutomotiveDocument49 pagesIntro To AutomotiverezoltNo ratings yet

- Robin Ey15-3d - Ey20-3d Operations ManualDocument11 pagesRobin Ey15-3d - Ey20-3d Operations ManualEdgardo M. DiololaNo ratings yet

- D5H Pruebas y Ajustes PDFDocument24 pagesD5H Pruebas y Ajustes PDFLuis Eduardo100% (1)

- Citroen Bosch EDC16 PDFDocument104 pagesCitroen Bosch EDC16 PDFNenad Chip Tuning Aleksic100% (2)

- Hydraulic Cylinder DatasheetDocument25 pagesHydraulic Cylinder DatasheetAlican DevecioğluNo ratings yet

- 02-02 Qwiklift HTB - Pds-76-14rev1Document2 pages02-02 Qwiklift HTB - Pds-76-14rev1Josh SchmitzNo ratings yet

- Manual de Taller Transmisión Automática A4Q y A4R Del Daihatsu Terios (Inglés)Document39 pagesManual de Taller Transmisión Automática A4Q y A4R Del Daihatsu Terios (Inglés)Omar Garrido Romero88% (8)

- EE205 DC Machines N TransformersDocument2 pagesEE205 DC Machines N TransformersAshik AhmedNo ratings yet

- zf4hp24 PDFDocument4 pageszf4hp24 PDFAymzNo ratings yet

- Horizontal and Vertical PumpsDocument13 pagesHorizontal and Vertical PumpsRehime SalmanNo ratings yet