Professional Documents

Culture Documents

A - Part - 59 Adsfasf

Uploaded by

betabet GeorgeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A - Part - 59 Adsfasf

Uploaded by

betabet GeorgeCopyright:

Available Formats

SERVICE MANUAL NUMBER 14 TROUBLESHOOTING

Corrosion On Underwater Parts, Without MerCathode Or Impressed Current

Protection

Cause Special Instructions

Sacrificial anode(s) consumed. Replace anode(s) when 50% consumed.

Stainless steel propeller installed. Add MerCathode (impressed current

protection) or additional sacrificial anodes.

Sacrificial anode(s) not grounded to drive. Remove anode(s), clean contact surface,

reinstall and check continuity.

Loss of continuity between underwater Provide good ground connections.

parts & ground.

Shore power causing overload of anode(s) Disconnect shore power or install

and/or MerCathode. Quicksilver isolator.

Paint on drive heavily worn (exposing Prime and repaint and/or install additional

more metal). anode(s).

Sacrificial anode(s) painted. Remove paint or replace anode(s).

Leave drive down, install additional anode

Drive tilted so far that anode(s) are out of (below waterline) or transom mount a

the water.

MerCathode.

Only power trim cylinders are corroded. Provide good ground to drive. All parts

must be grounded.

Corrosion in area of exhaust outlets. Remove deposits with marine or auto wax.

Exhaust deposits can cause corrosion.

Corrosion occurring after unit removed Wash exterior and flush interior with fresh

from saltwater. water.

Corrosion and/or salt build up between Exclude moisture from between mating

mating parts. parts with Quicksilver 2-4-C with Teflon.

Stainless Steel parts corroding:

Tightly wrapped fishing line or foreign

material excludes oxygen, causing

corrosion. Clean parts, remove foreign material,

Iron particles, such as from a wire brush, ensure continuity.

cause rusting.

Propeller pitting can occur if electrical

continuity is lost.

90-818177--3 APRIL 2001 Page 1C-27

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 9 14 Pages MCQS CSWIP 3.1 Question Answers Solved Past Papers Cswip 3.1Document14 pages9 14 Pages MCQS CSWIP 3.1 Question Answers Solved Past Papers Cswip 3.1Mohammed Amjad Ali86% (21)

- A Part 66Document1 pageA Part 66betabet GeorgeNo ratings yet

- A Part 65Document1 pageA Part 65betabet GeorgeNo ratings yet

- A Part 57Document1 pageA Part 57betabet GeorgeNo ratings yet

- A Part 58Document1 pageA Part 58betabet GeorgeNo ratings yet

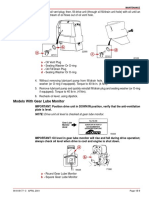

- Power Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky MovementsDocument1 pagePower Trim Hydraulic System: Drive Unit Cannot Be Trimmed OUT/UP or Trims Slowly or With Jerky Movementsbetabet GeorgeNo ratings yet

- A Part 54Document1 pageA Part 54betabet GeorgeNo ratings yet

- Oil Foams Out of Pump Fill/Vent Screw: Cause Special InstructionsDocument1 pageOil Foams Out of Pump Fill/Vent Screw: Cause Special Instructionsbetabet GeorgeNo ratings yet

- A Part 55Document1 pageA Part 55betabet GeorgeNo ratings yet

- A Part 60Document1 pageA Part 60betabet GeorgeNo ratings yet

- A Part 51Document1 pageA Part 51betabet GeorgeNo ratings yet

- A Part 62Document1 pageA Part 62betabet GeorgeNo ratings yet

- Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN DirectionDocument1 pagePower Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN Directionbetabet GeorgeNo ratings yet

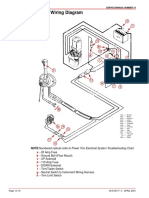

- Power Trim System Wiring Diagram: Troubleshooting Service Manual Number 14Document1 pagePower Trim System Wiring Diagram: Troubleshooting Service Manual Number 14betabet GeorgeNo ratings yet

- Power Steering: Poor Boat Performance And/Or Poor Maneuverability-Bow Too HighDocument1 pagePower Steering: Poor Boat Performance And/Or Poor Maneuverability-Bow Too Highbetabet GeorgeNo ratings yet

- Drive Unit Shifts Hard: "Troubleshooting Shift Problems."Document1 pageDrive Unit Shifts Hard: "Troubleshooting Shift Problems."betabet GeorgeNo ratings yet

- Compact Hydraulic Steering: Important InformationDocument1 pageCompact Hydraulic Steering: Important Informationbetabet GeorgeNo ratings yet

- Power Trim Electrical System: Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN DirectionDocument1 pagePower Trim Electrical System: Power Trim Pump Motor Will Not Run in The OUT/UP or IN/DOWN Directionbetabet GeorgeNo ratings yet

- Table of Contents (Continued) : Troubleshooting Service Manual Number 14Document1 pageTable of Contents (Continued) : Troubleshooting Service Manual Number 14betabet GeorgeNo ratings yet

- Important Information: Section 1C - TroubleshootingDocument1 pageImportant Information: Section 1C - Troubleshootingbetabet GeorgeNo ratings yet

- Performance Troubleshooting: Low WOT Engine RPMDocument1 pagePerformance Troubleshooting: Low WOT Engine RPMbetabet GeorgeNo ratings yet

- Troubleshooting: Sterndrive Unit Will Not Slide Into Bell HousingDocument1 pageTroubleshooting: Sterndrive Unit Will Not Slide Into Bell Housingbetabet GeorgeNo ratings yet

- Boat Bottom Care: Maintenance Service Manual Number 14Document1 pageBoat Bottom Care: Maintenance Service Manual Number 14betabet GeorgeNo ratings yet

- A Part 21Document1 pageA Part 21betabet GeorgeNo ratings yet

- Abstract of ASTM F871M 1991Document10 pagesAbstract of ASTM F871M 1991Jesse ChenNo ratings yet

- Cleaning vs. Sanitizing Quiz Sheet: True or FalseDocument2 pagesCleaning vs. Sanitizing Quiz Sheet: True or FalseRci-Ched Mira CaparasNo ratings yet

- LEEA Correspondence Courses: Assignment 1.8Document3 pagesLEEA Correspondence Courses: Assignment 1.8Primelift Safety Resources LimitedNo ratings yet

- NG GalvanizingHandbook DigitalversionDocument31 pagesNG GalvanizingHandbook DigitalversionRafee RevaldiNo ratings yet

- Jotun Block Filler Under Coat Technical SheetDocument4 pagesJotun Block Filler Under Coat Technical SheetMarjanalbahar TecSerNo ratings yet

- Narrow - Gap - TIG - 2P R0 2018 11 19Document2 pagesNarrow - Gap - TIG - 2P R0 2018 11 19gikkederkiNo ratings yet

- V Lite Foamed PVC PanelsDocument8 pagesV Lite Foamed PVC PanelsJose EvoraNo ratings yet

- Block 60 Syaldey - ResourceRate - LabourDocument2 pagesBlock 60 Syaldey - ResourceRate - LabourManojNo ratings yet

- Ag. Power, Machinery, and Allied Subject - Part 6Document101 pagesAg. Power, Machinery, and Allied Subject - Part 6Vonne Bryan IhalasNo ratings yet

- Well Plug and Abandonment Using HwuDocument1 pageWell Plug and Abandonment Using HwuJuan Pablo CassanelliNo ratings yet

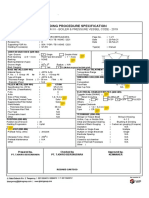

- Welding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Document3 pagesWelding Procedure Specification: Asme Section Ix - Boiler & Pressure Vessel Code - 2019Budi Setia RahmanNo ratings yet

- L12 - Tool Failure Tool LifeDocument28 pagesL12 - Tool Failure Tool LifeAditya AdityaNo ratings yet

- Note: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldDocument2 pagesNote: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldTadaya KasaharaNo ratings yet

- Calender IngDocument4 pagesCalender IngchrisgargeNo ratings yet

- Natural Gas Production and OperationsDocument2 pagesNatural Gas Production and OperationsHossam M. Abd El RahmanNo ratings yet

- En 43400Document2 pagesEn 43400shivendrakumarNo ratings yet

- Tabla Grados de Acero DisponiblesDocument1 pageTabla Grados de Acero DisponiblesJimena Gonzales MejiaNo ratings yet

- Academic Site Visit Report On Design of Steel Structures at Kimaya SteelDocument16 pagesAcademic Site Visit Report On Design of Steel Structures at Kimaya SteelKiranMDeoreNo ratings yet

- Tinplate and Tin Free SteelDocument18 pagesTinplate and Tin Free SteelMartinNo ratings yet

- Utp Af Robotic 600 Brochure 2018.12Document2 pagesUtp Af Robotic 600 Brochure 2018.12Claude BouillotNo ratings yet

- Lab ManualDocument10 pagesLab ManualKen MakNo ratings yet

- Shaper Planner SlotterDocument49 pagesShaper Planner SlottershahidNo ratings yet

- Essentials of Shielded Metal Arc Welding Nc1Document5 pagesEssentials of Shielded Metal Arc Welding Nc1melkie oganoNo ratings yet

- Product List: Agglomerated Flux (/Product/Agglomerated-Flux/)Document5 pagesProduct List: Agglomerated Flux (/Product/Agglomerated-Flux/)ArfanAliNo ratings yet

- Q SEP BrochureDocument6 pagesQ SEP BrochureHerik AziziNo ratings yet

- Training Basic Requirements of Fixture DesignDocument21 pagesTraining Basic Requirements of Fixture DesignAnurag V NjoyNo ratings yet

- Fosroc Nitofill WS60: Crack Injection Resin For Stopping Water FlowDocument4 pagesFosroc Nitofill WS60: Crack Injection Resin For Stopping Water FlowVincent JavateNo ratings yet

- Process Piping Required Pressure Design Wall Thickness For Bends (ASMEB31.3) .FlowDocument3 pagesProcess Piping Required Pressure Design Wall Thickness For Bends (ASMEB31.3) .FlowBensmatNo ratings yet

- Abrasive Jet Machine - AbstractDocument6 pagesAbrasive Jet Machine - AbstractManju KbNo ratings yet