Professional Documents

Culture Documents

Technical Data Sheet

Uploaded by

syamprasadCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Technical Data Sheet

Uploaded by

syamprasadCopyright:

Available Formats

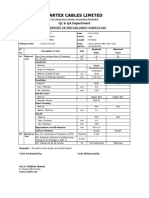

HAVELLS INDIA LTD.

(CABLE DIVISION) - ALWAR

Technical Particulars

ID: 14935 Date: 03.12.2021

Sr.No.Descriptions Unit 3.5CX95

A General Detail

1 SAP Code CHLABLTFHK3H095

2 Nos. of Core NO. 3.50

3 Nominal cross sectional area SQ.MM 95.00

4 Type of Cable(Cable Code) A2XFY(T)

5 Applicable Standard IS: 7098 PART-1/88, IS: 8130/2013, IS: 3975/99, IS: 5831/84 With up to date

amendment

6 Voltage Grade KV 1.1

B Conductor

1 Material ALUMINIUM E. C. GRADE

2 Shape of Conductor Stranded compacted shaped

3 Nominal size

a) Main SQMM 95.00

b) Reduced Neutral SQMM 50.00

4 Minimum No.of Strand in each Conductor

a) Main NO. 15

b) Reduced Neutral NO. 6

Min. Size of strand shall be corresponding to meet the requirements of

conductor Resistance as per relevant clause of I.S. -8130 with upto date

amendment

C Screening on Conductor

1 Type & Material NA

2 Thickness Approx 0.00

3 Continuous working temperature. 0.00

D Insulation

1 Type & Material Extruded X.L.P.E. conforming to IS: 7098 PT-1

2 Thickness Nominal

a) Main MM 1.10

b) Reduced Neutral MM 1.00

E Screening on Insulation(Non-Metallic Part)

1 Type & Material NA

2 Thickness Approx 0.00

F Copper Taping/Metallic Part

1 Type & Material NA

2 Approx. thickness 0.000

3 Cores Identification By Providing Red, Yellow, Blue & Black color

4 Fictitious calculated Laid up dia MM 30.01

G Inner Sheath

1 Type & Material Thermoplastic

2 Application Wrapped

3 Thickness Minimum MM 0.40

H Filler

1 Material NA

I Armour

1 Type & Material Single Layer of Galvanized steel Flat Strip, Conforming to IS : 3975

2 Nom. Dim. of Armour Flat Strip / Round Wire MM 4X0.8 ± 10%

HAVELLS INDIA LTD. (CABLE DIVISION) - ALWAR

Technical Particulars

I Armour

J Outer Sheath

1 Type & Material Extruded PVC Type ST-2 , conforming to IS : 5831

2 Application BY-Extruded

3 Thickness Nominal (For unarmoured cables) MM 0.00

4 Thickness Minimum (For armoured/unarmoured cables) MM 1.56

5 Colour of outer sheath BLACK

K Special Properties of outer sheath

1 Oxygen index test -

2 Temperature Index Test -

3 Acid Gas Generation -

4 Smoke generation Test -

5 Flammability test -

L Electrical Characteristics

1 Max. Conductor DC Resistance at 20°C

a) Main OHM/KM 0.3200

b) Reduced Neutral OHM/KM 0.6410

2 Approx. Conductor AC Resistance at max. Operating Temp

a) Main OHM/KM 0.4110

b) Reduced Neutral OHM/KM 0.8200

3 Approx. Reactance at 50 Hz OHM/KM 0.0740

4 Approx. Capacitance of Cable MICROF/KM 0.2900

5 Min. volume resistivity of insulation OHM-CM 1 X 10^14 at 27 Deg. C & 1 X 10^12 at 90 Deg.C

6 Cont. Current Rating for Standard IS Condition when Laid

a) In Ground at 30°C AMPS 200.00

b) In Duct at 30°C AMPS 165.00

c) In Air. at 40°C AMPS 221.00

7 Allowable max. cond. Temp. When carrying Cont. rated DEG.C 90.00

current

8 Short Circuit Current Rating for 1 Sec. Duration KAMPS 8.93

9 Max. Conductor Temperature allowed for the short circuit DEG.C 250.00

condition

M General Information

1 Overall Diameter of cable(approx.) MM 34.00

2 Net weight of cable (approx.) KG/KM 1850.00

3 Standard drum length Meter 1000/500 ± 5%

4 Non Standard drum length Max. 5 % of ordered quantity

5 Recommended min. Bending radius of cable MM 12 X D (WHERE D IS OVERALL DIAMETER OF CABLE IN MM)

6 Recommended Max. Safe pulling force

a) When cond. pulled by pulling eye N 30 x T ( where T is total cross sectional area of cond . In sqmm

b) When cable pulled by stocking N 9 X D^2 (where D is overall diameter of cable in mm)

7 Marking Detail ( by embossing / printing ) HAVELLS 1100V XLPE ELECTRIC CABLE (SIZE IN SQ.MM)

8 Sequential marking of length Shall be printed at every meter of length on outer sheath

9 Packing Material Non Returnable wooden drums

* Values indicated as " Approx." are for guidelines only

* In case of any Typographical Error / Discrepancy , relevant standards shall be prevailed.

You might also like

- Acoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsFrom EverandAcoustic Wave Sensors: Theory, Design and Physico-Chemical ApplicationsNo ratings yet

- GTP 3.5X120Document2 pagesGTP 3.5X120Rajat KesarwaniNo ratings yet

- 1.93.3KV 3Cx 35 SQMM Cable GTPDocument1 page1.93.3KV 3Cx 35 SQMM Cable GTPDarshit VyasNo ratings yet

- GEN GP 208 5143 SRNo A1 141010 PDFDocument4 pagesGEN GP 208 5143 SRNo A1 141010 PDFdamlanNo ratings yet

- GTP 50Document2 pagesGTP 50er.manishnhpcNo ratings yet

- Technical Data Sheet: Item Name Description Item Code Spec. Ref. Customer RG 62 93 Ohm Coaxial CableDocument1 pageTechnical Data Sheet: Item Name Description Item Code Spec. Ref. Customer RG 62 93 Ohm Coaxial CableManoj GuptaNo ratings yet

- 2.5mm Two Core: Description Units DetailDocument2 pages2.5mm Two Core: Description Units DetailMuhammad Shabbir AwanNo ratings yet

- Instrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 4 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- Partex Cables Limited: QC & QA DepartmentDocument6 pagesPartex Cables Limited: QC & QA DepartmentAbdullah Al AsikNo ratings yet

- 1PX12PSCNARMDDocument1 page1PX12PSCNARMDJainam ShahNo ratings yet

- 6 RR FR LSHDocument1 page6 RR FR LSHGaurav MittalNo ratings yet

- Technical Specifications of The 2 Core, 1.5 Sq. MM, Un-Armoured Cable: Sr. No Description DataDocument4 pagesTechnical Specifications of The 2 Core, 1.5 Sq. MM, Un-Armoured Cable: Sr. No Description DataNikhil KarkeraNo ratings yet

- Technical Data Sheet (Triad Cable For Gas Detector)Document3 pagesTechnical Data Sheet (Triad Cable For Gas Detector)Vinod RajputNo ratings yet

- GTP - 1.1kv 1c Copper Xlpe Armd CableDocument1 pageGTP - 1.1kv 1c Copper Xlpe Armd CableShivam DwivediNo ratings yet

- Lvis09axsfy23 5c300sa002sDocument1 pageLvis09axsfy23 5c300sa002sVishal SharmaNo ratings yet

- Fsis09cxswyl004c006sa (FR LSH)Document1 pageFsis09cxswyl004c006sa (FR LSH)pkNo ratings yet

- DS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstDocument3 pagesDS - (Q-0456-R2) Agrawal Machinery Stroes - LT Screen & InstAppzNo ratings yet

- Instrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDSDocument2 pagesInstrumentation-Cables 1.5SQMM 6P 300-500-V Copper Stranded Pvc-Type-A Overall-Al-Mylar PVC-ST1 Gi-Wire FRLSH TDShydrothermsNo ratings yet

- LT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02Document2 pagesLT Xlpe Cable: Design Code: Lvis09Cxswyl002C1.5Sa004S Document ID:TE/QMS/F/02y8jkfz98m9No ratings yet

- Datasheet CableDocument2 pagesDatasheet CableVyrax FalconNo ratings yet

- 0 75px1tscnarmdDocument2 pages0 75px1tscnarmdnmpkumarNo ratings yet

- DATA SHEET of C&I Cable For VF 1 - Rev 01Document2 pagesDATA SHEET of C&I Cable For VF 1 - Rev 01soumya voraNo ratings yet

- Test Report: SL Unit Required Observed No Value Value 01 Physical 120 120 Test Description of TestDocument1 pageTest Report: SL Unit Required Observed No Value Value 01 Physical 120 120 Test Description of TestSarowar HossainNo ratings yet

- GTP 120Document2 pagesGTP 120er.manishnhpcNo ratings yet

- GTP HavellsDocument24 pagesGTP HavellsPradeep GoelNo ratings yet

- 2c x1.5 FAS CableDocument1 page2c x1.5 FAS CableSanjay KumarNo ratings yet

- Keystone Fire Alarm Cables (Twisted Pair Non Sheathed)Document3 pagesKeystone Fire Alarm Cables (Twisted Pair Non Sheathed)Edwin LoquinaNo ratings yet

- Universal Cable (M) Berhad: Schedule of Technical ParticularsDocument1 pageUniversal Cable (M) Berhad: Schedule of Technical Particularsmohd darusNo ratings yet

- NA2XS (F) 2Y 12-20 KV 1x400Document2 pagesNA2XS (F) 2Y 12-20 KV 1x400plavi10No ratings yet

- GTP 240Document2 pagesGTP 240er.manishnhpcNo ratings yet

- LVIS09CXSFYL004C010SA001SDocument1 pageLVIS09CXSFYL004C010SA001Ssuvir VigneshNo ratings yet

- FWD Document From Sameer Bani HaniDocument2 pagesFWD Document From Sameer Bani HaniImad HabboubNo ratings yet

- CATM3Document4 pagesCATM3Shaswat JhaNo ratings yet

- GTP 185Document3 pagesGTP 185er.manishnhpcNo ratings yet

- Cable GTPDocument1 pageCable GTPtukaram.pawarNo ratings yet

- Belden 8762Document1 pageBelden 8762AlerianoNo ratings yet

- 11kV AbcDocument2 pages11kV AbcJeetendra Dev ChhetriNo ratings yet

- FICHA TECNICA - 3X 35+50 SQ - MM AB CableDocument1 pageFICHA TECNICA - 3X 35+50 SQ - MM AB Cablejohana leonNo ratings yet

- 3SFL 2core Power Cable SpecsDocument1 page3SFL 2core Power Cable Specssandeep bagulNo ratings yet

- 10X4 A2xfy (FRLS) Alum ArmdDocument2 pages10X4 A2xfy (FRLS) Alum ArmdParth DhobiNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C120SA001S Date: Rev No.rajesh1200No ratings yet

- Caract Tecnicas Opgw Lsgs-11-Po0186 24sDocument4 pagesCaract Tecnicas Opgw Lsgs-11-Po0186 24sKamal ArreazaNo ratings yet

- Solar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Document1 pageSolar Cable GTP 2.5 TO 50 SQ - MM - XLPE 1 1Koushik KarmakarNo ratings yet

- Data Sheet For LT XLPE Cable: S.No Particulars 3.5 X 50Document2 pagesData Sheet For LT XLPE Cable: S.No Particulars 3.5 X 50AteebNo ratings yet

- Technical Specification of 1x10 RM 2XY-LSZH (Fire Resistance)Document1 pageTechnical Specification of 1x10 RM 2XY-LSZH (Fire Resistance)jamilNo ratings yet

- GTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5Document3 pagesGTP - 12PX0.5,6PX0.75,2PX0.5,10PX0.5santhoshNo ratings yet

- Polycab 10mm 3 Core Copper Armoured Cable Specification SheetDocument2 pagesPolycab 10mm 3 Core Copper Armoured Cable Specification SheetbharathNo ratings yet

- Manufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.Document2 pagesManufacturing Data Sheet: Low Voltage XLPE Cable Design Code: LVIS09AXSFY23.5C070SA002S Date: Rev No.JayagurunathanNo ratings yet

- CATM4Document4 pagesCATM4Shaswat JhaNo ratings yet

- Electrical Cable - GTPDocument3 pagesElectrical Cable - GTPNawfel ArafathNo ratings yet

- Ficha Tecnica - 3X70+50 MM y 3X95+50 MMDocument1 pageFicha Tecnica - 3X70+50 MM y 3X95+50 MMjohana leonNo ratings yet

- 400PX3 5caywyxlpeDocument2 pages400PX3 5caywyxlpeAnonymous SDeSP1No ratings yet

- TPG Xiii.2.4 - Opgw 60 MMDocument5 pagesTPG Xiii.2.4 - Opgw 60 MMALVINNo ratings yet

- Sc. Cl. - 001 - SAR0214HFESL-F3 (IE) CDocument1 pageSc. Cl. - 001 - SAR0214HFESL-F3 (IE) CSudarshika SumathipalaNo ratings yet

- 1x50 RM 2xHSYRaY (CTS)Document2 pages1x50 RM 2xHSYRaY (CTS)Rakib HasanNo ratings yet

- 10X4 A2xfy Alum - ArmdDocument2 pages10X4 A2xfy Alum - ArmdParth DhobiNo ratings yet

- Technical Delivery Condition: LBST Specification Code: LB 304Document2 pagesTechnical Delivery Condition: LBST Specification Code: LB 304Prasenjit PuriNo ratings yet

- Form 31 Application and Intimation of Transfer of Ownership in The Name of The Person Succeeding To The Possession of The VehicleDocument2 pagesForm 31 Application and Intimation of Transfer of Ownership in The Name of The Person Succeeding To The Possession of The VehiclesyamprasadNo ratings yet

- COVID-19 Vaccination Appointment Details: Center Date Time Preferred Time SlotDocument1 pageCOVID-19 Vaccination Appointment Details: Center Date Time Preferred Time SlotEKLAVYA JANGIRNo ratings yet

- Tamilnadu Coke and Power 2kva On Grid Solar SystemDocument1 pageTamilnadu Coke and Power 2kva On Grid Solar SystemsyamprasadNo ratings yet

- Tamilnadu Coke and Power 2kva +2kvaDocument1 pageTamilnadu Coke and Power 2kva +2kvasyamprasadNo ratings yet

- SDT G2 Series: Technical DataDocument1 pageSDT G2 Series: Technical DataAshik MahmudNo ratings yet

- 169 KW Solar Power Plant - SLDDocument1 page169 KW Solar Power Plant - SLDsyamprasadNo ratings yet

- 33kv Line FDocument1 page33kv Line FsyamprasadNo ratings yet

- ABT Meter Specification GeneralDocument4 pagesABT Meter Specification GeneralsyamprasadNo ratings yet

- Solar Panel and Inverter - Serial NosDocument4 pagesSolar Panel and Inverter - Serial NossyamprasadNo ratings yet

- Tamil Nadu Coke-24 V DCDocument14 pagesTamil Nadu Coke-24 V DCsyamprasadNo ratings yet

- 36 KV, 1250a VCB GTP - r1Document3 pages36 KV, 1250a VCB GTP - r1t_syamprasadNo ratings yet

- Bus Bar Design and ProtectionDocument58 pagesBus Bar Design and ProtectionMohammedSaadaniHassani100% (4)

- Lan Details0122Document1 pageLan Details0122t_syamprasadNo ratings yet

- Lan Details0122Document1 pageLan Details0122t_syamprasadNo ratings yet

- Ball and Roller BearingsDocument105 pagesBall and Roller Bearingssamurai7_77No ratings yet

- Lan Details0122Document1 pageLan Details0122t_syamprasadNo ratings yet

- 160, 161, 60, S60, 618, 62, .2ZR (.2Z) .2RSR (.2RS) S62, 622, 623, 63, S63, 64Document17 pages160, 161, 60, S60, 618, 62, .2ZR (.2Z) .2RSR (.2RS) S62, 622, 623, 63, S63, 64hengki wibowoNo ratings yet

- Cleaning Mounting and Removal of BearingDocument23 pagesCleaning Mounting and Removal of Bearingt_syamprasadNo ratings yet

- WL 41520 SpindleDocument18 pagesWL 41520 Spindlehengki wibowoNo ratings yet

- Technical Specification FOR: Aluminium Tubular Bus BarDocument11 pagesTechnical Specification FOR: Aluminium Tubular Bus BarMadhan KannanNo ratings yet

- Properties of Extruded Aluminum PipeDocument1 pageProperties of Extruded Aluminum PipesyamprasadNo ratings yet

- Javascript Notes For ProfessionalsDocument490 pagesJavascript Notes For ProfessionalsDragos Stefan NeaguNo ratings yet

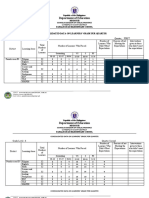

- Department of Education: Consolidated Data On Learners' Grade Per QuarterDocument4 pagesDepartment of Education: Consolidated Data On Learners' Grade Per QuarterUsagi HamadaNo ratings yet

- TIA Guidelines SingaporeDocument24 pagesTIA Guidelines SingaporeTahmidSaanidNo ratings yet

- IJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyDocument12 pagesIJRHAL - Exploring The Journey of Steel Authority of India (SAIL) As A Maharatna CompanyImpact JournalsNo ratings yet

- MPI Unit 4Document155 pagesMPI Unit 4Dishant RathiNo ratings yet

- ChatGPT & EducationDocument47 pagesChatGPT & EducationAn Lê Trường88% (8)

- 2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyDocument9 pages2014 - Intelligence As A Predictor of Outcome in Short-And Long-Term PsychotherapyZayne CarrickNo ratings yet

- L GSR ChartsDocument16 pagesL GSR ChartsEmerald GrNo ratings yet

- CHAPTER 2 Part2 csc159Document26 pagesCHAPTER 2 Part2 csc159Wan Syazwan ImanNo ratings yet

- BPS C1: Compact All-Rounder in Banknote ProcessingDocument2 pagesBPS C1: Compact All-Rounder in Banknote ProcessingMalik of ChakwalNo ratings yet

- Group Case Study Rubric 3Document3 pagesGroup Case Study Rubric 3Saraswathi Asirvatham67% (3)

- Documentation Report On School's Direction SettingDocument24 pagesDocumentation Report On School's Direction SettingSheila May FielNo ratings yet

- Installation Instructions INI Luma Gen2Document21 pagesInstallation Instructions INI Luma Gen2John Kim CarandangNo ratings yet

- HRM Practices in NepalDocument22 pagesHRM Practices in NepalBodhiNo ratings yet

- Ilovepdf MergedDocument503 pagesIlovepdf MergedHemantNo ratings yet

- Installing Surge Protective Devices With NEC Article 240 and Feeder Tap RuleDocument2 pagesInstalling Surge Protective Devices With NEC Article 240 and Feeder Tap RuleJonathan Valverde RojasNo ratings yet

- FIR FliterDocument10 pagesFIR FliterasfsfsafsafasNo ratings yet

- Engineering Ethics in Practice ShorterDocument79 pagesEngineering Ethics in Practice ShorterPrashanta NaikNo ratings yet

- Swelab Alfa Plus User Manual V12Document100 pagesSwelab Alfa Plus User Manual V12ERICKNo ratings yet

- Internal Resistance To Corrosion in SHS - To Go On WebsiteDocument48 pagesInternal Resistance To Corrosion in SHS - To Go On WebsitetheodorebayuNo ratings yet

- 28 TerminalsDocument42 pages28 TerminalsAlin FazacasNo ratings yet

- Logistic RegressionDocument7 pagesLogistic RegressionShashank JainNo ratings yet

- 2.a.1.f v2 Active Matrix (AM) DTMC (Display Technology Milestone Chart)Document1 page2.a.1.f v2 Active Matrix (AM) DTMC (Display Technology Milestone Chart)matwan29No ratings yet

- For Accuracy and Safety: Globally ApprovedDocument4 pagesFor Accuracy and Safety: Globally ApprovedPedro LopesNo ratings yet

- Designed For Severe ServiceDocument28 pagesDesigned For Severe ServiceAnthonyNo ratings yet

- Trucks Part NumbersDocument51 pagesTrucks Part NumbersBadia MudhishNo ratings yet

- Categorical SyllogismDocument3 pagesCategorical SyllogismYan Lean DollisonNo ratings yet

- Strategic Management SlidesDocument150 pagesStrategic Management SlidesIqra BilalNo ratings yet

- SM EFATEX Rev D2 3 1 2018 PDFDocument20 pagesSM EFATEX Rev D2 3 1 2018 PDFGuilhermePlacidoNo ratings yet

- FT2020Document7 pagesFT2020Sam SparksNo ratings yet