Professional Documents

Culture Documents

Chap3 Lect03 Economics

Uploaded by

vtvrOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chap3 Lect03 Economics

Uploaded by

vtvrCopyright:

Available Formats

Design Verication & Testing

Economics

CMPE 418

Test Economics Engineers concerned with optimizing technological efciency. Economists prefer to minimize cost. Fixed and variable costs of material, equipment, labor, etc. are important. Test economics focuses on the relationship between testing cost and product quality. The relationship is complex. For complex systems, testing cost is > 30% of the total cost. Testing is responsible for the quality of VLSI chips. Goal: obtain required quality level at minimum cost. Costs include: Cost of ATE (initial and running). Cost of test development (CAD tools, test generation, test programming). Cost of DFT (scan reduces cost of test generation, BIST reduces complexity and cost of ATE, both reduce yield however).

1

Design Verication & Testing

Economics

CMPE 418

Yield Process yield: Fraction of acceptable parts among all parts fabricated. Wafer yield: average number of good chips/wafer. Normalizing wafer yield by the # of chip sites on the wafer can be used as process yield. Many factors affect yield including die area, process maturity and number of process steps. It is difcult to obtain an exact value of yield: Tests are based on fault models that do not detect all defects. Lack of data once the product is sold. Defect Level (DL) are the fraction of bad chips that pass nal package tests. DL is usually expressed in Defect-Per-Million or DPM.

Design Verication & Testing

Economics

CMPE 418

Defect Modeling Two scenarios for defect modeling: Defects Good chips Bad chips

Unclustered defects Wafer yield = 12/22 = 0.55

Clustered defects Wafer yield = 17/22 = 0.77

Fortunately, clustered defect model better represents reality. Random defects are characterized by two parameters: defect density, d, which is the average number of defects per unit area. clustering parameter, a. The average number of defects on a chip of area A is Ad.

3

Design Verication & Testing

Economics

CMPE 418

Defect Modeling In any random chip, the number of defects, x, is an integer-valued random variable. Defect clustering is best modeled assuming a negative binomial probability density function for x: p ( x ) = Prob ( # of defects on chip=x ) x ( + x) ( Ad ) p ( x ) = --------------------- ----------------------------------------x! ( ) +x ( 1 + Ad ) where

( x)

(1)

is the gamma function given by

x n 1 e x dx 0 2 The mean, E(x), and variance, ( x ) are dened as: ( x) = E ( x ) = Ad 2 ( x ) = Ad ( 1 + Ad ) (1a)

Design Verication & Testing

Economics

CMPE 418

Yield Models In order to predict the yield, we need the mean and variance for the number of defects on a chip. Obtain either from experimental measurements or process simulation. Substitution of the mean and variance in equations (1a) gives yield parameters, d and a. Yield is obtained as the probability, p(0), of no defect on a chip. Substituting x=0 into the equation (1) gives: Y = ( 1 + Ad ) (2)

For the unclustered model: x Ad ( Ad ) e p ( x ) = ---------------------------x! with x = 0, the yield is: Y Poisson = e Ad (3)

Design Verication & Testing

Economics

CMPE 418

Yield Models However, this model predicts low yields. If Ad = 1.0 and a = 0.5 (typical of a large VLSI chip) then using (3): 1 Y Poisson = -- = 0.37 (4) e Using (2), a more realistic prediction of 0.58 is obtained. Yield may be low when fabricating a new design, and more accurately predicated by (3) than by (2). Consider the impact of testability (the cost of testability overhead): d = 1.25 defects/cm2 a = 0.5 chip area, A, is 8mm X 8mm = 0.64cm2. Equation (2) gives: 0.5 1 + 0.64 1.25 Y = -------------------------= 0.62 0.5

Design Verication & Testing

Economics

CMPE 418

Example Now suppose: The process uses 8-inch wafers The cost of processing a wafer is $100 Each wafer has 400 chips Processing cost per chip is: $100 Cost chip = ----------------------------- = 40 cents ( 400 0.62 ) Assume the chip size increases by 10% after DFT is included. Yield is then: 0.5 1 + 0.64 1.10 1.25 2% reduction in yield = 0.60 Y DFT = ------------------------------------------ 0.5 With DFT, a wafer contains 400/1.1 ~= 364 chips. Therefore, processing cost is: $100 Cost chip = ----------------------------- = 46 cents 15% increase over no DFT ( 364 0.60 )

7

Design Verication & Testing

Economics

CMPE 418

DL and Quality DL (or reject ratio) is a measure of the effectiveness of the tests. Objective is to develop a test that reduces the number of outgoing faulty parts to an acceptable level It's too expensive to try to get them all. The DL can be determined from the eld return data. Chips are returned if they fail acceptance test, fail system test or fail in the eld during a maintenance test. For commercial VLSI chips, a DL >500ppm is considered unacceptable. Actual DL is difcult to determine: Some failed parts are not returned Some returned parts are damaged in handling It takes a long time (a year) to collect sufcient data The DL reduces over time Therefore, computed DL is usually overly pessimistic. Test data analysis from manufacturing test data gives estimate.

8

Design Verication & Testing

Economics

CMPE 418

Estimating Defect Level The yield equation (1) can be modied to do this. Fault density (as opposed to defect density) dened as f = average number of SA faults per unit chip area. Fault clustering parameter, b Stuck-At fault coverage, T. Y ( T ) = ( 1 + TA f )

Here, we obtain the measured yield when a test with fault coverage T is applied. Assume that tests with 100% fault coverage (T=1.0) remove all faulty chips: Y = Y (1) = (1 + A f ) (multiply by 106 to get PPM). (5) (6)

Y (T ) Y (1) + TAf DL ( T ) = ------------------------------ = 1 ------------------ + Af Y (T )

Af (average number of faults) and b are determined from test data.

9

Design Verication & Testing

Economics

CMPE 418

Estimating Defect Level from SEMATECH data This model can be evaluated on IBMs SEMATECH data. CUT characteristics: CUT is a bus interface controller ASIC containing 116,000 equivalent 2-input NAND gates. CUT has 249 I/O and a 304-pin package. Some portions of chip operate at 40MHz, others at 50MHz. Full scan, with 5,280 scan latches. 3.3V power supply, 3 metal, 0.45um technology, 9.4mm x 8.8 mm die size. Four types of tests applied, SA, functional, delay and IDDQ. IBMs LSSD scan chain design allows a scan ush test. With scan tests, total SA coverage was 99.79% for a total of 375,142 faults. Advantest 3381 ATE used. 18,466 chips tested at 2.5MHz test clock. (Data provided courtesy Phil Nigh, IBM).

10

Design Verication & Testing

Economics

CMPE 418

Estimating Defect Level from SEMATECH data Fault coverage computed using a fault simulator:

1.0

SA fault coverage

0.8 0.6 0.4 0.2 0.0 0

Approximated

See text for graph of actual data

1000

2000

3000

4000

5000

6000

7000

Vector number

Chip fallout vs. test vector number: Measured chip fallout

0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.00 0 1000 2000 3000 4000 5000 6000 7000 Approximated See text for graph of actual data Wafer level test of 18,466 chips

These graphs are consistent, i.e., as the fault coverage rises, more chips fail (fallout). ~0.24 (Yield is ~76%)

Vector number

11

Design Verication & Testing

Economics

CMPE 418

Estimating Defect Level from SEMATECH data The data from the two graphs can be plotted and tted. Measured chip fallout and computed 1-Y(T)

0.40 0.35 0.30 0.25 0.20 0.15 0.10 0.05 0.00 0 Measured fallout 0.2 0.4 0.6 Approximated See text for graph of actual data 0.8 1.0 Fit: Y(T) for Af=2.1 and beta=0.083

Y(1) = 0.7623

SA fault coverage Plotted fallout rate function, 1 - Y(T), given by: 1 Y ( T ) = 1 [ 1 + TAf ] Fitting yields Af=2.1 and b=0.083. This gives f = Af/A = 2.1/(0.94*0.88) = 2.54 faults/sq. cm. Using these values, Eq (5) gives Y = 76.23 and (6) gives DL = 168 for T=0.9979

12

Design Verication & Testing

Economics

CMPE 418

Estimating Defect Level from SEMATECH data This type of analysis allows the yield and fault distribution parameters to be determined. The fab process must be diagnosed and corrected if they are not as expected. Also, if the defect level is too high, the fault coverage of the patterns must be improved. Bear in mind, the tests in this study were run at slow speed. Therefore, some chips that passed have delay faults. Other tests may be necessary to make other defects have a non-zero probability of detection. Deriving better tests is the focus of some recent research. Eq (6) can be used to plot DL as a function of fault coverage. Y (T ) Y (1) + TAf DL ( T ) = ------------------------------ = 1 ------------------ + Af Y (T )

13

Design Verication & Testing

Economics

CMPE 418

Estimating Defect Level from SEMATECH data Note, a reverse logarithmic scale is used for the x-axis. Defect level in ppm

1,000,000 100,000 10,000 1,000 100 10 1 0 90 99 99.9 99.99 237,700 ppm (Y=76.23%)

Approximated See text for graph of actual data

SA fault coverage (T) in %.

For zero fault coverage, the DL is 237,700 ppm. Therefore, the lot of chips contains 76.23% good chips. For fault coverage at 99%, DL reduces to <1000 ppm. For 99.9% -> <100 ppm, for 99.99 -> <10ppm. Remember, these DLs are realistic only if testing emulates real conditions. Another view: these are the DL if the chips are used at 2.5MHz.

14

Design Verication & Testing

Economics

CMPE 418

Yield and Testing Testing cannot improve process yield. It is only a screening process for bad chips. Process yield can be improved by: Diagnosis and Repair Parts that fail Go/No-Go can be diagnosed and repaired in some situations. This strategy improves yield but also increases production cost. Process Diagnosis and Correction Failure analysis determines the root cause and the process is corrected. Therefore, this strategy is more cost effective.

15

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Service Manual: SV01-NHX40AX03-01E NHX4000 MSX-853 Axis Adjustment Procedure of Z-Axis Zero Return PositionDocument5 pagesService Manual: SV01-NHX40AX03-01E NHX4000 MSX-853 Axis Adjustment Procedure of Z-Axis Zero Return Positionmahdi elmay100% (3)

- Project - New Restuarant Management System The Grill HouseDocument24 pagesProject - New Restuarant Management System The Grill HouseMayank Mahajan100% (3)

- Report Card Grade 1 2Document3 pagesReport Card Grade 1 2Mely DelacruzNo ratings yet

- Chapter 1 To 5 For Printing.2Document86 pagesChapter 1 To 5 For Printing.2Senku ishigamiNo ratings yet

- Pt3 English Module 2018Document63 pagesPt3 English Module 2018Annie Abdul Rahman50% (4)

- Chronic Kidney DiseaseDocument15 pagesChronic Kidney Diseaseapi-270623039No ratings yet

- Human EpigenomicsDocument234 pagesHuman EpigenomicsHeron HilárioNo ratings yet

- IKEA SHANGHAI Case StudyDocument5 pagesIKEA SHANGHAI Case StudyXimo NetteNo ratings yet

- German Atv-Dvwk Rules and StandardsDocument25 pagesGerman Atv-Dvwk Rules and StandardsMehmet Emre Bastopcu100% (1)

- Digital MetersDocument47 pagesDigital MetersherovhungNo ratings yet

- Anatomy Anal CanalDocument14 pagesAnatomy Anal CanalBela Ronaldoe100% (1)

- Howard R700X - SPL - INTDocument44 pagesHoward R700X - SPL - INTJozsefNo ratings yet

- Financial Accounting 2 SummaryDocument10 pagesFinancial Accounting 2 SummaryChoong Xin WeiNo ratings yet

- Origami Oso HormigueroDocument9 pagesOrigami Oso HormigueroRogelio CerdaNo ratings yet

- Pavement Design1Document57 pagesPavement Design1Mobin AhmadNo ratings yet

- Richardson Heidegger PDFDocument18 pagesRichardson Heidegger PDFweltfremdheitNo ratings yet

- The Magic DrumDocument185 pagesThe Magic Drumtanishgiri2012No ratings yet

- Environmental Economics Pollution Control: Mrinal Kanti DuttaDocument253 pagesEnvironmental Economics Pollution Control: Mrinal Kanti DuttashubhamNo ratings yet

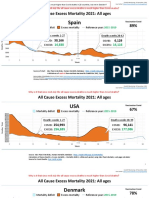

- Countries EXCESS DEATHS All Ages - 15nov2021Document21 pagesCountries EXCESS DEATHS All Ages - 15nov2021robaksNo ratings yet

- AntibioticsDocument36 pagesAntibioticsBen Paolo Cecilia RabaraNo ratings yet

- Golf Croquet Refereeing Manual - Croquet AustraliaDocument78 pagesGolf Croquet Refereeing Manual - Croquet AustraliaSenorSushi100% (1)

- Theories of International InvestmentDocument2 pagesTheories of International InvestmentSamish DhakalNo ratings yet

- The Homework Song FunnyDocument5 pagesThe Homework Song Funnyers57e8s100% (1)

- Objective & Scope of ProjectDocument8 pagesObjective & Scope of ProjectPraveen SehgalNo ratings yet

- Introduction-: Microprocessor 68000Document13 pagesIntroduction-: Microprocessor 68000margyaNo ratings yet

- Shostack ModSec08 Experiences Threat Modeling at MicrosoftDocument11 pagesShostack ModSec08 Experiences Threat Modeling at MicrosoftwolfenicNo ratings yet

- ISO 9001 2015 AwarenessDocument23 pagesISO 9001 2015 AwarenessSeni Oke0% (1)

- Bana LingaDocument9 pagesBana LingaNimai Pandita Raja DasaNo ratings yet

- The Indonesia National Clean Development Mechanism Strategy StudyDocument223 pagesThe Indonesia National Clean Development Mechanism Strategy StudyGedeBudiSuprayogaNo ratings yet

- Application of Graph Theory in Operations ResearchDocument3 pagesApplication of Graph Theory in Operations ResearchInternational Journal of Innovative Science and Research Technology100% (2)