Professional Documents

Culture Documents

Ss SSL s450 s3a-Av9v-En

Ss SSL s450 s3a-Av9v-En

Uploaded by

alexandremtbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ss SSL s450 s3a-Av9v-En

Ss SSL s450 s3a-Av9v-En

Uploaded by

alexandremtbCopyright:

Available Formats

SERVICE SCHEDULE

Maintenance Intervals

Maintenance work must be done at regular intervals.

Failure to do so will result in excessive wear and early

failures. WARNING

The service schedule is a guide for correct maintenance

of the Bobcat loader. AVOID INJURY OR DEATH

Instructions are necessary before operating or

servicing machine. Read and understand the

Operation & Maintenance Manual, Operator’s

Handbook and signs (decals) on machine. Follow

warnings and instructions in the manuals when

making repairs, adjustments or servicing. Check for

correct function after adjustments, repairs or

service. Untrained operators and failure to follow

instructions can cause injury or death.

W-2003-0807

Every 10 Hours (Before Starting The Loader)

• Engine Oil – Check level and add as needed. (See Page 148.)

• Engine Air Filters and Air System – Check display panel. Service only when required. Check for leaks and damaged

components. (See Page 141.)

• Engine Cooling System – Clean debris from hydraulic fluid cooler and radiator assembly, air conditioning condenser

(if equipped), and rear grille. Check coolant level COLD and add premixed coolant as needed. (See Page 151.) and

(See Page 154.)

• Fuel Filter – Remove the trapped water. (See Page 145.)

• Lift Arms, Lift Links, Cylinders, Bob-Tach, Pivot Pins, Wedges – Lubricate with multipurpose lithium based grease.

(See Page 186.)

• Seat Belt, Seat Belt Retractors, Seat Bar, Control Interlocks – Check the condition of seat belt. Clean or replace

seat belt retractors as needed. Check the seat bar and control interlocks for correct operation. Clean dirt and debris

from moving parts. (See Page 125.) and (See Page 127.)

• Bobcat Interlock Control Systems (BICS™) – Check for correct function. Lift and Tilt functions MUST NOT operate

with seat bar raised. (See Page 124.)

• Front Horn – Check for proper function. (See Page 51.)

• Tyres – Check for damaged tyres and correct air pressure. Inflate to MAXIMUM pressure shown on the sidewall of

the tyre. (See Page 178.)

• Operator Cab – Check the fastening bolts, washers, and nuts. Check the condition of the cab. (See Page 133.)

• Indicators and Lights – Check for correct operation of all indicators and lights. (See Page 38.)

• Wheel Nuts – Perform every 10 hours or daily for the first 30 hours, then as scheduled. Check for loose wheel nuts

and tighten to correct torque. (See Page 178.)

• Safety Signs and Safety Treads – Check for damaged signs (decals) and safety treads. Replace any signs or safety

treads that are damaged or worn. (See Page 19.) and (See Page 91.)

• Hydraulic Fluid – Check fluid level and add as needed. (See Page 168.)

• Heater and Air Conditioning Filters (if equipped) – Clean or replace filters as needed. (See Page 138.)

121 S450 Operation & Maintenance Manual

SERVICE SCHEDULE (CONT’D)

Maintenance Intervals (Cont’d)

Every 50 Hours

• Hydraulic Hoses and Tubelines – Check for damage and leaks. Repair or replace as needed.

• Final Drive Transmission (Chaincase) – Check fluid level and add as needed. (See Page 179.)

• Parking Brake, Foot Pedals, Hand Controls and Steering Levers, or Joysticks – Check for correct operation.

Repair or adjust as needed.

• Wheel Nuts – Check for loose wheel nuts and tighten to correct torque. (See Page 178.)

• Engine / Hydrostatic Drive Belt – Perform at first 50 hours, then as scheduled. Check for wear or damage. Replace

as needed. (See Page 183.)

• Engine Oil and Filter – Perform at first 50 hours, then as scheduled. Replace oil and filter. (See Page 149.)

Every 100 Hours

• Spark Arrester – Empty spark chamber. (See Page 177.)

• Battery – Check cables and connections. (See Page 160.)

• Engine Oil and Filter – Perform every 100 hours when operating under severe conditions. Replace oil and filter. (See

Page 149.)

Every 250 Hours or Every 12 Months

• Fuel Filters – Replace filter elements. (See Page 145.)

• Engine / Hydrostatic Drive Belt – Check for wear or damage. Replace as needed. (See Page 183.)

• Drive Belts (Alternator, air conditioning, water pump) – Check condition. Adjust or replace as needed. (See Page

180.) and (See Page 181.)

• Bobcat Interlock Control System (BICS™) – Check the function of the lift arm bypass control. (See Page 124.)

• Engine Oil and Filter – Replace oil and filter. (See Page 149.)

Every 500 Hours or Every 12 Months

• Hydraulic Charge Filter, Hydraulic Reservoir Breather Cap – Replace the charge filter and the reservoir breather

cap. (See Page 173.) and (See Page 176.)

• Heater Coil and Air Conditioning Evaporator (if equipped) - Clean the heater coil and air conditioning evaporator.

Clean the plenum drains. (See Page 139.)

Every 1000 Hours or Every 12 Months

• Hydraulic / Hydrostatic Filter – Replace the hydraulic / hydrostatic filter. (See Page 172.)

• Hydraulic Reservoir – Replace the fluid. (See Page 169.)

• Final Drive Transmission (Chaincase) – Replace the fluid. (See Page 179.)

• Engine Valves – Adjust the engine valve clearance.

Every 24 Months

• Coolant – Replace the coolant. (See Page 155.)

NOTE: The Inspection Checkbook can be ordered for you by your local dealer. Part number 7296478.

122 S450 Operation & Maintenance Manual

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5810)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- ECM - No CommunicationDocument22 pagesECM - No CommunicationMohamed ZakiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Cummins Engine ISF 2.8, ISB, ISC, ISLe, 4ISBe, 6ISBe, ISDe, ISM, QSM, ISX, QSX Fault CodesDocument72 pagesCummins Engine ISF 2.8, ISB, ISC, ISLe, 4ISBe, 6ISBe, ISDe, ISM, QSM, ISX, QSX Fault CodesMohamed ZakiNo ratings yet

- Taski Swingo 755bDocument31 pagesTaski Swingo 755bAdıl SurekNo ratings yet

- Smacna Duct ConstructionDocument23 pagesSmacna Duct ConstructionKaustubh Bidkar100% (2)

- BOP Stack DesignDocument4 pagesBOP Stack DesignAjeet PriyanshaNo ratings yet

- Ingersoll Rand-Vibratory Pump AssemblyDocument8 pagesIngersoll Rand-Vibratory Pump AssemblyMohamed ZakiNo ratings yet

- Workshop Manual Serie C Cummins EnginesDocument31 pagesWorkshop Manual Serie C Cummins EnginesMohamed Zaki100% (1)

- PT 980421catalog Training Panel System 2014-6-41 - 60Document22 pagesPT 980421catalog Training Panel System 2014-6-41 - 60Fastabiq AhmadNo ratings yet

- Bidang Keahlian Teknika (Att-Ii) Tingkat ManajemenDocument7 pagesBidang Keahlian Teknika (Att-Ii) Tingkat ManajemenGopi SivasamyNo ratings yet

- دليل توعية لفيروس كرونا.pdf.pdfDocument15 pagesدليل توعية لفيروس كرونا.pdf.pdfMohamed ZakiNo ratings yet

- Course Completion CertificateDocument1 pageCourse Completion CertificateMohamed ZakiNo ratings yet

- General Infomation 07-2019Document7 pagesGeneral Infomation 07-2019Mohamed ZakiNo ratings yet

- Tiggo 8Document6 pagesTiggo 8Mohamed ZakiNo ratings yet

- Report CompressedDocument14 pagesReport CompressedMohamed ZakiNo ratings yet

- Grammar Revision-Term 1 (Model Answer)Document14 pagesGrammar Revision-Term 1 (Model Answer)Mohamed ZakiNo ratings yet

- 019-201 Weather Pak Connector Series: Pin ReplacementDocument9 pages019-201 Weather Pak Connector Series: Pin ReplacementMohamed ZakiNo ratings yet

- 019-197 Ring Terminal: Connector ReplacementDocument3 pages019-197 Ring Terminal: Connector ReplacementMohamed ZakiNo ratings yet

- Vibration System Components LocationDocument2 pagesVibration System Components LocationMohamed ZakiNo ratings yet

- Vibration Pump, Description: Service InformationDocument2 pagesVibration Pump, Description: Service InformationMohamed ZakiNo ratings yet

- Crankcase Gases (Blowby) Excessive: Symptom Tree t027Document1 pageCrankcase Gases (Blowby) Excessive: Symptom Tree t027Mohamed ZakiNo ratings yet

- Vibration Pump Operation 2Document2 pagesVibration Pump Operation 2Mohamed ZakiNo ratings yet

- Mobile Elevating Work PlatformsDocument64 pagesMobile Elevating Work PlatformsMohamed ZakiNo ratings yet

- Map ViennaDocument2 pagesMap ViennaMohamed ZakiNo ratings yet

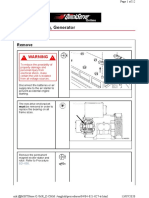

- 021-027 Bearing, Generator: RemoveDocument12 pages021-027 Bearing, Generator: RemoveMohamed ZakiNo ratings yet

- 6C33CDocument7 pages6C33CPeter KilburnNo ratings yet

- Fire Shield ManualDocument68 pagesFire Shield ManualMike SaundersNo ratings yet

- Technical Results With Driving Power: Drive Systems For DecantersDocument6 pagesTechnical Results With Driving Power: Drive Systems For DecantershaggNo ratings yet

- Danfoss Electronic Oil Burner Control OBC 82.10Document4 pagesDanfoss Electronic Oil Burner Control OBC 82.10Olegs GrNo ratings yet

- Mie12166-Cba1000 Introductory GuideDocument113 pagesMie12166-Cba1000 Introductory GuideEmir KamberovićNo ratings yet

- Astero E0201E-20 991063Document186 pagesAstero E0201E-20 991063Thinh Nguyen100% (1)

- Brochure - Cat C6-6 ACERT Marine GensetsDocument6 pagesBrochure - Cat C6-6 ACERT Marine GensetsmouradNo ratings yet

- LG 32LX2RDocument64 pagesLG 32LX2Ranon_49680389No ratings yet

- Opel Combo Cargo Specsheets A4l HR DigiDocument2 pagesOpel Combo Cargo Specsheets A4l HR DigiChidi OkoloNo ratings yet

- Current Sensitivity of A Galvanometer: Mustafa Anwar & Ahmed Ali - Electronic Measurements LabDocument4 pagesCurrent Sensitivity of A Galvanometer: Mustafa Anwar & Ahmed Ali - Electronic Measurements LabMustafa AnwarNo ratings yet

- 5742-Datasheet-Unibus 8relay Auxiliary ExpanderDocument2 pages5742-Datasheet-Unibus 8relay Auxiliary ExpanderIsaacNo ratings yet

- Transmission Digest Vol.26 #8 PDFDocument5 pagesTransmission Digest Vol.26 #8 PDFalvaromexNo ratings yet

- Audio System: E4 (A), E5 (B), E6 (C), E53 (D)Document4 pagesAudio System: E4 (A), E5 (B), E6 (C), E53 (D)dadang lukmanulhakimNo ratings yet

- 4 - Technical Newsletter - Trimming MethodsDocument3 pages4 - Technical Newsletter - Trimming MethodsTaha TlijaniNo ratings yet

- DX Basic ToolDocument2 pagesDX Basic ToolCristian m VizcainoNo ratings yet

- Cooling Tower Specs - Cti Certified Cross FlowDocument2 pagesCooling Tower Specs - Cti Certified Cross FlowShahab Z AhmedNo ratings yet

- Speed LogsDocument2 pagesSpeed LogsPrashant Baldia0% (1)

- DrentechSimple BrochureDocument2 pagesDrentechSimple BrochureyaniNo ratings yet

- Transmission Repair Manuals AW 55-50SN 55-51SN - Rebuild InstructionsDocument13 pagesTransmission Repair Manuals AW 55-50SN 55-51SN - Rebuild InstructionsomarNo ratings yet

- Manual Eu So e Manu Tenzi One FranzDocument92 pagesManual Eu So e Manu Tenzi One Franzl2fNo ratings yet

- Understanding The RV8 Engine Management System: Software That Is Very Helpful For All RV8 Owners Who Want To SeeDocument7 pagesUnderstanding The RV8 Engine Management System: Software That Is Very Helpful For All RV8 Owners Who Want To SeeJohn GalaNo ratings yet

- Mos Integrated Circuit: Data SheetDocument12 pagesMos Integrated Circuit: Data SheetsindbadNo ratings yet

- Vertical Mill Drives US FinalDocument12 pagesVertical Mill Drives US FinalpavelNo ratings yet

- Closing - Instructions For Jerrycans PDFDocument5 pagesClosing - Instructions For Jerrycans PDFJhumberto MontorNo ratings yet

- 5278 SP-IDLU-32UL40-UNBOO-OPP (EnV060318)Document3 pages5278 SP-IDLU-32UL40-UNBOO-OPP (EnV060318)eltioelpanNo ratings yet