Professional Documents

Culture Documents

Garlock Style 9900 Spec Sheet - (NA) 2021-09 EN

Uploaded by

Drojanle MezbraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Garlock Style 9900 Spec Sheet - (NA) 2021-09 EN

Uploaded by

Drojanle MezbraCopyright:

Available Formats

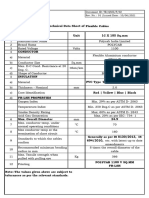

Style 9900

MATERIAL PROPERTIES*:

Color: Mahogany

Composition: Graphite fibers with a nitrile binder

Fluid Services (see chemical resistance guide): Saturated steam2 , water, oils, inert gases, aliphatic hydrocarbons &

gasoline

Temperature1, °F (°C)

Minimum: -100 (-75)

Continuous Max: +650 (+343)

Maximum: +1000 (+537)

Pressure1, Maximum, psig (bar): 2000 (138)

P x T (max.)1, psig x °F (bar x °C):

1/32 and 1/16”: 700,000 (25,000)

1/8” 350,000 (12,000)

Meets Specifications: ABS (American Bureau of Shipping), STR 508 and Fire Safe

TYPICAL PHYSICAL PROPERTIES*:

ASTM F36 Compressibility , average, %: 9

ASTM F36 Recovery, %: 55

ASTM F38 Creep Relaxation, %: 9

ASTM F152 Tensile, Across Grain, psi (N/mm2): 1800 (12)

ASTM F1315 Density, lbs./ft.3 (grams/cm3): 110 (1.76)

ASTM F433 Thermal Conductivity (K), W/m°K (Btu.·in./hr.·ft.2·°F): 0.87 (6.0)

ASTM D149 Dielectric Properties, range, volts/mil.

Sample conditioning 1/16” 1/8”

3 hours at 250oF <2 -

96 hours at 100% Relative Humidity: - -

ASTM F586 Design Factors 1/16” & Under 1/8”

"m" factor: 4.5 5

"y" factor, psi (N/mm2): 4100 (28.3) 4100 (28.3)

ROTT Gasket Constants, 1/16”: Gb=2,322 a=0.133 Gs=18.0

SEALING CHARACTERISTICS*

ASTM F37B – Fuel A ASTM F37B - Nitrogen DIN 3535 – Nitrogen

Gasket Load, psi (N/mm2): 500 (3.5) 3000 (20.7) 4640 (32)

Internal Pressure, psig (bar): 9.8 (0.7) 30 (2) 580 (40)

Leakage 0.3 ml/hr. 0.6 ml/hr. 0.015 cc/min

Notes:

* This is a general guide and should not be the sole means of selecting or rejecting this material. ASTM test results in accordance with ASTM F-104; properties

1

Based on ANSI RF flanges at our preferred torque. When approaching maximum pressure, continuous operating temperature, minimum temperature or 50% of

maximum PxT, consult Garlock Applications Engineering. Minimum temperature rating is conservative.

2 Minimum recommended assembly stress = 4,800psi. Preferred assembly stress = 6,000-10,000psi. Gasket thickness of 1/16" strongly preferred. Retorque the

bolts/studs prior to pressurizing the assembly. For saturated steam above 150psig or superheated steam, consult Garlock Engineering.

REV: 9/2/2021

GARLOCK Tel: 1-877-GARLOCK / 315.597.4811

an EnPro Industries family of companies Fax: 800.543.0598 / 315.597.3216

1666 Division Street www.garlock.com

Palmyra, NY 14522

You might also like

- Garlock Style 5500 Spec Sheet - (NA) 2016-11 ENDocument1 pageGarlock Style 5500 Spec Sheet - (NA) 2016-11 ENALONSO GOMEZNo ratings yet

- Garlock Style 700 Spec Sheet - (NA) 2016-11 enDocument1 pageGarlock Style 700 Spec Sheet - (NA) 2016-11 enMarín HernándezNo ratings yet

- Garlock Style 3000 Spec Sheet - (NA) 2016-11 enDocument1 pageGarlock Style 3000 Spec Sheet - (NA) 2016-11 enalan2003_1_29040No ratings yet

- 3504 Blue Gylon Data Sheet PDFDocument1 page3504 Blue Gylon Data Sheet PDFYnuzneNo ratings yet

- Garlock 9900 Data Sheet PDFDocument1 pageGarlock 9900 Data Sheet PDFMartin Andrew TugadeNo ratings yet

- Garlock GYLON 3500Document1 pageGarlock GYLON 3500echavarriNo ratings yet

- Garlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENDocument1 pageGarlock GYLON Style 3510 Spec Sheet - (NA) 2016-12 ENSu Kil SungNo ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040No ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 EN PDFalan2003_1_29040No ratings yet

- Garlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3545 Spec Sheet - (NA) 2016-12 enAndres Rodriguez HerreraNo ratings yet

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDocument1 pageGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsChristian SanhuezaNo ratings yet

- Garlock Graph Lock 3125ssDocument1 pageGarlock Graph Lock 3125ssJhon AlarconNo ratings yet

- Garlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 enDocument1 pageGarlock GYLON Style 3501 - Spec Sheet - (NA) 2016-12 ennmosilvaNo ratings yet

- Garlock 700Document1 pageGarlock 700Jairo ArroyoNo ratings yet

- Garlock Hi TempDocument4 pagesGarlock Hi Temprock starNo ratings yet

- Garlock Style 706 Data SheetDocument1 pageGarlock Style 706 Data SheetArturo Gasperin BarrigaNo ratings yet

- Garlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsDocument1 pageGarlock 5500: Saturated Steam, Most Refrigerants, Water, Oils, Gasoline and Aliphatic HydrocarbonsRicardo Perez VerdugoNo ratings yet

- Style 2900 Data SheetDocument1 pageStyle 2900 Data SheetRicardo OrdoñezNo ratings yet

- 3510 Off White Gylon Data SheetDocument1 page3510 Off White Gylon Data SheetJose CarlosNo ratings yet

- Garlock Blue Gard 3000 Data SheetDocument1 pageGarlock Blue Gard 3000 Data SheetMatheus TorresNo ratings yet

- 8600 Aramid-Inorganic/SBR Rubber Binder: ApplicationDocument2 pages8600 Aramid-Inorganic/SBR Rubber Binder: ApplicationIrving Alan Uc FernandezNo ratings yet

- 1.9.1.2-80T - 18 8 Stainless SteelDocument4 pages1.9.1.2-80T - 18 8 Stainless SteelDevan ShanmughaNo ratings yet

- Garlock 3504 Blue Gylon Data SheetDocument1 pageGarlock 3504 Blue Gylon Data SheetdanielbustNo ratings yet

- 1.9.1.2-85T - 316 Stainless SteelDocument4 pages1.9.1.2-85T - 316 Stainless SteelfendynovapamelaNo ratings yet

- Ficha Tecnica Teadit 1082Document2 pagesFicha Tecnica Teadit 1082damianNo ratings yet

- RF-35TC thermally conductive low loss laminateDocument4 pagesRF-35TC thermally conductive low loss laminateElectronic BoyNo ratings yet

- Garlock 22 Red SBR Rubber Sheet Data SheetDocument1 pageGarlock 22 Red SBR Rubber Sheet Data SheetkasebNo ratings yet

- Compressed Sheet With Carbon Fibers, NBR Binder: ApplicationDocument2 pagesCompressed Sheet With Carbon Fibers, NBR Binder: ApplicationEmmanuelNo ratings yet

- Technical Data Sheet Arcapro Positioner Type 827A TD - 827ADocument15 pagesTechnical Data Sheet Arcapro Positioner Type 827A TD - 827AMakshoof GulNo ratings yet

- 04 HT - Chockfast OrangeDocument2 pages04 HT - Chockfast OrangeGESTION Y CONTROL DE PROYECTOS IngeminNo ratings yet

- UV Resistant PC Grade with High Tensile StrengthDocument2 pagesUV Resistant PC Grade with High Tensile Strengthjulius hasan33No ratings yet

- Polyolefin Copolymer Halogen free Cable Insulation CompoundDocument2 pagesPolyolefin Copolymer Halogen free Cable Insulation CompoundAMARENDRA SINo ratings yet

- ABS Cycolac X37Document3 pagesABS Cycolac X37countzeroaslNo ratings yet

- Polyethylene 2EDocument25 pagesPolyethylene 2EJohn SuperdetalleNo ratings yet

- 131 - 1.9.1.2-01T - Aluminum WireDocument4 pages131 - 1.9.1.2-01T - Aluminum WireDiidaii MontañoNo ratings yet

- Ki LSHF 3401 IsDocument2 pagesKi LSHF 3401 IsjamilNo ratings yet

- TDS - Flexible AluminiumDocument3 pagesTDS - Flexible Aluminiumvysakh5588No ratings yet

- 10X4 A2xfy (FRLS) Alum ArmdDocument2 pages10X4 A2xfy (FRLS) Alum ArmdParth DhobiNo ratings yet

- Flexitallic SF5000 DATA CURRENTDocument2 pagesFlexitallic SF5000 DATA CURRENTGlobal VillageNo ratings yet

- Conarc85 EngDocument2 pagesConarc85 EngRaviTeja Bhamidi100% (1)

- Chockfast Orange PDFDocument2 pagesChockfast Orange PDFKaharul AfandiNo ratings yet

- Alpha Om-338-T CNP TB SM871 EnglishDocument4 pagesAlpha Om-338-T CNP TB SM871 Englishachref jebaliNo ratings yet

- Iig - ENERWRAP - MA - 960DataSheetDocument1 pageIig - ENERWRAP - MA - 960DataSheettmp_rootsNo ratings yet

- 5000W ABS Taita TaiwanDocument1 page5000W ABS Taita TaiwanPhạm Thanh TùngNo ratings yet

- BS7531 Grade X. MASTERDocument1 pageBS7531 Grade X. MASTERKishor JadhavNo ratings yet

- sl502 EngDocument2 pagessl502 EngArsalan QutbiNo ratings yet

- Thyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetDocument3 pagesThyssenkrupp Materials (UK) LTD Stainless Steel 1.4878: Material Data SheetShariq KhanNo ratings yet

- 1.9.1.2-75B - BondArc WireDocument6 pages1.9.1.2-75B - BondArc WireGiovanni Cervera FerriolNo ratings yet

- FSL 960 (2305843009232006947)Document1 pageFSL 960 (2305843009232006947)luis angel armadilloNo ratings yet

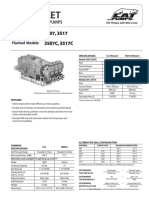

- Data Sheet: 35 Frame Plunger PumpsDocument4 pagesData Sheet: 35 Frame Plunger PumpsJordan aguilarNo ratings yet

- Product: Chocking & Anchor Bolt Setting CompoundDocument2 pagesProduct: Chocking & Anchor Bolt Setting CompoundFajri AnnamlaNo ratings yet

- FR-PA66 PRODUCT INFORMATION AND TEST RESULTSDocument1 pageFR-PA66 PRODUCT INFORMATION AND TEST RESULTSSơn Nguyễn ĐắcNo ratings yet

- Optimize Pneumatic Transmitter SpecsDocument4 pagesOptimize Pneumatic Transmitter SpecsMohammad HosseinNo ratings yet

- Elix ABS M220: Technical InformationDocument3 pagesElix ABS M220: Technical InformationDiegoTierradentroNo ratings yet

- Foam Glass Data SheetDocument2 pagesFoam Glass Data SheetMohamed KareemNo ratings yet

- GP100ORXP enUS ASTMDocument1 pageGP100ORXP enUS ASTMRaul ArmendarizNo ratings yet

- Especificaciones Pintura Macropoxi NavalDocument4 pagesEspecificaciones Pintura Macropoxi NavalVicenteRojasLeonNo ratings yet

- AP ArmaFlex SA FSSA SheetRoll - Sub.EN - US.2021Document4 pagesAP ArmaFlex SA FSSA SheetRoll - Sub.EN - US.2021DJNo ratings yet

- PBVFLG FLT Ball 506Document24 pagesPBVFLG FLT Ball 506Drojanle MezbraNo ratings yet

- VEL2178 CAT Aviation Vessels and HousingsDocument44 pagesVEL2178 CAT Aviation Vessels and HousingsDrojanle MezbraNo ratings yet

- Funnel LauncherDocument1 pageFunnel LauncherDrojanle MezbraNo ratings yet

- G4mini Brochure 2019 - Rev0 Web DesbloqueadoDocument4 pagesG4mini Brochure 2019 - Rev0 Web DesbloqueadoDrojanle MezbraNo ratings yet

- Diablo MFL, Perdida Por CorrosionDocument2 pagesDiablo MFL, Perdida Por CorrosionDrojanle MezbraNo ratings yet

- Base Relevador Rxze2m114m 250V Ac 14 PinesDocument4 pagesBase Relevador Rxze2m114m 250V Ac 14 PinesDrojanle MezbraNo ratings yet

- Regulated SMPS datasheet summaryDocument6 pagesRegulated SMPS datasheet summaryDrojanle MezbraNo ratings yet

- ANTENA 7dbi LM253 RP SMADocument2 pagesANTENA 7dbi LM253 RP SMADrojanle MezbraNo ratings yet

- Training Feed Forward Networks With The Marquardt AlgorithmDocument5 pagesTraining Feed Forward Networks With The Marquardt AlgorithmsamijabaNo ratings yet

- PDF Cci Trading CompressDocument7 pagesPDF Cci Trading CompressefendygtNo ratings yet

- Inductive and Deductive Bible StudiesDocument9 pagesInductive and Deductive Bible StudiesgethornNo ratings yet

- MongoDB Update One or More Fields of One or All DocumentsDocument1 pageMongoDB Update One or More Fields of One or All DocumentsYusto Malik Omondi100% (1)

- Class 12 TH Unacademy NotesDocument54 pagesClass 12 TH Unacademy NotesArpita JaiswalNo ratings yet

- Factors That Determine Reaction SpontaneityDocument5 pagesFactors That Determine Reaction SpontaneityDavid PetalcurinNo ratings yet

- MAT 214 Course Compact - 18 - 19Document3 pagesMAT 214 Course Compact - 18 - 19seyiNo ratings yet

- Switched Reluctance MotorDocument52 pagesSwitched Reluctance Motorkoppulabro75% (8)

- DOP-C02demo Exam Practice QuestionsDocument7 pagesDOP-C02demo Exam Practice Questionslovegeorge393No ratings yet

- Current Pillar DesignDocument24 pagesCurrent Pillar DesignjmgumbwaNo ratings yet

- Introduction To Data StructureDocument145 pagesIntroduction To Data StructurePunidha PriyaNo ratings yet

- Chapter 10 - Propositional LogicDocument66 pagesChapter 10 - Propositional LogicĐiền Mẫn NghiNo ratings yet

- Charly ChalkboardDocument9 pagesCharly ChalkboardOscar PachecoNo ratings yet

- T5L 400 PR221DS-LS/I in 400 3p F FDocument3 pagesT5L 400 PR221DS-LS/I in 400 3p F FLê Xuân ĐịnhNo ratings yet

- Essential Safety GuideDocument112 pagesEssential Safety GuideKVD100% (1)

- Sample Papers 230-311 PDFDocument82 pagesSample Papers 230-311 PDFMohamed Anas100% (2)

- IEEE Standard Requirements, Terminology, and Test Code For Bushings For DC Applications - Corrigendum 1Document12 pagesIEEE Standard Requirements, Terminology, and Test Code For Bushings For DC Applications - Corrigendum 1abdou samiNo ratings yet

- McqsDocument14 pagesMcqschandramohan muruganNo ratings yet

- Analog Vs DigitalDocument6 pagesAnalog Vs DigitalMohan AwasthyNo ratings yet

- FINA 4250 Applications of Risk ModelsDocument67 pagesFINA 4250 Applications of Risk ModelsChristopherNo ratings yet

- Hybrid Audio Amplifier: The Best of Both Worlds?Document9 pagesHybrid Audio Amplifier: The Best of Both Worlds?Yeison MedranoNo ratings yet

- 2 2023 Lesson Plan CS2012 DAADocument4 pages2 2023 Lesson Plan CS2012 DAAAbhishek RajNo ratings yet

- Introduction to Microprocessor and Computer OrganizationDocument26 pagesIntroduction to Microprocessor and Computer OrganizationVishal GaurNo ratings yet

- Numerical Method For Engineers-Chapter 14Document8 pagesNumerical Method For Engineers-Chapter 14MrbudakbaekNo ratings yet

- Info - Tech - Uk 09 - 08Document52 pagesInfo - Tech - Uk 09 - 08georossi46No ratings yet

- Important Shortcuts and Mind Tricks For Simplification Questions in Aptitude Section (IBPS PO Prelims Special)Document6 pagesImportant Shortcuts and Mind Tricks For Simplification Questions in Aptitude Section (IBPS PO Prelims Special)devipreethiNo ratings yet

- Body Matched Antennas For Microwave Medical Applications: Xuyang LiDocument230 pagesBody Matched Antennas For Microwave Medical Applications: Xuyang LiMai VũNo ratings yet

- Drowsy Driving A Look at The Monitoring and Detection SystemDocument4 pagesDrowsy Driving A Look at The Monitoring and Detection SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Wk4 Formulating HypothesisDocument19 pagesWk4 Formulating HypothesisChaela GonzagaNo ratings yet

- Calibre Fundamentals Writing DRC Lvs Rules - 058450 PDFDocument12 pagesCalibre Fundamentals Writing DRC Lvs Rules - 058450 PDFSai Goutham0% (1)