Professional Documents

Culture Documents

Inline Duplex Filter Technical Specs

Uploaded by

Pietro ChiocchiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Inline Duplex Filter Technical Specs

Uploaded by

Pietro ChiocchiCopyright:

Available Formats

Low / Medium Pressure Duplex Filter

Inline mounting

Filters . Accumulators Type : 40/160-LD/LDN

Hydraulic Symbol

Technical Data

Material of Construction Design : Simplex Inline

Head : GGG50. Max. Pressure (PS) : 40 / 160 Bar.

Bowl : Carbon Steel. Test Pressure (PT) : 1.43 x PS

Seals : Nitrile / Viton / EPDM. Temperature range : -20°C to +100°C (Standard)

Paint : Bowl Externally painted in RAL-5010. Connection : Upto SAE 1-1/2”

Others on request. Element design : LD Series - EPE standard

LDN Series - As per DIN-24550

Description Filter Element

The 40/160-LD/LDN series Filters are used for direct

installation in the pipeline and provide wear protection of The Filter Element is of star-pleated design with optimised

downstream components & systems. Duplex in design for pleat density for providing prolonged life.

inline mounting the filter inlet & outlet are located the

opposite sides. The flow path arrow (inlet to outlet) is The filter element is of Out-to-In design and the

marked on filter head. contaminant is retained outside the filter element and

The Filter head is provided with two element locating collected in the filter bowl.

spigots - one in each housing - and a change-over valve

with metal to metal sealing and integral pressure The elements are available in various media options and

equalization valve. The change-over handle points to the selected based on the required oil cleanliness, initial

housing in operation. The integral pressure equalization is pressure drop and dirt holding capabilities.

activated when the change-over handle is lifted to effect

change over and deactivated once the change-over handle Media options for the filter element include

is released at the end position. SS Wire Mesh - Cleanable, Nominal filtration.

The Filter bowls are mounted below the filter head and Paper - Non-cleanable, Nominal filtration.

unscrewed for maintenance. Non-woven - Non-cleanable, Nominal filtration.

Inorganic glass fibre - Non-cleanable, Absolute filtration

acc. to ISO-16889.

Accessories Aquasorb - Water absorbing media, Non-cleanable.

Maintenance indicator - for monitoring the filter element

contamination status. Available in various designs For special applications / fluids the filter elements are

including supplied with SS hardware (end caps & inner tube) and / or

Optical (pop-up version) with Electrical option. different adhesives.

Optical (dual dial version) with Electrical option.

Optical-Electrical with 2 switching points.

Magnet - to protect the filter from ferrous contamination.

Bypass valve - to protect the filter element during start-up

and over pressurisation due to clogging.

Vent valve - for removing the air from the filter during

starting and for safe depressurisation. Technical specifications subject to change.

Drain valve - for draining the filter during servicing.

1

Ordering Code - Filter

1 2 3 4 5 6ab 7 8 9ab 10 11 12 13

160 - LD - 0013 - H10XL - A - 00 - 0 - 9 - A5.0 - R0 - P - 0 - 0 /

Max. working 40 Bar = 40

1 pressure 160 Bar = 160

2 Filter type Duplex Inline - EPE Standard Element = LD

Duplex Inline - Element acc. to DIN 24550 = LDN

Filter type LD = 0003 (* 2.0004 element)

= 0005 0008 0013

0015 0018

3 Nominal Size

0020 0030 0045

Filter type LDN = 0040 0063 0100

0160 0250 0400

Nominal Filtration Grade in µm

SS Wire Mesh | Cleanable = G10 G25 G40

G60 G80 G100

Others on request

Paper | Non-cleanable = P5 P10 P25

Non-Woven | Non-cleanable = VS10 VS25 VS40

Filtering Media VS60

4 & Absolute Filtration Grade (ISO16889) in µm

Filtration Grade Glass Fibre with epoxy wire mesh support = H1XL H3XL H5XL

| Non-cleanable H6XL H10XL H16XL

H20XL

Glass Fibre with plastic mesh support = H1XP H3XP H5XP

| Non-cleanable H6XP H10XP H16XP

H20XP

Water Absorbing Glass Fibre | Non-cleanable = AS1 AS3 AS6

AS10 AS20

Maximum allowed differential pressure

Differential

30 Bar = A (standard)

5 Pressure

60 Bar =D

of Element

160 Bar =C

Element Standard Adhesive T=100°C = 0 (standard)

6a Epoxy Adhesive (for fuels) =1

Adhesive

High Temp. Adhesive T=160°C =E

Element Standard (Carbon Steel / Polyamide) = 0 (standard)

6b

Hardware All Stainless Steel (30 Bar DP) =V

Magnet Without = 0 (standard)

7

With ring magnet(a) =X

Without =0

With Bypass Valve - 0.3 Bar =1

With Bypass Valve - 0.8 Bar =2

With Bypass Valve - 1.5 Bar =3

With Bypass Valve - 2.0 Bar =4

8 Bypass Valve With Bypass Valve - 2.5 Bar =5

With Bypass Valve - 3.0 Bar =6

With Bypass Valve - 3.5 Bar = 7 (std for 40-LD/LDN)

With Bypass Valve - 5.0 Bar =8

With Bypass Valve - 7.0 Bar = 9 (std for 160-LD/LDN)

With special setting Bypass valve = Bx (x = pressure)

(a)

* Before ordering, check for availability. 2 Magnets kept loose under the elements.

Ordering Code - Filter

1 2 3 4 5 6ab 7 8 9ab 10 11 12 13

160 - LD - 0013 - H10XL - A - 00 - 0 - 9 - A5.0 - R0 - P - 0 - 0 /

Without = 0 (standard)

Optical (Pop-up) = A..

Optical(Pop-up) + Electrical with DIN Plug = B..

Optical(Pop-up) + Electrical with Lamp = D..

Maintenance Optical + Electrical with 2 Switching points = T..

9a

Indicator - type - set to operate at 75% and 100%

Optical (Dual dial) = AD..

Optical(dial) + Electrical with DIN Plug = BD..

Optical(dial) + Electrical with Lamp = DD..

Special = SP

Without = - (standard)

0.8 Bar = ..0.8

1.5 Bar = ..1.5

Maintenance 2.5 Bar = ..2.5 (std- 40-LD/LDN)

9b Indicator - 4.2 Bar = ..4.2

cracking pressure 5.0 Bar = ..5.0 (std- 160-LD/LDN)

6.0 Bar = ..6.0

7.0 Bar = ..7.0

Other pressure (in Bar) = ...... as applicable

Catalogue Standard Connections = R0

Inlet / Outlet (G1 | G1-1/4 | G 1-1/2)

10 - connections = S0 (1-1/2 SAE 3000)

(Refer C1 on pg.5) Special connection = X0 (to be specified)

With adaptor = RA0 (to be specified)

Nitrile =P

11 Seal Material Viton =V

Standard - as per catalogue =0

12 Housing Material

Special = SP

Without =0

With 1/4” air vent port - duly plugged = EP

With 1/4” BSP Air Vent Valve =E

Other Options With 1/4” drain port - duly plugged =4

13 (multiple options possible) With 1/4” CS drain valve in bowl = DV

With 1/4” SS drain valve in bowl = DVX

Design with 3 mounting inserts = 3I

Filter Element with Outer Sleeve =X

* Before ordering, check for availability

Ordering Code - Filter Element

3 4 5 6ab 8 11

2. 0013 - H10XL - A - 00 - 0 - P

Ordering Code - Filter Seal Kit

1 2 3 9a 10 11 12

D - 160 - LD - 0013 - A - R0 - P - 0

3

Maintenance Indicators

70 70

25

70 70 70

A = Optical (Pop-up) B = Optical (Pop-up) + D = Optical (Pop-up) +

Electrical Electrical with 2 LEDs

Ordering Code Ordering Code Ordering Code

F-xx-A0-00-00-P F-xx-GW-02-00-P F-xx-GW-26-00-P

70 70

25

70 70 70

AD = Optical (Dual Dial) BD = Optical (Dual Dial) + DD = Optical (Dual Dial) +

Electrical Electrical with 2 LEDs

Ordering Code Ordering Code Ordering Code

FD-xx-A0-00-00-P FD-xx-GW-02-00-P FD-xx-GW-26-00-P

Maintenance Indicator functioning

These indicators work on the differential pressure and operate when a

110

preset pressure differential is reached between the inlet & outlet ports.

In the pop-up version a red indicator pin pops out in the housing chamber

thereby indicating the state whereas in the dual dial version two dial 40

gauges - with green, yellow & red bands - placed on opposite side indicate 130

the condition. If available, the electronic switching element is also

triggered.

In the 2-switching points version (type T) the green LED glows in T = Optical/Electrical with 3

operating condition, yellow LED glows when 75% of the preset pressure LEDs & 2 Switching points

differential is reached and red LED at 100%. Ordering Code

R-xx-GW-09-Z0-P

Tightening Torque Values (Nm ±10%)

Inlet/Outlet Ports Bowl to head Mounting Holes

Type

Size Torque Torque Size Torque

40/160 LD 0003-0013 G 1” 150 40 M10 12

40/160 LD 0015-0018 G 1-1/4” 160 50 M12 15

40/160 LD 0020-0045 G 1-1/2” 175 60 M16 18

40/160 LDN 0040-0100 G 1” 150 40 M10 12

40/160 LDN 0160-0250 G 1-1/2” 175 60 M16 18

40/160 LDN 0400 SAE 1-1/2” 60 M16 18

xx - preset differential pressure (bar)

4

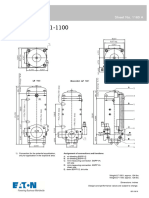

Dimensions

B1

D1

C1

C4

A6 A5

A2

A4

C3

A1

B4 SW C2

A3

B4

B2

B3

Fig.1

Filter housing for Filter Elements in accordance with EPE standard

Type Capacity Weight A1 A2 A32) A4 A5 A6 B1 B2 B3 B4 C1 C2 C3 C4 D1 SW

1)

in ltr in kg Connection

40/160 LD 0003 2x0.23 6.8 117 80

40/160 LD 0005 2x0.23 7.0 117 100 G 1”

105 77 8 50 168 54 115 80 Ø55 M10 - 15 19

40/160 LD 0008 2x0.36 7.5 182 20 dp

40/160 LD 0013 2x0.53 8.8 269

40/160 LD 0015 2x0.80 13.2 218 G 1¼”

109 120 73 10 50 220 68 120 105 Ø76 M12 - 18 24

40/160 LD 0018 2x0.99 16.3 263 25 dp

40/160 LD 0020 2x1.19 19.0 182

G 1½”

40/160 LD 0030 2x1.76 20.0 276 127 81 17 55 278 102 115 134 Ø98 M16 Ø61 24 27

25 dp

40/160 LD 0045 2x2.72 23.0 422

Filter housing for Filter Elements in accordance with DIN 24550

Type Capacity Weight A1 A2 A32) A4 A5 A6 B1 B2 B3 B4 C1 C2 C3 C4 D1 SW

1)

in ltr in kg Connection

40/160 LDN 0040 2x0.23 7.0 117 100

G 1”

40/160 LDN 0063 2x0.36 7.5 182 105 77 8 50 168 54 115 80 Ø55 M10 - 15 19

20 dp

40/160 LDN 0100 2x0.53 8.8 269

120

40/160 LDN 0160 2x1.19 19.0 182 G 1½”

40/160 LDN 0250 2x1.76 20.0 276 127 81 17 55 278 102 115 134 25 dp Ø98 M16 Ø61 24 27

40/160 LDN 0400 2x2.72 23.0 422 SAE 1-1/2”

1)

= Weight including standard filter element and maintenance indicator

2)

= Servicing height for filter element replacement

5

Spare parts list

5

7

8

12

13 1

14

15

16 11

17 3

18

4

19 2

10

Fig.2

Spare Parts List

Size LD 0003 0005 0008 0013 0015 0018 0020 0030 0045

Size LDN 0040 0063 0100 0160 0250 0400

Item # Qty. Description Material

1 1 Filter Head GGG50 -

2 2 Filter Bowl Carbon steel -

3 2 Filter Element Various As per “Ordering Code - Filter Element”

4 2 Housing O-Ring Buna-N/Viton Sold as kit - “Ordering Code - Filter Seal Kit”

5 1 Bypass Valve Various Part No.BYP01/xx Part No.BYP02/xx Part No.BYP03/xx

6 1 Maintenance Indicator Aluminium As per Section “Maintenance Indicator”

7 2 Indicator O-Rings Buna-N/Viton Sold as kit - “Ordering Code - Filter Seal Kit”

8 2 Air Vent Plug / Valve Various Part No.AVP01/AOO001

9 2 Seal Ring for air vent Copper Sold as kit - “Ordering Code - Filter Seal Kit”

10 2 Drain Plug Steel Part No.DBP01

11 2 Return Valve Assembly Various LMBB79 LMBD79 LMBF79

12 1 Change-over Valve Body En8 LMBJ12

13 1 Flange Cover GGG50 LMBJ44

14 4 Hex Socket Head Screw 8.8 H0715X

15 2 Hex Socket Head Screw 8.8 H0406X

16 1 Handle Bush Steel LMBJ45

17 1 Spring Spring Steel LMBJ18

18 1 Dowel Pin Steel LMBJ43

19 1 Handle Al Si 9 Mg LMBJ35

xx - Cracking pressure (bar)

6

Installation, Maintenance & Special Instructions

Installation that the changeover handle is at the extreme depressed

Before installation, conduct a visual check to ensure that position. The pointer on the changeover handle always

the filter has not suffered any damage during shipping / shows the housing in operation .

handling. Verify that the requested type matches with Filter is now ready for operation.

what stamped on the nameplate.

Verify operating pressure with name plate information. Maintenance

During assembly of the filter the tightening torques (refer The filter element is clogged and must be changed or

page 4), the flow direction (direction arrows on the filter cleaned when at operating temperature the red pointer on

head) and the required service height (A3 in fig.1) of the the pop-up indicator (6) is hard against the plastic cap / the

filter element are to be taken into consideration. pointer on the dual dial indicator (6) is at the end of the red

Mount the filter assembly using the mounting holes on the marking and / or the switching process on the electrical

filter head (C3) considering the flow direction. Failure to indicator is triggered.

observe flow direction during assembly with cause damage

to the filter element and components downstream. Filter element service

Tighten the mounting bolts to specified torques (page 4). Lift the change-over handle (19) to ensure that the second

We recommend using a suitable safety relief valve in the housing (housing not in use) is also filled with fluid or wait

system to ensure the user and equipment are protected for about 15 seconds.

against possible damage caused by pressure surges. Move the change-over handle (19) from the first housing

Provide for the required servicing clearance below the filter (henceforth under maintenance) to the second housing

for cleaning / replacing the filter element. (henceforth in use).

These filters must preferably be installed in vertical Release the change-over handle (19) making sure that the

position with the filter bowl at the bottom to ensure proper changeover handle is at the extreme depressed position.

venting and draining. Release the pressure of the housing under maintenance by

Proceed to the assembly ensuring the filter is not subjected opening the vent plug (8) / vent valve.

to any abnormal forces and also fastened to avoid the Drain the filter housing through the drain plug (10) / drain

transmission of vibrations. Tighten the inlet and outlet valve. Unscrew filter bowl (2) and remove filter element

connections to the specified torques. (3), turning slightly off from its locator in the filter head (1).

Make sure the optical part of the indicator is visible and the Check filter bowl inside and clean if necessary.

electricals connected appropriately. Filter element of type H...-XL,, H...-XP, AS..., P... and VS ... is

If the maintenance indicator is ignored the bypass valve, if to be replaced.

available, will open when the pressure differential Filter element with G... media is cleanable. The

increases thereby bypassing the filter element and effectiveness of cleaning depends on the type of dirt and

contaminated fluid will pass to the clean side of the filter the level of the differential pressure at the time of changing

outlet thereby compromising the filtration effectiveness the filter element. If the differential pressure after the

and risking the downstream components. filter element's cleaning process exceeds more than 50%

of the pre-service value the G...filter element also needs to

Connecting electrical indicator be replaced.

Connect indicator using the three wired cable. Verify Remove the safety packing from the new filter element

electrical ratings on the indicator (6) name plate. before installing in the filter.

Connection settings: Replace filter element by slightly turning it back on its

1. Closer 1 (black) + 3 (blue) locator. Check Housing O-Ring (4) on filter bowl (2),

2. Opener 1 (black) + 2 (brown) replace in case of damage or wear. Screw filter bowl and

3. Changer 1 (black) + 2 (brown) + 3 (blue) tighten to the specified torque (page 4) at hexagon bolt

using a suitable tool.

Special Instructions Operate filter as described above.

It is strictly forbidden to:

- weld or solder or carry out any mechanical operations on Pressure Directives

the filter. Pressure Line Filters for hydraulic application are pressure

- engrave or permanently stamp the surfaces of the filter holding equipment according to Article 2 Section 5 of the

and / or carry out other operations that could affect or Pressure Equipment Directive 2014/68/EU. However, on

change the mechanical properties of the filter. the basis of the exception in Article 1, Section 2(f) of the

- use the filter as a structural element: it should not be PED the pressure line filters are exempt from the PED if

subjected to stresses or loads. they are not classified higher than category I (Guideline A-

- change the data of the nameplate and / or filter without 19) & do not receive any CE mark.

the permission of the manufacturer.

- use a different fluid than those designed for.

Disposal / Environmental Protection

Careless disposal of the filter, filter element and the

Starting Operation residual fluid contained therein can cause environmental

Switch on the service pump. pollution.

Bring the change-over handle (19) to the middle position, Dispose the filter / filter element in accordance with

to fill both housings. provisions applicable in the country of use.

During start-up and filling of the filter ensure that the Filter Fluid residues are to be disposed according to the

is properly vented through the vent plugs (8) / vent valve, respective safety data sheets valid for the specific hydraulic

close when operating fluid appears. fluids.

Put desired filter housing in operation position making sure

7

Performance Curves (Flow rate Vs Pressure Drop) - for complete filters

Oil Viscosity : 30 mm2/s

Specific gravity < 0.9 kg/dm3

Recommended initial Pressure Drop (ΔP) for assembly = 0.8 bar.

... LD-0005 / LDN-0040 ... LD-0018

Differential Presure ΔP (bar)

Differential Presure ΔP (bar)

H3XL

H3XL H10XL

P10

H20XL

H20XL

P10

H10XL

G10

G10

Flow rate (l/min) Flow rate (l/min)

... LD-0008 / LDN-0063 ... LD-0020 / LDN-0160

Differential Presure ΔP (bar)

Differential Presure ΔP (bar) H3XL

H3XL P10

H10XL H20XL

P10

H20XL

H10XL

G10

G10

Flow rate (l/min) Flow rate (l/min)

... LD-0013 / LDN-0100 ... LD-0030 / LDN-0250

P10

Differential Presure ΔP (bar)

Differential Presure ΔP (bar)

H3XL H10XL

H20XL

P10

H3XL H20XL

H10XL

G10

G10

Flow rate (l/min) Flow rate (l/min)

... LD-0015 ... LD-0045 / LDN-0400

H10XL P10

Differential Presure ΔP (bar)

Differential Presure ΔP (bar)

H3XL H20XL

H3XL

H10XL

P10

G10

H20XL

G10

Flow rate (l/min) Flow rate (l/min)

EPE Process Filters & Accumulators Pvt. Ltd., Techni Towers, C-54/A, TSIIC, Balanagar, Hyderabad - 500 037, Telangana, INDIA

Ph : +91 40 23778803 | Fax : +91 40 23871447 | business@epe-india.com | www.epe-india.com

8 EPE/05.001/LD Rev.1/09-2018

You might also like

- Eaton Filter Elements Overview Brochure US LowResDocument8 pagesEaton Filter Elements Overview Brochure US LowResAzmi AhmadNo ratings yet

- Filter Elements: FeaturesDocument14 pagesFilter Elements: FeaturesJamin SmtpngNo ratings yet

- Internormen Eaton 2Document8 pagesInternormen Eaton 2augusto cesarNo ratings yet

- High Efficiency Filter Elements For Hydraulic and Lubrication OilsDocument8 pagesHigh Efficiency Filter Elements For Hydraulic and Lubrication OilsAzmi AhmadNo ratings yet

- HF 570 / HF 575 / HF 578 Series: Tank Mounted Return Line FiltersDocument36 pagesHF 570 / HF 575 / HF 578 Series: Tank Mounted Return Line FilterssitnikovsNo ratings yet

- Duplex-40 - 160-LD - Nov'11Document6 pagesDuplex-40 - 160-LD - Nov'11Sagar NaduvinamaniNo ratings yet

- Линейные фильтры 40..160 LEDocument6 pagesЛинейные фильтры 40..160 LEDelio Rafael Sánchez FernandezNo ratings yet

- 245LEN0040H10XLB00V50MR2Document16 pages245LEN0040H10XLB00V50MR2Sting DâuNo ratings yet

- Filtro Hidráulico Pi260 MahleDocument6 pagesFiltro Hidráulico Pi260 MahleHIDRAFLUIDNo ratings yet

- Inline Filter With Filter Element According To DIN 24550: FeaturesDocument22 pagesInline Filter With Filter Element According To DIN 24550: FeaturesДимитър ТанкишевNo ratings yet

- Re 51400Document14 pagesRe 51400Jamin Smtpng0% (1)

- Delta-Sks (En)Document2 pagesDelta-Sks (En)maserrasNo ratings yet

- E7200 10 02 08 - D Type FilterDocument8 pagesE7200 10 02 08 - D Type FiltermecambNo ratings yet

- ME (Parker DF60 Duplex Filter F160 - 40 I - v1)Document7 pagesME (Parker DF60 Duplex Filter F160 - 40 I - v1)TuyenNo ratings yet

- Duplex Filter EPE 450LD0020 - SteeringDocument6 pagesDuplex Filter EPE 450LD0020 - SteeringVitor hugo AlvimNo ratings yet

- Deep F.C KitDocument6 pagesDeep F.C KitVipul SharmaNo ratings yet

- Produktprospekt 1 12 2 Eng BelDocument2 pagesProduktprospekt 1 12 2 Eng BelLassané KINDONo ratings yet

- Efficient filtration for suction filtersDocument20 pagesEfficient filtration for suction filtersJesus Nilton Pantoja OrdoñezNo ratings yet

- Hydraulic Catalogue. Reservoir EquipmentDocument43 pagesHydraulic Catalogue. Reservoir Equipmentdini WFENo ratings yet

- Automatic Filter Type 6.64 en BOLLFILTER 01Document7 pagesAutomatic Filter Type 6.64 en BOLLFILTER 01Vannex MensidorNo ratings yet

- HFS-HFD SeriesDocument8 pagesHFS-HFD SeriesBreixo HarguindeyNo ratings yet

- (ENG) Product Catalogue: Push-Fit Polypropylene Wastewater SystemDocument20 pages(ENG) Product Catalogue: Push-Fit Polypropylene Wastewater SystemyaseraleweNo ratings yet

- Duplex Filters Max. 200 L/min. 40 Bar: Cast Iron Duplex Filter For Marine ApplicationsDocument4 pagesDuplex Filters Max. 200 L/min. 40 Bar: Cast Iron Duplex Filter For Marine ApplicationshidagamersNo ratings yet

- LN Series PDFDocument18 pagesLN Series PDFLa Factoría de la CreatividadNo ratings yet

- Filters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersDocument2 pagesFilters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersRafael PaivaNo ratings yet

- Duplex Filter: 1. FeaturesDocument4 pagesDuplex Filter: 1. FeaturesChalbelaroNo ratings yet

- PCT 3557915Document4 pagesPCT 3557915earquaz23No ratings yet

- Ikron HF-547-02-T-ADocument28 pagesIkron HF-547-02-T-ACaio GiarettaNo ratings yet

- Pi8300 enDocument4 pagesPi8300 enJamin SmtpngNo ratings yet

- Duplex FilterDocument24 pagesDuplex FilterAnirudh JavagalNo ratings yet

- New: UH310 Series: Athalon High Pressure FiltersDocument3 pagesNew: UH310 Series: Athalon High Pressure FiltersGustavo FreitasNo ratings yet

- Filter ElementsDocument8 pagesFilter ElementsSheikh ZakirNo ratings yet

- Duplex Filter PDFDocument4 pagesDuplex Filter PDFmd abNo ratings yet

- ALFA24Document13 pagesALFA24Ariana GrandeNo ratings yet

- RF Return Line FilterDocument8 pagesRF Return Line Filterboobalan_shriNo ratings yet

- Carcasa Filtro Mahle Eg2Document4 pagesCarcasa Filtro Mahle Eg2HIDRAFLUIDNo ratings yet

- HF 554 Series: Tank Mounted Return Line FiltersDocument36 pagesHF 554 Series: Tank Mounted Return Line FilterssitnikovsNo ratings yet

- Filson Product CatalogDocument9 pagesFilson Product CatalogDaniel Sandoval FernándezNo ratings yet

- Tecnologia XLDM en HFUDocument6 pagesTecnologia XLDM en HFULuis Alejandro Mariño - RamguzNo ratings yet

- Filter 169-460-...Document1 pageFilter 169-460-...ANo ratings yet

- Automatic Self-Cleaning Back Wash Filters for High Viscous LiquidsDocument6 pagesAutomatic Self-Cleaning Back Wash Filters for High Viscous LiquidsKAVITANo ratings yet

- Elements Re51420 2010-10Document14 pagesElements Re51420 2010-10Admir TalicNo ratings yet

- Rexroth Filter SelectionDocument28 pagesRexroth Filter SelectionEbrahim Abd El HadyNo ratings yet

- 302222 (NBR)Document4 pages302222 (NBR)Youghorta TIRNo ratings yet

- 1145 Series: Medium Pressure FiltersDocument8 pages1145 Series: Medium Pressure FiltersRangga NugrahaNo ratings yet

- Filters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor FiltersDocument2 pagesFilters: NEW: Coralon Filter Elements Upgrade Filter Elements For Ultipor Filtersвлад камрNo ratings yet

- HF 620 / HF 625 Series: Suction and Return in Line Spin-On FiltersDocument32 pagesHF 620 / HF 625 Series: Suction and Return in Line Spin-On FilterssitnikovsNo ratings yet

- Filtro Hidráulico Pi2300 MahleDocument5 pagesFiltro Hidráulico Pi2300 MahleHIDRAFLUIDNo ratings yet

- Wire Mesh Filter ElementsDocument4 pagesWire Mesh Filter ElementsQuy HoangNo ratings yet

- Intro PF en V4Document6 pagesIntro PF en V4plasticos_jfm6580No ratings yet

- New: UR610 Series: Athalon Return Line FiltersDocument3 pagesNew: UR610 Series: Athalon Return Line FiltersMelyssa Motta da SilvaNo ratings yet

- HP140 Series: Hy-Pro G5 DualglassDocument2 pagesHP140 Series: Hy-Pro G5 DualglassOscar NavarroNo ratings yet

- Filter ElementsDocument8 pagesFilter ElementsKing LongNo ratings yet

- Rigimesh Filter Elements: Description Operating CharacteristicsDocument2 pagesRigimesh Filter Elements: Description Operating CharacteristicsAli YassineNo ratings yet

- E7104 14-07-15 RFL Schweiss KatalogversionDocument4 pagesE7104 14-07-15 RFL Schweiss KatalogversionMohamed SemedaNo ratings yet

- M&EUR310ENDocument3 pagesM&EUR310ENRizqi AchsanulNo ratings yet

- Offline Filtration Systems GuideDocument7 pagesOffline Filtration Systems GuideKristianto CahyonoNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- High Dust Air Filter - BrochureDocument2 pagesHigh Dust Air Filter - BrochurePietro ChiocchiNo ratings yet

- Compressed Air TreatmentDocument46 pagesCompressed Air TreatmentPietro ChiocchiNo ratings yet

- Ufi-Sofima HYD Catalogo 2018 WebDocument304 pagesUfi-Sofima HYD Catalogo 2018 WebPietro ChiocchiNo ratings yet

- Fai Filtri Cross ReferenceDocument381 pagesFai Filtri Cross ReferencePietro ChiocchiNo ratings yet

- Schedule of Work TemplateDocument9 pagesSchedule of Work TemplateLorens RiezaNo ratings yet

- Coding & Decoding - QuestionsDocument4 pagesCoding & Decoding - QuestionsmoulieswaranNo ratings yet

- Mram PPTDocument16 pagesMram PPTShipra MathurNo ratings yet

- Application Ward-Leonard Block 76 PDFDocument21 pagesApplication Ward-Leonard Block 76 PDFDeMen NguyenNo ratings yet

- Fibre MeasurementsDocument44 pagesFibre MeasurementsKathirrveluSubramainanNo ratings yet

- Vijaya Bhanu Kote : Training Transcript Educator CenterDocument33 pagesVijaya Bhanu Kote : Training Transcript Educator CenterVijayaBhanuKoteNo ratings yet

- Deepak Raj BBA-4th Data BaseDocument48 pagesDeepak Raj BBA-4th Data Basegargnipun16No ratings yet

- Troubleshooting: LunarDocument54 pagesTroubleshooting: Lunarsmm100% (1)

- KPM169x: Bipolar Insulation Guard For Live Non-Grounded DC NetworksDocument6 pagesKPM169x: Bipolar Insulation Guard For Live Non-Grounded DC NetworksRN NNo ratings yet

- Doppler-Radar Based Hand Gesture Recognition System Using Convolutional Neural NetworksDocument8 pagesDoppler-Radar Based Hand Gesture Recognition System Using Convolutional Neural NetworkslokeshNo ratings yet

- Arithmetic Sequences PDFDocument4 pagesArithmetic Sequences PDFCharmz Jhoy100% (1)

- Cisco Content Services SwitchDocument210 pagesCisco Content Services SwitchKishoNo ratings yet

- Gomory Cutting Plane MethodDocument26 pagesGomory Cutting Plane MethodAritra Guha Ray100% (1)

- U1560 Diode Datasheet PDFDocument8 pagesU1560 Diode Datasheet PDFDemóstenes Moraes OlintoNo ratings yet

- Garment Module User ManualDocument8 pagesGarment Module User ManualAredaNo ratings yet

- Guide to Multi-Sensor Fusion Research and ApplicationsDocument17 pagesGuide to Multi-Sensor Fusion Research and ApplicationsRuchi Singh RaghuvanshiNo ratings yet

- Push - Fold - Call - CL TEAMDocument561 pagesPush - Fold - Call - CL TEAMJoão Alisson MendesNo ratings yet

- Computer Shop Feasibility StudyDocument56 pagesComputer Shop Feasibility StudyKC Mendoza67% (9)

- 218477these Stufy of An in Vehicule Infotainement SystemDocument79 pages218477these Stufy of An in Vehicule Infotainement SystemKhaled GharbiNo ratings yet

- Replace hard drive read/write headDocument12 pagesReplace hard drive read/write headΖαχος Τσελιος100% (2)

- Vol2 No 2Document148 pagesVol2 No 2IJCNSNo ratings yet

- Mock Test & SPOT PRELIMSDocument4 pagesMock Test & SPOT PRELIMSHrid 2No ratings yet

- Quiz 2Document6 pagesQuiz 2Shaukat Ali ShahNo ratings yet

- Menvier sd3 DiallerDocument2 pagesMenvier sd3 DiallerpalmerwolfNo ratings yet

- Intern Report (Erkin KarahayitDocument55 pagesIntern Report (Erkin KarahayitErkin KarahayitNo ratings yet

- How To Hack 38 - 73% Response Rates From LinkedInDocument17 pagesHow To Hack 38 - 73% Response Rates From LinkedInMichael HauptNo ratings yet

- Serial Card and Series 2 SDocument3 pagesSerial Card and Series 2 Sscribd_thakur0% (1)

- Lab # 07 Implementation of SQL Statements (DDL)Document14 pagesLab # 07 Implementation of SQL Statements (DDL)Mehak FatimaNo ratings yet

- S - R - Module - 3 Inter-VLAN RoutingDocument43 pagesS - R - Module - 3 Inter-VLAN Routingyoussef hossamNo ratings yet

- Backup Restore Complete Concepts 3.3 PDFDocument28 pagesBackup Restore Complete Concepts 3.3 PDFJohnsNo ratings yet