Professional Documents

Culture Documents

Polyolefin Copolymer Halogen free Cable Insulation Compound

Uploaded by

AMARENDRA SIOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Polyolefin Copolymer Halogen free Cable Insulation Compound

Uploaded by

AMARENDRA SICopyright:

Available Formats

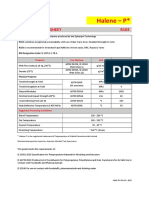

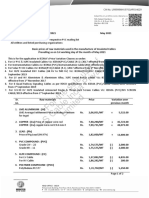

An ISO 9001:2015 company

TECHNICAL DATA

Polyolefin Copolymer Halogen free Cable Insulation Compound: KI-LSHF-3401- IS

DESCRIPTION :

KI-LSHF-3401-IS is a thermoplastic, halogen free, fire retardant, low smoke compound

designed for cable insulation application at high speed extrusion.

SPECIFICATION:

EN 50362-7: 2005 Type TI 6 and TI 7

IEC 332-1/IEC-332-2

TYPICAL PROPERTIES :

Typical

Property Test Method Unit

Value

Density ASTM-D-792 gm / cm3 1.46

Melt Flow Index, 1500C-21.6 kgs ASTM D-1238 gm/ 10 min 8

Hardness ASTM-D-2240 Shore D 50

Tensile Strength at break ASTM D-638 MPa 12

Elongation at break ASTM D-638 % 200

Variation in Tensile strength* IEC 60811 % ±20

Variation in Elongation at break* IEC 60811 % ±20

Limiting Oxygen Index ASTM-D-2863 % 34

Temperature Index ASTM-D-2863 °C 300

Smoke Density Rating ASTM-D-2843 % 8

Halogen acid gas emission IEC 60754-1 % Nil

Corrosivity of gases

PH IEC 60754-2 - 5.5

Conductivity µS/cm 16

Toxicity Index NES 713 - 2.5

Volume Resistivity ASTM D 257 Ohm-cm 3 x 1014

* After Heat ageing at 100°C for 168 hours.

* Data is for information purpose only and should not be used for specification work.

MKT: TDS – LSHF/3401-IS – 11/17

Pg. 1 of 2

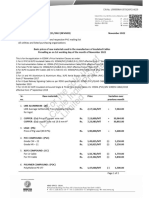

PRE DRYING: Dehumidified hopper drying at 60-70°C for 2 – 3 hours prior to extrusion

may be used to remove moisture.

RECOMMENDED PROCESSING CONDITIONS:

KI-LSHF-3401-IS can be processed using an 18-25 L/D extruder with proper control of the

barrel temperature. A low compression screw (halogen free type) is recommended. PVC / PE

screw are normally not suitable.

Name of the Zone Zone 1 Zone 2 Zone 3 Zone 4 Zone 5 Zone 6 Zone 7

Temperature Range

130-140 140-145 140-145 140-145 145-150 150-160 160-165

(°C)

These conditions are for guideline only and may vary depending on the extruder and

crosshead type and size and tools design.

The use of breaker plate is advisable, in particular low compression screws.

A wide range of PE based colour master batches are applicable; it is suggested an addition of

1- 2% (approx.) by weight.

STORAGE :

The compound must be stored in the following conditions.

Closed and unopened bags.

Ambient temperature generally not exceeding 30°C

Avoid direct exposure to sunlight and weathering.

The compound can be adversely affected by long storage time. KIIL suggest its use within 6

months from the date of manufacturing.

PACKAGE :

25 kg packed in woven sack bags containing inner liner.

The information given in the document is believed to be reliable and is given in the good faith but

without warranty. The user should test the product to ascertain the suitability for the intended use.

Product specification or the whole document is subject to change without any prior notice.

MKT: TDS – LSHF/3401-IS – 11/17

Pg. 2 of 2

You might also like

- Lista Cuvinte in Limba RomanaDocument1,333 pagesLista Cuvinte in Limba Romanabazup53% (17)

- Ki LSHF 3401 IsDocument2 pagesKi LSHF 3401 IsjamilNo ratings yet

- TDS Pe 100 Ub5206h 02 PDFDocument2 pagesTDS Pe 100 Ub5206h 02 PDFOktaviandri SaputraNo ratings yet

- TDS LSZH 4001Document2 pagesTDS LSZH 4001Rasel AhmedNo ratings yet

- TDS Pe 100 Ub5206h 01 PDFDocument2 pagesTDS Pe 100 Ub5206h 01 PDFOktaviandri SaputraNo ratings yet

- Shakun Polymers Limited: Spl-Afosr High Performance PVC CompoundDocument2 pagesShakun Polymers Limited: Spl-Afosr High Performance PVC CompoundquycoctuNo ratings yet

- 02 Bab IiDocument2 pages02 Bab IiariefNo ratings yet

- Enersyn RC-S RangeDocument2 pagesEnersyn RC-S RangecarmaNo ratings yet

- FR-PA66 PRODUCT INFORMATION AND TEST RESULTSDocument1 pageFR-PA66 PRODUCT INFORMATION AND TEST RESULTSSơn Nguyễn ĐắcNo ratings yet

- TDS Pe 201 Sf5008eDocument2 pagesTDS Pe 201 Sf5008eOktaviandri SaputraNo ratings yet

- Controlled Volatility RTV Ablative Silicone: Description ApplicationDocument3 pagesControlled Volatility RTV Ablative Silicone: Description ApplicationLU CHUNHUINo ratings yet

- TDS Pe 003 Uf1810s1 03Document2 pagesTDS Pe 003 Uf1810s1 03qc jrpNo ratings yet

- Ultradur® B 6550 LN en SI - Product DatasheetDocument2 pagesUltradur® B 6550 LN en SI - Product Datasheetnoto.sugiartoNo ratings yet

- PP Trilene Hi10hoDocument2 pagesPP Trilene Hi10hoLaili AzkiyahNo ratings yet

- TDS-PE-102-UB5502H (Provisional) 2019Document2 pagesTDS-PE-102-UB5502H (Provisional) 2019Oktaviandri SaputraNo ratings yet

- Ekran Resmi 2024-01-06 - Gece 9.58.56Document1 pageEkran Resmi 2024-01-06 - Gece 9.58.56tahmasebi.hadi2017No ratings yet

- Surat Jastifikasi - (SANFAB PE - ST)Document5 pagesSurat Jastifikasi - (SANFAB PE - ST)arungrifqy putraaditNo ratings yet

- Pink Anti Static Bag BondlineDocument2 pagesPink Anti Static Bag Bondlineeky susilowatiNo ratings yet

- L-TSA Classic Turbine OilDocument3 pagesL-TSA Classic Turbine OilQuy NguyenNo ratings yet

- Driscoplex 3100 Series Pipe Data Sheet: Property Unit Test Procedure Typical ValueDocument2 pagesDriscoplex 3100 Series Pipe Data Sheet: Property Unit Test Procedure Typical ValuemariannyNo ratings yet

- ULTRASON Sup ® Sup +E1010+NATURALDocument2 pagesULTRASON Sup ® Sup +E1010+NATURALnikos.a.kyriakouNo ratings yet

- Epofine 184-Finehard 907 - Acc 062Document4 pagesEpofine 184-Finehard 907 - Acc 062Karishma PrabhuNo ratings yet

- Terluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Document3 pagesTerluran Gp-22: Acrylonitrile Butadiene Styrene (ABS)Jose VillarrealNo ratings yet

- Hdpe Me8000 (En)Document1 pageHdpe Me8000 (En)Judith Casstañeda AgurtoNo ratings yet

- TB Coroflake 23 PDFDocument2 pagesTB Coroflake 23 PDFHatem JafouraNo ratings yet

- POLYMER C150Y - Jan15 - New - Rev1Document2 pagesPOLYMER C150Y - Jan15 - New - Rev1W I Prayogo100% (1)

- RHODIA Technyl A218 V30Document3 pagesRHODIA Technyl A218 V30paquienNo ratings yet

- TDS Pe 001 Uf1810Document2 pagesTDS Pe 001 Uf1810asrilNo ratings yet

- TDS Pe 008 Up4806hDocument2 pagesTDS Pe 008 Up4806hariefNo ratings yet

- Data SheetDocument2 pagesData SheetDridi BadreddineNo ratings yet

- Heat Shrink Sleeve Technical Data SheetDocument4 pagesHeat Shrink Sleeve Technical Data SheetdakidofdaboomNo ratings yet

- Ultramid: Product Information ®Document2 pagesUltramid: Product Information ®muthuNo ratings yet

- Si6008 TDS PDFDocument2 pagesSi6008 TDS PDFBelalang NgantukNo ratings yet

- L-TSA Turbine OilDocument3 pagesL-TSA Turbine OilQuy NguyenNo ratings yet

- PP Trilene He2.0tfDocument2 pagesPP Trilene He2.0tfLaili AzkiyahNo ratings yet

- PU SEAL Jed-337 008 en ADocument4 pagesPU SEAL Jed-337 008 en Aரஞ்சன் ஞானயோளிNo ratings yet

- Product Data Energol THB: DescriptionDocument2 pagesProduct Data Energol THB: Descriptionkarim karimNo ratings yet

- Ultrason® E 2010 G6 UN en SI - Product DatasheetDocument2 pagesUltrason® E 2010 G6 UN en SI - Product Datasheetshahin_723No ratings yet

- TDS Pe 202 SP4808Document2 pagesTDS Pe 202 SP4808Desri AkbarNo ratings yet

- 009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Document1 page009 Polyester Ortho SP 5119 Am Tds Amr Egypt Pa. No 4Yousef LotfyNo ratings yet

- Haldia PP Raffia - R103 DatasheetDocument2 pagesHaldia PP Raffia - R103 DatasheetNarender RawatNo ratings yet

- Weko-Seal EPDM Material Specifications : Water/Waste Water ApplicationsDocument4 pagesWeko-Seal EPDM Material Specifications : Water/Waste Water ApplicationscarlosNo ratings yet

- PEADM5372Document2 pagesPEADM5372nicolas yoris marcoglieseNo ratings yet

- Top Coat Blue Pool Iso-Npg enDocument4 pagesTop Coat Blue Pool Iso-Npg enVICTOR MARCOSNo ratings yet

- TDS Pe 200 SF5007Document2 pagesTDS Pe 200 SF5007Oktaviandri SaputraNo ratings yet

- R03RRDocument1 pageR03RRPiyush A JoshiNo ratings yet

- Ficha Técnica - FRAYÖL GEAR S 2 EP - 680Document2 pagesFicha Técnica - FRAYÖL GEAR S 2 EP - 680Julio Oliveira Goncalves JuniorNo ratings yet

- Guida Coprax Eng 2015 LightDocument82 pagesGuida Coprax Eng 2015 Lightairsys7projec100% (1)

- HPB-0354 Technical Data Sheet for Blow Molding HDPEDocument1 pageHPB-0354 Technical Data Sheet for Blow Molding HDPEHichamSalamaNo ratings yet

- Ficha Tecnica Castrol Perfecto X RangeDocument3 pagesFicha Tecnica Castrol Perfecto X Rangeel pro jajaja GonzalezNo ratings yet

- Driscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetDocument2 pagesDriscoplex 5300 Series Pe3608 / (Pe3408) : Geothermal Systems Data SheetmariannyNo ratings yet

- 01ML0030 ES-08009 - C - Especificação de MPDocument2 pages01ML0030 ES-08009 - C - Especificação de MPRafah1212No ratings yet

- TDS PP 305 HF10TQ 02Document2 pagesTDS PP 305 HF10TQ 02Lungkoneng HRDNo ratings yet

- Product Technical InformationDocument3 pagesProduct Technical Informationtedak2No ratings yet

- TGSB(M) Turbine OilDocument3 pagesTGSB(M) Turbine OilQuy NguyenNo ratings yet

- PP Homopolymer for Spunbond FibersDocument1 pagePP Homopolymer for Spunbond FibersMohit MohataNo ratings yet

- Driscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetDocument2 pagesDriscoplex 6500 Pe2708 / (Pe2406) Pipe: Pipe & Fittings Data SheetmariannyNo ratings yet

- TDS PP 306 Hi10ho 03Document2 pagesTDS PP 306 Hi10ho 03indahNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

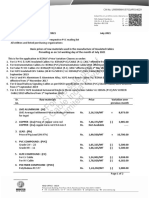

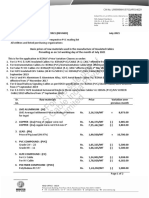

- IEEMA Circular For Nov 2022REVDocument2 pagesIEEMA Circular For Nov 2022REVAMARENDRA SINo ratings yet

- Book IRCTC ticket onlineDocument2 pagesBook IRCTC ticket onlineHimanshu GuptaNo ratings yet

- Immunization - Schedule (Rudransh Kumar Si)Document2 pagesImmunization - Schedule (Rudransh Kumar Si)AMARENDRA SINo ratings yet

- 1 s2.0 S2468023022004229 MainDocument16 pages1 s2.0 S2468023022004229 MainAMARENDRA SINo ratings yet

- Maths Assignment 2Document2 pagesMaths Assignment 2AMARENDRA SINo ratings yet

- Case Studies Practice QuestionsDocument17 pagesCase Studies Practice QuestionsAMARENDRA SINo ratings yet

- Book IRCTC ticket onlineDocument2 pagesBook IRCTC ticket onlineHimanshu GuptaNo ratings yet

- Membership Rights & BenefitsDocument1 pageMembership Rights & BenefitsAMARENDRA SINo ratings yet

- IEEMA Circular For July 2021Document2 pagesIEEMA Circular For July 2021AMARENDRA SINo ratings yet

- Practice Paper.. TodayDocument8 pagesPractice Paper.. TodayAMARENDRA SINo ratings yet

- Raw material prices for cablesDocument2 pagesRaw material prices for cablesAMARENDRA SINo ratings yet

- IEEMA Circular For June 2020Document2 pagesIEEMA Circular For June 2020AMARENDRA SINo ratings yet

- Units and Dimmension Important MaterialDocument11 pagesUnits and Dimmension Important MaterialAMARENDRA SINo ratings yet

- Baby - Milestones (Rudransh Kumar Si)Document2 pagesBaby - Milestones (Rudransh Kumar Si)AMARENDRA SINo ratings yet

- IEEMA cable raw material pricesDocument2 pagesIEEMA cable raw material pricesAMARENDRA SINo ratings yet

- 00092021012MMDocument2 pages00092021012MMAMARENDRA SINo ratings yet

- IEEMA Circular - Feb 2023Document2 pagesIEEMA Circular - Feb 2023AMARENDRA SINo ratings yet

- 00092021012MMDocument2 pages00092021012MMAMARENDRA SINo ratings yet

- 00092021007MMREVDocument2 pages00092021007MMREVAMARENDRA SINo ratings yet

- IEEMA Circular Aug 2020Document2 pagesIEEMA Circular Aug 2020AMARENDRA SINo ratings yet

- IEEMA Circular Aug 2020Document2 pagesIEEMA Circular Aug 2020AMARENDRA SINo ratings yet

- IEEMA Circular For June 2020Document2 pagesIEEMA Circular For June 2020AMARENDRA SINo ratings yet

- IEEMA Circular Aug 2020Document2 pagesIEEMA Circular Aug 2020AMARENDRA SINo ratings yet

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationSarat KumarNo ratings yet

- Chapter 7 Diversity CLass 9.Document18 pagesChapter 7 Diversity CLass 9.Mr. HellNo ratings yet

- Solar Photovoltaic Wire 600V: DescriptionDocument1 pageSolar Photovoltaic Wire 600V: DescriptionAMARENDRA SINo ratings yet

- 00092021005MMDocument2 pages00092021005MMAMARENDRA SINo ratings yet

- Scan 09 Jan 2022Document8 pagesScan 09 Jan 2022AMARENDRA SINo ratings yet

- Impedance Calculation of Cables Using Subdivision of The Cable ConductorsDocument76 pagesImpedance Calculation of Cables Using Subdivision of The Cable ConductorsOneil ZárateNo ratings yet

- USE2 C350 USE 2RHHRHW 2XLP USE 2CopperConductor600V 90°CWetorDryDocument2 pagesUSE2 C350 USE 2RHHRHW 2XLP USE 2CopperConductor600V 90°CWetorDryAMARENDRA SINo ratings yet

- Caring Formula High Flow Glass Filled PA6Document3 pagesCaring Formula High Flow Glass Filled PA6ratz23695No ratings yet

- Anexo 2. Smith-Acidity Scale For Oxides 1987Document2 pagesAnexo 2. Smith-Acidity Scale For Oxides 1987Ivan ArroyoNo ratings yet

- Revision - Year 7 ScienceDocument15 pagesRevision - Year 7 ScienceFarah AinaNo ratings yet

- Materials Science in Semiconductor ProcessingDocument10 pagesMaterials Science in Semiconductor ProcessingAlejandro NigendaNo ratings yet

- H Calculations - Enthalpy of SolutionDocument3 pagesH Calculations - Enthalpy of SolutionArif PurwadanaNo ratings yet

- Carbonyl Compounds 1654147338445Document33 pagesCarbonyl Compounds 1654147338445Harsh VardhanNo ratings yet

- Complexation and Precipitation Reactions and TitrationsDocument53 pagesComplexation and Precipitation Reactions and TitrationsDivya TripathyNo ratings yet

- CONTROLLED DRUG DELIVERY SYSTEMSDocument19 pagesCONTROLLED DRUG DELIVERY SYSTEMSPramod ChoudharyNo ratings yet

- Spectro ParacetamolDocument5 pagesSpectro ParacetamolAdang FirmansyahNo ratings yet

- Numerical Simulation of The Effect of Sa/Pa On Combustion and Flow Characteristics in A Front-Rear Burner 400 Mwe BoilerDocument9 pagesNumerical Simulation of The Effect of Sa/Pa On Combustion and Flow Characteristics in A Front-Rear Burner 400 Mwe BoilerFaridNo ratings yet

- CH CH 1 PDFDocument36 pagesCH CH 1 PDFZahra HassanNo ratings yet

- CCC Pta 2023 Final PaperDocument5 pagesCCC Pta 2023 Final Paperchenxi ZhangNo ratings yet

- Laboratory Assignment Ska 3013-Analytical Chemistry: SEMESTER 2 2019/2020Document15 pagesLaboratory Assignment Ska 3013-Analytical Chemistry: SEMESTER 2 2019/2020Nabila HusnaNo ratings yet

- 2-RLT9VZ10S16D5 Low - Pressure - FiltersDocument1 page2-RLT9VZ10S16D5 Low - Pressure - FiltersNibin OdukkathilNo ratings yet

- Experiment No.1 TitrationDocument4 pagesExperiment No.1 Titrationoc dhogs TvNo ratings yet

- ONMEDDocument3 pagesONMEDTyas DesmaniasNo ratings yet

- Effect of The Synthesis Route On The Microstructure and The Dielectric Behavior of Cacu3ti4o12 CeramicsDocument5 pagesEffect of The Synthesis Route On The Microstructure and The Dielectric Behavior of Cacu3ti4o12 CeramicsArindam SenNo ratings yet

- Ref. 1002210 Spintrol H P Lot. 5568Document4 pagesRef. 1002210 Spintrol H P Lot. 5568domz dizonNo ratings yet

- Road Surfacing: STP LimitedDocument8 pagesRoad Surfacing: STP LimitedRana MahatoNo ratings yet

- Electroorganic Chemistry: Brandon Rosen 8 November 2014Document6 pagesElectroorganic Chemistry: Brandon Rosen 8 November 2014Praveen KumarNo ratings yet

- Microbial Life at Extremely Low Nutrient LevelsDocument12 pagesMicrobial Life at Extremely Low Nutrient LevelsMd. Rashedul IslamNo ratings yet

- Engineering Chemistry II: Course DescriptionDocument4 pagesEngineering Chemistry II: Course DescriptionSubas ShresthaNo ratings yet

- Measure Distances with Laser AccuracyDocument210 pagesMeasure Distances with Laser Accuracydan_1967No ratings yet

- CL - 1000i Immunofluorescence Analyzer.Document6 pagesCL - 1000i Immunofluorescence Analyzer.bikouvoNo ratings yet

- 2020 05 10 Foreva Composite TFC350 ACI EN V1Document2 pages2020 05 10 Foreva Composite TFC350 ACI EN V1pabloNo ratings yet

- Balancing Equations: Practice ProblemsDocument10 pagesBalancing Equations: Practice ProblemsAdeenaNo ratings yet

- Duke 2018-19Document219 pagesDuke 2018-19Manasi GhadageNo ratings yet

- Ethylene Glycol PLantDocument15 pagesEthylene Glycol PLantBangeen JalalNo ratings yet

- Resistance: Guide To ChemicalDocument32 pagesResistance: Guide To ChemicaleragornNo ratings yet