Professional Documents

Culture Documents

Highway

Highway

Uploaded by

Jake BaltazarOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Highway

Highway

Uploaded by

Jake BaltazarCopyright:

Available Formats

6.12.

1 Feasibility A bonded overlay of JPCP, JRCP, or CRCP is a

workable rehabilitation option for PCC pavements unless the condition

of the old pavement requires significant removal and replacement or

if durability issues are present (28). Design Guidelines, Criteria

and Standards: Volume 4 - Highway Design 6-104 The level of

deteriorated slab cracking and joint spalling is so considerable that

a significant portion of removal and replacement of the current

surface is mandated. Durability issues (such as "D" cracking or

reactive aggregates) have led to a significant deterioration of the

PCC slab. Performance of the overlay will suffer as a result. When it

comes to the requisite overlay thickness, vertical clearance at

bridges is insufficient. Normally, this poses no issues.

6.12.2 Pre-overlay Repair The types of distress should be repaired

prior to placement of the bonded PCC overlay as shown in Table 6-23.

Table 6-23

Full-depth repairs in CRCP should be PCC and should be continuously

reinforced with steel which is tied or welded to reinforcing steel in

the existing slab, to provide load transfer across joints and slab

continuity. Full-depth AC repairs should not be used prior to

placement of a bonded PCC overlay, and any existing AC patches should

be removed and replaced with PCC.

6.12.3 Reflection Crack Control In the course of a year, any active

(spalled) cracks in the old JPCP, JRCP, or CRCP slab may reflect

through the bonded concrete overlay. In bonded overlays, reflection

cracks can be reduced by fully repairing any active cracks in the

original pavement and, in the case of JPCP or JRCP, sawing and

sealing joints through the overlay over the repair joints. Since not

all tight non-working cracks will reflect through the overlay and

those that do often stay tight, only certain cracks need to be

corrected. It will take several years for tight cracks in the CRCP to

reflect through, and even then, they will still be tight.

6.12.4 Subdrainage The state of an existing pavement's subdrainage

typically has a significant impact on how effectively the overlay

functions. The current pavement should have its subdrainage

evaluated. The performance of an overlay will be enhanced by

improving substandard drainage conditions. Removing extra water from

the cross-section of the pavement will lessen erosion and strengthen

the foundation and subgrade, which will lessen deflections. Improved

subdrainage may also slow down stripping in AC pavement and "D"

cracking in PCC pavement.

6.12.5 Thickness Design If the overlay is being placed for some

functional purpose such as roughness or friction, a minimum thickness

overlay that solves the functional problem should be placed.

6.12.6 Shoulders When traffic lanes are overlay, the shoulders must

typically be layered to match the grade line of the lanes. The

quantity of traffic that will use the shoulder as well as the state

of the current shoulder should be taken into account by the designer

when choosing an overlay material and thickness for it. For instance,

the design of the shoulder overlay should take into account the fact

that trucks frequently park on the shoulder at particular spots. Any

damaged parts of a shoulder should be mended if the shoulder is still

in good condition. The shoulder grade might then be adjusted to match

the grade of the traffic lanes using an overlay. If an existing

shoulder is in such bad shape that it cannot be repaired affordably,

it ought to be removed and to be replaced

6.12.7 Existing JPCP and JRCP Joints As soon as curving permits after

overlay application, the transverse and longitudinal joint should be

saw cut entirely through the overlay thickness (plus 0.5-inch depth).

Joint debonding and cracking may occur if joints are not sawed

promptly after insertion. In these joints, no dowels or reinforcing

steel ought to be used. As quickly as feasible, a suitable sealant

reservoir needs to be sawed and filled with sealant. The bonded

overlay cannot have any existing CRCP transverse joints severed

because they are not required. For fulldepth reinforced tied concrete

patches, end joints do not require transverse joints either. Similar

to JPCP and JRCP, longitudinal joints should be sawed in the same

way.

6.12.8 Bonding Procedures and Material The successful performance of

the bonded overlay depends on a reliable bond with the existing

surface. The following guidelines are provided: 1. The existing

surface must be cleaned and roughened, through a mechanical process

that removes a thin layer of concrete, but does not damage (crack)

the surface. Shot blasting is the most used system. Cold milling has

been used, but may cause damage to the surface and thus requires sand

blasting afterward to remove loose particles. 2. A bonding agent is

recommended to help achieve a more reliable bond. Water, cement, and

sand mortar; water and cement slurry; and low-viscosity epoxy have

been used for this purpose. Bonded overlays constructed without a

bonding agent have performed well in some instances.

You might also like

- Magneti Marelli Rt6 ManualDocument3 pagesMagneti Marelli Rt6 ManualRenato M Faria0% (4)

- Telephone Directory 2020Document126 pagesTelephone Directory 2020Divyesh Makwana100% (1)

- A Practical Guide to Concrete Pavement Technology for Developing CountriesFrom EverandA Practical Guide to Concrete Pavement Technology for Developing CountriesNo ratings yet

- Video Script: Unit 1 Another Country Part 1 Living Abroad Part 2 Adriana: Life in EnglandDocument22 pagesVideo Script: Unit 1 Another Country Part 1 Living Abroad Part 2 Adriana: Life in EnglandZeynep Sulaimankulova100% (2)

- Guide To Fixings For GRC CladdingDocument55 pagesGuide To Fixings For GRC CladdingThompson Lai100% (4)

- Reverse Circulation Cementing: The Complete PictureDocument104 pagesReverse Circulation Cementing: The Complete PictureJoan Corso100% (1)

- The Risky Business of Hiring StarsDocument16 pagesThe Risky Business of Hiring StarsAspiring StudentNo ratings yet

- HIGHWAYDocument5 pagesHIGHWAYJan Edcel CruzNo ratings yet

- Rigid Pavement ManualDocument30 pagesRigid Pavement ManualSarfaraj KhanNo ratings yet

- Performance and Structural Evaluation of Cracked and Seated ConcreteDocument7 pagesPerformance and Structural Evaluation of Cracked and Seated ConcreteKingJsNo ratings yet

- Designing Facing Concrete of RCC DamDocument11 pagesDesigning Facing Concrete of RCC DamAnonymous KHIyWRIWma100% (1)

- RCC DamDocument28 pagesRCC DamRiqicha Jaalalaa100% (1)

- Launching of Pre Stressed Girder by James R LibbyDocument19 pagesLaunching of Pre Stressed Girder by James R LibbyhammadhouseNo ratings yet

- Hollow Core Building BrochureDocument18 pagesHollow Core Building BrochureWahyu Wawan Tulit SetiawanNo ratings yet

- Guidelines For Routine MaintenanceDocument86 pagesGuidelines For Routine Maintenanceakohar MohamadNo ratings yet

- Modernization of TrackDocument7 pagesModernization of TrackShipra MishraNo ratings yet

- FAQ Parking Lot2021Document4 pagesFAQ Parking Lot2021Bernd CastellarNo ratings yet

- Rigid Pavement: Topic 621 - Types of Rigid PavementsDocument29 pagesRigid Pavement: Topic 621 - Types of Rigid PavementsMaejann CuarteroNo ratings yet

- Hollow Core Building BrochureDocument16 pagesHollow Core Building Brochurelbhnsw5930No ratings yet

- 2015 Pavement Design Manual - Final - Part 3 PDFDocument201 pages2015 Pavement Design Manual - Final - Part 3 PDFosama hourani100% (1)

- Roller-Compacted Concrete Pavements For Highways and StreetsDocument15 pagesRoller-Compacted Concrete Pavements For Highways and StreetsJohnNo ratings yet

- Bridge Design PhilosophyDocument21 pagesBridge Design PhilosophyAddrien Daniel100% (1)

- Required RC Jacket Thickness and Reinforcement Ratio For Repairing RC Tied Rectangular and Circular Concrete ColumnsDocument18 pagesRequired RC Jacket Thickness and Reinforcement Ratio For Repairing RC Tied Rectangular and Circular Concrete ColumnsAbubakr OsmanNo ratings yet

- Coek - Info Skid-GroutingDocument14 pagesCoek - Info Skid-Groutingkaty parraNo ratings yet

- Sub Con Unit 2 NotesDocument15 pagesSub Con Unit 2 NotesDarshan KrishnaNo ratings yet

- Holorib gndf3Document12 pagesHolorib gndf3_jessecaNo ratings yet

- Failures in Asphalts and How To Avoid Them PDFDocument21 pagesFailures in Asphalts and How To Avoid Them PDFhfco95No ratings yet

- Unit 3 PDF (1) TransportationDocument57 pagesUnit 3 PDF (1) TransportationKhweziNo ratings yet

- Hollow Core Building BrochureDocument16 pagesHollow Core Building BrochureGeorge GeorgianNo ratings yet

- Casting Box Girder Segments - tcm45-342871Document3 pagesCasting Box Girder Segments - tcm45-342871AuYongTheanSengNo ratings yet

- Accelerated Short Span Bridge-PowellDocument6 pagesAccelerated Short Span Bridge-PowellNurali MamenNo ratings yet

- Riser DesgnDocument13 pagesRiser Desgnplatipus_8575% (4)

- AC Mitigation Case Histories: Nebraska Pipeline Safety Seminar Mike Ames March 26, 2013 Grand Island, NEDocument32 pagesAC Mitigation Case Histories: Nebraska Pipeline Safety Seminar Mike Ames March 26, 2013 Grand Island, NEMattNo ratings yet

- Hif12039 PDFDocument12 pagesHif12039 PDFSaad Butt100% (1)

- Design of R.C Bridge Deck: Solid Slab BridgesDocument5 pagesDesign of R.C Bridge Deck: Solid Slab BridgesJunaid AminNo ratings yet

- PCCP Design PDFDocument61 pagesPCCP Design PDFKeeperNo ratings yet

- AASHTO Guide For Design of Pavement Structures PDFDocument593 pagesAASHTO Guide For Design of Pavement Structures PDFTams Cot-omNo ratings yet

- Aashto Design97Document593 pagesAashto Design97coolcolombo100% (8)

- Road Over Bridge - Presen ScenarioDocument8 pagesRoad Over Bridge - Presen ScenariosombansNo ratings yet

- 08 - Prof Su QianDocument9 pages08 - Prof Su QianS.m. MoniruzzamanNo ratings yet

- Road Construction DetailsDocument29 pagesRoad Construction DetailsARUNKUMAR KNo ratings yet

- URS Fatigue Evaluation and Redundancy AnalysisDocument2 pagesURS Fatigue Evaluation and Redundancy Analysismadhu.nandha9285No ratings yet

- 5.14.1.4 Simple Spans Made ContinuousDocument2 pages5.14.1.4 Simple Spans Made ContinuousHermann PankowNo ratings yet

- Wall Bracing To Slab-On-Ground FloorsDocument7 pagesWall Bracing To Slab-On-Ground Floorsmurdicks0% (1)

- Presentation GirderDocument53 pagesPresentation GirderIrfan KhanNo ratings yet

- Link Slab Deck JointsDocument20 pagesLink Slab Deck JointsAnton Husen PurboyoNo ratings yet

- Cap. 5 - AASHTO 93 RefuerzosDocument79 pagesCap. 5 - AASHTO 93 RefuerzosCarlos JulcaNo ratings yet

- Concrete Construction Article PDF - Mechanical vs. Lap SplicingDocument4 pagesConcrete Construction Article PDF - Mechanical vs. Lap SplicingGilven MedinaNo ratings yet

- Mechanically Stabilized EmbankmentsDocument6 pagesMechanically Stabilized EmbankmentsScribdmarificNo ratings yet

- Jacketing Techniques For Retrofitting of RC Column and BeamDocument28 pagesJacketing Techniques For Retrofitting of RC Column and BeamJai Keerthi100% (4)

- Guia Pratico ContabeisDocument2 pagesGuia Pratico ContabeisGBNo ratings yet

- AISC - Splice ConferenceDocument4 pagesAISC - Splice ConferenceKamal HalawiNo ratings yet

- Accelerated Brideg Construction in Washington StateDocument16 pagesAccelerated Brideg Construction in Washington StatesyedabdulhannanNo ratings yet

- 2012 6th Int Symp On RCC Dams-Innovations of Significance and Their Development On Some Recent RCC Dams-ForBESDocument25 pages2012 6th Int Symp On RCC Dams-Innovations of Significance and Their Development On Some Recent RCC Dams-ForBESMelissa AustinNo ratings yet

- CN Chap06 - Continuous Construction Design ConsiderationsDocument25 pagesCN Chap06 - Continuous Construction Design Considerationshaihuynh3073No ratings yet

- Strasky 2004 CBCDocument17 pagesStrasky 2004 CBCMangesh kevadkarNo ratings yet

- FAA Eng Brief 66 RubilizationDocument16 pagesFAA Eng Brief 66 Rubilizationjscurrie6614No ratings yet

- DSI-USA DYWIDAG Ductile Connectors UsDocument4 pagesDSI-USA DYWIDAG Ductile Connectors UssertackcdgNo ratings yet

- Technical Paper (FINAL)Document10 pagesTechnical Paper (FINAL)jarabos8609No ratings yet

- Offshore Oil Production Riser Desgn PDFDocument13 pagesOffshore Oil Production Riser Desgn PDFdndudcNo ratings yet

- Roller Compacted Concrete: A New Material For Faster Highway ConstructionDocument92 pagesRoller Compacted Concrete: A New Material For Faster Highway Constructionabhineet srivastavaNo ratings yet

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Case Analysis Guidelines and FormatDocument6 pagesCase Analysis Guidelines and FormatJake BaltazarNo ratings yet

- Lab No.1Document2 pagesLab No.1Jake BaltazarNo ratings yet

- Case StudyDocument2 pagesCase StudyJake BaltazarNo ratings yet

- Sample LabDocument7 pagesSample LabJake BaltazarNo ratings yet

- Pavement OverlayDocument5 pagesPavement OverlayJake BaltazarNo ratings yet

- Cost Estimation of Structures in Commercial Buildings by Surinder SinghDocument196 pagesCost Estimation of Structures in Commercial Buildings by Surinder SinghJake BaltazarNo ratings yet

- Vicinity MapDocument1 pageVicinity MapJake BaltazarNo ratings yet

- English For Specific Purposes. Needs Ana PDFDocument7 pagesEnglish For Specific Purposes. Needs Ana PDFTegar Ghalih PrasetyoNo ratings yet

- Rome (Roma) Italy Port Guide - Toms Port GuidesDocument21 pagesRome (Roma) Italy Port Guide - Toms Port GuidessocialcornieNo ratings yet

- Fascia Repair DetailsDocument2 pagesFascia Repair DetailsPatricia TicseNo ratings yet

- CA 125 Calibrator - CLIA Series v.1Document3 pagesCA 125 Calibrator - CLIA Series v.1susey tepaNo ratings yet

- Faradic Current: Avanianban Chakkarapani Lecture 8 & 9 Venue:K 205 A 28.1.15 11.00 Am To 1.00 PMDocument44 pagesFaradic Current: Avanianban Chakkarapani Lecture 8 & 9 Venue:K 205 A 28.1.15 11.00 Am To 1.00 PMArshad ShaikhNo ratings yet

- School of Computer Science and Engineering: Report On Artificial Intelligence in DefenceDocument32 pagesSchool of Computer Science and Engineering: Report On Artificial Intelligence in DefenceAmogh VarshneyNo ratings yet

- EBCR Refreshing For ResidentsDocument47 pagesEBCR Refreshing For ResidentsJohn Patria Maruli SinagaNo ratings yet

- Healthy Alternatives: by Jung Joo Kim & Jennifer WongDocument11 pagesHealthy Alternatives: by Jung Joo Kim & Jennifer WongJJ KimNo ratings yet

- BUS5112 - Unit 1 - Developing A Marketing Strategy - AssignmentDocument7 pagesBUS5112 - Unit 1 - Developing A Marketing Strategy - AssignmentxwereNo ratings yet

- Electron Microscopy in Cell BiologyDocument68 pagesElectron Microscopy in Cell BiologyDouglasCastroNo ratings yet

- Test Bank For Elementary Statistics Picturing The World 5 e 5th Edition 0321891872Document11 pagesTest Bank For Elementary Statistics Picturing The World 5 e 5th Edition 0321891872utopiapermix3rNo ratings yet

- IBR IMBUS Datasheet No LogoDocument12 pagesIBR IMBUS Datasheet No Logoenamicul50No ratings yet

- Projeto Web Services Spring Boot JPADocument12 pagesProjeto Web Services Spring Boot JPAJackson LopesNo ratings yet

- Absorption II. Abstrip-Packed - ColumnsDocument58 pagesAbsorption II. Abstrip-Packed - ColumnsAnonymous wCDPbgMLJNo ratings yet

- Specular Reverb v.3 - User Manual enDocument10 pagesSpecular Reverb v.3 - User Manual enAndrew AlexisNo ratings yet

- Big Cable GuideDocument54 pagesBig Cable Guided1sc0stuNo ratings yet

- Stone VesselsDocument42 pagesStone VesselsVesna MatićNo ratings yet

- Increases Revenue Per Visitor Using Ezoic's Machine Learning and Google Ad ManagerDocument1 pageIncreases Revenue Per Visitor Using Ezoic's Machine Learning and Google Ad Managerraja sinhjNo ratings yet

- Cleft Lip PalateDocument37 pagesCleft Lip PalateMuhammad Hamid Muktashim100% (1)

- Company Profile. Aston HOtelDocument23 pagesCompany Profile. Aston HOtelQahhaar PrabuNo ratings yet

- Quantum CryptographyDocument8 pagesQuantum Cryptographyapi-3777036No ratings yet

- Consumer Behaviour (Cma 206) Course Outline 2017Document4 pagesConsumer Behaviour (Cma 206) Course Outline 2017Faustino KufakunesuNo ratings yet

- Discussion & Conclusion + Screenshot PDFDocument2 pagesDiscussion & Conclusion + Screenshot PDFRex LeopardNo ratings yet

- List of MaterialsDocument5 pagesList of MaterialsNONI ZERIMARNo ratings yet

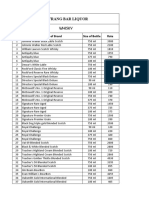

- Hotel Navrang Liquor NON-1Document6 pagesHotel Navrang Liquor NON-1gourav.damadeNo ratings yet

- Introduction To DSDM AternDocument13 pagesIntroduction To DSDM AternYexeon ChewNo ratings yet