Professional Documents

Culture Documents

601R-52-41-0235 Service Door Handle CHAFING

Uploaded by

Structures AirsupOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

601R-52-41-0235 Service Door Handle CHAFING

Uploaded by

Structures AirsupCopyright:

Available Formats

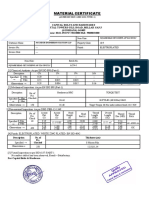

REPAIR ENGINEERING ORDER (REO)

10 REV -- 2 REO NUMBER 4 SHEET

601R-52-41-235 2

DESCRIPTION CONTINUED:

FIGURE 2 – TYPICAL CHAFE/GOUGE DAMAGE PICTURES

LIMITATIONS:

EACH BLENDED CHAFE/GOUGE DAMAGE MUST NOT BE LARGER THAN 0.50” (LENGTH) X 0.10” (WIDTH)

X 0.100” (DEPTH).

MAXIMUM OF QTY 5-OFF BLENDED CHAFE AND/OR GOUGE DAMAGE ARE ALLOWED ON ENTIRE OUTER

HANDLE CUTOUT.

ADJACENT BLENDED AREAS MUST BE SEPARATED BY A MINIMUM OF 0.50” FROM EACH OTHER.

BT0214-03 MW REV 2006-05

REPAIR ENGINEERING ORDER (REO)

10 REV -- 2 REO NUMBER 4 SHEET

601R-52-41-235 3

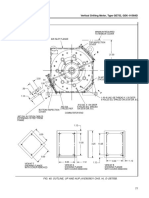

STRUCTURE ASSEMBLY,

UP SERVICE DOOR

(DWG. 601R38304 REF.)

FWD

VIEW ‘B’

STRUCTURE ASSEMBLY, SERVICE DOOR

(VIEW ON OUTER SURFACE, TAKEN FROM DWG. 601R38304 REF.)

FIGURE 3

BT0214-03 MW REV 2006-05

REPAIR ENGINEERING ORDER (REO)

10 REV -- 2 REO NUMBER 4 SHEET

601R-52-41-235 4

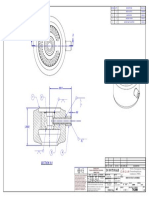

BONDED ASSEMBLY,

DWG. 601R38304 (REF.) OUTER HANDLE ASSEMBLY,

DWG 601R38305 REF. 0.50” MAX. LENGTH

0.50” MIN.

NOTE: UNDERLYING STRUCTURE AND

ATTACHMENTS OMITTED FOR

CLARITY. TYPICAL BLENDED DAMAGE (REF.)

VIEW ‘B’

NOTE: HANDLE OMITTED FOR

SKIN (DWG. 601R38304 REF.), CLARITY.

0.058” THK. REF. TYP.

VIEW ‘D’

0.10”

MAX.

(WIDTH)

0.100” MAX

(DEPTH).

DOUBLER (DWG. 601R38304 REF.),

NOTE: MAKE SURE BLEND DIMENSIONS DO NOT

0.050” THK. REF. TYP.

EXCEED 0.10” (WIDTH) X 0.100” (DEPTH).

SECTION ‘C-C’ VIEW ‘D’

BT0214-03 MW REV 2006-05

REPAIR ENGINEERING ORDER (REO)

10 REV -- 2 REO NUMBER 4 SHEET

601R-52-41-235 5

PERMANENT DISPOSITION:

1) BLEND OUT DAMAGE TO A SMOOTH CONTOUR PER SRM 51-12-00 EXCEPT USE A 10:1 TRANSITION.

ENSURE BLENDED AREA(S) ARE WITHIN THE LIMITATIONS GIVEN IN SHEETS 2 TO 4.

NOTE: TAKE CARE NOT TO DAMAGE THE OUTER HANDLE ASSEMBLY.

2) CLEAN REPAIR AREA(S) PER SRM 51-26-00.

3) ROUGHNESS OF REWORKED SURFACE(S) TO BE SIMILAR WITH ADJACENT UNDAMAGED SURFACE.

4) LPI PER NDTM 51-20-08 OR EDDY CURRENT INSPECT PER NDTM 51-20-06 TO ENSURE REWORKED AREA(S)

ARE CRACK FREE AND NO OTHER DAMAGE EXISTS.

NOTE: ITEM #4 MAY BE DEFERRED FOR 50 FLIGHT HOURS PROVIDED A DETAILED VISUAL INSPECTION

PER NDTM 51-20-09 IS PERFORMED AND NO CRACKS ARE FOUND AT THE TIME OF INCORPORATION.

5) PERFORM DETAILED VISUAL INSPECTION PER NDTM 51-20-09 TO ENSURE OUTER HANDLE ASSEMBLY IS

DAMAGE FREE.

6) RESTORE FINISH BY APPLYING CHEMICAL CONVERSION COATING MIL-C-5541, CLASS 1A FOLLOWED BY

1 COAT OF BAMS 565-008 AND 2 COATS OF BAMS 565-009 (SRM 51-25-10 REF.). ALTERNATIVELY USE A023

PER SRM 51-21-16.

BT0214-03 MW REV 2006-05

You might also like

- Slab Punching Design According ACI318-08Document6 pagesSlab Punching Design According ACI318-08Mohammed HanafiNo ratings yet

- Trench Wall Design SheetDocument7 pagesTrench Wall Design SheetramyaNo ratings yet

- Peb Staad Rev 04 Enclosed Mbma 2012Document18 pagesPeb Staad Rev 04 Enclosed Mbma 2012Vasantha KumarNo ratings yet

- Bracket DesignDocument4 pagesBracket DesignAnonymous JUn5jis0No ratings yet

- PEB-STAAD-Rev 04-ENCLOSED-MBMA-2012Document17 pagesPEB-STAAD-Rev 04-ENCLOSED-MBMA-2012sumanthNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document8 pagesRCC92 Ribbed Slabs (Tables)lucianduNo ratings yet

- Materials For Rockets and MissilesDocument18 pagesMaterials For Rockets and MissilesDiamoundDomeProgram R&D100% (1)

- En 10008Document40 pagesEn 10008TaTi Roecker100% (1)

- Design of Shear Wall For Shear & Torsionl (ACI318-05) R0 - DAR...Document4 pagesDesign of Shear Wall For Shear & Torsionl (ACI318-05) R0 - DAR...Mohammed HanafiNo ratings yet

- RCC92 Ribbed Slabs (Tables)Document7 pagesRCC92 Ribbed Slabs (Tables)Cioabla BogdanNo ratings yet

- Beam Shear ConnDocument26 pagesBeam Shear Connraghav abudhabiNo ratings yet

- Spreadsheets To BS 8110Document10 pagesSpreadsheets To BS 8110Alma M. LaraNo ratings yet

- Welcome To Grcuk One of EuropeDocument8 pagesWelcome To Grcuk One of EuropeIqbal F AwaluddinNo ratings yet

- Standard Practice For Liquid Penetrant Testing 1Document11 pagesStandard Practice For Liquid Penetrant Testing 1k4piii100% (1)

- Tce Consulting Engineers Limited Design Guide For Auxiliary Steam HeaderDocument12 pagesTce Consulting Engineers Limited Design Guide For Auxiliary Steam HeaderbandithaguruNo ratings yet

- M2-CV-RC-D-005 (Anchor Bolt Details)Document19 pagesM2-CV-RC-D-005 (Anchor Bolt Details)neerajNo ratings yet

- RIBBED SLAB DESIGN To BS 81101997 Using Table 3.12 CoefficientsDocument8 pagesRIBBED SLAB DESIGN To BS 81101997 Using Table 3.12 CoefficientsShekh Muhsen Uddin AhmedNo ratings yet

- T-707-Calculations Based On Actual Thickness-R2Document25 pagesT-707-Calculations Based On Actual Thickness-R2SachinNo ratings yet

- Section B H Tension Reinforcement Compression Reinforcement MM MM MM MM MM No. Dia No. Dia No. Dia No. Dia No. Dia No. C C CDocument4 pagesSection B H Tension Reinforcement Compression Reinforcement MM MM MM MM MM No. Dia No. Dia No. Dia No. Dia No. Dia No. C C Cazamislam726537No ratings yet

- COLUMN DESIGN (STAAD OUPUT) ExcelDocument250 pagesCOLUMN DESIGN (STAAD OUPUT) Excelyedida viswanadhNo ratings yet

- 72 50 02Document6 pages72 50 02alvaro lemosNo ratings yet

- Ranjit CulmDocument4 pagesRanjit CulmBibhuti Bhushan BasuNo ratings yet

- Anchor Bolt DesignDocument3 pagesAnchor Bolt DesignDanielNo ratings yet

- Project Job Number EngineerDocument1 pageProject Job Number Engineerrukesh104No ratings yet

- Corbel Design by Eng'r. Edito M. Bautista Jr.Document4 pagesCorbel Design by Eng'r. Edito M. Bautista Jr.JD HemaNo ratings yet

- Bill of Material Description Size Material Remark NO. Qty. (NOS.) WT. (KGS.)Document3 pagesBill of Material Description Size Material Remark NO. Qty. (NOS.) WT. (KGS.)MasoodMiyanNo ratings yet

- As Staked 22FB0280 Layout3Document1 pageAs Staked 22FB0280 Layout3ber gularNo ratings yet

- UntitledDocument2 pagesUntitledBruno AbudNo ratings yet

- Detail 61Document5 pagesDetail 61SantosoNo ratings yet

- HST3Document8 pagesHST3Con CanNo ratings yet

- BiodieselDocument1 pageBiodieselPeter DouseNo ratings yet

- 5.22.1.1 Faying Surface. (AWS D1.1 2000)Document3 pages5.22.1.1 Faying Surface. (AWS D1.1 2000)david_baena8586No ratings yet

- 101 Calc Free TypeDocument1 page101 Calc Free TypeJacksonNo ratings yet

- Ho-001 - Section Modulus Calc - Teras 002Document5 pagesHo-001 - Section Modulus Calc - Teras 002Bayu Arya SNo ratings yet

- Singly Reinforced BeamDocument9 pagesSingly Reinforced BeamkalpanaadhiNo ratings yet

- RC10 ServiceDocument32 pagesRC10 Serviceidrees barlasNo ratings yet

- Pedestal Nave 2Document4 pagesPedestal Nave 2Jesús AlvaNo ratings yet

- ETABS 2016 Concrete Frame Design: ACI 318-14 Column Section DesignDocument2 pagesETABS 2016 Concrete Frame Design: ACI 318-14 Column Section DesignjccajamarcaNo ratings yet

- ETABS Concrete Frame Design: ACI 318-19 Column Section DesignDocument2 pagesETABS Concrete Frame Design: ACI 318-19 Column Section DesignYaserNo ratings yet

- Ge Ge752 User Manual 77 78Document2 pagesGe Ge752 User Manual 77 78RICHARDNo ratings yet

- Steel Connections: ResultsDocument4 pagesSteel Connections: ResultsTensaX Tensile StructureNo ratings yet

- Emirates National Oil Co. LTD: Belleli Energy SRLDocument7 pagesEmirates National Oil Co. LTD: Belleli Energy SRLKhairul JaggerNo ratings yet

- CBH-22-293 DIN 603 M10 X 20 BTZP 8.8Document1 pageCBH-22-293 DIN 603 M10 X 20 BTZP 8.8qualityNo ratings yet

- Maple STP QtyDocument30 pagesMaple STP QtyMunagala Madhu ReddyNo ratings yet

- CBH-22-166 Square Head Bolt 3-8 X 1 WZP 10.9Document1 pageCBH-22-166 Square Head Bolt 3-8 X 1 WZP 10.9qualityNo ratings yet

- HST3Document16 pagesHST3marcol99No ratings yet

- Connection Design ReportDocument97 pagesConnection Design ReportTrungNguyenNo ratings yet

- Proposed 3-Storey Residence With Lower GroundDocument92 pagesProposed 3-Storey Residence With Lower Groundfrancis sebastian lagamayoNo ratings yet

- Do Not Scale: SR - No. Qty. 1 1 2 1 3 1 4 1Document1 pageDo Not Scale: SR - No. Qty. 1 1 2 1 3 1 4 1vinothNo ratings yet

- RCC31R Rigorous One-Way SlabsDocument152 pagesRCC31R Rigorous One-Way Slabsali billNo ratings yet

- HUS3 Screw Anchor: Approvals / CertificatesDocument9 pagesHUS3 Screw Anchor: Approvals / CertificatesashaikhNo ratings yet

- Docking Drawer Cutout TemplatesDocument4 pagesDocking Drawer Cutout TemplatesJake PetersNo ratings yet

- Docking Drawer Cutout TemplatesDocument4 pagesDocking Drawer Cutout TemplatesJake PetersNo ratings yet

- Wednesday, August 31, 2022, 10:26 AM: Page 103 of 354 D:/Work/Sujit Bose/Sujit Bose .AnlDocument16 pagesWednesday, August 31, 2022, 10:26 AM: Page 103 of 354 D:/Work/Sujit Bose/Sujit Bose .AnlRajat DeyNo ratings yet

- Scale 1:1: REV Ecn # Date APRDocument1 pageScale 1:1: REV Ecn # Date APRKevinNo ratings yet

- Eccentic Footing (One Side)Document25 pagesEccentic Footing (One Side)Raaj NagpalNo ratings yet

- 2017 - Numerical Analysis of Die Wear Characteristics in Hot Forging of Titanium Alloy Turbine BladeDocument29 pages2017 - Numerical Analysis of Die Wear Characteristics in Hot Forging of Titanium Alloy Turbine BladeNguyen Hoang DungNo ratings yet

- Structural Calculation Report of Platform Str-2Document91 pagesStructural Calculation Report of Platform Str-2SaifullahNo ratings yet

- Design of Reinforced Concrete BeamsDocument16 pagesDesign of Reinforced Concrete Beamsabdul kareeNo ratings yet

- Exhaust Stack: Engineering With The SpreadsheetDocument8 pagesExhaust Stack: Engineering With The SpreadsheetZain Saeed0% (1)

- Public Introduction 30 Super Carry 2022-06-30Document2 pagesPublic Introduction 30 Super Carry 2022-06-30John DoeNo ratings yet

- D Concretestruc N20Document8 pagesD Concretestruc N20kuttyNo ratings yet

- Solid State Physics - Ii: Dr. N.Balasundari Assistant Professor Physics Department Sri K.G.S Arts College SrivaikundamDocument112 pagesSolid State Physics - Ii: Dr. N.Balasundari Assistant Professor Physics Department Sri K.G.S Arts College SrivaikundamGamma FactsNo ratings yet

- Inspection and Test Plan 4 - Trackworks: ConstructionDocument74 pagesInspection and Test Plan 4 - Trackworks: ConstructionTAMILNo ratings yet

- Buenasher Learning Academy IncDocument4 pagesBuenasher Learning Academy IncEl CruzNo ratings yet

- Zinc Sulfate 35 Maxi Granular Spec Sheet CCIDocument1 pageZinc Sulfate 35 Maxi Granular Spec Sheet CCIricko4001No ratings yet

- SDS Linear Alkylbenzene Sulfonate (NEOPELEX F65)Document6 pagesSDS Linear Alkylbenzene Sulfonate (NEOPELEX F65)yusufkurniawan.smNo ratings yet

- Tom3000 Elro RS250 PumpDocument16 pagesTom3000 Elro RS250 PumpahmadNo ratings yet

- 4 - Class Notes (CH-101 &CH-201) Module-4 - PolymerizationDocument9 pages4 - Class Notes (CH-101 &CH-201) Module-4 - PolymerizationMtabazi SahiniNo ratings yet

- TPSA US (English)Document7 pagesTPSA US (English)Henrique OliveiraNo ratings yet

- Determination of Arrhenius Kinetic Constants Differential Scanning CalorimetryDocument5 pagesDetermination of Arrhenius Kinetic Constants Differential Scanning CalorimetryNgocDiep PhamNo ratings yet

- Masonry and RCC ArchesDocument10 pagesMasonry and RCC ArchesSathish Selva0% (1)

- BKC4543 Environmental EngineeringDocument16 pagesBKC4543 Environmental EngineeringHarshini SivanganamNo ratings yet

- Mini Air BlowerDocument19 pagesMini Air BlowerudaypavanNo ratings yet

- TDS 3M Cavity Wax PlusDocument2 pagesTDS 3M Cavity Wax PlusIago Mouriño FernándezNo ratings yet

- Module 3Document27 pagesModule 3justineNo ratings yet

- Petrochemicals SbuDocument4 pagesPetrochemicals SbuAbhishek MishraNo ratings yet

- Brochure Agro Green PDFDocument16 pagesBrochure Agro Green PDFLuís Felipe MinelloNo ratings yet

- SFS Solid Front Process Pressure GaugeDocument2 pagesSFS Solid Front Process Pressure GaugeTlehony HaryNo ratings yet

- Gusset Plate Connection To Round HSS Tension MembersDocument7 pagesGusset Plate Connection To Round HSS Tension Membersglav1309No ratings yet

- Is 651Document27 pagesIs 651sach24iitNo ratings yet

- Komet Dihart Reamax TS: Modular Reaming SystemDocument8 pagesKomet Dihart Reamax TS: Modular Reaming SystemLuis LopezNo ratings yet

- MADICA 2018 ProgramDocument17 pagesMADICA 2018 ProgramathmaniNo ratings yet

- PRINTED ChemT4HLQDocument18 pagesPRINTED ChemT4HLQtaengooNo ratings yet

- 1982, Leja, Surface Chemistry of Froth FlotationDocument393 pages1982, Leja, Surface Chemistry of Froth FlotationFernando Lotero50% (4)

- CeramicsDocument21 pagesCeramics05DWI BILQIIS KHAIRUNNISANo ratings yet

- Convection: Cooling TowersDocument11 pagesConvection: Cooling Towersantolincy6706No ratings yet

- Process Flow Description - LatestDocument3 pagesProcess Flow Description - LatestJheffersonNo ratings yet