Professional Documents

Culture Documents

Sr. No. 2 Datasheet 0.5PX3PSCNARMD

Sr. No. 2 Datasheet 0.5PX3PSCNARMD

Uploaded by

hemantmech0992000 ratings0% found this document useful (0 votes)

7 views1 pageOriginal Title

Sr. No. 2 Datasheet 0.5PX3PSCNARMD

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

7 views1 pageSr. No. 2 Datasheet 0.5PX3PSCNARMD

Sr. No. 2 Datasheet 0.5PX3PSCNARMD

Uploaded by

hemantmech099200Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

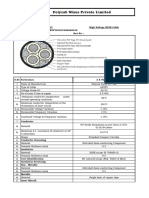

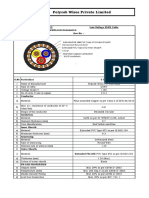

Document ID: TE/QMS/F/02

Rev. No. : 00 Issued Date : 02/04/2018

Cable Description: 300/500 V ,Str Copper, PVC Type A

Insulation, Overall shielded with Al-mylar tape along with 0.5

mm² ATC Drain Wire, Extr. PVC ST-1 Inner Sheath, GS

Armoured, FR-LSH PVC ST-1 sheathed Cable generally as per

IS/BS

I Technical Data of Instrumentation Cables CABLE SIZE

II CABLE CODE ICIS04CYSWYL003P0.5SA003S

S.No Particulars 3 Pair X 0.5 sq mm

1 Name of Manufacturer POLYCAB INDIA LTD

2 Type of Cable Overall Screened

3 No of Elements X Size in mm² 3P X 0.5

4 Voltage Grade (V) 300/500

5 Conductor

a) Material Plain Stranded Copper (Class-2) as per IS: 8130/2013

b) Maximum d.c. resistance of conductor at 20° C (Ω/km) 36.7

c) Shape of conductor Stranded Circular

6 Insulation

a) Material PVC Type A as per IS:5831

b) Minimum Thickness mm 0.44

White & Blue with numbered Polyester tape (OR)

c) Pair/Triad identification

White & Blue with number printing on core

7 Collective Screen

a) Material Aluminium mylar tape

b) Nominal Thickness mm 0.018

c) Material of Drain Wire Flexible ATC

d) Size of Drain Wire (Approx.) 0.5 mm²(16/0.2 mm)

8 Innersheath

a) Material Extruded PVC Type ST1 to IS: 5831

b) Minimum Thickness mm 0.3

9 Armouring

a) Material Galvanised Steel

b) Type of armouring Round Wire

c) Nominal size of armour (mm) 0.9

d) Tolerance on armour dimensions ± 0.030 mm

10 Outersheath

a) Material Extruded FR-LSH PVC Type ST1 to IS: 5831

b) Thickness mm 1.24 (Min.)

c) colour of sheath Blue

11 FR-LSH PROPERTIES

a) Oxygen Index Min. 29% as per ASTM D- 2863

b) Temperature Index Min. 250 Deg.C as per ASTM D- 2863

c) Smoke Density Rating Max. 60% as per ASTM D- 2843

d) Acid Gas Generation Max. 20% as per IEC- 754- 1

e) Flammability Test As per IEC:332-I

Maximum conductor temperature under normal operating

12 70

conditions °C

13 Minimum bending radius 12 times Overall diameter

14 Electrical Parameters

a) Mutual capacitance nf/km <250

b) Insulation resistance MΩ/km 10

c) Inductance to resistance ratio (L/R) µH/Ω <25

d) Dielectric strength for 1 minute (H.V Test) kV 2.0

Max. tensile strength for Cables pulled with stocking

15 9 x D², D is the cable OD in mm

(Newtons)

16 Approximate Overall diameter of cable mm 13 ± 2.0

17 Applicable Standard Generally as per IS 1554 Part I/88 & BSEN 50288-7

18 Standard Drum Length (Mtr.) 1000 ± 5%

19 Non-Standard Drum Length (Mtr.) Maximum 5% of order quantity

20 Embossing POLYCAB 300/500 VOLTS GRADE FR-LSH

YEAR POLYCAB 300/500 VOLTS GRADE FR-LSH CABLE SIZE

21 Printing SCREENED with SEQUENTIAL LENGTH MARKING at EVERY ONE

METER INTERVAL

Note:-The values given above are subject to tolerances as per the relevant standards.

You might also like

- Milas, Turkey Ltfe/Bjv: 1.1. Atis 1.2. Preferential Rwy System Operations 1. GeneralDocument26 pagesMilas, Turkey Ltfe/Bjv: 1.1. Atis 1.2. Preferential Rwy System Operations 1. GeneralTweed3A100% (2)

- Instrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- Instrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- GTP - 33KV (E) 3C AL XLPE Armd CableDocument1 pageGTP - 33KV (E) 3C AL XLPE Armd Cableshivam dwivediNo ratings yet

- GTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5Document3 pagesGTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5santhoshNo ratings yet

- Hmnjopl PDFDocument1 pageHmnjopl PDFAjay PrajapatiNo ratings yet

- 0 75px1tscnarmdDocument2 pages0 75px1tscnarmdnmpkumarNo ratings yet

- GTP - 11KV (E) 3C AL XLPE Armd CableDocument1 pageGTP - 11KV (E) 3C AL XLPE Armd Cableshivam dwivedi100% (1)

- Lvis09axsfy23 5c300sa002sDocument1 pageLvis09axsfy23 5c300sa002sVishal SharmaNo ratings yet

- GTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding CableDocument1 pageGTP - 1.9 (3.3) KV 240 SQ - MM Sheath Bonding Cableshivam dwivedi100% (1)

- Technical Data Sheet (Triad Cable For Gas Detector)Document3 pagesTechnical Data Sheet (Triad Cable For Gas Detector)Vinod RajputNo ratings yet

- DATA SHEET of C&I Cable For VF 1 - Rev 01Document2 pagesDATA SHEET of C&I Cable For VF 1 - Rev 01soumya voraNo ratings yet

- Electrical Cable - GTPDocument3 pagesElectrical Cable - GTPNawfel ArafathNo ratings yet

- LVIS09CXSFYL004C010SA001SDocument1 pageLVIS09CXSFYL004C010SA001Ssuvir VigneshNo ratings yet

- Fsis09cxswyl004c006sa (FR LSH)Document1 pageFsis09cxswyl004c006sa (FR LSH)pkNo ratings yet

- 400PX3CHT33UEFLATDocument2 pages400PX3CHT33UEFLATjayesh95395No ratings yet

- 10X4 A2xfy (FRLS) Alum ArmdDocument2 pages10X4 A2xfy (FRLS) Alum ArmdParth DhobiNo ratings yet

- Cable GTPDocument1 pageCable GTPtukaram.pawarNo ratings yet

- LT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02Document2 pagesLT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02y8jkfz98m9No ratings yet

- GTP - 1.1kv 1c Copper Xlpe Armd CableDocument1 pageGTP - 1.1kv 1c Copper Xlpe Armd CableShivam DwivediNo ratings yet

- Data Sheet For LT XLPE Cable: S.No Particulars 3.5 X 50Document2 pagesData Sheet For LT XLPE Cable: S.No Particulars 3.5 X 50AteebNo ratings yet

- 2c x1.5 FAS CableDocument1 page2c x1.5 FAS CableSanjay KumarNo ratings yet

- 10X4 A2xfy Alum - ArmdDocument2 pages10X4 A2xfy Alum - ArmdParth DhobiNo ratings yet

- Polycab 300mm 3 Core Aluminium Armoured Cable Specification SheetDocument2 pagesPolycab 300mm 3 Core Aluminium Armoured Cable Specification SheetZIRWA ENTERPRISESNo ratings yet

- Polycab 16mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 16mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- Datasheet CableDocument2 pagesDatasheet CableVyrax FalconNo ratings yet

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- 3SFL 2core Power Cable SpecsDocument1 page3SFL 2core Power Cable Specssandeep bagulNo ratings yet

- 4C X 10 EPR PCP Rubber GTPDocument1 page4C X 10 EPR PCP Rubber GTPsyamprasadNo ratings yet

- 1C X 2.50 SQMM PTFE Single Core CableDocument1 page1C X 2.50 SQMM PTFE Single Core CablerijoNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.JayagurunathanNo ratings yet

- 1 Triad AbcDocument4 pages1 Triad AbcAnamulKabirNo ratings yet

- Datasheet For Cable: 1 Pair Overall Shielded Armoured Cable, Type F (Single Pair Cable Shall Have Only Overall Shielding)Document4 pagesDatasheet For Cable: 1 Pair Overall Shielded Armoured Cable, Type F (Single Pair Cable Shall Have Only Overall Shielding)AnamulKabirNo ratings yet

- Lvbs09cxswy2004c1 5sa002sDocument1 pageLvbs09cxswy2004c1 5sa002sKrishNo ratings yet

- 2 5px3cywystrfrlsDocument2 pages2 5px3cywystrfrlsKrish0% (1)

- Cable GTPDocument1 pageCable GTPAnwar HussainNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.rajesh1200No ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSWYL003C004SA001S Date: Rev No.rajesh1200No ratings yet

- 400PX3 5caywyxlpeDocument2 pages400PX3 5caywyxlpeAnonymous SDeSP1No ratings yet

- 2 5px12cywyfrlsstrDocument2 pages2 5px12cywyfrlsstramzad aliNo ratings yet

- 4374 - Ep - Q0111 - Ca12 - Eda010 - 005 - 02 Cable DatasheetDocument2 pages4374 - Ep - Q0111 - Ca12 - Eda010 - 005 - 02 Cable DatasheetMokasabiNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.rajesh1200No ratings yet

- GEN GP 208 5143 SRNo A1 141010 PDFDocument4 pagesGEN GP 208 5143 SRNo A1 141010 PDFdamlanNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSFY2012C2.5SA004S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09CXSFY2012C2.5SA004S Date: Rev No.Anonymous SDeSP1No ratings yet

- 33 KV 3 Core Aluminium XLPE CableDocument3 pages33 KV 3 Core Aluminium XLPE CableSai KumarNo ratings yet

- FSBS07CXSWLS002C2 5saDocument1 pageFSBS07CXSWLS002C2 5sapradeepyellurNo ratings yet

- L&T Bhilai Gtp-01 Dated 24-04-12Document3 pagesL&T Bhilai Gtp-01 Dated 24-04-12ashokbathwalNo ratings yet

- Sr. No. 3A Datasheet 4PX3CYWY 100Document2 pagesSr. No. 3A Datasheet 4PX3CYWY 100hemantmech099200No ratings yet

- GTP 3.5X120Document2 pagesGTP 3.5X120Rajat KesarwaniNo ratings yet

- 3C1.5 2xwy LSZHDocument1 page3C1.5 2xwy LSZHAkhil SasidharanNo ratings yet

- Document ID: TE/QMS/F/02 Rev. No.: 00 - Issued Date: 02/04/2018Document1 pageDocument ID: TE/QMS/F/02 Rev. No.: 00 - Issued Date: 02/04/2018dhanishlNo ratings yet

- Technical Specifications of The 2 Core, 1.5 Sq. MM, Un-Armoured Cable: Sr. No Description DataDocument4 pagesTechnical Specifications of The 2 Core, 1.5 Sq. MM, Un-Armoured Cable: Sr. No Description DataNikhil KarkeraNo ratings yet

- (62-110kV) NKT 1x630mm2 XLPE AlDocument4 pages(62-110kV) NKT 1x630mm2 XLPE AlFahad UsmanNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSWY2004C010SA003S Date: Rev No.rajesh1200100% (1)

- Technical Data SheetDocument2 pagesTechnical Data SheetsyamprasadNo ratings yet

- 33kv Cables GTPDocument3 pages33kv Cables GTPManohar Potnuru100% (1)

- 2 5PX3CBLKFRLS100 PDFDocument1 page2 5PX3CBLKFRLS100 PDFSushil Kumar ShuklaNo ratings yet

- 11kV AbcDocument2 pages11kV AbcJeetendra Dev ChhetriNo ratings yet

- 1.93.3KV 3Cx 35 SQMM Cable GTPDocument1 page1.93.3KV 3Cx 35 SQMM Cable GTPDarshit VyasNo ratings yet

- 1.5sqmm X 3C Arm DatasheetDocument2 pages1.5sqmm X 3C Arm DatasheetAshwin SupeNo ratings yet

- 1 Revised MRP Metal 100723Document24 pages1 Revised MRP Metal 100723Jainam ShahNo ratings yet

- Bosch GSB 501 DatasheetDocument7 pagesBosch GSB 501 DatasheetJainam ShahNo ratings yet

- Crompton Mini Series PumpDocument172 pagesCrompton Mini Series PumpJainam ShahNo ratings yet

- ts1w1 1 20aDocument1 pagets1w1 1 20aJainam ShahNo ratings yet

- Kova Brochure 2019Document12 pagesKova Brochure 2019Jainam ShahNo ratings yet

- Dipl.-Ing. W. Bender GMBH & Co. KG - Londorfer Str. 65 - 35305 Grünberg - Tel.: 06401 807-0 - Fax: 06401 807-259Document3 pagesDipl.-Ing. W. Bender GMBH & Co. KG - Londorfer Str. 65 - 35305 Grünberg - Tel.: 06401 807-0 - Fax: 06401 807-259Hoang Minh HungNo ratings yet

- Factors Affecting The Purchase Decision of Investors in The Residential Property Market in MalaysiaDocument13 pagesFactors Affecting The Purchase Decision of Investors in The Residential Property Market in MalaysiaieymaNo ratings yet

- AR and Sales Audit ProgramDocument10 pagesAR and Sales Audit ProgramHarold Dan AcebedoNo ratings yet

- POETRYDocument16 pagesPOETRYvj hernandezNo ratings yet

- Android SQLite Database With Multiple Tables ExampleDocument27 pagesAndroid SQLite Database With Multiple Tables Examplehabaoanh100% (1)

- Basic 7 - Computing - Emt 1 - Prof DukerDocument5 pagesBasic 7 - Computing - Emt 1 - Prof DukerEdd NoddNo ratings yet

- Bank of America Merrill Lynch Q3 2010 Hedge Fund Industry OverviewDocument31 pagesBank of America Merrill Lynch Q3 2010 Hedge Fund Industry OverviewYA2301No ratings yet

- Virus or Bacteria - What's The Difference?Document1 pageVirus or Bacteria - What's The Difference?vallabhaneni rajeshNo ratings yet

- Experimental and Numerical Evaluation of Transparent BulletproofDocument12 pagesExperimental and Numerical Evaluation of Transparent BulletproofAlfonso TenaNo ratings yet

- 1267379259Document7 pages1267379259sinasayedanaNo ratings yet

- Instructional Module: Republic of The Philippines Nueva Vizcaya State University Bayombong, Nueva VizcayaDocument3 pagesInstructional Module: Republic of The Philippines Nueva Vizcaya State University Bayombong, Nueva VizcayaJershon DulnuanNo ratings yet

- SCDF fsc02 RFSP Oct 2020 v2Document6 pagesSCDF fsc02 RFSP Oct 2020 v2Jason HeNo ratings yet

- Genesis-DT enDocument6 pagesGenesis-DT enabdoNo ratings yet

- Welcome To The Presentation: Unit 27 - Identifying Entrepreneurial OpportunitiesDocument13 pagesWelcome To The Presentation: Unit 27 - Identifying Entrepreneurial OpportunitiesBadhon RahmanNo ratings yet

- SOR Civil Engineering Works 2016Document31 pagesSOR Civil Engineering Works 2016guees897067100% (1)

- Atomic Clock: by Saad GillaniDocument6 pagesAtomic Clock: by Saad GillaniMuhammad HamzaNo ratings yet

- Full Download Human Memory 2nd Radvansky Test Bank PDF Full ChapterDocument36 pagesFull Download Human Memory 2nd Radvansky Test Bank PDF Full Chaptersugarysestine.fllo5z100% (19)

- Ra 7719Document7 pagesRa 7719misterdodiNo ratings yet

- Schlumberger Azimuthal LWD Tool DescriptionDocument9 pagesSchlumberger Azimuthal LWD Tool DescriptionSteven Marinoff100% (1)

- Gearless MGI27SDocument3 pagesGearless MGI27SMk KuraNo ratings yet

- Danone PMDocument9 pagesDanone PMnghia_ho_15No ratings yet

- Big Picture Big Picture Practice July 2017Document2 pagesBig Picture Big Picture Practice July 2017Edison halim100% (1)

- Orth Update 2023 16 105-105Document1 pageOrth Update 2023 16 105-105jlkdsjfljsdlfNo ratings yet

- Fabric ControllerDocument2 pagesFabric Controllernaveenkj16No ratings yet

- Homework Oh Homework by Jack PrelutskyDocument7 pagesHomework Oh Homework by Jack PrelutskyafodbdskjhibkoNo ratings yet

- Ratna Nur AtikahDocument90 pagesRatna Nur AtikahSHAFANISA SAZLEANA BILQISNo ratings yet

- (Alain M. Gowing) Empire and Memory The Represent PDFDocument194 pages(Alain M. Gowing) Empire and Memory The Represent PDFlivrosNo ratings yet

- Datasheet+Fech3+Fixed+03gf0348 2Document2 pagesDatasheet+Fech3+Fixed+03gf0348 2andalibazarNo ratings yet

- Feed Refernce Standard in The PhilippinesDocument3 pagesFeed Refernce Standard in The PhilippinesbbandojaNo ratings yet