Professional Documents

Culture Documents

Everything You Need to Know About Low Temperature Carbon Steel (LTCS

Uploaded by

POOL MASTEROriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Everything You Need to Know About Low Temperature Carbon Steel (LTCS

Uploaded by

POOL MASTERCopyright:

Available Formats

www.ferrofpf.

com

Low Temperature Carbon Steel (LTCS)

As the name says LTCS is the steel used in low temperature and low pressure applications. In low temperature carbon

steel the alloying composition of carbon is limited to a maximum of 0.30% and with acceptable maximum limits up to

0.60% of silicon and 1.06% of manganese and impact tested at a minimum temperature of -45°c. Above the maximum

allowed limit of 1.06% an increase of manganese at 0.05% to a maximum of 1.35% is allowed for each reduction of

0.01% of carbon below the maximum allowed 0.30%.

For low temperature applications ASTM A333 is the most widely used specification covering the carbon and alloy steel

pipes in seamless construction and welded construction with no addition of filler in welding process. Based on the service

requirements and steel making processes this specification covers several steel grades even with addition of nickel as well,

which are capable to handle extreme low temperature environments as low as -195°c. Even though various ferritic grades

are covered under ASTM A333, the most common stock available and preferred grade is of Grade.6 with proven

character in negative temperature environments, however Grade.3 will also be available in a limited quantity.

It is to be noted hydrostatic test is not a mandatory requirement under ASTM A333 meanwhile manufacturer can opt for

other non-destructive electric testings like eddy current or ultrasonic referring to ASTM A999, unless specified by the

purchaser.

Common characteristics of LTCS are suitability to perform in low temperature services below -29°c, non-brittle, good

weldability and machinability, hardening by carburization, strengthening by cold working, non-expensive etc. These proven

characteristics and excellent properties make this grade very preferred among piping experts to use in several applications

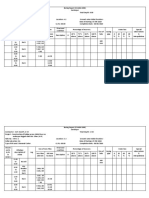

Chemical and Mechanical properties of Carbon steel grades available from stock

Grade UNS C% Mn % P% S% Si % Ni% Tensile Yield Point

A333 Gr. 6 K03006 0.30 0.29-1.06 0.025 0.025 0.10 min - 415 240

A333 Gr. 3 K31918 0.19 0.31-0.64 0.025 0.025 0.18-0.37 3.18 -3.82 450 240

The chemical and mechanical properties of Grade.6 is very much similar to ASTM A106 and it’s often to find multiple

certified

The casting grades for equivalent to the forging grades are of A352 LCB and A352 LC3

Stock available size ranges in Carbon Steel to ASME B36.10 / ASME B36.19 specifications

Category Construction Size Range (DN) SCH/Ratings Standard

Seamless 015 - 600 ASTM A333

Pipe 10S - XXS

Welded 350 - 900 ASTM A333 / A671

Seamless 015 - 400

BW Fittings 10S - XXS ASTM A420

Welded 250 - 750

SW Fittings Forged 015 - 100 CL 3000 - 6000 ASTM A350

Flanges Forged 015 - 900 CL 150 - 1500 ASTM A350

Stock Certifications, Testings and Reports

All stock available materials from Ferro FPF are coming with full traceability and necessary testing reports along with

Material Test Certificates to EN 10204 3.1. Most of our process piping materials from stock is coming with dual

certification. This is achieved according to the international standards by controlling the chemical composition and

mechanical properties in the permissible ratio meeting different grades and standards. This is an optimal way of providing

our customers with a comprehensive range of material grades in the most efficient way suiting the project requirements.

Any client and project requirements over and above the normal standards are achieved with possible additional testings,

modifications and inspections using in-house and approved third party facilities. All project confirmed modifications are

performed according to relevant international standards and backed with conformity reports.

Ferro Pipe and Fittings is having a demonstrated experience in managing project package supplies of Pipes, Fittings,

Flanges and Valves for various national and international projects directly with end users and through international EPC’s.

Contact us to discuss on our capacities and custom solutions we can offer to your project piping requirements.

This article is to be considered only as a general reference guide and for any detailed accurate information, please contact us directly and or refer to relevant

standards and specifications. Any trade names and registered trademarks mentioned belong to their respective owners.

You might also like

- Mat Const Grade UNS C% MN% P% S% Si% Tensile Yield Point: Contact UsDocument1 pageMat Const Grade UNS C% MN% P% S% Si% Tensile Yield Point: Contact UsPOOL MASTERNo ratings yet

- A516 NormalizedDocument3 pagesA516 Normalizediran1362No ratings yet

- Quality Oriented and ISO Approved Stainless Steel 310s Buttweld Pipe Fittings Manufacturer in IndiaDocument4 pagesQuality Oriented and ISO Approved Stainless Steel 310s Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Stud Bolt Specification 3Document7 pagesStud Bolt Specification 3santoshblonkarNo ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- ASTM A325: ScopeDocument2 pagesASTM A325: ScopetylerstearnsNo ratings yet

- Valve Material Application PDFDocument16 pagesValve Material Application PDFSudherson Jagannathan100% (1)

- Technical DataDocument17 pagesTechnical Datat_syamprasadNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material ApplicationMuhammadShabbirNo ratings yet

- Welding Practice For Duplex-1 PDFDocument18 pagesWelding Practice For Duplex-1 PDFBipin Rohit100% (1)

- ASTM A210 Seamless Medium Carbon Steel Tube1 PDFDocument5 pagesASTM A210 Seamless Medium Carbon Steel Tube1 PDFaditya ekaNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 310h Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 310h Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Electric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingDocument20 pagesElectric-Resistance-Welded Carbon and Alloy Steel Mechanical TubingMohamad ShafeyNo ratings yet

- SG Iron and Cast Iron Material SpecificationsDocument9 pagesSG Iron and Cast Iron Material Specificationsvtsusr fvNo ratings yet

- Awwa C200 PDFDocument6 pagesAwwa C200 PDFangel darioNo ratings yet

- ASTM A333 Grade 6 Pipe Specification and DimensionsDocument10 pagesASTM A333 Grade 6 Pipe Specification and DimensionsArmandito ZamudioNo ratings yet

- HTTP WWW - Wermac.org Fittings Buttweld Fittings Part5Document4 pagesHTTP WWW - Wermac.org Fittings Buttweld Fittings Part5prabu prasad100% (1)

- Quality Oriented and ISO Approved Stainless Steel 316 Buttweld Pipe Fittings Manufacturer in IndiaDocument4 pagesQuality Oriented and ISO Approved Stainless Steel 316 Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Kaiser Aluminum Soft Alloy Tube PDFDocument31 pagesKaiser Aluminum Soft Alloy Tube PDFgerrzen64No ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationme100% (1)

- Propiedades Aceros InoxDocument2 pagesPropiedades Aceros Inoxjarv7910No ratings yet

- Metallic Ring Joint Gaskets: Type Nominal Pipe Size Class RatingsDocument1 pageMetallic Ring Joint Gaskets: Type Nominal Pipe Size Class RatingsqzdaniNo ratings yet

- Asme Sa 106 Grade B PipesDocument1 pageAsme Sa 106 Grade B PipesFerroPipENo ratings yet

- Astm Bolt & NutsDocument24 pagesAstm Bolt & NutsDinesh Radhakrishnan100% (3)

- 310 Buttweld FittingsDocument4 pages310 Buttweld FittingsPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- 20 TMSS 01 R0Document0 pages20 TMSS 01 R0renjithas2005No ratings yet

- Data Sheet SS316L Seamless Tube Fluidline CustomerDocument2 pagesData Sheet SS316L Seamless Tube Fluidline Customerinstrument.engineer.123No ratings yet

- Tabela Aço Inox PDFDocument8 pagesTabela Aço Inox PDFjucalele77No ratings yet

- Din 1681-GS 60Document9 pagesDin 1681-GS 60Vishnu AgawaneNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Technical Catalogue: Pipes Tubes Fittings FlangesDocument121 pagesTechnical Catalogue: Pipes Tubes Fittings FlangesDANIELVENZUELAANo ratings yet

- Duplex Stainless SteelDocument24 pagesDuplex Stainless SteeljeffreymacaseroNo ratings yet

- 20 TMSS 02 R0Document0 pages20 TMSS 02 R0renjithas2005No ratings yet

- ASME Specification For Fastener MaterialsDocument11 pagesASME Specification For Fastener MaterialsAnonymous IwqK1Nl100% (1)

- Steel Plates ASTM A 516 Gr. 70, ASTM A283 Grade C (Plate) ASTM A284 (C) (Plate) ASTM A515 (60) (Plate), A529Gr50, A529Gr55, 1010-1050, ASTM A 573 Gr7Document2 pagesSteel Plates ASTM A 516 Gr. 70, ASTM A283 Grade C (Plate) ASTM A284 (C) (Plate) ASTM A515 (60) (Plate), A529Gr50, A529Gr55, 1010-1050, ASTM A 573 Gr7Akhi IsMailNo ratings yet

- A53 Seamless & Welded (ERW) Steel Pipe - ASTM A53 Welded or Seamless ProductDocument7 pagesA53 Seamless & Welded (ERW) Steel Pipe - ASTM A53 Welded or Seamless ProductRyan Joseph QuebrarNo ratings yet

- ASTM A335 P92 SpecificationDocument4 pagesASTM A335 P92 SpecificationTarun ChandraNo ratings yet

- United States Steel Corporation - Application Considerations - Steel Designations - 2016-06-23Document5 pagesUnited States Steel Corporation - Application Considerations - Steel Designations - 2016-06-23Humberto GalvezNo ratings yet

- Materials Castings E00510 SulzerDocument5 pagesMaterials Castings E00510 SulzerAmir SafdarNo ratings yet

- API Vs A53 Vs A106 Vs A333Document8 pagesAPI Vs A53 Vs A106 Vs A333Ibrahim BashaNo ratings yet

- 317L Buttweld FittingsDocument5 pages317L Buttweld FittingsPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- AISC 13th - Material GradesDocument5 pagesAISC 13th - Material GradesUpadrasta HarishNo ratings yet

- ASTM A213 T22 ASME SA213 T22 Specification - 3 PDFDocument6 pagesASTM A213 T22 ASME SA213 T22 Specification - 3 PDFbagus asmoroNo ratings yet

- Astm A192 Asme Sa192 PDFDocument4 pagesAstm A192 Asme Sa192 PDFWil Vasquez C100% (1)

- Materials Stud Bolts: ASTM A197 B7Document5 pagesMaterials Stud Bolts: ASTM A197 B7scribddisantoNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyFrom EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNo ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Boiler Making for Boiler Makers - A Practical Treatise on Work in the ShopFrom EverandBoiler Making for Boiler Makers - A Practical Treatise on Work in the ShopRating: 4.5 out of 5 stars4.5/5 (2)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Die Casting Metallurgy: Butterworths Monographs in MaterialsFrom EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsRating: 3.5 out of 5 stars3.5/5 (2)

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Control and Analysis in Iron and SteelmakingFrom EverandControl and Analysis in Iron and SteelmakingRating: 3 out of 5 stars3/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Breaking and Yield Loads for FastenersDocument6 pagesBreaking and Yield Loads for FastenersJamesNo ratings yet

- Rubber Isolator 1921Document10 pagesRubber Isolator 1921Mario Daniel MLNo ratings yet

- Integration Course For Architecture IDocument2 pagesIntegration Course For Architecture IKim KwonNo ratings yet

- Aircraft Hardware CATDocument4 pagesAircraft Hardware CATJowiNo ratings yet

- Astm C884C884M-16Document3 pagesAstm C884C884M-16adolfo camayoNo ratings yet

- Syllabus For B.Arch - 2014 15 Onwards IX To X Sem PDFDocument18 pagesSyllabus For B.Arch - 2014 15 Onwards IX To X Sem PDFManish Singh RathorNo ratings yet

- Amr Ashraf Abdallah C.V - Mechanical Project EngineerDocument4 pagesAmr Ashraf Abdallah C.V - Mechanical Project EngineerAmr AshrafNo ratings yet

- SikaCor VEMYDocument5 pagesSikaCor VEMYboyzesNo ratings yet

- Elevator Chapter 6Document65 pagesElevator Chapter 6Pedro AmorsoloNo ratings yet

- Manual de PuertasDocument32 pagesManual de PuertasCarlos PrietoNo ratings yet

- Boring ReportDocument8 pagesBoring Reportsourabh_gupta_54No ratings yet

- Instrument Pipe & ISO Conversion Fittings: Catalog 4260 May 2014Document40 pagesInstrument Pipe & ISO Conversion Fittings: Catalog 4260 May 2014Mohammed JalalNo ratings yet

- Uji KekerasanDocument55 pagesUji KekerasanShiezkhaede ShirakawaNo ratings yet

- Inspection and Test Plans (Itps) : Centrifugal PumpsDocument3 pagesInspection and Test Plans (Itps) : Centrifugal PumpsbahlakeNo ratings yet

- Case Study Residential Building PresentationDocument26 pagesCase Study Residential Building PresentationAyushree RajbhandariNo ratings yet

- Air Release Valve Val - 3Document1 pageAir Release Valve Val - 3Coordinador TecnicoNo ratings yet

- PE 06 Seepage FlownetsDocument22 pagesPE 06 Seepage FlownetsIshmam Shahid100% (1)

- Don Tomas Bautista Mapua: First Registered Filipino ArchitectDocument2 pagesDon Tomas Bautista Mapua: First Registered Filipino ArchitectEXTRA VIDEOSNo ratings yet

- 2017 New Eim NC IiDocument4 pages2017 New Eim NC IiThorgay AvengersNo ratings yet

- Cales and Wire July 2013-HavellsDocument45 pagesCales and Wire July 2013-HavellsAnonymous yD6Qpiq3No ratings yet

- Ceramic Tile BenefitsDocument18 pagesCeramic Tile BenefitsAditi JalaNo ratings yet

- Din 6332Document3 pagesDin 6332Dule JovanovicNo ratings yet

- Valve Specification SummaryDocument136 pagesValve Specification Summarysumit kumarNo ratings yet

- Design of SpillwaysDocument29 pagesDesign of SpillwaysALvin SaLvaNo ratings yet

- Mix Design Essay - Nur Fatihah Binti Anuar (1625518)Document5 pagesMix Design Essay - Nur Fatihah Binti Anuar (1625518)fatihahanuarNo ratings yet

- STEM1-06 FinalPaperDocument21 pagesSTEM1-06 FinalPaperReuben Wei PalmaresNo ratings yet

- Solenoid VALVES ASCODocument4 pagesSolenoid VALVES ASCOGeorgios MariolisNo ratings yet

- P2H+P3H en MetricDocument6 pagesP2H+P3H en MetricRafay SaeedNo ratings yet

- MANGUITO ETA 17 0081 - AssessmentDocument23 pagesMANGUITO ETA 17 0081 - AssessmentJavier Gómez CorreaNo ratings yet