Professional Documents

Culture Documents

20041214-93 70 02 005-000031 01 VDR 01 01

20041214-93 70 02 005-000031 01 VDR 01 01

Uploaded by

carlosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

20041214-93 70 02 005-000031 01 VDR 01 01

20041214-93 70 02 005-000031 01 VDR 01 01

Uploaded by

carlosCopyright:

Available Formats

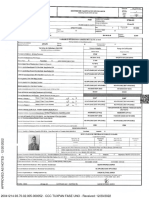

DOCUMENT NUMBER: 22032-TF1-ITP-01

INSPECTION AND TEST PLAN

PROJECT NUMBER: 22032-TF1

DATE: 10/05/2022

REVISION NUMBER: 1

PAGE 1 OF 2

R REVIEW / REVISIÓN DOCUMENTAL H HOLD POINT / PUNTO DE ESPERA W WITNESS POINT / ATESTIGUAMIENTO S SURVEILLANCE / VIGILANCIA

REQUIREMENTS INSPECTION

Colo

SELLER BUYER CUSTOMER

REMARKS

(STEELGO QA/QC) ( ) ( )

ITEM ACTIVITIES / PROCESSES REFERENCE DOCUMENTS ACCEPTANCE CRITERIA REQUIREMENT / SPECIFICATION CONTROL RECORDS TYP Signature and initials TYP Signature and initials TYP Signature and initials

1 KICK-OFF MEETING

1.1 KICK-OFF MEETING AGENDA PER AGENDA PER CUSTOMER DISPOSITION MEETING MINUTES H H H

2 MATERIALS (RECEPTION)

2.1 PIPING -ASTM A53 B 1) ACCORDING TO MTR: FOR EVENT - MTR H/R R R

- HEAT NUMBER

- ASTM A106 B - MATERIAL GRADE - INCIDENCE REPORT

- MATERIAL TYPE

- ASME B36. - SCHEDULE -NON-CONFORMITY REPORT (IF REQUIRED)

- DIAMETER

- PR-AL-02 RECEPTION OF

MATERIALS 2) PHYSICAL INSPECTION:

- MATERIAL SHOULD MEET THE PERMISSIBLE LIMITS OF

- SPECIFICATIONS FOR INDICATIONS, LACK OF MATERIAL MARKING, SURFACE

UNDERGROUND STEEL CONDITIONS, THE DIMENSIONAL INSPECTION WILL BE

PIPING PERFORMED BASED ON MTR.

93.70.02.005

CCC TUXPAN FASE UNO

SECTION M2

2.2 FITTINGS -ASME B16.9 1) ACCORDING TO MTR: FOR EVENT - MTR H/R R R

- HEAT NUMBER

-ASME B16.25 - MATERIAL GRADE - INCIDENCE REPORT (IF REQUIRED)

- MATERIAL TYPE

-ASTM A234 / A234M - SCHEDULE -NON-CONFORMITY REPORT (IF REQUIRED)

- DIAMETER

- PR-AL-02 RECEPTION OF

MATERIALS 2) PHYSICAL INSPECTION:

- MATERIAL SHOULD MEET THE PERMISSIBLE LIMITS OF

- SPECIFICATIONS FOR INDICATIONS, LACK OF MATERIAL MARKING, SURFACE

UNDERGROUND STEEL CONDITIONS, THE DIMENSIONAL INSPECTION WILL BE

PIPING PERFORMED BASED ON MTR.

93.70.02.005

CCC TUXPAN FASE UNO

SECTION M2

2.3 FLANGES -ASME B16.5 1) ACCORDING TO MTR: FOR EVENT - MTR H/R R R

- HEAT NUMBER

-ASME B16.11 - MATERIAL GRADE - INCIDENCE REPORT (IF REQUIRED)

- MATERIAL TYPE

-ASME B16.47 - SCHEDULE -NON-CONFORMITY REPORT (IF REQUIRED)

- DIAMETER

-ASME B16.25

2) PHYSICAL INSPECTION:

-ASTM A105 - MATERIAL SHOULD MEET THE PERMISSIBLE LIMITS OF

INDICATIONS, LACK OF MATERIAL MARKING, SURFACE

- PR-AL-02 RECEPTION OF CONDITIONS, THE DIMENSIONAL INSPECTION WILL BE

MATERIALS PERFORMED BASED ON MTR.

- SPECIFICATIONS FOR

UNDERGROUND STEEL

PIPING

93.70.02.005

CCC TUXPAN FASE UNO

SECTION M2

3 MATERIAL PRESERVATION

3.1 - FLANGES MUST HAVE FLANGE FACE PROTECTORS - PR-AL-03 MATERIALS THE MATERIAL SHOULD BE PROPERLY STORED FOR EVENT PHYSICAL APPRECIATION R/S R R

- WILL CARRY OUT A PROGRAM FOR THE PRESERVATION OF MATERIALS. PRESERVATION

- GENERAL REQUIREMENTS

93.70.02.005 SECTION M2

4 FIT-UP AND BEVELING

4.1 - FIT UP (TACKWELDING AND GAP) - SHOP DRAWINGS AND APPLICABLE PROCEDURE 100% ING-H01-F01 (RED LINE) W *W / S R *ONLY THE FIRST

- BEVELING (END PREPARATION) GENERAL REQUIREMENTS PREPARATIONS

93.70.02.005 M3

- APPLICABLE WPS

5 WELDING

5.1 WELDING PROCEDURE SPECIFICATION AND PROCEDURE QUALIFICATION - WPS + PQR - ASME SEC.IX 100% WPS + PQR R H/R R

RECORD

- GENERAL REQUIREMENTS

93.70.02.005 SECTION M3

These are WITNESS points for Kiewit

as indicated in our BITP

5.2 WELDER PERFORMANCE QUALIFICATION RECORDS (WPQ) - WPQ - ASME SEC.IX 100% WPQR R H/R R

- GENERAL REQUIREMENTS

93.70.02.005 SECTION M3

RETURNED FOR CORRECTION - 10/18/2022

5.3 QUALIFIED NDE PERSONNEL - PR-QC-01 QUALIFICATION SNT-TC-1A FOR ALL PERSONNEL WHO CERTIFICATION R H/R R

AND CERTIFICATION OF PERFORM VT

PERSONNEL PERFORMING

NON-DESTRUCTIVE

TESTING

This is a Witness point for Kiewit as

- PR-QC-02 STORAGE AND

DELIVERY OF QUALLITY indicated in our BITP

RECORDS (DOSSIER)

- GENERAL REQUIREMENTS

93.70.02.005 SECTION M4

5.4 VT EXAMINATION ON WELDING - PR-QC-07-IT-02 VT ASME B31.1 100% ING-H01-F01 (RED LINE) W /S S / *H S *ONLY THE FIRST WELDS

EXAMINATION ASME SEC. V

5.5 NON-DESTRUCTIVE EXAMINATION ON WELDING - RM-AF-01E ASME B31.1 APPLICABLE RECORDS S *W / S R * AT THE BEGINNING OF THE

ASME SEC. V R ACTIVITY

- RM-MT-01E

- RM-PMI-01E

- RM-PT-01E

- RM-RT-01E

- RM-UT-01E

5.6 DIMENSIONAL EXAMINATION CHECKING - SHOP DRAWINGS AND LATEST APPROVED DRAWINGS 100% ING-H01-F01 (RED LINE) W /S S / *H S *ONLY THE FIRST WELDS

GENERAL REQUIREMENTS

93.70.02.005 M3

- APPLICABLE WPS

Change to Witness point for Kiewit as

Indicaticated in BITP

20041214-93.70.02.005-000031 - CCC TUXPAN FASE UNO - Received: 10/05/2022

DOCUMENT NUMBER: 22032-TF1-ITP-01

INSPECTION AND TEST PLAN

PROJECT NUMBER: 22032-TF1

DATE: 10/05/2022

REVISION NUMBER: 1

PAGE 2 OF 2

R REVIEW / REVISIÓN DOCUMENTAL H HOLD POINT / PUNTO DE ESPERA W WITNESS POINT / ATESTIGUAMIENTO S SURVEILLANCE / VIGILANCIA

REQUIREMENTS INSPECTION

SELLER BUYER CUSTOMER

REMARKS

(STEELGO QA/QC) ( ) ( )

ITEM ACTIVITIES / PROCESSES REFERENCE DOCUMENTS ACCEPTANCE CRITERIA REQUIREMENT / SPECIFICATION CONTROL RECORDS TYP Signature and initials TYP Signature and initials TYP Signature and initials

6 PAINTING

6.1 SURFACE PREPARATION INSPECTION AND TESTING - PR-PR-02 PREPARATION PER SPECIFICATION 100% PR-PR-02-FR-05 ANCHOR PROFILE W /S S / *H S *ONLY AT THE BEGINNING OF

OF METAL SURFACES AND INSPECTION THE ACTIVITY

APPLICATION OF

ANTICORROSIVE COATINGS PR-PR-02-FR-08 SHOT BLAST INSPECTION

REPORT

- GENERAL REQUIREMENTS

93.70.02.005 SECTION P1 PR-PR-02-FR-12 PRODUCTION CONTROL

INSPECTED

6.2 ANCHOR PROFILE MEASUREMENT - PR-PR-02 PREPARATION PER SPECIFICATION 100% PR-PR-02-FR-05 ANCHOR PROFILE W /S S / *H S *ONLY AT THE BEGINNING OF

OF METAL SURFACES AND INSPECTION THE ACTIVITY

APPLICATION OF

ANTICORROSIVE COATINGS PR-PR-02-FR-08 SHOT BLAST INSPECTION

REPORT

- GENERAL REQUIREMENTS

93.70.02.005 SECTION P1 PR-PR-02-FR-12 PRODUCTION CONTROL

INSPECTED

6.3 COATING APPLICATION - PR-PR-02 PREPARATION PER SPECIFICATION 100% PR-PR-02-FR-11 PRIMARY PAINT INSPECTION W / S S / *H S *ONLY AT THE BEGINNING OF

OF METAL SURFACES AND REPORT THE ACTIVITY

APPLICATION OF

ANTICORROSIVE COATINGS PR-PR-02-FR-12 PRODUCTION CONTROL

INSPECTED

- GENERAL REQUIREMENTS

93.70.02.005 SECTION P1

6.4 VISUAL INSPECTION (PER COAT) - PR-PR-02 PREPARATION PER SPECIFICATION 100% PR-PR-02-FR-12 PRODUCION CONTROL W /S S / *H S *ONLY AT THE BEGINNING OF

INTERMEDIATE OF METAL SURFACES AND INSPECTED THE ACTIVITY

APPLICATION OF

ANTICORROSIVE COATINGS PR-PR-02-FR-13 INTERMEDIATE-FINISHED

PÁINT INSPECTION REPORT

- GENERAL REQUIREMENTS

93.70.02.005 SECTION P1

6.5 DRY-FILM THICKNESS MEASUREMENT (PER COAT) - PR-PR-02 PREPARATION PER SPECIFICATION 25% PR-PR-02-FR-12 PRODUCION CONTROL W /S S / *H S *ONLY AT THE BEGINNING OF

OF METAL SURFACES AND INSPECTED THE ACTIVITY

APPLICATION OF

ANTICORROSIVE COATINGS PR-PR-02-FR-13 INTERMEDIATE-FINISHED

PÁINT INSPECTION REPORT

- GENERAL REQUIREMENTS

93.70.02.005 SECTION P1

6.6 HOLIDAY TESTING LOW VOLTAGE (IF APPLIES) - PR-PR-02 PREPARATION PER SPECIFICATION 25% PR-PR-02-FR-09 HOLIDAY VISUAL INSPECTION W / S S / *H S *ONLY AT THE BEGINNING OF

OF METAL SURFACES AND (LOW-HIGH VOLTAGE) THE ACTIVITY

APPLICATION OF

ANTICORROSIVE COATINGS

- GENERAL REQUIREMENTS

93.70.02.005 SECTION P1

6.7 ADHERENCE TESTING - PR-PR-02 PREPARATION PER SPECIFICATION 25% PR-PR-02-FR-14 CHEMICAL CLEANING W /S S / *H S *ONLY AT THE BEGINNING OF

OF METAL SURFACES AND REPORT (PICKLING) THE ACTIVITY

APPLICATION OF

ANTICORROSIVE COATINGS

- GENERAL REQUIREMENTS

93.70.02.005 SECTION P1

7 FINAL INSPECTION FOR SHIPMENT

7.1 -TAGGING / MARKING PER APPROVED DRAWINGS PER SPECIFICATION FOR EVENT - PR-PR-01-FR-02 SPOOL CERTIFICATION S W* R * EACH TIME WHEN A

- ALL SHOP NCRs, INSPECTION FINDINGS ARE CLOSED OUT BEFORE REPORT + AS BUILT SHIPMENT NEEDS TO BE

SHIPPING RELEASED

- VERIFICATION ALL DEBRIS / WATER REMOVED

8 MANUFACTURING DATA BOOK REVIEW

8.1 - PR-QC-02 STORAGE AND 100% AS BUILT R/H H

'- FINAL DOCUMENTATION REVIEW DELIVERY OF QUALLITY

- VERIFY ALL CONTRACT REQUIREMENTS ARE MET RECORDS (DOSSIER)

- SIGNED INSPECTION AND TEST PLAN (ITP).

- LIST OF MATERIAL USED AND CERTIFICATION - PURCHASE ORDER

APPROVED WELDING PROCEDURE SPECIFICATIONS AND These are all First Article WITNESS

QUALIFICATIONS (WPS/PQR).

GRANTED CONCESSION REQUESTS/NCR REPORTS

points as indicated in the BITP

LIST OF QUALIFIED WELDERS OR WELDING OPERATORS

CERTIFICATION OF ALL NDE WITH REFERENCE TO CODES, PROCEDURES,

EQUIPMENTS AND LOCATIONS.

Residual magnetism testing needs to

RETURNED FOR CORRECTION - 10/18/2022

be performed per tech specification,

Ref. line item 4.7 of BITP submitted

8 ADDITIONAL FABRICATION REQUIREMENTS (CSEF) by Kiewit

8.1 PROJECT SPECIFIC REQUIREMENTS PURCHASE ORDER PURCHASE ORDER APPLICABLE RECORDS S R/W R

ELABORATED BY PROCESSES CHIEF

VERIFIED BY PROCESSES COORDINATOR

AUTHORIZED BY QUALITY MANAGER

20041214-93.70.02.005-000031 - CCC TUXPAN FASE UNO - Received: 10/05/2022

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Boehler Welding QLine OverviewDocument4 pagesBoehler Welding QLine OverviewcarlosNo ratings yet

- Yes/No QS:: What's My Job?Document4 pagesYes/No QS:: What's My Job?carlosNo ratings yet

- 20041214-93 70 02 005-000052 02 VDR 02 01Document3 pages20041214-93 70 02 005-000052 02 VDR 02 01carlosNo ratings yet

- PWHT EC SH 034 - EncryptedDocument7 pagesPWHT EC SH 034 - EncryptedcarlosNo ratings yet

- PWHT EC SH 032 - EncryptedDocument3 pagesPWHT EC SH 032 - EncryptedcarlosNo ratings yet

- Ec01 0020Document2 pagesEc01 0020carlosNo ratings yet

- QEP-SOP-2267 Rev 1 - PMDocument12 pagesQEP-SOP-2267 Rev 1 - PMcarlosNo ratings yet

- Ingles Clase 2Document48 pagesIngles Clase 2carlos100% (1)

- Bu-Sp-207-20-R1-Audit-Guide-Building-Fabricator-With-Coatings-Endorsement EspañolDocument20 pagesBu-Sp-207-20-R1-Audit-Guide-Building-Fabricator-With-Coatings-Endorsement EspañolcarlosNo ratings yet

- Ingles 5Document134 pagesIngles 5carlosNo ratings yet

- Trabajo Final Ingles V.Document135 pagesTrabajo Final Ingles V.carlosNo ratings yet

- Supplemental Requirements For Applicators of Complex Coatings Endorsement (CCE)Document3 pagesSupplemental Requirements For Applicators of Complex Coatings Endorsement (CCE)carlosNo ratings yet

- Aisc 207-20 Audit Guide All Fabricator, Manufacturer and Erector Programs and EndorsementsDocument18 pagesAisc 207-20 Audit Guide All Fabricator, Manufacturer and Erector Programs and EndorsementscarlosNo ratings yet

- Astm A6Document62 pagesAstm A6carlos100% (1)

- Mock Exercise Instructions For Fabricators of Simple BridgesDocument7 pagesMock Exercise Instructions For Fabricators of Simple BridgescarlosNo ratings yet

- Supplemental Requirements For Building Fabricators (BU) : Section 1 Before Your AuditDocument2 pagesSupplemental Requirements For Building Fabricators (BU) : Section 1 Before Your AuditcarlosNo ratings yet

- Sample Management Review Form ErectorsDocument15 pagesSample Management Review Form ErectorscarlosNo ratings yet

- Application Document Submittal - Fab and Manuf Rev. 5 14 21Document7 pagesApplication Document Submittal - Fab and Manuf Rev. 5 14 21carlosNo ratings yet

- 207-20 CambiosDocument74 pages207-20 CambioscarlosNo ratings yet

- Mock Exercise Instructions For Fabricators of Steel BuildingsDocument8 pagesMock Exercise Instructions For Fabricators of Steel BuildingscarlosNo ratings yet