Professional Documents

Culture Documents

SWIFT - H2S Management Part 2 - Sep22-21 R2

Uploaded by

Sathia ShekarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWIFT - H2S Management Part 2 - Sep22-21 R2

Uploaded by

Sathia ShekarCopyright:

Available Formats

H2S Management Strategy Report - Part 2

Synergy Approach to Revive H2S Producing Wells

Generally, H2S measured at the separator gas outlet (SP5) without any samples collected

upstream of the separator resulting less frequent monitoring in the piping corrosion rates. H2S STRATEGY SUMMARY

SWIFT’s recommend a further improvement in H2S measurement strategy on the pilot data

sampling frequency of SP 1 to 5 by

• H2S Concentration (ppm)

• Hourly basis until the well pressure stabilized • pH

• CO2

Drager Tube

• Subsequent data sample is required every 12 hours to ensure that the defense layer (Moderate Precision)

is not compromised

• Analyzed against SP1

• Fine-tune chemical dosage

CURTAIL H2S PRODUCTION • 1st post treatment measurement

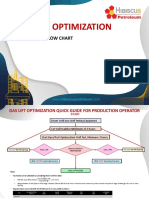

H2S MITIGATION DECISION-MAKING:

Measurement

• Sampled H2S concentration, if any

• 2nd post treatment measurement H2S Analyzer

Tools

When addressing H2S problems production wells, a corrective action plan that describes the (Moderate Precision)

• Fine-tune chemical dosage

type of information must be compiled and a decision must be made, based on:

• Expecting the production to sour based on similar field history

• Sampled H2S concentration, if any

• Perform H2S material balance including estimated H2S in reservoir and compare with • 3rd post treatment measurement

field measurement • Fine-tune chemical dosage

• Capabilities on using H2S Scavenger Lab Titration

(High Precision)

• The chemical injected into mixed production streams or required a contact tower • Sampled H2S concentration, if any

• Gas Sampling Bomb - high

Once the reservoir souring quantification is determined, a mitigation plan must be selected pressure gas samples for lab test

LEGEND

and implemented, as shown below:

• Safety concern in production streams - immediately

• Souring based on field history • Capabilities on using H2S Scavenger

• Absence of CO2 or pH conditions - Alkanolamines/Triazines should be used as it has • Chemical injected into mixed production

• H2S Material balance and compare with field

the least toxic of scavengers measurement samples 1 streams or required a contact tower

• If CO2 and low pH presents, amines may deactivated and other scavengers such as

Aldehydes, Acrolein or Oxidants must be used

Figure 1. Schematic of a H2S producing well with recommended data sample point, static mixer and test separator The preferred H2S Scavenger injection into the piping is at the corrosion coupon of the well

1. Background PRAGMATIC SURVEILLANCE flowline prior to the proposed static mixer.

• On-site measurement

It needs to be in contact with the crude oil for a suitable time (retention time) to reduce the 2 • Multiple methods

(Drager Tube/Analyzer/ Titration)

It is pivotal to a souring strategy where measuring H2S in crude oil brings a challenge to H2S concentration below the required value of 5 ppm without any necessary modification

A characteristic of reservoir souring is that not all production wells show the same increase in hydrogen the industry. depending on several variables

sulfide (H2S) concentration at the same time with a proven data measurement within Malaysia When H S is detected in a production system, analysis must be performed immediately to • Injection dose rate

2 • H2S Production more than 100

production assets (Cendor, St. Joseph and Dulang) from 100 ppm to as high as 1100 ppm (Cendor, determine • Crude velocity

2021; St. Joseph, 2020; Dulang, 2020). 3 ppm/ high watercut

• Determine H2S Scavenger

• Concentration of H2S present • Pipe length and diameter

The root cause can be determined by inconsistent monitoring and poor compliance over an extended • Source of sulfides • Pressure

period of time, which are divided into 3 types:

• If the H2S levels observed will cause operational problems • H2S concentration at the inlet

• Attempt to deal with H2S after it has been generated and produced from the reservoir • Safety concern

The importance of monitoring H S in the continuous operation of equipment allows • Corrosion 4 5 (Immediately)

KEY ENABLERS

2

• Reduce the mass of H2S generated by over injecting chemicals management to

• Identify any abnormality to the integrity of assets SCAVINATOR (NON-TRIAZINE):

• Prevent H2S from being produced (Shut-in the well)

• Quick turnaround in remedial actions can be implemented effectively

• A water-soluble scavenger to control H2S and removes sulfide from gases and liquids.

Recent assessment from SWIFT Water Injection Program (WIP) benchmark – estimated Loss-in-

Although, accurate data from 1 sampling point is the minimum requirement, it is impossible • Has the least effect on pH • CO2

Production (LIP) from idle beneficial oil producers are

to determine the presence of corrosion or microbial activity and its effect on the sulfide • Low pH

• Reduce the formation of mineral scale plus contains a solid inhibitor that can prevent

• 3 at Cendor (470 bopd) concentration.

accumulation without affecting the efficiency of the scavenger, with a record on the

• 3 at Dulang (987 bopd) As shown in Figure 1, collecting 5 data sampling point (SP) will be more representative and H2S removal up to 95%

able to see if the sulfide concentration in the entire production line is increased by the SRB. • Aldehydes

STATIC MIXER • Acrolein • Alkanolamines

Amounting to a total of RM 84 mil/year (Oil price of USD 40 per bbl and an exchange rate of RM 4). Sampling Point 1: 6 • Oxidants 7 • Triazines

• Recommendation to install after the injection of H2S scavenging agent • Scavinator

This paper focuses on technical solutions in a conscientious approach to address reservoir souring by • The collected samples at the upstream of chemical Injection post X-mas tree is free of

proactive remedial treatments and synergistic approach to revive well production. • Allow for the inline continuous blending of crude and chemical within a pipeline and

chemical contamination and required on H2S concentration, pH and C02

expedite the retention time from 2 minutes to 1.2 minutes (40% reduction)

Sampling Point 2:

• Cost-effective manner (minimum modification required)

2. Key Strategy • Once the crude oil passes through the Static Mixer, further sampling is required to ensure

the success rate of effective H2S removal

• If sampling data is unfavorable, a quick turn-around on the H2S Scavenger can be done

Profound understanding of the field is required and corrective actions must be taken to formulate by adjusting the chemical dosage 3. References

decision making strategies.The key strategies are intended to be used for an effective reservoir souring Test Separator Sampling Point (Sampling Point 3 -5):

management approach focusing on 3 pillars: • A final sampling point is required at the outlet of the SP 3 to 5 test separator. This will

• Pragmatic Surveillance ensure that the H2S concentration is below the expected 5 ppm and the partial pressure 1. SWIFT_WIP H2S Wells_Aug20-21 R1 • Retention Time Reduction

• Minimum modification (Cost-efficient)

lower than 0.05 psi

2. MPM_Cendor AMIR Report_Aug01-2020

• Curtail H2S production with viable decision-making strategies • For analysis in laboratory, a gas sampling bomb specially designed for collecting and

3. SEAH_StJoseph AMIR_Jul10-2020 • Reduce high H2S concentration to 5 ppm

• Key Enablers with in state-of-the-art methods storing high pressure gas samples is required at the gas outlet (SP5) • Least effect on pH and reduce formation mineral scale

4. MPM_Dulang AMIR Report_Jul15-2020

2021 - Copyright of Petrovirtus/Vision Petroleum

Title :

LIMITATION OF LIABILITY: This document is prepared by and is the property of Petrovirtus (Virtus) and Vision

Petroleum International (Vision); neither it nor any part nor a copy thereof is to be published or disclosed

without first securing the express written approval from Virtus/Vision. Accordingly, any user of this document

Client : PETRONAS RESOURCE MASTERPLAN Originator : SAM E-mail :

sam@petrovirtus.com H2S Management Strategy Report - Part 2

agrees that Virtus/Vision shall not be liable for any loss or damage, regardless of cause, including any act

Prepared by :

SAM E-mail :

sam@petrovirtus.com

or omission of Virtus/Vision resulting from the use of the data reported herein; and Virtus/Vision makes no

warranties, expressed or implied, whether of fitness for a particular purpose, merchantability or otherwise, as Reviewed by : E-mail :

to the accuracy of the document reported. This document may however, be used at the sole risk of the user, Project : PROVISION OF WATER INJECTION PERFORMANCE KPT/LBH/IIM/MAS

in the course of regular business operation by any person or concern and employees thereof receiving such MANAGEMENT UNDER SPECIALIZED WATER Rev :

report from Virtus/Vision. INJECTION FAST TRACK (SWIFT)

Approved by : ARY E-mail : ary@visionpetroleum.com Date : Status : Project/Ref No. : Document No.: Sheet No./Sheets :

Aug27-21 Review TBA 1 of 1 R2

You might also like

- Pitt V Holt CA (2011) 3 WLR 19Document66 pagesPitt V Holt CA (2011) 3 WLR 19Soo VibesNo ratings yet

- Amchem Products Private LimitedDocument19 pagesAmchem Products Private LimitedAtika malikNo ratings yet

- United India Insurance Company LimitedDocument7 pagesUnited India Insurance Company Limitedyatishduggal4No ratings yet

- Current Report Item Is Not Supported in This Report Format.: Retail / Tax Invoice (Original For Recipient)Document1 pageCurrent Report Item Is Not Supported in This Report Format.: Retail / Tax Invoice (Original For Recipient)Yogesh BohraNo ratings yet

- The Genetics and Typical Traits of Thoracic Aortic Aneurysm and DissectionDocument34 pagesThe Genetics and Typical Traits of Thoracic Aortic Aneurysm and DissectionTlally Itzel Zamora CastroNo ratings yet

- Price Monitoring September 2 2022Document5 pagesPrice Monitoring September 2 2022Miggy Peralta RafaelNo ratings yet

- Bharamappa SDDocument4 pagesBharamappa SDPRASHANTH REDDYNo ratings yet

- 99 Available Name Ideas For A Vape or Smoke ShopDocument5 pages99 Available Name Ideas For A Vape or Smoke ShopMartin SandersonNo ratings yet

- 2018 - Regression Solar Auction IndiaDocument13 pages2018 - Regression Solar Auction IndiaRajat AggarwalNo ratings yet

- Annual Report 2021 2022Document312 pagesAnnual Report 2021 2022PRIYA TIWARINo ratings yet

- Sbi One India FundDocument16 pagesSbi One India Fundpuneeth achanalaNo ratings yet

- AccuraCap PMSDocument35 pagesAccuraCap PMSAnkur100% (1)

- Case Study 278 PDF FreeDocument6 pagesCase Study 278 PDF Freewaqas farooqNo ratings yet

- Panjetani Buildwell Private Limited-454Document1 pagePanjetani Buildwell Private Limited-454Huba ZehraNo ratings yet

- JioMart ICICI Cashback OfferDocument2 pagesJioMart ICICI Cashback OfferNSNo ratings yet

- Growth Hormone DeficiencyDocument11 pagesGrowth Hormone DeficiencyIgor VasićNo ratings yet

- Campus Placement Jaro EducationDocument31 pagesCampus Placement Jaro EducationSHRASTINo ratings yet

- UnlockedDocument30 pagesUnlockedAvinitsahaNo ratings yet

- OD126164812918973000Document1 pageOD126164812918973000Manoj SirsatNo ratings yet

- Portfolio 3Document21 pagesPortfolio 3Kiand Albert 9CNo ratings yet

- SIG-Epi Eng AllDocument102 pagesSIG-Epi Eng AllMOHAMMED SHARFNo ratings yet

- Tax InvoiceDocument1 pageTax Invoice5 ROINo ratings yet

- Airline Strategy During Covid-19 Outbreak: A Case Study From Air AsiaDocument9 pagesAirline Strategy During Covid-19 Outbreak: A Case Study From Air AsiaBrian TeoNo ratings yet

- Ugb 252Document7 pagesUgb 252Abdumalik KakhkhorovNo ratings yet

- Budget 224: PremiumDocument25 pagesBudget 224: PremiumHiralal patilNo ratings yet

- VolkswagenDocument12 pagesVolkswagenKanchan KhujuNo ratings yet

- CFO Macro12 PPT 18Document43 pagesCFO Macro12 PPT 18Pedro ValdiviaNo ratings yet

- Section25 Companies 6nov2008-17-19Document3 pagesSection25 Companies 6nov2008-17-19GSMPNo ratings yet

- JDLQR2022Q2Document38 pagesJDLQR2022Q2Kit WooNo ratings yet

- The National Law Institute University, Bhopal: I Trimester II Trimester III TrimesterDocument7 pagesThe National Law Institute University, Bhopal: I Trimester II Trimester III TrimesterYashvendra SinghNo ratings yet

- IRDA CreDocument8 pagesIRDA CreAayush SoniNo ratings yet

- Texto 2014 SECRETARIADO 1Document35 pagesTexto 2014 SECRETARIADO 1luisnyder chapi espinozaNo ratings yet

- Indian Economy - Docx Unit-1Document14 pagesIndian Economy - Docx Unit-1Aditi SinghNo ratings yet

- Research and Data Priorities For Improving Economic and Social Mobility: Proceedings of A Workshop (2022)Document17 pagesResearch and Data Priorities For Improving Economic and Social Mobility: Proceedings of A Workshop (2022)Mon MacutayNo ratings yet

- Flipkart See FinalDocument18 pagesFlipkart See FinalRavi ganganiNo ratings yet

- PILLARDocument7 pagesPILLARLorelyn de la TorreNo ratings yet

- QuizzesDocument56 pagesQuizzesMimiNo ratings yet

- Bcom - Hons Cet 2021Document292 pagesBcom - Hons Cet 2021Himanshu RajputNo ratings yet

- Momentum PicksDocument29 pagesMomentum Picksjiteshdoshi25No ratings yet

- You Got Tickets To Maroon 5Document3 pagesYou Got Tickets To Maroon 5yumie canivelNo ratings yet

- Chapter 10 (Crafting The Positioning & Differentiation)Document21 pagesChapter 10 (Crafting The Positioning & Differentiation)Magued MamdouhNo ratings yet

- Business Journal March 2012 B SectionDocument16 pagesBusiness Journal March 2012 B SectionThe Delphos HeraldNo ratings yet

- Linhai Limin Chemicals Co., LTDDocument7 pagesLinhai Limin Chemicals Co., LTDfluorinatedliminNo ratings yet

- Math &esp With Tos 1st QuarterDocument24 pagesMath &esp With Tos 1st QuarterCristitaPobreSanchezNo ratings yet

- PVR CinemasDocument17 pagesPVR CinemasNeha SinghNo ratings yet

- Globalization in Contemporary WorldDocument14 pagesGlobalization in Contemporary WorldVicente Salazar AstorgaNo ratings yet

- LJ3 Murugappa Case From SumanDocument5 pagesLJ3 Murugappa Case From SumanSuman NayakNo ratings yet

- SJC Response To Resident QuestionsDocument28 pagesSJC Response To Resident QuestionsSantiago FloresNo ratings yet

- DLF Split Raises Questions: 50 P/unit Incentive For Wind Power ProducersDocument1 pageDLF Split Raises Questions: 50 P/unit Incentive For Wind Power ProducerssbravalNo ratings yet

- SAEPN (PVT) LTD: Fee Invoice (Student Copy)Document1 pageSAEPN (PVT) LTD: Fee Invoice (Student Copy)waseemNo ratings yet

- Consent FormDocument1 pageConsent FormGlenda AbellaNo ratings yet

- Jayesh Gupta PDF 1Document11 pagesJayesh Gupta PDF 1Jayesh GuptaNo ratings yet

- ED456557Document11 pagesED456557Juan RodriguezNo ratings yet

- NikeadidasDocument2 pagesNikeadidasNgọc Huyền NguyễnNo ratings yet

- 4 M 0 o 8 XBTZDCD 18 SKZBKKDocument1 page4 M 0 o 8 XBTZDCD 18 SKZBKKSuman kumari Admission no-4477No ratings yet

- Jus de Rose PerfumesDocument8 pagesJus de Rose Perfumesgorengan kikilNo ratings yet

- Pe MidtermDocument8 pagesPe MidtermJham L. PatraNo ratings yet

- PL Power Yellow - 01 Apr 22Document9 pagesPL Power Yellow - 01 Apr 22Dunia FantasiNo ratings yet

- Form RPS112179Document2 pagesForm RPS112179Dev PandeyNo ratings yet

- SWIFT - H2S Management Part 2 - Aug27-21 R1Document1 pageSWIFT - H2S Management Part 2 - Aug27-21 R1Sathia ShekarNo ratings yet

- School Bus - Van Listing With Photos - V2 - 08122020Document1 pageSchool Bus - Van Listing With Photos - V2 - 08122020Sathia ShekarNo ratings yet

- Light Pink Rainbow Steaks Magazine CoverDocument3 pagesLight Pink Rainbow Steaks Magazine CoverSathia ShekarNo ratings yet

- MPRC Ogse100 Fy2021 - 1Document52 pagesMPRC Ogse100 Fy2021 - 1Sathia ShekarNo ratings yet

- Management MatrixDocument1 pageManagement MatrixSathia ShekarNo ratings yet

- Sarapar Drilling FluidDocument54 pagesSarapar Drilling FluidSathia ShekarNo ratings yet

- 2021 RoadmapDocument2 pages2021 RoadmapSathia ShekarNo ratings yet

- Swift VRR Pir Comparison May19-21Document3 pagesSwift VRR Pir Comparison May19-21Sathia ShekarNo ratings yet

- Market Survey QuestionDocument3 pagesMarket Survey QuestionSathia ShekarNo ratings yet

- 20210531-GDR Ship Brochure EN Eew0a0Document8 pages20210531-GDR Ship Brochure EN Eew0a0Sathia ShekarNo ratings yet

- SWIFT - 2020 Year End Updates - Dec22-2020 R3 ARY ReviewedDocument9 pagesSWIFT - 2020 Year End Updates - Dec22-2020 R3 ARY ReviewedSathia ShekarNo ratings yet

- Performance Analytics ModuleDocument1 pagePerformance Analytics ModuleSathia ShekarNo ratings yet

- C-1 IIUM MYRA Section Coordinator 2021.Document1 pageC-1 IIUM MYRA Section Coordinator 2021.Sathia ShekarNo ratings yet

- Antifoam and O2 Scav Value AnalysisDocument1 pageAntifoam and O2 Scav Value AnalysisSathia ShekarNo ratings yet

- Reservoir Souring Control Action ItemDocument1 pageReservoir Souring Control Action ItemSathia ShekarNo ratings yet

- Petroleum: Shuyong Hu, Yi Deng, Yongkai Li, Ran WangDocument5 pagesPetroleum: Shuyong Hu, Yi Deng, Yongkai Li, Ran WangSathia ShekarNo ratings yet

- Mercury ManagementDocument12 pagesMercury ManagementSathia ShekarNo ratings yet

- GL Optimization Flow ChartDocument2 pagesGL Optimization Flow ChartSathia ShekarNo ratings yet

- SWIFT - Souring Strategy Apr15-21 R1Document1 pageSWIFT - Souring Strategy Apr15-21 R1Sathia ShekarNo ratings yet

- Value Creation MatrixDocument19 pagesValue Creation MatrixSathia ShekarNo ratings yet

- SWIFT - H2S Management Part 2 - Aug27-21 R1Document1 pageSWIFT - H2S Management Part 2 - Aug27-21 R1Sathia ShekarNo ratings yet

- Data Analytics Module OutlineDocument1 pageData Analytics Module OutlineSathia ShekarNo ratings yet

- SWIFT - Reservoir Souring Control Action Item - Aug16-21 R3Document1 pageSWIFT - Reservoir Souring Control Action Item - Aug16-21 R3Sathia ShekarNo ratings yet

- VRR PIR ComparisonDocument3 pagesVRR PIR ComparisonSathia ShekarNo ratings yet

- Spe 178368 MsDocument25 pagesSpe 178368 MsSathia ShekarNo ratings yet

- SWIFT - Reservoir Souring Control Action Item - Aug13-21 R2Document1 pageSWIFT - Reservoir Souring Control Action Item - Aug13-21 R2Sathia ShekarNo ratings yet