Professional Documents

Culture Documents

Fundamentals MIG Welding 25.06.13

Fundamentals MIG Welding 25.06.13

Uploaded by

Sridhar CnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fundamentals MIG Welding 25.06.13

Fundamentals MIG Welding 25.06.13

Uploaded by

Sridhar CnCopyright:

Available Formats

8 Consumables

Fundamentals of Metal

Inert Gas (MIG) Welding

Welding Technique Common Materials Welded with BOC MIG Wire

Successful welding depends on the following factors:

1� Selection of correct consumables Material BOC MIG Wire

2� Selection of the correct power source AS2074 C1, C2, C3, C4-1, BOC Mild Steel MIG Wire

C4-2, C5, C6

3� Selection of the correct shielding gas

AS/NZS 3678-9 250, 300, 350, 400 BOC Mild Steel MIG Wire

4� Selection of the correct application techniques:

AS1548-430, 460, 490 BOC Mild Steel MIG Wire

a Correct angle of electrode to work

b Correct electrical stick-out ASTM A36, A106 BOC Mild Steel MIG Wire

c Correct travel speed Stainless Steel

5� Selection of the welding preparation.

Grade 304 BOC Stainless Steel 308LSi

Selection of correct consumables Stainless to Carbon-Mn steels

Chemical composition Grade 316 BOC Stainless Steel 316LSi

As a general rule, the selection of a wire is straightforward, in that Aluminium

it is only a matter of selecting an electrode of similar composition 1080 BOC Aluminium MIG 1080

to the parent material. However, there are certain applications

6061, 3004 BOC Aluminium MIG 4043

for which electrodes will be selected on the basis of mechanical

properties or the level of residual hydrogen in the weldmetal. Solid 5005 BOC Aluminium MIG 5356

MIG wires are all considered to be of the ‘low hydrogen type’

consumables. Physical condition

The following table gives a general overview of some of the Surface condition.

BOC range of MIG wires for the most common materials. More

The welding wire must be free from any surface contamination,

detailed selection charts for specific materials can be found in the

including mechanical damage such as scratch marks.

appropriate materials sections.

A simple test for checking the surface condition is to run the wire

through a cloth that has been dampened with acetone for 20sec. If

Material Page No a black residue is found on the cloth, the surface of the wire is not

Mild and Alloy steel 351 properly cleaned.

Quench and tempered steels 353 Cast and Helix.

Ferritic materials 352 The cast and helix of the wire has a major influence on the

Stainless steel 406

feedability of MIG wire.

Aluminium 425

Cast

Helix

WARNING W elding can give rise to electric shock, excessive noise, eye and skin burns due to the arc rays, and a potential health hazard if you breathe in the emitted fumes and gases.

Read all the manufacturer’s instructions to achieve the correct welding conditions and ask your employer for the Materials Safety Data Sheets. Refer to www.boc.com.au or www.boc.co.nz

318 AU : IPRM 2007 : Section 8 : consumables

Fundamentals of Metal Inert Gas (MIG) Welding 8

Cast – Diameter of the circle Different grades of shielding are required for materials such as

Helix – Vertical height stainless steel, aluminium and copper.

If the cast is too small, the wire will dip down from the tip. The The following table gives an indication of the most common

result of this is excessive tip wear and increased wear in the liners. shielding gases used for carbon manganese and alloy steels:

If the helix is too large, the wire will leave the tip with a corkscrew

Material thickness Recommended shielding gas

effect and cause feeding problems.

1–8 mm Argoshield Light

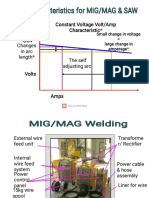

Selection of the Correct Power Source 5–12 mm Argoshield Universal

Power sources for MIG / MAG welding is selected on a number of >12 mm Argoshield Heavy

different criteria, including:

1� Maximum output of the machine More detailed selection charts, including recommendations for

welding parameters (voltage, amperage, electrical stick-out, travel

2� Duty cycle

speed and gas flow rate) can be found in the following sections:

3� Output control (voltage selection, wire feed speed control)

4� Portability

Material Page

The following table gives an indication of the operating amperage

C-Mn and Alloy Steels

for different size wires

Argoshield Light 60

Argoshield Universal 61

Wire Size Amperage Range (A)

Argoshield Heavy 62

0.8 mm 60–180

Argoshield 52 63

0.9 mm 70–250

1.0 mm 90–280 Stainless Steel

1.2 mm 120–340 Stainshield 65

Stainshield Heavy 65

A BOC power sources selection chart is contained in the arc

equipment section of this manual (see pages 240–241). Aluminium

Argon 54

Selection of the Correct Shielding Gas

Alushield Light 67

The selection of the shielding gas has a direct influence on the

Alushield Heavy 67

appearance and quality of the weldbead.

The type and thickness of the material to be welded will determine Copper

the type of shielding gas that is selected. As a general rule, the Specshield Copper 80

thicker the material (C-Mn and Alloy Steels), the higher the

percentage of CO2 in the shielding gas mixture.

Wire Operating Limits

35

Undercutting and burnback

30 Spray Transfer

Optimum Parameters

1.0mm 1.2mm

Burnback and arc instability DipTransfer

25

Optimum Parameters

Voltage (V)

Defect Free Zone

20

0.9mm 1.0mm

Electrode (wire) stubbing and spatter

0.8mm

Defect Zone

15

No working condition

0 1 2 3 4 5

10

Dip Transfer (Steel Thickness (mm))

0 1 2 3 4 5

Spray Transfer (Steel Thickness (mm))

5

0 50 100 150 200 250 300 350 400

Current (A)

WARNING W elding can give rise to electric shock, excessive noise, eye and skin burns due to the arc rays, and a potential health hazard if you breathe in the emitted fumes and gases.

Read all the manufacturer’s instructions to achieve the correct welding conditions and ask your employer for the Materials Safety Data Sheets. Refer to www.boc.com.au or www.boc.co.nz

AU : IPRM 2007 : Section 8 : consumables 319

8 Fundamentals of Metal Inert Gas (MIG) Welding

Correct Application Techniques Torch position for fillet welds

When welding fillet welds, the torch should be positioned at an

Direction of welding

angle of 45° from the bottom plate, with the wire pointing into the

MIG welding with solid wires takes place normally with a push fillet corner. Welding is still performed in the push technique

technique. The welding gun is tilted at an angle of 10° towards the

direction of welding (push technique). Electrical stick-out

1 Gas Nozzle

2 Contact Tube Setback

3 Consumable Electrode

4 Workpiece

5 Standoff Distance

1 6

6 Contact Tube

7 Visible Stick-out

2 8 Arc length

9 Electrical Stick-out

7 9

3

The influence of changing the torch angle and the welding direction 5

on the weld bead profile can be seen below 8

The electrical stick-out is the distance between the end of the

contact tip and the end of the wire. An increase in the electrical

stick-out results in an increase in the electrical resistance. The

resultant increase in temperature has a positive influence in the

melt-off rate of the wire that will have an influence on the weldbead

profile

Torch perpendicular to workpiece Narrow bead width with

increased reinforcement

10°

Short Normal Long

Influence of the change in electrical stick-out length on the

weldbead profile

Torch positioned at a drag angle of 10° narrow bead with excessive Travel speed

reinforcement

0–15°

Slow Normal Fast

The travel speed will influence the weldbead profile and the

reinforcement height.

90° 90°

If the travel speed is too slow, a wide weldbead with excessive

rollover will result. Conversely, if the travel speed is too high, a

narrow weldbead with excessive reinforcement will result.

Recommendations for travel speed are contained in the detailed

Torch position for butt welds gases datasheets found in pages 58–68 of this manual.

When welding butt welds, the torch should be positioned within the

centre of the groove and tilted at an angle of ±15° from the vertical

plane. Welding is still performed in the push technique

WARNING W elding can give rise to electric shock, excessive noise, eye and skin burns due to the arc rays, and a potential health hazard if you breathe in the emitted fumes and gases.

Read all the manufacturer’s instructions to achieve the correct welding conditions and ask your employer for the Materials Safety Data Sheets. Refer to www.boc.com.au or www.boc.co.nz

320 AU : IPRM 2007 : Section 8 : consumables

You might also like

- Air Products Welder's Handbook 2018Document60 pagesAir Products Welder's Handbook 2018Ronaldo HeannaNo ratings yet

- Dissolved Air FlotationDocument26 pagesDissolved Air FlotationAzman Bin KadirNo ratings yet

- Welding Process and ConsumableDocument64 pagesWelding Process and Consumablenizar_ikmps100% (1)

- Lec 8 Pavement DesignDocument87 pagesLec 8 Pavement DesignMay de Vera100% (1)

- Chapter 25 - Machining Centers, Machine Tool Structures and Machining EconomicsDocument40 pagesChapter 25 - Machining Centers, Machine Tool Structures and Machining EconomicsVirgilioNo ratings yet

- Tray Column Design - FAYFDocument1 pageTray Column Design - FAYFsriman12340% (1)

- Handbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantFrom EverandHandbook of Structural Welding: Processes, Materials and Methods Used in the Welding of Major Structures, Pipelines and Process PlantRating: 3.5 out of 5 stars3.5/5 (3)

- Colligative Properties of Non ElectrolytesDocument20 pagesColligative Properties of Non ElectrolytesHans Sicangco0% (1)

- The Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39From EverandThe Mechanical and Physical Properties of the British Standard EN Steels (B.S. 970 - 1955): EN 21 to EN 39Rating: 5 out of 5 stars5/5 (1)

- ASTM A510 - 02 Steel WireDocument7 pagesASTM A510 - 02 Steel WireRamirez IndelebleNo ratings yet

- Weld DefectsDocument23 pagesWeld DefectsSridhar CnNo ratings yet

- Fence Fittings: Standard Specification ForDocument5 pagesFence Fittings: Standard Specification ForEnriqueVe100% (1)

- Ucs 66Document44 pagesUcs 66kjsvonbNo ratings yet

- 2nd QUARTER SCIENCE COMPENDIUM G8Document42 pages2nd QUARTER SCIENCE COMPENDIUM G8kreiosromolusNo ratings yet

- Handbook MetrodeDocument371 pagesHandbook Metrodejf2587No ratings yet

- Application Notes Welding (English)Document8 pagesApplication Notes Welding (English)metallurgist100% (6)

- General Requirements For Wire Rods and Coarse Round Wire, Carbon Steel (Metric)Document6 pagesGeneral Requirements For Wire Rods and Coarse Round Wire, Carbon Steel (Metric)Jesús Luis Arce GuillermoNo ratings yet

- Esas 12Document8 pagesEsas 12Marche SebastianNo ratings yet

- Astm A510 6 PDFDocument7 pagesAstm A510 6 PDFNafiou KamelNo ratings yet

- B 86 - 13Document7 pagesB 86 - 13phaindikaNo ratings yet

- Acid Dew PointDocument3 pagesAcid Dew PointapminshullNo ratings yet

- Section 16 QuestionsDocument5 pagesSection 16 QuestionsSameer MohammadNo ratings yet

- Welding Process Description PDFDocument31 pagesWelding Process Description PDFcentaury2013No ratings yet

- Del Giudice, Emilio Preparata, Giuliano Vitiello, Giuseppe - Water As A Free Electric Dipole Laser PDFDocument4 pagesDel Giudice, Emilio Preparata, Giuliano Vitiello, Giuseppe - Water As A Free Electric Dipole Laser PDFЮрий ЮрийNo ratings yet

- Astm B240-09 PDFDocument4 pagesAstm B240-09 PDFRaúlNo ratings yet

- Fundamentals MIG WeldingDocument3 pagesFundamentals MIG WeldingSreejith MenonNo ratings yet

- 2 UTP-Welding in Tool ShopDocument53 pages2 UTP-Welding in Tool ShopBilal AhmedNo ratings yet

- A Study of Mechanical Properties of MIGDocument10 pagesA Study of Mechanical Properties of MIGFred BosmanNo ratings yet

- ASTM Welding Tips A410 To A643Document20 pagesASTM Welding Tips A410 To A643MARIO HUAMANNo ratings yet

- Selection of Welding ConsumablesDocument13 pagesSelection of Welding ConsumablesbassemaeNo ratings yet

- Mig/Tig Arc Welding For Stainless Steels & Carbon SteelsDocument10 pagesMig/Tig Arc Welding For Stainless Steels & Carbon SteelsTrương Ngọc SơnNo ratings yet

- WeldingDocument53 pagesWeldingshek nd100% (1)

- 309mo Stainless Steels: Data SheetDocument5 pages309mo Stainless Steels: Data SheetFilipe CordeiroNo ratings yet

- Characterization of Astm A516 Grade 70 Fusion Welded Joints: Aidy Ali, A. B. SanuddinDocument11 pagesCharacterization of Astm A516 Grade 70 Fusion Welded Joints: Aidy Ali, A. B. SanuddinIgor GrujićNo ratings yet

- Welding and Characterization of 5083 Aluminium Alloy PDFDocument6 pagesWelding and Characterization of 5083 Aluminium Alloy PDFPatricio G. ArrienNo ratings yet

- Microstructure and Mechanical Properties of Borated Stainless Steel (304B) GTA and SMA WeldsDocument6 pagesMicrostructure and Mechanical Properties of Borated Stainless Steel (304B) GTA and SMA WeldsReza nugrahaNo ratings yet

- 2018 - Microstructure and Mechanical Properties of Ti6321 - Andi Septian - 21050115120031 - LasDocument5 pages2018 - Microstructure and Mechanical Properties of Ti6321 - Andi Septian - 21050115120031 - LasAndi Septian NasrulohNo ratings yet

- BW FOX+NiCuCr EN 2019 GL 233 PreviewDocument2 pagesBW FOX+NiCuCr EN 2019 GL 233 PreviewRaviTeja BhamidiNo ratings yet

- IEA06 - 22 PaperDocument4 pagesIEA06 - 22 Paperjunkuse506No ratings yet

- Dissimilar Welding of AISI 309 Stainless Steel To AISI 1020 Carbon Steel Using Arc Stud WeldingDocument6 pagesDissimilar Welding of AISI 309 Stainless Steel To AISI 1020 Carbon Steel Using Arc Stud WeldingFiras RocktNo ratings yet

- Gas Metal Arc Welding ElectrodeDocument1 pageGas Metal Arc Welding Electrodeadib nassarNo ratings yet

- Circular 0Document2 pagesCircular 0meisNo ratings yet

- B 177 - 93 - Qje3ny05mw - PDFDocument4 pagesB 177 - 93 - Qje3ny05mw - PDFSamuelNo ratings yet

- 328.4.2 End Preparation: ASME B31.3-2012Document2 pages328.4.2 End Preparation: ASME B31.3-2012Stephen Raj100% (1)

- Section 4: Specification ClassificationDocument1 pageSection 4: Specification ClassificationRudi SyamNo ratings yet

- Optimization of Aluminium Alloy Using Mig Welding Process: Sri Ramakrishna Engineering CollegeDocument11 pagesOptimization of Aluminium Alloy Using Mig Welding Process: Sri Ramakrishna Engineering CollegeVARUNBALAJI SELVAMNo ratings yet

- Astm B545 13Document4 pagesAstm B545 13heryyanto8086No ratings yet

- Notes On Welding & Metal CuttingDocument69 pagesNotes On Welding & Metal CuttingSaptarshi PalNo ratings yet

- WIS5 Paper 2 Rev 3Document4 pagesWIS5 Paper 2 Rev 3Ali ClubistNo ratings yet

- Mig Mag Saw CswipDocument35 pagesMig Mag Saw CswipHamza DhariwalNo ratings yet

- Gas Metal Arc WeldingDocument3 pagesGas Metal Arc Weldingvarun100% (1)

- Part - I Technical Bid: Indian Institute of Technology, Bombay (Maharashtra)Document24 pagesPart - I Technical Bid: Indian Institute of Technology, Bombay (Maharashtra)Venkatesh KumarNo ratings yet

- CHM 316LDocument1 pageCHM 316LImmalatulhusnaNo ratings yet

- Defect Analysis of Electric Arc Welding Seams With Coated Electrode by Non-Destructive Testing of Different ThicknessesDocument10 pagesDefect Analysis of Electric Arc Welding Seams With Coated Electrode by Non-Destructive Testing of Different ThicknessesChaka BertheNo ratings yet

- Copper Clad Steel Earth Rod AssemblyDocument13 pagesCopper Clad Steel Earth Rod AssemblyprabathnilanNo ratings yet

- 8 Consumables 309-320Document12 pages8 Consumables 309-320Márcio FerreiraNo ratings yet

- WOWLibrary-Fundamentals MMA WeldingDocument9 pagesWOWLibrary-Fundamentals MMA WeldingRahul BalaNo ratings yet

- Module - IIDocument48 pagesModule - IIsivasaNo ratings yet

- Section 8 - Arc Equipment and Processes - tcm266-154565Document42 pagesSection 8 - Arc Equipment and Processes - tcm266-154565Maxmore KarumamupiyoNo ratings yet

- Aluminum 5083 With 5183Document9 pagesAluminum 5083 With 5183johnknight000No ratings yet

- Application Note Metallography of WeldsDocument8 pagesApplication Note Metallography of WeldsLorena Grijalba LeónNo ratings yet

- Aalco Metals LTD - Aluminium Alloy 5083 H32 Sheet - 140 PDFDocument2 pagesAalco Metals LTD - Aluminium Alloy 5083 H32 Sheet - 140 PDFAhmad Renaldy Jurais0% (1)

- Inception Report Air SelangorDocument3 pagesInception Report Air SelangorNurul IzzatiNo ratings yet

- Mig Mag Welding 0Document22 pagesMig Mag Welding 0CamiloSalinasNo ratings yet

- Arch-2.2-Protective Treatments For MetalsDocument2 pagesArch-2.2-Protective Treatments For MetalsSherazNo ratings yet

- Single-Pass Laser Beam Welding of Clad Steel PlateDocument7 pagesSingle-Pass Laser Beam Welding of Clad Steel PlatetazzorroNo ratings yet

- Surface & Coatings Technology: M.H. Amushahi, F. Ashra Fizadeh, M. ShamanianDocument6 pagesSurface & Coatings Technology: M.H. Amushahi, F. Ashra Fizadeh, M. ShamanianCesar10TNo ratings yet

- Zinc and Zinc-Aluminum (ZA) Alloys in Ingot Form For Foundry and Die CastingsDocument4 pagesZinc and Zinc-Aluminum (ZA) Alloys in Ingot Form For Foundry and Die CastingsLuis BadoffNo ratings yet

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Mig Wire Burn Back DetailsDocument23 pagesMig Wire Burn Back DetailsSridhar CnNo ratings yet

- Black Glass GuideDocument2 pagesBlack Glass GuideSridhar CnNo ratings yet

- Cast & Helix 0F Wire.Document1 pageCast & Helix 0F Wire.Sridhar CnNo ratings yet

- Chapter 11 - Surfacing and Shape Welding PDFDocument15 pagesChapter 11 - Surfacing and Shape Welding PDFCarlos GarcíaNo ratings yet

- Piping Work Package 1 (Shop and Ffield Weld)Document12 pagesPiping Work Package 1 (Shop and Ffield Weld)Erick SavrinaldoNo ratings yet

- A Monte Carlo Treatment For Reacting and Coalescing Dispersed Phase Systems - L. Spielman, O. LevenspielDocument8 pagesA Monte Carlo Treatment For Reacting and Coalescing Dispersed Phase Systems - L. Spielman, O. LevenspielAlejandro PedezertNo ratings yet

- DissertationDocument207 pagesDissertationhadrienNo ratings yet

- PMMA Denture Base Material Enhancement: A Review of Fiber, Filler, and Nanofiller AdditionDocument12 pagesPMMA Denture Base Material Enhancement: A Review of Fiber, Filler, and Nanofiller AdditionPhoebe DavidNo ratings yet

- Laser Lamp Kit: Instruction ManualDocument18 pagesLaser Lamp Kit: Instruction ManualpowerdaggerNo ratings yet

- Yuken MP-03Document3 pagesYuken MP-03ari sukantiNo ratings yet

- Dynamics 5 - Free Body DiagramsDocument17 pagesDynamics 5 - Free Body DiagramswelcometotheswampNo ratings yet

- Optics Lab Practical 4Document7 pagesOptics Lab Practical 4Pratik Dash.No ratings yet

- Rotaxanes Review PDFDocument104 pagesRotaxanes Review PDFRikardo Pino RiosNo ratings yet

- NUS SampleDocument7 pagesNUS SampleVũ LêNo ratings yet

- Da 1Document8 pagesDa 1ananNo ratings yet

- Answers To EOC Questions: Cambridge International AS Level PhysicsDocument2 pagesAnswers To EOC Questions: Cambridge International AS Level PhysicsharshanauocNo ratings yet

- Perception Sheet (Point of Change, Point of Modification, Point of Concern) DRBFM Extraction Matrix Worksheet 1/2Document1 pagePerception Sheet (Point of Change, Point of Modification, Point of Concern) DRBFM Extraction Matrix Worksheet 1/2Mau TauNo ratings yet

- F1472 1479757-1Document5 pagesF1472 1479757-1Thaweekarn Changthong100% (1)

- 1 Soalan 1Document7 pages1 Soalan 1Radziah MohamedNo ratings yet

- Colloids Exp. 2Document5 pagesColloids Exp. 2Chris K. Ramirez100% (1)

- Engineering Science Question and AnswersDocument57 pagesEngineering Science Question and Answerssimon hoveNo ratings yet

- Autonomous University of Baja California: Faculty of Engineering Aerospace EngineeringDocument18 pagesAutonomous University of Baja California: Faculty of Engineering Aerospace EngineeringOscar Oreste Salvador CarlosNo ratings yet

- USSMARTPIPE - SmartPipe KAESERDocument4 pagesUSSMARTPIPE - SmartPipe KAESERseiman23No ratings yet