Professional Documents

Culture Documents

Assignment 2 - Storage Systems

Uploaded by

Trịnh Thị Khánh Trâm0 ratings0% found this document useful (0 votes)

74 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views2 pagesAssignment 2 - Storage Systems

Uploaded by

Trịnh Thị Khánh TrâmCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

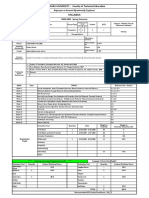

Assignment 2

Due date: 25/12/2022

Group work – Submit on GG Form

Accepted format:

1. WORD (Typing full) OR

2. PDF (Scanned version of hand-writing)

1. A carousel storage system is to be designed to serve a mechanical assembly plant.

The specifications on the system are that it must have a total of 400 storage bins and

a throughput of at least 125 storage and retrieval transactions/hr. Two alternative

configurations are being considered: (1) a one-carousel system and (2) a two-

carousel system. In either case, the width of the carousel is to be 4.0 ft and the

spacing between carriers = 2.5 ft. One picker-operator will be required for the one-

carousel system and two picker-operators will be required for the two-carousel

system. In either system, vc = 75 ft/min. For the convenience of the picker-operator,

the height of the carousel will be limited to five bins. The standard time for a pick-

and-deposit operation at the load/unload station = 0.4 min if one part is picked or

stored per bin and 0.6 min if more than one part is picked or stored. Assume that

50% of the transactions will involve more than one part. Determine:

(a) The required length of the one-carousel system and

(b) The corresponding throughput rate;

(c) The required length of the two-carousel system and

(d) The corresponding throughput rate.

(e) Which system better satisfies the design specifications?

2. Your company is seeking proposals for an automated storage/retrieval system that

will have a throughput rate of 300 storage/retrieval transactions/hr during the one 8-

hr shift per day. The request for proposal indicates that the number of single-

command cycles is expected to be four times the number of dual-command cycles.

The first proposal received is from a vendor who specifies the following: 10 aisles,

each aisle 150 ft long and 50 ft high; horizontal and vertical speeds of the S/R

machine = 200 ft/min and 66.67 ft/min, respectively; and pick-and-deposit time =

0.3 min. As the responsible engineer for the project, you must analyze the proposal

and make recommendations accordingly. One of the difficulties you see in the

proposed AS/RS is the large number of S/R machines that would be required—one

for each of the 10 aisles. This makes the proposed system very expensive. Your

recommendation is to reduce the number of aisles from 10 to 6 and to select an S/R

machine with horizontal and vertical speeds of 300 ft/min and 100 ft/min,

respectively. Although each high-speed S/R machine is slightly more expensive than

the slower model, reducing the number of machines from 10 to 6 will significantly

reduce total cost. Also, fewer aisles will reduce the cost of the rack structure even

though each aisle will be somewhat larger since total storage capacity must remain

the same. The problem is that throughput rate will be adversely affected by the larger

rack system.

(a) Determine the throughput rate of the proposed 10-aisle AS/RS and calculate its

utilization relative to the specified 300 transactions/hr.

(b) Determine the length and height of a 6 aisle AS/RS whose storage capacity would

be the same as the proposed 10-aisle system.

(c) Determine the throughput rate of the 6-aisle AS/RS and calculate its utilization

relative to the specified 300 transactions/hr.

(d) Given the dilemma now confronting you, what other alternatives would you

analyze and recommendations would you make to improve the design of the system?

You might also like

- Tutorial 2 Storage SystemDocument2 pagesTutorial 2 Storage SystemSu YiNo ratings yet

- Review MHS So N PDFDocument11 pagesReview MHS So N PDFNhan DONo ratings yet

- Tutorial 2 Storage System PDF FreeDocument2 pagesTutorial 2 Storage System PDF Freepeter oumaNo ratings yet

- ASRS ExercisesDocument2 pagesASRS ExercisesPhan Gia Nghi100% (1)

- Reviews 1 - AnswerDocument13 pagesReviews 1 - AnswerQuỳnh NguyễnNo ratings yet

- Chapter 4 Single Item Probabilistic DemandDocument92 pagesChapter 4 Single Item Probabilistic DemandQuỳnh NguyễnNo ratings yet

- Phạm Thị Yến Ngọc IELSIU19215 Homework 4aDocument3 pagesPhạm Thị Yến Ngọc IELSIU19215 Homework 4aNguyễn QuỳnhNo ratings yet

- INVENTORY MANAGEMENT HOMEWORKDocument3 pagesINVENTORY MANAGEMENT HOMEWORKYolo PhongNo ratings yet

- Hw2-Nguyễn Thị Tâm Thanh-ielsiu19263Document11 pagesHw2-Nguyễn Thị Tâm Thanh-ielsiu19263Nguyễn Thị Tâm ThanhNo ratings yet

- Hw3- Trần Thị Thanh Ngân-ielsiu18223Document11 pagesHw3- Trần Thị Thanh Ngân-ielsiu18223ngan tran100% (1)

- Hw6-Nguyễn Thị Phương Hoàng-ielsiu19160Document10 pagesHw6-Nguyễn Thị Phương Hoàng-ielsiu19160Quỳnh NhưNo ratings yet

- Time Series Forecasting TechniquesDocument11 pagesTime Series Forecasting TechniquesBảo TrânNo ratings yet

- Name: Đào Ngọc Thùy Linh ID: IELSIU19187 Class: Thursday AfternoonDocument6 pagesName: Đào Ngọc Thùy Linh ID: IELSIU19187 Class: Thursday AfternoonNguyễn QuỳnhNo ratings yet

- Challenge C VSCCDocument33 pagesChallenge C VSCCTrần Viết ThanhNo ratings yet

- Đào-Ngọc-Thùy-Linh IELSIU19187 HW3 Invent ThursDocument12 pagesĐào-Ngọc-Thùy-Linh IELSIU19187 HW3 Invent ThursQuỳnh NguyễnNo ratings yet

- XYZ Car Engine Forecasting AccuracyDocument4 pagesXYZ Car Engine Forecasting AccuracyDavid García Barrios100% (1)

- Student's homework on supply chain design and capacity planningDocument4 pagesStudent's homework on supply chain design and capacity planningMinh Hoàng TrầnNo ratings yet

- Nguyễn Thị Như Quỳnh - IELSIU19252 - HW2Document6 pagesNguyễn Thị Như Quỳnh - IELSIU19252 - HW2Nguyễn QuỳnhNo ratings yet

- DocxDocument5 pagesDocxSelinnur GöklerNo ratings yet

- School of Industrial Engineering & Management (IEM) International University, VNU-HCM Inventory Management Instructor: Dr. Nguyen Van HopDocument4 pagesSchool of Industrial Engineering & Management (IEM) International University, VNU-HCM Inventory Management Instructor: Dr. Nguyen Van Hopngan tranNo ratings yet

- Cash Flow and Equivalence PDFDocument6 pagesCash Flow and Equivalence PDFIscandar Pacasum DisamburunNo ratings yet

- Homework 4Document1 pageHomework 4ngan tranNo ratings yet

- INVEN HW7 SolutionDocument6 pagesINVEN HW7 SolutionYolo PhongNo ratings yet

- 17 SolutionsDocument7 pages17 Solutionsbrynner16No ratings yet

- Homework4 SolutionDocument2 pagesHomework4 Solutionngan tranNo ratings yet

- Assignment o Tom at I OnDocument22 pagesAssignment o Tom at I OnphyrdowsNo ratings yet

- David Acharya Assignment 2 - Random Numbers and Chi-Square TestDocument4 pagesDavid Acharya Assignment 2 - Random Numbers and Chi-Square TestDay-Veed AcharyaNo ratings yet

- Optimize Inventory Costs with EOQ and EPQ ModelsDocument40 pagesOptimize Inventory Costs with EOQ and EPQ Modelswagdy87No ratings yet

- Operations Research II Homework SolutionsDocument2 pagesOperations Research II Homework SolutionsArticleDownloaderNo ratings yet

- IEM Inventory Management HomeworkDocument10 pagesIEM Inventory Management HomeworkNguyễn Quỳnh100% (1)

- Crystal Sparkle Co. capacity planning problemsDocument6 pagesCrystal Sparkle Co. capacity planning problemsvita sarasi100% (1)

- Chapter 3 Resource PlanningDocument70 pagesChapter 3 Resource PlanningHieu TruongNo ratings yet

- INTERNATIONAL UNIVERSITY – VNU HCMC SCHOOL OF BUSINESS FINAL EXAM PROBLEMS FOR CHAPTER 9 AND 12 LAYOUT STRATEGY AND INVENTORY MANAGEMENTDocument20 pagesINTERNATIONAL UNIVERSITY – VNU HCMC SCHOOL OF BUSINESS FINAL EXAM PROBLEMS FOR CHAPTER 9 AND 12 LAYOUT STRATEGY AND INVENTORY MANAGEMENTThanh Ngân0% (2)

- Tutorial 1 Material TransportDocument2 pagesTutorial 1 Material TransportSu YiNo ratings yet

- Lecture 4 Logistics ManagementDocument4 pagesLecture 4 Logistics ManagementLeoryAnne GalleonNo ratings yet

- Assignment ExamplesDocument8 pagesAssignment Exampleswhatever152207No ratings yet

- Optimal inventory order sizes and profits for four sweater stylesDocument7 pagesOptimal inventory order sizes and profits for four sweater stylesJyothi VenuNo ratings yet

- HW 2 Chap 1 Jxip Final PDFDocument11 pagesHW 2 Chap 1 Jxip Final PDFJuan Xavier Izurieta Pineda100% (1)

- Material para El Tercer ParcialDocument10 pagesMaterial para El Tercer ParcialjuljotaNo ratings yet

- MECH 6076 Quiz II Supply Chain Modeling and OptimizationDocument3 pagesMECH 6076 Quiz II Supply Chain Modeling and OptimizationCostina Luc0% (1)

- AGV Problems: Calculating Vehicle RequirementsDocument1 pageAGV Problems: Calculating Vehicle RequirementsLương Bảo HânNo ratings yet

- Sport Zone Shoe Sourcing & Profit MaximizationDocument2 pagesSport Zone Shoe Sourcing & Profit MaximizationJotham HensenNo ratings yet

- IE 45 - Waiting Line Problems PDFDocument5 pagesIE 45 - Waiting Line Problems PDFTrixiNo ratings yet

- Homework 2Document3 pagesHomework 2Tú QuyênNo ratings yet

- Mg2451 Engineering Economics and Cost Analysis Unit I Introduction To EconomicsDocument36 pagesMg2451 Engineering Economics and Cost Analysis Unit I Introduction To EconomicsSrinivasNo ratings yet

- How Work Sampling Determines Time StandardsDocument25 pagesHow Work Sampling Determines Time StandardsassaNo ratings yet

- Inventory ModelDocument43 pagesInventory Modelndc6105058No ratings yet

- Assignment 2: in Chapters 3 and 4Document4 pagesAssignment 2: in Chapters 3 and 4Menna SultanNo ratings yet

- Sample Problems in or and StatisticDocument6 pagesSample Problems in or and StatisticHinata UzumakiNo ratings yet

- MSIS 511 Operations Management Problem SetsTITLEMSIS 511 Operations Management Problem Set SolutionsDocument8 pagesMSIS 511 Operations Management Problem SetsTITLEMSIS 511 Operations Management Problem Set SolutionsjarjonaeNo ratings yet

- (Ordering, Holding, Unit Cost,..), Discount PolicyDocument4 pages(Ordering, Holding, Unit Cost,..), Discount PolicyLe Thi Nhu QuynhNo ratings yet

- IEOR 3402 Assignment 5 SolutionsDocument5 pagesIEOR 3402 Assignment 5 SolutionsSrikar VaradarajNo ratings yet

- Supply Chain Management Solutions for Lowering Shipping CostsDocument2 pagesSupply Chain Management Solutions for Lowering Shipping CostsMd MonirNo ratings yet

- Ch13 Exercise+9Document1 pageCh13 Exercise+9Ashley WilkeyNo ratings yet

- Solutions ExosDocument11 pagesSolutions ExosazratNo ratings yet

- Automation in Manufacturing exam questionsDocument2 pagesAutomation in Manufacturing exam questionsJoy SummersNo ratings yet

- Best of Mia Khalifa HDDocument5 pagesBest of Mia Khalifa HDWayne Ü TadiqueNo ratings yet

- ExercisesDocument4 pagesExercisesTôn Nữ Minh UyênNo ratings yet

- Mid EXDocument4 pagesMid EXsabeaxNo ratings yet

- Modicon LMC078: Motion Controller Programming GuideDocument276 pagesModicon LMC078: Motion Controller Programming GuideHugo OnqueNo ratings yet

- CM108AH Datasheet v1.90Document27 pagesCM108AH Datasheet v1.90getfiredupNo ratings yet

- Control Unit For Emergency Gensets With Analogue Inputs Kea 071 AnlDocument1 pageControl Unit For Emergency Gensets With Analogue Inputs Kea 071 AnlrafatNo ratings yet

- C++ NotesDocument68 pagesC++ NotesGopinath AbaranjiNo ratings yet

- Options On Request: Item Code: 88139 Model No.: RS-UW3W316XDocument4 pagesOptions On Request: Item Code: 88139 Model No.: RS-UW3W316XHernando Fang PedrozaNo ratings yet

- SDLC: Software Development Life Cycle ExplainedDocument1 pageSDLC: Software Development Life Cycle ExplainedYamlaknew TibebuNo ratings yet

- ST 2310 DhiDocument6 pagesST 2310 Dhigabriel taberneroNo ratings yet

- LogDocument9 pagesLogDarmansyah FirdausNo ratings yet

- SRX Transparent ModeDocument4 pagesSRX Transparent ModeSon Tran Hong NamNo ratings yet

- Java MCQ byDocument23 pagesJava MCQ byhiteshNo ratings yet

- Project Information: Project Proposing Networking and Internet Infrastructure SolutionDocument2 pagesProject Information: Project Proposing Networking and Internet Infrastructure Solutiondave takele100% (1)

- Tef Elc470 4bk BaharDocument1 pageTef Elc470 4bk Bahar1fenerbahceNo ratings yet

- Chapter 3 - Implementing Advanced Network ServicesDocument38 pagesChapter 3 - Implementing Advanced Network ServicesSULTAN SksaNo ratings yet

- 2 - Unit-2 - Study Material - Wireless Links and Network CharacteristicsDocument2 pages2 - Unit-2 - Study Material - Wireless Links and Network CharacteristicsAnita DeshmukhNo ratings yet

- Series 90 Programmable Coprocessor Module and Support Software User's Manual, GFK-0255Kgfk0255kDocument316 pagesSeries 90 Programmable Coprocessor Module and Support Software User's Manual, GFK-0255Kgfk0255kARTURO TZITZIHUA HERNANDEZ100% (1)

- IMS Profile For Voice and SMS 19 May 2016: This Is A Non-Binding Permanent Reference Document of The GSMADocument49 pagesIMS Profile For Voice and SMS 19 May 2016: This Is A Non-Binding Permanent Reference Document of The GSMAdineshNo ratings yet

- Commands Reference Volume 1 A Through CDocument680 pagesCommands Reference Volume 1 A Through CPeter SzamosfalviNo ratings yet

- Manual Service VaioDocument31 pagesManual Service Vaiomaluxro50% (2)

- AN17831ADocument9 pagesAN17831AJose LeonNo ratings yet

- Service Guide GB: IXION S10/12/12S, S12F/16DDocument44 pagesService Guide GB: IXION S10/12/12S, S12F/16DК ШNo ratings yet

- A en GB - System 800xa Course GB850 PCDeviceLib SV5Document2 pagesA en GB - System 800xa Course GB850 PCDeviceLib SV5vantaipcNo ratings yet

- UCC28950 Green Phase-Shifted Full-Bridge Controller With Synchronous RectificationDocument76 pagesUCC28950 Green Phase-Shifted Full-Bridge Controller With Synchronous RectificationSaikumarNo ratings yet

- Dell Guide To Server BasicsDocument11 pagesDell Guide To Server Basicsswaroop24x7No ratings yet

- Technology in Action Complete 15th Edition Ebook PDFDocument41 pagesTechnology in Action Complete 15th Edition Ebook PDFpatricia.morrison594100% (35)

- PHP OOP and Yii Framework Pre-Test Multiple Choice QuestionsDocument12 pagesPHP OOP and Yii Framework Pre-Test Multiple Choice QuestionsApdev OptionNo ratings yet

- Kode Produk DahuaDocument42 pagesKode Produk DahuaJack ManiaNo ratings yet

- Google Cloud Platform TutorialDocument51 pagesGoogle Cloud Platform Tutorialpavan varma100% (2)

- Control M Plug-In For DatabasesDocument26 pagesControl M Plug-In For Databasesgssamerica100% (2)

- ChordanaPlay Manual enDocument37 pagesChordanaPlay Manual enBen ZhouNo ratings yet

- CSE-311 Microprocessor & Interfacing Course OutlineDocument2 pagesCSE-311 Microprocessor & Interfacing Course OutlineEngnrMemonNo ratings yet