Professional Documents

Culture Documents

Acmm 56-11-21 Rev10 - Jun21

Uploaded by

rüşdi işlerOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Acmm 56-11-21 Rev10 - Jun21

Uploaded by

rüşdi işlerCopyright:

Available Formats

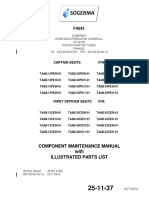

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

SAINT-GOBAIN SULLY

16 Route d’Isdes

45600 SULLY SUR LOIRE

FRANCE

Tel : (33) 2 38 37 30 00

Fax : (33) 2 38 37 30 05

TRANSMITTAL SHEET

TO : HOLDERS OF ABBREVIATED COMPONENT MAINTENANCE MANUAL FOR FRONT

WINDOW ATA 56-11-21

Revision No.10, dated Jun 09/21 is attached and covers all components held by every operator.

HIGHLIGHTS

DESIG-

PAGES DESCRIPTION OF CHANGE

NATION

DESCRIPTION AND OPERATION

Page 7 R Weight correction

MAINTENANCE

Page 11 and 24 R Add of Silicone seal erosion damage

Page 12 R Delamination definition updated

Page 14 R Bubbles definition updated

Page 15 R Yellowing discoloration definition updated

Page 19 and 20 R Inside/Outside view indicated on Fig 10a/10b

Page 21 R “in” and “Note” added in Line Cracks chapter

Page 22 R Heating Film Arcing title updated

Page 25 R Weather Seal Repair definition updated

56-11-21 Page 1/1

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

SAINT-GOBAIN SULLY FRONT WINDOW F.S.C.M.

16 Route d’Isdes

45600 SULLY SUR LOIRE Right : F0360

FRANCE

STA320-2-3-1 STA320-2-6-1A

STA320-2-4-1 STA320-2-6-1D

Tel. (33) 2 38 37 30 00 STA320-2-4-1A STA320-2-7-1

Fax : (33) 2 38 37 30 05 STA320-2-4-1B STA320-2-7-1A

STA320-2-4-1C STA320-2-8-2

Issue : APR 92

ARINC/SITA : ORYZXCR STA320-2-5-1 STA320-2-8-2 Amendt A

STA320-2-5-1A STA320-2-8-2 Amendt B

STA320-2-5-1B STA320-2-9-3

STA320-2-5-1C

STA320-2-4-1D

STA320-2-4-1E

Left :

STA320-1-3-1 STA320-1-6-1A

STA320-1-4-1 STA320-1-6-1D

STA320-1-4-1A STA320-1-7-1

STA320-1-4-1B STA320-1-7-1A

STA320-1-4-1C STA320-1-8-2

STA320-1-5-1 STA320-1-8-2 Amendt A

STA320-1-5-1A STA320-1-8-2 Amendt B

STA320-1-5-1B STA320-1-9-3

STA320-1-5-1C

STA320-1-4-1D

STA320-1-4-1E

LIST OF REVISIONS

Rev. N° 1 2 3 4 5 6

Rev. Date Jan 01/94 Apr 01/95 May 01/96 May 01/97 Oct 30/00 Feb 01/11

Rev. N° 7 8 9 10

Rev. Date Dec 16/14 Sep 01/17 Jul 24/20 Jun 09/21

LIST OF EFFECTIVE PAGES

Page Date Page Date Page Date Page Date

1 of 26 R Jun 09/21 8 of 26 R Jun 09/21 15 of 26 R Jun 09/21 22 of 26 R Jun 09/21

2 of 26 R Jun 09/21 9 of 26 R Jun 09/21 16 of 26 R Jun 09/21 23 of 26 R Jun 09/21

3 of 26 R Jun 09/21 10 of 26 R Jun 09/21 17 of 26 R Jun 09/21 24 of 26 R Jun 09/21

4 of 26 R Jun 09/21 11 of 26 R Jun 09/21 18 of 26 R Jun 09/21 25 of 26 R Jun 09/21

5 of 26 R Jun 09/21 12 of 26 R Jun 09/21 19 of 26 R Jun 09/21 26 of 26 R Jun 09/21

6 of 26 R Jun 09/21 13 of 26 R Jun 09/21 20 of 26 R Jun 09/21

7 of 26 R Jun 09/21 14 of 26 R Jun 09/21 21 of 26 R Jun 09/21

ECCN EAR99

56-11-21 Page 1/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

LIST OF MATERIALS

C T R A S

L E E S T

DESIGNATION SUPPLIER CODE AIRLINE E S P S O

AND (NAME, ADDRESS, FSCM) CODE A T A E R

SPECIFICATION N I I M A

I N R B G

N G L E

G Y

EUROPE

CIE DE RAFFINAGE SHELL BERRE X

42, rue Washington

75008 PARIS FRANCE F1858

ISOPROPYL ALCOHOL

ESSO-SAF X

2, rue de Martinets

92569 RUEIL MALMAISON

FRANCE F3528

BOLIT X

BOLIT 707

77260 LA FERTE SOUS JOUARRE

BOLIT 710

FRANCE : Tel : (33) 0 1.60.22.16.01

Fax : (33) 0 1.60.22.27.39

ATOHASS X

USINE DE BERNOUVILLE B.P 1

ALTUNET

27660 - BEZU SAINT ELOI

FRANCE : Tel : (33) 0 2.32.27.72.72

Fax : (33) 0 2.32.27.72.00

PMPS X

58, Avenue de Wagram

75017 PARIS

FRANCE : Tel : (33)

MEGUIAR’s N° 10

Fax : (33)

MEGUIAR’s N° 17

MEGUIAR’S X

S. VESTDIJKERF 167

3315 CW DORDRECHT

NETHERLAND

56-11-21 Page 2/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

C T R A S

L E E S T

DESIGNATION SUPPLIER CODE AIRLINE E S P S O

AND (NAME, ADDRESS, CODE A T A E R

SPECIFICATION FSCM) N I I M A

I N R B G

N G L E

G Y

LE JOINT FRANCAIS X

PR1784 84 - 116, rue Salvador Allende

PR186 95870 BEZONS

FRANCE : Tel : (33) 0 1.34.23.34.23

Fax : (33) 0 1.34.23.34.99

NORTH AMERICA

UNION CARBIDE CORP CHEM & X

ISOPROPYL ALCOHOL

PLASTICS DIVISION

STAMFORD CT USA

20638

MEGUIAR’S INC X

17991 MITCHELL SOUTH

IRVINE, CALIFORNIA 92714

USA

MEGUIAR’S

MEGUIAR’S X

5496 GORVAN DRIVE

MISSISSAUGA ONTARO

CANADA LW4 3E6

ASIA

VOLUME ENTERPRISES X

143 HSING AN ST.

MEGUIAR’s N° 10 TAIPEI TAIWAN ROC

MEGUIAR’s N° 17

SPEEDY CO.LTD X

1-24-15 MATSUSHIMA EDOGAWA-KU

TOKYO

JAPAN

56-11-21 Page 3/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

C T R A S

L E E S T

DESIGNATION SUPPLIER CODE AIRLINE E S P S O

AND (NAME, ADDRESS, CODE A T A E R

SPECIFICATION FSCM) N I I M A

I N R B G

N G L E

G Y

AUSTRALIA / NEW ZEALAND X

MEGUIAR’S

MEGUIAR’s N° 10

20/23 SOUTH STREET

MEGUIAR’s N° 17

RYDALRRIERE SYDNEY

NEW SOUTH WALES 211C

AUSTRALIA

LIST OF ABBREVIATIONS

None.

56-11-21 Page 4/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

1. DESCRIPTION AND OPERATION

A. Location (See figure 1)

Rear window

Sliding window

Rear window

Front window

Sliding window

Forward Aftward

Figure 1- Location

B. Overall dimensions (See figure 2)

890 mm (35 in)

639 mm (25.16 in)

Electrical

connector

841.41 mm (33.13 in) 130 mm (5.1 in)

(27.6 in)

70 mm

1002 mm (39.45 in)

Figure 2 – Front window (R/H viewed from inside)

56-11-21 Page 5/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

C. Cross section (See figure 3)

Polysulphide seal

Thermally strengthened glass 4 mm (0.16in)

Silicone seal Heating film (ITO)

Structural plies Polyurethane + PVB 6 mm (0.24 in)

Chemically strengthened glass 8 mm (0.31 in)

Polyurethane + PVB 3.7 mm (0.31 in)

Chemically strengthened glass 8 mm (0.31 in)

Bumpers

Soft liner (applicable for P/N STA320-X-5-1)

Packer

Figure 3a - Composition of layers (STA320-2-4-1 and STA320-1-4-1/ STA320-2-5-1 and STA320-1-5-1)

Polysulphide seal

Thermally strengthened glass 3 mm (0.12 in)

Silicone seal Heating film (ITO)

Polyurethane 7.1 mm (0.28 in)

Structural plies

Chemically strengthened glass Solidion 8 mm (0.31in)

PVB 2.0 mm (0.08 in)

Bumpers Chemically strengthened glass Solidion 8 mm (0.31 in)

Closure plate (Bottom edge only)

Packer

Figure 3b - Composition of layers (STA320-2-6-1 and STA320-1-6-1)

Polysulphide seal

“Z” retainer

Silicone seal Thermally strengthened glass 3 mm (0.12 in)

Heating film (ITO)

Structural plies Polyurethane 7.1 mm (0.28 in)

Chemically strengthened glass Solidion 8 mm (0.31 in)

PVB 2 mm (0.08 in)

Chemically strengthened glass Solidion 8 mm (0.31 in)

Bumpers

Closure plate

Packer

Figure 3c - Composition of layers (STA320-2-7-1 and STA320 -1-7-1/ STA320-2-8-2 and STA320-1-8-2

STA320-2-9-3 and STA320-1-9-3)

56-11-21 Page 6/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

D. Technical characteristics

(1) Physical characteristics

- Overall dimensions : See figure 2

- Composition of layers : See figure 3. Note the flat surface shape of the window.

- Weight : 36.3 kg (80 lbs) (P/N STA320-2-4-1, -1-4-1 and -2-5-1, -1-5-1)

34.0 kg (75 lbs) (P/N STA320-2-6-1, -1-6-1)

34.7 kg (76.5 lbs) (P/N STA320-2-7-1, -1-7-1, -2-8-2, -1-8-2)

34.7 kg (76.5 lbs) (P/N STA320-2-9-3, 1-9-3)

(2) Electrical characteristics

Applicability : P/N STA320-2-4-1, -1-4-1, -2-5-1, -1-5-1, -2-6-1, -1-6-1

(From S/N 54001 up to 54189 for L/H, and from S/N 4000 up to

4170 for R/H)

NEW MATERIAL IN SERVICE

- Heated area : 48.62 dm² (753.6 sq. in) 48.62 dm² (753.6 sq. in)

- Power density : 70 W dm² (4.5 W/ sq. in) 70 W dm² (4.5 W/ sq. in)

- Total power : 3360 W 3360 W

- Voltage at panel terminals : 200 V – 400 Hz 200 V – 400 Hz

- Current : 21 A 21 A

- Heating element resistance : 11.90 10% 11.90 10%

- Resistance of temperature sensors : 600 1.5 % at 20°C (68°F) 600 1.5 % at 20°C (68°F)

- Coefficient of variation of sensors : 0.0045 //°C 0.0045 //°C

Connection diagram See figure 4a

B A

C

G Sensor 1

C H Heating D

system E

F

D Sensor 2

E F

Socket electrical B

connection Figure 4a - Connection diagram

56-11-21 Page 7/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

Applicability : P/N STA320-2-6-1, -1-6-1 (from S/N 54191 for L/H, and 4172 for

R/H) ; P/N STA320-2-7-1, -1-7-1, -2-8-2, -1-8-2, -2-9-3, 1-9-3.

NEW MATERIAL IN SERVICE

- Heated area : 48.62 dm² (753.6 sq. in) 48.62 dm² (753.6 sq. in)

- Specific power : 70 W dm² (4.5 W/ sq. in) 70 W dm² (4.5 W/ sq. in)

- Total power : 3360 W 3360 W

- Voltage at panel terminals : 200 V – 400 Hz 200 V – 400 Hz

- Current : 21 A 21 A

- Heating element resistance : 11.90 10% 11.90 10%

- Resistance of temperature sensors : 600 1.5 at 20°C (68°F) 600 1.5 at 20°C (68°F)

- Coefficient of variation of sensors : 0.0045 //°C 0.0045 //°C

Connection diagram See figure 4b

B A

C

G Sensor 1

C H

Heating D

F System Sensor 3

D

E E

Sensor 2

F

Socket electrical B

connection

Figure 4b - Connection diagram

56-11-21 Page 8/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

(3) Optical characteristics

- Optical deviation: 3’ (5’on periphery : from 0 to 50 mm (2 in)

- Luminous transmittance: 65 %

(Illuminant C)

2. MAINTENANCE

A. Scope

The following paragraphs define the in-use limits of acceptable defects for the front window.

Failure to observe these standards could jeopardize the airworthiness of the windows.

B. Applicability

The acceptable limits of defects are applicable to all the part numbers listed in the following

table ; All are fully interchangeable both ways.

PART NUMBER SERIAL

SPSA320-2-X-X : R/H NUMBERS MODIFICATION

SPSA320-1-X-X : L/H (from...step 2)

STA320-2-3-1 02 Initial design

STA320-1-3-1 50001

STA320-2-4-1 70 Replaced outer ply 5 mm (0.2 in) by thermally

strengthened glass 4 mm (0.16 in).

STA320-1-4-1 50071 Replaced tempered glass 2 x 10 mm (2 x 0.4 in) by

chemically strengthened glass

2 x 8 mm (2 x 0.31 in).

STA320-2-4-1A 1000 Introduction of INDIEX coating

STA320-1-4-1A 1001

Slip plane on all periphery.

STA320-2-4-1B 1200 HYVIZ coating

STA320-2-4-1C INDIEX coating

STA320-1-4-1B 51001 HYVIZ coating

STA320-1-4-1C INDIEX coating

56-11-21 Page 9/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

SERIAL

PART NUMBER MODIFICATION

NUMBERS

Addition of urethane liner over

STA320-2-5-1 1234 HYVIZ coating

STA320-2-5-1A INDIEX coating

STA320-1-5-1 51017 HYVIZ coating

STA320-1-5-1A INDIEX coating

Urethane interlayer overlays the edges

STA320-2-5-1B 1600 HYVIZ coating

STA320-2-5-1C INDIEX coating

STA320-1-5-1B 51200 HYVIZ coating

STA320-1-5-1C INDIEX coating

Urethane liner deleted

STA320-2-4-1D 3000 HYVIZ coating

STA320-2-4-1E INDIEX coating

STA320-1-4-1D 53001 HYVIZ coating

STA320-1-4-1E INDIEX coating

New construction using Solidion glass

STA320-2-6-1A 4000 INDIEX coating

STA320-1-6-1A 54001 INDIEX coating

STA320-2-6-1D 4094 Electrical connection improvement

STA320-1-6-1D 54101

STA320-2-7-1 4400 Adjunction of a stainless “Z” retainer

STA320-1-7-1 54401 Third sensor connected.

STA320-2-7-1A 5500 Addition of an identification label

STA320-1-7-1A 55601

STA320-2-8-2 13000 Electrical wire routing modification

STA320-1-8-2 63001

STA320-2-8-2 Amendt A 22000 Bus-bar enamel reference change on outer ply

STA320-1-8-2 Amendt A 70001

STA320-2-8-2 Amendt B 26000 Polysulfide reference change in filler notch

STA320-1-8-2 Amendt B 92001 Seal between connector and terminal block

removed

STA320-2-9-3 30000 Water tightness barrier improvement / Sleeve

STA320-1-9-3 96001 material change, power & sensors braids and

sleeve protection improvement

56-11-21 Page 10/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

C.Defect table

PERMISSIBLE IN

NOT

DEFECTS USE OBSERVATIONS

PERMISSIBLE

SEE PARAGRAPH

- Delamination 2.D.(1) On conditions

- Bubbles 2.D.(2) On conditions See 2.D.(2)

- Yellowing discoloration 2.D.(3) On conditions

- Microflakes 2.D.(4) On conditions See 2.D.(4)

- Burning 2.D.(5) On conditions See 2.D.(5)

- Line cracks 2.D.(6) On conditions See 2.D.(6)(b)

- Laminar cracks - Replace part

- Scratches 2.D.(7) On conditions See 2.D.(7)(b)

- Splinters - Replace part

- Electrical defects 2.D.(8) On conditions See 2.D.(8)(a, b)

- Silicone seal erosion 2.D.(9) - See 2.D.(9)

- Edge seal damaged - - Repair by manufacturer

- Terminal block or - - Repair by manufacturer

plug damaged

- Weather-seal 3F Repair by operator

56-11-21 Page 11/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

D. Limits of defects permissible in use

(1) Delamination

- Delamination is separation of interlayer from glass

- Delamination usually may occur along window edges

- Normal ageing phenomenon accelerated in case of moisture ingress.

- The structural integrity is not affected.

- Delamination is acceptable provided that vision is not seriously impaired and

the electric heating system is not affected (characteristics: See 1.D (2)).

- Acceptable limits of delamination: - Permitted in zone 2.

- Not permitted in zone 1.

Zone 1

Figure 5 - Delamination limits

56-11-21 Page 12/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

P/N STA320-2-4-1, -1-4-1 P/N STA320-2-6-1, -1-6-1 P/N STA320-2-7-1, -1-7-1

and -2-5-1, -1-5-1 and -2-8-2, -1-8-2

and -2-9-3, -1-9-3

Possible locations of delamination

Figure 6 – Delamination picture

56-11-21 Page 13/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

(2) Bubbles

- The structural integrity is not affected.

- Bubbles usually may occur on the periphery in interlayers.

- Normal ageing phenomenon.

- Providing vision is not seriously impaired, the window may remain in

service.

Check heating system (characteristics : see 1.D. (2)).

- Acceptable limits of bubbles :

* Bubbles up to 5 mm (.2 in) in diameter shall be allowed without limit in

quantity.

* 3 bubbles up to 10 mm (.4 in) in diameter shall be allowed

- Non approved reflective sun-shields installed inside cockpit can caused

bubbling

P/N STA20-2-4-1, -1-1-1 P/N STA320-2-6-1, -1-6-1 P/N STA320-2-7-1, -1-7-1

and -2-5-1, -1-5-1 and -2-8-2, -1-8-2

and -2-9-3, -1-9-3

Figure 7 - Bubbles picture

56-11-21 Page 14/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

(3) Yellowing discoloration

- Yellowing or brown discoloration may occur around the periphery of the

window.

- Discoloration is regarded as a possible defect.

- Structural integrity is not affected by discoloration.

- The window may remain in service unless vision is seriously impaired or

electric system becomes inoperative.

- Acceptable limits of discoloration: - Permitted in zone 2.

- Not permitted in zone 1.

Zone 1

Figure 7a - Discoloration limits

56-11-21 Page 15/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

P/N STA20-2-4-1, -1-1-1 P/N STA320-2-6-1, -1-6-1 P/N STA320-2-7-1, -1-7-1

and -2-5-1, -1-5-1 and -2-8-2, -1-8-2

and -2-9-3, -1-9-3

Possible location of discoloration

Microflakes

Figure 8 - Discoloration picture

Figure 8 - Discoloration picture

56-11-21 Page 16/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

(4) Microflakes

In some conditions, moisture ingress can generate chemical reactions in

urethane interlayers that produce visible microflakes. Since moisture

penetration can only occur at window periphery, microflakes always

appear in this area.

Structural integrity of affected windows is fully maintained provided that

the degraded areas do not exceed those allowed for delamination.

Microflakes may have different appearances :

* Multiple criss-crossed lines (“Snake skin” appearance) = typical

microflakes (See figure 9a)

* “Single line” microflakes (See figure 9b)

- Acceptable limits of microflakes: - Permitted in zone 2.

- Not permitted in zone 1

Zone 1

Figure 8a - Microflakes limits

56-11-21 Page 17/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

P/N STA20-2-4-1, -1-1-1 P/N STA320-2-6-1, -1-6-1 P/N STA320-2-7-1, -1-7-1

and -2-5-1, -1-5-1 and -2-8-2, -1-8-2

and -2-9-3, -1-9-3

Possible location of microflakes

Figure 9a – Typical microflakes Figure 9b – “Single line”microflakes

56-11-21 Page 18/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

(5) Burning (Applicable for P/N up to STA320-2-5-1C and 1-5-1C)

- Burning occurs when the heating element shows a hot spot where repeated high

temperatures make the interlayer turn brownish.

- Black or brown discoloration is regarded as a possible defect.

- Structural integrity is not affected by discoloration.

The window may remain in service unless vision is seriously impaired or

electric system becomes inoperative.

Burning location

Figure 10a – Burning picture- Inside View

56-11-21 Page 19/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

Weather-seal

Bus-Bar

Burning

Forward

Aftward Aftward

Outside View

Figure 10b – Burning picture – Outside view

56-11-21 Page 20/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

(6) Line cracks

(a) Outer ply

Consult applicable aircraft MMEL and/or flight manual for actions to be

taken.

Note: Window replacement is recommended as soon as replacement is available.

(b) Structural component

Consult applicable aircraft MMEL and/or flight manual for actions to be taken.

Note: In case of structural ply crack in flight operation, the window must be sent to

SG Sully for investigation and Airbus contacted.

(7) Scratches

(a) Outer ply

Scratches on outer-ply surface are structurally acceptable. Removal of

windshield not required.

(b) Structural component

STA320-2-5-1 and -1-5-1 windshields have an internal liner of self-healing

material that protects the inner ply from accidental scratches. Due to the

material properties, scratches and marks disappear in a limited period of time

depending on temperature and damage severity. In case of persistent

scratches, see 2.E (1)(b) page 21.

STA320-2-4-1 and -1-4-1 windshields have no liner. No scratches greater than

0.2 mm (0.008 in) in width or 0.02 mm (0.0008 in) in depth shall be allowed

whatever could be its length.

STA320-2-6-1, -1-6-1, STA320-2-7-1, -1-7-1, STA320-2-8-2, -1-8-2 and

STA320-2-9-3, -1-9-3

Solidion windshields have no liner. No scratches greater than 0.2 mm (0.008 in)

in width or 0.05 mm (0.002 in) in depth shall be allowed whatever could be its

length.

The use of the Surftest P/N : SJ-201-SPS or SGSSJ-210 is recommended to measure

the scratch depth.

56-11-21 Page 21/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

(8) Electrical defects

(a) Heating film arcing

- Consult applicable aircraft MMEL and/or flight manual for action to be

taken.

- The structural integrity is not affected but the electrical system may be

inoperative.

- Continued arcing in windshield could result in outer-ply cracking. The

heating element resistance shall not exceed the value listed in paragraph 1.D

(2) page 7-8.

- If cumulated length of brown/black marks reaches or exceeds 200 mm along

each bus-bar, windshield replacement is recommended at first opportunity.

Arcing location

Figure 11a – Arcing picture

56-11-21 Page 22/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

Bus-bar Weather-seal Arcing symptom

FORWARD

AFTWARD AFTWARD

OUTSIDE VIEW

Figure 11b

(b) Defect of sensing elements

- The failure of a sensing element will not necessarily entail the removal of

the transparency in so far as there is a second sensing element in reserve (Up

to P/N STA320-2-5-1, -1-5-1), or a third sensing element in reserve (from

P/N STA320-2-6-1, -1-6-1).

- In case of failure of the second (Up to P/N STA320-2-5-1, -1-5-1) or third

(from P/N STA320-2-6-1, -1-6-1) sensing element, the window should be

removed.

STA320-2-6-1, -1-6-1 windshields (from S/N 54001 to 54189 for L/H, from

S/N 4000 to 4170 for R/H) have a third sensor that can be connected through

an approved SAINT-GOBAIN SULLY repair station. (Re-figure 4a page 7,

and see 3.G.(5) page 25).

56-11-21 Page 23/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

(9) Silicone seal erosion

Silicone seal is subject to wind and rain erosion. Silicone seal erosion occurs along the

FWD and bottom edges, the FWD top and lower corners of the windshields.

Typical erosion patterns are shown in Figure 12 below. (The Z bar may be partially visible).

The silicone seal erosion is not a criterion to remove the windshield from aircraft.

The windshield may remain in service.

Top corner

Location

FWD

F

Lower corner

Without erosion With erosion

Location

Z bar

Figure 12 – Silicone seal erosion

56-11-21 Page 24/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

E. Cleaning instructions

1) Products to be used

(a) On glass surfaces

- Solution of : 1/3 isopropyl alcohol + 2/3 water.

(b) On internal soft liner (STA320-2-5-1, -1-5-1)

- Water, water + ethanol, water + methanol, soap and all products that combine

these components.

- The liner surface can be restored with BOLIT 707 or MEGUIAR’s n°10 and

polished with ALTUNET or MEGUAR’s n°17.

- Persistent scratches can be rubbed off with a soft pencil-eraser before

application of BOLIT 707 or MEGUIAR’s n°10. (For products, name and address

: See page 2,3 and 4).

2) Forbidden products

(a) On seal : Hexane, cyclo-hexane, acetone, toluene, baltane, trichloroethylene

(b) On glass : Abrasive products, florhydric acid, methyl ethyl ketone

(c) On soft liner : Pure ethanol, pure methanol, acetone, abrasive materials.

F. Weather Seal repair

Weather seal is comprised of black polysulphide which is subject to erosion.

Inspect the weather seal every twelve months.

The weather seal should be repaired before it reached the minimum values indicated in the

below table.

The weather seal has to be repaired before the Z bar is exposed.

When needed, repair the weather seal as per “Repair procedure weather seal”.

56-11-21 Page 25/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

When new

With erosion

Up to P/N STA320-2-6-1D, -1-6-1D P/N STA320-2-7-1, -1-7-1,

-2-8-2, -1-8-2 and -2-9-3, -1-9-3

Minimum thickness = 1 mm Maximum 2 mm Maximum 3 mm

Minimum width = 10 mm Maximum 14 mm Maximum 22 mm

Maximum length = 100 mm Not applicable Not applicable

(in one location or more)

Should white “Sirilite” composite material (See figure 12a page 23) appear, this

automatically indicates that PR erosion is out of tolerance.

Should “Z” retainer (See figure 12b page 24) appear, this automatically indicates that

PR erosion is out of tolerance.

Repair procedure of weather seal

1) Components required

- Spatula : P/N SGSST01

- Plastic scraper

- Lint-free cloth

- Adhesive tape

- PR 1784 sealant, PR186 primer: please contact SAINT-GOBAIN SULLY for

provisioning.

- Alcohol

2) Repair procedure

(a) Examine the seal for erosion, cracking and adhesion to the glass surface.

With a plastic scraper, remove all the loose, cracked or perished sealant.

(b) Clean surface of seal with alcohol and Lint-free cloth.

(c) Apply adhesive tape to the periphery of the glass pane.

(d) Apply PR186 primer on weather seal and exposed “Z” profile, glass surface.

(e) Allow the PR186 to air dry a minimum of 30 minutes.

56-11-21 Page 26/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

(f) Apply PR1784 sealant on the weather seal with a spatula to get the dimensions in

the figure 12.

(g) Allow the sealant to cure a minimum of 6 hours.

(h) Remove the adhesive tape

(i) Clean the windshield.

Without “Z” retainer

WITHOUT EROSION WITH EROSION : NEED TO BE REPAIRED

100

100 mm

mm

100 mm

100 mm

14 mm 2 mm Max 10 mm 1 mm min

Outer ply Outer ply

Median resistant ply Median resistant ply

Inner resistant ply Inner resistant ply

Figure 12a – (P/N up to STA320-2-6-1D, STA320-1-6-1D)

56-11-21 Page 27/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

With “Z” retainer

WITHOUT EROSION WITH EROSION : NEED TO BE REPAIRED

100

100 mm

mm

100 mm

100 mm

22 mm 10 mm

3 mm Max 1 mm min

Z retainer Z retainer

Outer ply Outer ply

Medium resistant ply Medium resistant ply

Inner resistant ply Inner resistant ply

Figure 12b – (P/N STA320-2-7-1, STA320-1-7-1, STA320-2-8-2, STA320-1-8-2 and

STA320-2-9-3, STA320-1-9-3)

56-11-21 Page 28/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

G. Repairs

Windshields can be repaired as following only in SAINT-GOBAIN SULLY Repair Station,

in accordance with SAINT-GOBAIN SULLY Repair Process and its approved and

qualified repair stations. In all cases, prior to the repair, the glass structural/core plies are

carefully inspected : Any critical damage will entail the window rejection.

Lastly, any repaired windshield has to be submitted to a final pressure and “cold edge”

proof-test (these tests are performed before and after repair) before returning to service.

This is valid for all repairs listed below.

1) Polishing

Soiled surfaces can be restored to their original brightness by polishing the glass.

2) Surfacing

One or several scratches can be buffed out by surfacing the glass in such a manner

that no optical distortion, greater than tolerated in new windows, is created.

3) Seal repairs

Depending on the damage severity, the operation can be a major repair, up to a

complete remolding of the window, or simply limited to minor hand repairs.

4) Connector repair

Defective internal connections (welded or crimped), detached terminal blocks, as

well as damaged connectors can be repaired.

5) Third sensor connection

STA320-2-6-1 and STA320–1-6-1 windshields (from S/N 54001 to 54189 for L/H,

and from S/N 4000 to 4170 for R/H) contain a 3rd temperature sensor, which is a

provision for repair and is not connected. Should one or both of the available

sensors fail, the 3rd sensor can be connected as a spare. (See figure 4a page 7).

56-11-21 Page 29/30

Jun 09/21

ABBREVIATED COMPONENT MAINTENANCE MANUAL STA320-2-X-X

STA320-1-X-X

6) Face-ply + sensor replacement

A damaged outer-ply can be removed and replaced with a new one. This operation is

completed together with the replacement of the facing interlayer and the temperature

sensors it contains, and entails a complete silicone seal remolding.

3. REMOVAL PROCEDURE

As windows are repairable, utmost care must be taken during removal. Sharp metallic objects

should not be used to ply out window from aircraft frame.

Unrepairable damages to structure may occur. Wood or plastic wedges should be used if necessary

to ply out window from aircraft frame.

4. STORAGE

The glass must be stored in its original ATA packing, preferably in a dry and ventilated room :

- Position : Lying flat, stacking is allowed.

56-11-21 Page 30/30

Jun 09/21

You might also like

- Acmm 56-11-24 Rev 5 - Jan 19Document16 pagesAcmm 56-11-24 Rev 5 - Jan 19rüşdi işlerNo ratings yet

- Acmm 56-11-25 Rev 6 - Jan 19Document14 pagesAcmm 56-11-25 Rev 6 - Jan 19rüşdi işlerNo ratings yet

- PR2E XYAA2112-07 Eng PDFDocument26 pagesPR2E XYAA2112-07 Eng PDFMichael ButlerNo ratings yet

- Samsung Chassis Ksca PDFDocument27 pagesSamsung Chassis Ksca PDFKornaek SaelimNo ratings yet

- CL 21Z43ML Chasis Ksca PDFDocument29 pagesCL 21Z43ML Chasis Ksca PDFFran's PoenyaNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (5/9) (N0.2 Pump)Document2 pagesPc800se-7-M1 S/N 40001-Up: Main Pump (5/9) (N0.2 Pump)midalllllNo ratings yet

- 4TNV88Document30 pages4TNV88parahu ariefNo ratings yet

- Yanmar 4tnv98t Gge Engine Parts CatalogDocument3 pagesYanmar 4tnv98t Gge Engine Parts Cataloglawrence100% (42)

- DA201 C1 Rev 24Document1,440 pagesDA201 C1 Rev 24JacquesNo ratings yet

- 4TNV98T 3 PDFDocument35 pages4TNV98T 3 PDFAnonymous khOZ5G5WeNo ratings yet

- Aircraft Maintenance Manual Diamond Da201-c1-Rev-22Document1,372 pagesAircraft Maintenance Manual Diamond Da201-c1-Rev-22Edwin Garay100% (3)

- Service BulletinDocument21 pagesService BulletinFalgon Islam100% (1)

- Parts Catalogue: 3TNV82A-GGEDocument30 pagesParts Catalogue: 3TNV82A-GGERahmat Santoso50% (2)

- Parts Catalog: 0CR10-M56600ENDocument25 pagesParts Catalog: 0CR10-M56600ENEdward De La CruzNo ratings yet

- Off-Road Pantograph Spares CatalogueDocument17 pagesOff-Road Pantograph Spares CatalogueJose MojicaNo ratings yet

- IM3039rev08 Spare PartsDocument12 pagesIM3039rev08 Spare PartsMariusNo ratings yet

- Shutdown SISDocument2 pagesShutdown SISYudi setiawanNo ratings yet

- 4TNV84T Parts CatalogueDocument40 pages4TNV84T Parts CatalogueHartech Genset Sby100% (1)

- Service Bulletin: CaravanDocument8 pagesService Bulletin: CaravanEric HenriqueNo ratings yet

- 21-26-62 Skin Air ValveDocument250 pages21-26-62 Skin Air ValveZPPT74No ratings yet

- Service Manual: Desktop Rapid ChargerDocument4 pagesService Manual: Desktop Rapid Chargerfazenda sao gabrielNo ratings yet

- Contact and electronics inventory for ship parts supplierDocument6 pagesContact and electronics inventory for ship parts supplierfotini100% (1)

- S07 Tramming CompartmentDocument10 pagesS07 Tramming CompartmentLuan MaxNo ratings yet

- A6WP - Bizhub 3320 - PM PDFDocument25 pagesA6WP - Bizhub 3320 - PM PDFAndrew KudrikNo ratings yet

- Parts Reference List: MODEL: HL-1030/1240/1250/1270NDocument25 pagesParts Reference List: MODEL: HL-1030/1240/1250/1270NOFBA srlNo ratings yet

- Sharp AR-M277-237-276-236 Part Catalog PDFDocument48 pagesSharp AR-M277-237-276-236 Part Catalog PDFmehdi_palangiNo ratings yet

- Yanmar 4tnv84t Gge Engine Parts CatalogDocument4 pagesYanmar 4tnv84t Gge Engine Parts Catalogmark100% (57)

- S09 Power TrainDocument48 pagesS09 Power TrainMep RoleroNo ratings yet

- 361-6372 Battery & Wiring GP - Heavy-Duty PDFDocument4 pages361-6372 Battery & Wiring GP - Heavy-Duty PDFEdgar TorresNo ratings yet

- S09 Power TrainDocument54 pagesS09 Power TrainalcidesNo ratings yet

- Electronic Component Reference Sheet with Parts List and FootprintsDocument5 pagesElectronic Component Reference Sheet with Parts List and FootprintsJeferson KelmNo ratings yet

- Parts Manual Yanmar VIO40 2Document14 pagesParts Manual Yanmar VIO40 2Charlene DiocadizNo ratings yet

- Yanmar Motor 4TNV84T Dsa3Document36 pagesYanmar Motor 4TNV84T Dsa3Lilly NovilloNo ratings yet

- Pc800se-7-M1 S/N 40001-Up: Main Pump (7/14) (N0.1 Pump)Document2 pagesPc800se-7-M1 S/N 40001-Up: Main Pump (7/14) (N0.1 Pump)midalllllNo ratings yet

- Summary Report analysis resultsDocument16 pagesSummary Report analysis resultsCRISTHNo ratings yet

- Parts Catalogue: 4TNV98-GGEDocument29 pagesParts Catalogue: 4TNV98-GGEAnilNo ratings yet

- S6225 W6 MMA 010 Tech ManuelDocument252 pagesS6225 W6 MMA 010 Tech ManuelYerixon Daniel Aguilar SequerasNo ratings yet

- Bom - Sentsor Core Esp32-MicroDocument1 pageBom - Sentsor Core Esp32-MicroAlexander Figueroa100% (1)

- 3.3.2.8 Lab - Configuring Basic PPP With AuthenticationDocument1 page3.3.2.8 Lab - Configuring Basic PPP With AuthenticationjoseNo ratings yet

- Ec 300 MDC500 Pallet Changer Assy June 2006Document6 pagesEc 300 MDC500 Pallet Changer Assy June 2006鄭慶輝No ratings yet

- LP Inglês 3tnv82a-Gge YANMARDocument27 pagesLP Inglês 3tnv82a-Gge YANMARtazjuan1No ratings yet

- Parts Reference List: Model: ADS-2000E / ADS-2100E ADS-2500WE / ADS-2600WEDocument21 pagesParts Reference List: Model: ADS-2000E / ADS-2100E ADS-2500WE / ADS-2600WESoodNo ratings yet

- WA320-5 S/N 60001-UP: Damper (Inner Parts)Document2 pagesWA320-5 S/N 60001-UP: Damper (Inner Parts)eshopmanual limaNo ratings yet

- How To Use Parts ListDocument36 pagesHow To Use Parts ListLukáš KadeřábekNo ratings yet

- Quad Copter Demo Board Parts List and SchematicDocument7 pagesQuad Copter Demo Board Parts List and SchematicHarsha19111999No ratings yet

- Optimize PIC Microcontroller Schematic Parts ListDocument5 pagesOptimize PIC Microcontroller Schematic Parts ListDe Carry AymardNo ratings yet

- ME-50 Service Notes EnglishdhDocument22 pagesME-50 Service Notes EnglishdhFederico AbellaNo ratings yet

- Exploded Views and Parts ListDocument22 pagesExploded Views and Parts ListgdelmoralsmcNo ratings yet

- 345-7649 Alternator Gp-ChargingDocument2 pages345-7649 Alternator Gp-ChargingAlexander LauraNo ratings yet

- 623FA27MT10Document9 pages623FA27MT10Anandharaj KrishnamoorthyNo ratings yet

- 17 - 01 - Montage Capotage Avant 17 - 01 - Front CoverDocument2 pages17 - 01 - Montage Capotage Avant 17 - 01 - Front CoversxturboNo ratings yet

- CMM 25-11-373096651938279948840Document298 pagesCMM 25-11-373096651938279948840Radmanovic Uros Mrmy50% (2)

- PC800SE-7-M1 Pump Parts ListDocument2 pagesPC800SE-7-M1 Pump Parts ListmidalllllNo ratings yet

- Vue de Gauche de La Boite 966CDocument4 pagesVue de Gauche de La Boite 966CYapi YapiNo ratings yet

- Soosan Hydraulic Breaker Part List PDFDocument44 pagesSoosan Hydraulic Breaker Part List PDFValentVee89% (9)

- Boss AB 2 2 Way Selector Service Manual PDFDocument7 pagesBoss AB 2 2 Way Selector Service Manual PDFJesus Galan ArribasNo ratings yet

- Cessna 208bDocument120 pagesCessna 208bDinuka WanigasekaraNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Fluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesFrom EverandFluidic Components and Equipment 1968–9: Pergamon Electronics Data SeriesNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Defibtech Lifeline View Owners Manual 8Document66 pagesDefibtech Lifeline View Owners Manual 8rüşdi işlerNo ratings yet

- CMM 52-11-01 1mxa1 15417738Document124 pagesCMM 52-11-01 1mxa1 15417738rüşdi işlerNo ratings yet

- 32-41!11!400-801-A - Installation of The MLG WheelDocument10 pages32-41!11!400-801-A - Installation of The MLG Wheelrüşdi işlerNo ratings yet

- CRS - Mcsa V1Document9 pagesCRS - Mcsa V1rüşdi işlerNo ratings yet

- ASA MEMBERSHIP Certificate 6365 13402Document1 pageASA MEMBERSHIP Certificate 6365 13402rüşdi işlerNo ratings yet

- 5517-Steel For Hardening & TemperingDocument15 pages5517-Steel For Hardening & TemperingSantosh100% (2)

- Acrypol 940 - Batch No.11018064Document1 pageAcrypol 940 - Batch No.11018064muhammad imran azizNo ratings yet

- Topic 20 Answers To ExercisesDocument4 pagesTopic 20 Answers To ExercisesSiti NuraqidahNo ratings yet

- Copper Wire Rods For Electrical Applications - SpecificationDocument10 pagesCopper Wire Rods For Electrical Applications - SpecificationDhruv.bhardwajNo ratings yet

- Nova Prime & Nova Plus ABG Analyzer BrochureDocument2 pagesNova Prime & Nova Plus ABG Analyzer BrochureMuhammad BilalNo ratings yet

- Drew Ameroid - Tank Cleaning ManualDocument99 pagesDrew Ameroid - Tank Cleaning ManualВиталий МакошибаNo ratings yet

- Science6 q1 Mod1les6 Suspensions and Their Characteristics FINAL08032020Document19 pagesScience6 q1 Mod1les6 Suspensions and Their Characteristics FINAL08032020KRISTINE JOAN BARREDO50% (2)

- Tetrahedral and octahedral void sizes in close packingDocument7 pagesTetrahedral and octahedral void sizes in close packingPrachi Agarwal100% (1)

- Chemistry Lecture Notes 2010Document120 pagesChemistry Lecture Notes 2010Doctora NourhanNo ratings yet

- Solubility, Similarity, and Compatibility: A General-Purpose Theory For The FormulatorDocument12 pagesSolubility, Similarity, and Compatibility: A General-Purpose Theory For The Formulatormarco_ravelo_10No ratings yet

- 8.2 Transport of Oxygen and Carbon DioxideDocument13 pages8.2 Transport of Oxygen and Carbon DioxideFarista KabirNo ratings yet

- Sypro Ruby ProtocolDocument7 pagesSypro Ruby ProtocolJack MaoNo ratings yet

- Resistivity and Resistance CalculationsDocument5 pagesResistivity and Resistance CalculationsJhac FamorNo ratings yet

- Gunshot ResidueDocument56 pagesGunshot ResidueMohammad Al-Rajie AguamNo ratings yet

- Lab 13 - Testing For Oxidising and Reducing AgentsDocument3 pagesLab 13 - Testing For Oxidising and Reducing AgentsFina ShoNo ratings yet

- تصبيغ البكتيرياDocument8 pagesتصبيغ البكتيرياcrtgyhujikNo ratings yet

- Dokumen - Pub Engineering Thermodynamics 9789352607969 9352607961Document306 pagesDokumen - Pub Engineering Thermodynamics 9789352607969 9352607961Hafis HasibuanNo ratings yet

- ME150MS HEAD SolutionsDocument2 pagesME150MS HEAD SolutionsdiablomatiNo ratings yet

- Fundamentals of Chemistry II, Laboratory ManualDocument170 pagesFundamentals of Chemistry II, Laboratory ManualReinold NdreuNo ratings yet

- Immobilization of E. Coli Expressing Bacillus Pumilus CynD in Three Organic Polymer MatricesDocument23 pagesImmobilization of E. Coli Expressing Bacillus Pumilus CynD in Three Organic Polymer MatricesLUIS CARLOS ROMERO ZAPATANo ratings yet

- Experimental Study of The Physical Properties of Concrete Prepared by Partial Replacement of Cement With Alccofine, Metakaolite and GGBSDocument21 pagesExperimental Study of The Physical Properties of Concrete Prepared by Partial Replacement of Cement With Alccofine, Metakaolite and GGBSIJRASETPublicationsNo ratings yet

- Advantages of Using Hot DI WaterDocument1 pageAdvantages of Using Hot DI WaterEduardo CastañedaNo ratings yet

- Qualitative and Quantitative Anion Analysis of Drinking Water by Ion ChromatographyDocument4 pagesQualitative and Quantitative Anion Analysis of Drinking Water by Ion ChromatographyRIMAYCHA TIARA SALCHABNo ratings yet

- Biology Internal Assessment 2Document9 pagesBiology Internal Assessment 2Hayley ChiuNo ratings yet

- Engineering Encyclopedia Distillation ProcessDocument57 pagesEngineering Encyclopedia Distillation ProcessPutra Nag CeSioNo ratings yet

- Modelling The Human Olfactory Stimulus Response FunctionDocument16 pagesModelling The Human Olfactory Stimulus Response Functionđạt lê tiếnNo ratings yet

- The Common Ion Effect and Buffer SolutionsDocument11 pagesThe Common Ion Effect and Buffer SolutionsAhmed goldenNo ratings yet

- 04 Honey AnalysisDocument3 pages04 Honey AnalysisNaz AliNo ratings yet

- Caffine in TeaDocument11 pagesCaffine in TeaPriyatosh YadavNo ratings yet

- Biocharasconstructionmaterial ReviewDocument15 pagesBiocharasconstructionmaterial ReviewAnura BandaraNo ratings yet