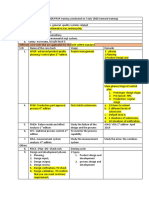

Material

Old material No.

MRP Group An organizational object that can be used to allocate special control parameters for planning to a group of materials.

Enter the material no for which we have Existing nomenclature of the materials to create the master data.

Raw sheet Raw struc BO Mech BOElec

Sheet structure BOMECH BOELE

�ABC indicator Indicator that classifies a material as an A, B, or C part according to its consumption value. This classification process is known as the ABC analysis. The three indicators have the following meanings: A - important part, high consumption value B - less important part, medium consumption value C - relatively unimportant part, low consumption value

MRP Type

MRP Controller

Key that determines whether and how The person responsible for a group of the material is planned: the following materials in MRP in a plant or Options are available: Material company. Requirements Planning, Master Production Scheduling, Re-Order Point Planning (Consumption Based) or with No Planning Run MRP = PD NO MRP RUN = ND Consumption Based Planning = VB, For Re Order Level Materials we have to maintain VB and for Finished materials without re order levels will be PD

A A A/B/C A/B/C

PD PD PD PD

Mr. Shriram Mr. Shriram Mr. Shriram Mr. Shriram

�Lot Size

Reorder Point

Fix Lot Size Qty Re Order Qty if MRP type mention is VB (Re Order Planning)

Key that determines which lot-sizing Re Order Level for specified material procedure the system uses within materials planning to calculate the quantity to be procured or produced. Lot for lot order qty = EX Fixed order Qty = FX Daily Lot size = TB Weekly Lot size = WB Generaly all materials with Re Order level will be with Fix lot size FX with Re Order Qty entered in Fix Lot size field.

EX EX EX EX

1 ton 3 ton

�Assembly Scrap in Percent

Procurement Type

Special procurement type You use special procurement when you want to be able to override the procurement type in the material master or define the procurement type more precisely. In Case of Materials which are used in Both plants like Generator or Powder which is manufactured in One plant and consume in another will be given Special Procurement key as 40 in Procuring Plant only

A percentage of the quantity of an selected based on Material Type by assembly that does not meet the system required production quality. This is All Materials which are Manufactured In maintained for a Material if it is an House only has to enter as E and Assembly (which has components within materials which are procred from out it and may be used as a component in side will be given key as F. Materials another assembly). In material which can be procured from outside and requirements planning (MRP), this can be Produce In House should be percentage scrap is considered for all given key as X components contained in the assembly. INSERT QUANTITY (%)

0.1 F 0.01 F F F

�Prod. stor. location In the case of a material produced inhouse, this is the key of the storage location that is copied to the planned order, production order, If the material is a component, it is the issuing storage location to which a backflush is posted. If the material is produced, it is the receiving storage location to which the receipt of the material is posted.

In-house production time Specifies the time in workdays needed to produce the material in-house. In-house production time is independent of the order quantity. The system requires the in-house production time to determine the planned dates for planned orders in materials planning.

Plnd delivery time Number of calendar days needed to obtain the material or service if it is procured externally.

1002 1003 1001 1001

depending on purchase lead time depending on purchase lead time depending on purchase lead time depending on purchase lead time

�GR Processing Time Number of workdays required after receiving the material for inspection and placement into storage.

Safety stock

Availability Check

the quantity whose purpose is to satisfy Specifies whether and how the system unexpectedly high demand in the checks availability and generates coverage period. requirements for materials planning Daily requirements = 01 Individual Requirements = 02 For all Raw materials it should be 01 where in for all semi finished and finished materials it will be 02

1 1 1 1

2 2 2 2

�Planning Strategy Group The strategy group groups all the planning strategies that can be used for a particular material. The planning strategy represents the procedure used for planning a material and is (technically speaking) controlled by the MRP types Make - to - stock = 10 Make - to - Order = 20 Planning with final assembly = 40 Planning w/o final assembly = 50

Mixed MRP This will be used in case of Materials used in Multi Plants Like Generator which is manufactured in EDM1 Generator Plant will be given with Mixed MRP indicator as 1 where as same material in EDM2 Machine plant will be left blank

40 40 20 20

�Plant.

Work center.

Work Center Description

Work center caategory. Person responsible.

Usage.

Standard value key.

Enter plant.

Enter name of the work center,you wish to Create or Edit.

Mention WC Cat. (0001,0003etc) whether man or M/C involved likewise.

Name of the person who is responsible for the W/C.

The purpose for which the W/C is used.

The key which controls which time to be taken into consideration like M/C, Labour time etc.

Power Plant

Power generation

50:50 Man: Mac

Mr. Rupesh Naik

Power generation for BF

M/C

Oxygen Plant

Production of Oxygen for BF and Nitrogen for PCI

95:5 ( Machine:Man)

Mr. Suresh Keshetty

Oxygen enrichment in M/C BF&nitrogen for PCI as a carrier

Sinter Plant Blast Furnace

Sinter Production for BF

25:75 (Man:machine)

Mr. Ashok Eluri Mr. B Lokareddy

Raw Material For BF Hot metal production

Reduction of iron bearing material into 40:60 (Machine:man) Hot metal and slag

�Control key.

Capecity category.

Teardown formula.

Capacity planner group.

Factory calander ID.

UoM

Key defining different type of Which defines whether production like inhouse its a Machine or Labour production, Outside processing Capacity etc.

Formula specification by the Person or the group who is help of which, the system responsible for planning calculates the teardown time.

The calander which the system takes into consideration while planning..

Use of Material

Inhouse production

Machine

Mr. Rupesh naik( Sr. Mgr)

IN

BF Gas

Inhouse production

Machine

Max Capacity Produced

IN

Oxygen enriment inBF&N2 gas for PCI as carrier

Max Capacity Produced [Link]

IN IN Finished Product For sale

�Base unit of measure.

Start,finish,length Supply Area of break.

Capacity utilization.

No of individual capacity.

Tear down formula.

Cost center.

Interms of Hour Or Minute.

To be given as per the company's policy.

The total effective timing(apart Individual or group from m/c down time during the who is responsible for shift,etc) from the total the available capacity operating time.

Formula specification by the Name of the relevant help of which, the system cost center to be given calculates the teardown time as per CO. for scheduling.

Kwh(Kilowatt)

Parallal with grid bus

24

5 Payroll, 43 contract

Power Plant

Nm3/Hr

BF

24

5 payroll, 9 contract per unit.

Air separation unit

Tonns T/m3/day( Productivit y) 51 on roll,70 skilled,25 semi skilled and 37 unskilled

�Cost center.

Activity type.

DESCRIPTION

Activity type to be specified as per CO.

�Material Code Enter the number of the material for which you want to create or edit a bill of material.

Header Plant Enter the plant for which you wish to create or process a bill of material.

Valid From date Specifies the start date for the validity period of BOM

Work center Where the operation will be carried out or performed

Operation Control key It specifies how the operation will be carried out, mention PP01 if it is In House Operation and specify PP02 if that operation will be externaly procured.

Steam

2 Air separation unit Power Plant

Boiler

PP01 Pressure-6 kg/cm2 Temp- 250

�Operation Desc of Operation

Activity Operation Details Std value 1 Std value 2 Prod. resource/ tool NO (Labor/ (Power etc) machine Hr) No of hours power Machine hours consumption for required to the operation perform this operation

Power generation

24 24

24 24 BF Gas

�Component Details Material Code Component material code which will be assigned to operation and will get consume when this operation will be confirmed in production order.

�Material Code Enter the number of the material for which you want to create or edit a bill of material.

Plant Enter the plant for which you wish to create or process a bill of material.

BOM Usage This key defines the area (such as engineering/design or production) where a BOM can be used.

Valid From date Specifies the start date for the validity period of BOM

Valid To date Specifies the End date for the validity period of BOM

Base Quantity Base qty will be header qty for which we r preparing BOM, generaly it should be 1.

�Item Cat generaly Stock Item with category as L and PM Element as I

Component Code Material number of the components that you enter, change or display as part of the BOM.

Quantity

Component Issue Storage Location Scrap % Number of the issue If any scrap is location from which the planned at material is issued during component level the production process. then need to enter Backflush is posted to this % issue location if required.

Special Procurement Key 70 - Withdrawl from Alternate Plant