Professional Documents

Culture Documents

PCU400 General Data Sheet

Uploaded by

Fuad Jahić0 ratings0% found this document useful (0 votes)

31 views2 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

31 views2 pagesPCU400 General Data Sheet

Uploaded by

Fuad JahićCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

PCU400

Process Communication Unit 400 is a universal, flexible, high performance

communication server solution. It supports a wide range of communication

protocols for connection to RTUs and HMIs/SCADA systems.

Applications Communication protocols

PCU400 is a flexible product and supports many

different applications. Protocols to RTUs/IEDs

Main applications: • IEC60870-5-101, including NUC

• SPIDER™ Front-End. • IEC60870-5-104, including NUC

• Distributed Front-End for SCADA systems • DNP 3.0

• Data Concentrator • RP570, RP571, RP07, ADLP180

• Protocol Converter • ADLP80

• Communication gateway and HMI for Substation • Indactic 33/41A, 2033

Automation • Indactic 35

• Siemens Sinaut 8, Sinaut ST1

• Communication gateway for Power Plants

• Telegyr TG800, TG065, TG709/TG709S

• Communication gateway for OperateIT Process • USART (Swiss)

Portal and OperateIT SCADA Portal • ECMA 24

• CONITEL 300

TCP/IP support • Mobitex

• PROCOL 240

TCP/IP connections are supported towards:

• NETCON 8830/8835

• HMI • Modbus RTU

• SPIDER™ Front-End • OPC Client (supports generic OPC)

• MiniSCADA® or other SCADA systems • DDE Client: LON-Bus, GCOM

• Asynchronous protocols with Device server in • HNZ ECP85

RTU • Teleconnect III, T2500 and T5000

• TCP/IP connection to OPC400 OPC server • SPABUS

• Westinghouse WISP, WISP+

• IEC870-5-104 (RTU/IED or Master Station)

• Robofon RB94

• EXO2

Web interface • Estel, Estel Variant, PUTU

PCU400 supports a web server providing an operator • Campbell Datalogger interface

interface (HMI) for supervision, control and simulation of • VIP Client

process data. The web server supports alarm-, event- and

sequence-of-event list functionality, including historical Protocols to Master Stations (HMI/SCADA)

event storage. The web server functionality is based on • IEC60870-5-101, including NUC

XML/XSL technology. • IEC60870-5-104, including NUC

• DNP 3.0

• RP570, RSP

• ADLP180

• Teleconnect III T5000

• OPC Server (OPC400)

• Siemens Sinaut ST1

Redundancy Technical data cont.

• Number of communication lines: Maximum 64

PCU400 supports redundancy on two levels. lines at 64 kbit/second per computer. Parallel

• Redundant PCU400 hardware (computers). Two computers can be used if more lines are required.

PCU400 computers are equally equipped. • DIN mounted communication module with 8

Automatic switching of communication lines from independent channels

one PCU to the other is supported. Line switches

• The supported protocols can be freely distributed /

of type RSX are supported.

combined on the available communication lines.

• Redundant RTU communication lines. PCU400

• Function tables: Supports FTAB download to

supports switching to a backup line when

RTUs with protocols RP570 and ADLP180.

communication on the main line fails.

• Supports multiple Master Stations.

Redundancy support is configuration dependent.

• Supports redundant LAN configurations.

• Clock synchronization of RTUs via

Analysis / Diagnosis communication lines with an accuracy of +- 5 ms

A standard terminal (Telnet client) can be connected to using minute pulse or high-accuracy NTP server.

PCU400. The client can be run on any computer The accuracy depends on the RTU and is valid for

connected to the same LAN/WAN as PCU400. The constant delay communication medium.

following is supported: • Supports any standard Windows serial (COM)

• Status on any PCU400 computer in the network port.

can be checked. • Supports old (non-asynchronous) bit oriented

• Logging the internal PCU400 data bus protocols (special communication board required).

• Logging external communication lines. Each • Supports remote software upgrades.

protocol supports an internal protocol analyser • Internal watchdog functionality, automatic

whose output can be fed to the Telnet client. computer reboot if a critical component fails.

Cyclic telegrams can be filtered from the log • Supports running as a Windows service.

output. • Supports mapping internal information (e.g.

• Analysis and diagnosis of internal processes communication line and RTU status information)

• All log output can be directed to files for later to internal indications. The internal indications are

analysis reported to connected Masters as regular

indications using the desired protocol.

Excel Data Engineering • Windows XP: Supports remote desktop connection

for configuration and check of status

For configuration of PCU400 data, an integrated data-

• Software development tool: Microsoft Visual

engineering tool can be used. This tool is based on Studio.

Microsoft Excel and XML, and is typically used in

• Environment specification:

standalone configurations.

Temperature: 0 - 45 degrees C

Relative humidity: 5 - 85% non-condensing

Technical data Supply Voltage: 85 - 264 V AC, 9 - 16 V DC,18 -

• Operating systems: Windows NT 4 and Windows 36 V DC, 36 - 72 V DC, 70 - 132 V DC

XP are supported.

• Hardware: Standard PC (Pentium or compatible).

Often an industry computer without monitor and

keyboard is used. Embedded hardware solution

without moving parts (fans, hard-disk) is also

available.

ABB AS, Div. Energi

P.O. Box 6540 Rodeløkka

N-0510 OSLO

Tel: +47 22 87 20 00

Fax: +47 22 35 28 11

www.abb.com

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Data Acquisition PCU400 Network Manager Rel1Document41 pagesData Acquisition PCU400 Network Manager Rel1Fuad JahićNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Pump Management SystemDocument1 pagePump Management SystemFuad JahićNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- KurtaDocument1 pageKurtaFuad JahićNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Autodesk student version schematic diagramDocument1 pageAutodesk student version schematic diagramFuad JahićNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Process Communication Unit monitoring and control with PCU400Document3 pagesProcess Communication Unit monitoring and control with PCU400Fuad JahićNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- CourseSchedule Spring2009 755032 ENnDocument2 pagesCourseSchedule Spring2009 755032 ENnFuad JahićNo ratings yet

- 701201UKDocument3 pages701201UKFuad JahićNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Osigurači Na RH 120Document2 pagesOsigurači Na RH 120Fuad JahićNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- PCU400e Datasheet 051007Document2 pagesPCU400e Datasheet 051007Fuad JahićNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- SIMEAS1Document2 pagesSIMEAS1Fuad JahićNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Modicon M241 - TM241CEC24TDocument15 pagesModicon M241 - TM241CEC24TFuad JahićNo ratings yet

- MFT200 6002819Document2 pagesMFT200 6002819Fuad JahićNo ratings yet

- MR 8MCR Plan 7205089Document1 pageMR 8MCR Plan 7205089Fuad JahićNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- PowerLogic PFC Capacitors - BLRCH500A000B44Document2 pagesPowerLogic PFC Capacitors - BLRCH500A000B44MirzaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- HURGADA AVIONOM IZ SARAJEVA I BEOGRADA Detaljna Ponuda 1Document1 pageHURGADA AVIONOM IZ SARAJEVA I BEOGRADA Detaljna Ponuda 1Fuad JahićNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 2. الدائره الرئيسيةDocument3 pages2. الدائره الرئيسيةالمهندسوليدالطويلNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

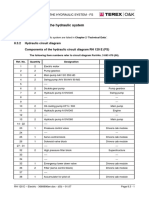

- 8.3 Description of The Hydraulic System: 8.3.1 Technical DataDocument12 pages8.3 Description of The Hydraulic System: 8.3.1 Technical DataFuad JahićNo ratings yet

- Modicon TM3 - TM3TI4Document9 pagesModicon TM3 - TM3TI4Fuad JahićNo ratings yet

- Buena Vista D.O.O. Zenica - Podruznica Sarajevo Cjenovnik HotelaDocument1 pageBuena Vista D.O.O. Zenica - Podruznica Sarajevo Cjenovnik HotelaFuad JahićNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Bucket Volume 4.2 M - 9.0 M Bucket Capacity 8,000 KG Operating Weight 24,600 KG Peak Net Power 320 HPDocument10 pagesBucket Volume 4.2 M - 9.0 M Bucket Capacity 8,000 KG Operating Weight 24,600 KG Peak Net Power 320 HPFuad JahićNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Section 3 Hydraulic SystemDocument2 pagesSection 3 Hydraulic SystemFuad JahićNo ratings yet

- 3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPDocument2 pages3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPLượng Nguyễn XuânNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- CCU!Fssps!Dpef!Nje!TJF!FYDBWBUPST!Fssps!DpeftDocument8 pagesCCU!Fssps!Dpef!Nje!TJF!FYDBWBUPST!Fssps!DpeftFuad Jahić100% (1)

- 8.5.2 Pressure Cut-Off: 8.5 Description of Hydraulic CircuitsDocument2 pages8.5.2 Pressure Cut-Off: 8.5 Description of Hydraulic CircuitsFuad JahićNo ratings yet

- Test Secondary Current Injection SetDocument3 pagesTest Secondary Current Injection SetJulio SantacruzNo ratings yet

- Ferromagnetic Hysteresis PDFDocument4 pagesFerromagnetic Hysteresis PDFFuad JahićNo ratings yet

- EcoStruxure Power Build - Rapsody Installation GuideDocument5 pagesEcoStruxure Power Build - Rapsody Installation GuideFuad JahićNo ratings yet

- An Open Source Power System Analysis Toolbox: 7% (%#/#,) "3 ? @AB A@C AD@Document56 pagesAn Open Source Power System Analysis Toolbox: 7% (%#/#,) "3 ? @AB A@C AD@Chandan KumarNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Liebherr France SAS 30/07/09Document8 pagesLiebherr France SAS 30/07/09Fuad JahićNo ratings yet

- 1911 - Celltick's MAGEN (Mass Alert Geo Emergency Notifications) Suite PDFDocument9 pages1911 - Celltick's MAGEN (Mass Alert Geo Emergency Notifications) Suite PDFAskederin MusahNo ratings yet

- Mobile Insights, Growth and Monetization 2022Document45 pagesMobile Insights, Growth and Monetization 2022Le Chi BangNo ratings yet

- MTG Teeth AdapterDocument2 pagesMTG Teeth AdapterMaimun maimunNo ratings yet

- Request For A Written ExplanationDocument5 pagesRequest For A Written ExplanationAmiel Gian Mario ZapantaNo ratings yet

- Point Cloud GuideDocument27 pagesPoint Cloud GuideFREDIELABRADORNo ratings yet

- Zargis Cardioscan Manual - ENDocument22 pagesZargis Cardioscan Manual - ENErWiN ChrisToNo ratings yet

- Ricoh SMB V2 and V3 SUPPORT PDFDocument4 pagesRicoh SMB V2 and V3 SUPPORT PDFmdungstNo ratings yet

- Micropython On ESP8266 Workshop Documentation: Release 1.0Document35 pagesMicropython On ESP8266 Workshop Documentation: Release 1.0Hendri Kus23No ratings yet

- Wireless ANDON & Production Monitoring Case StudyDocument7 pagesWireless ANDON & Production Monitoring Case Studyfazela shaukatNo ratings yet

- Final Semester Project Proposal (Department of Computer Science)Document2 pagesFinal Semester Project Proposal (Department of Computer Science)Rafia NaeemNo ratings yet

- Python For Nokia S60Document15 pagesPython For Nokia S60Hasan YüksektepeNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rebate ProcessingDocument10 pagesRebate ProcessingsNo ratings yet

- Koustav BigData ResumeDocument2 pagesKoustav BigData ResumeValorant SmurfNo ratings yet

- Profile Shailesh GabhaneDocument2 pagesProfile Shailesh GabhaneShalesh GabhaneNo ratings yet

- Chapter - 1: Aeroplane CrashDocument18 pagesChapter - 1: Aeroplane CrashBharaniNo ratings yet

- Research Proposal PaperworkDocument2 pagesResearch Proposal PaperworkEmeirul Ezzuddean Bin JefriNo ratings yet

- Windows 8: A New Era For MicrosoftDocument22 pagesWindows 8: A New Era For Microsoftjosean33No ratings yet

- Computer Studies - 7014-03 Nov 2014 Specimen PDFDocument6 pagesComputer Studies - 7014-03 Nov 2014 Specimen PDFjoe zimunyaNo ratings yet

- E-Mail BW Workbook As Attachment - ABAPDocument10 pagesE-Mail BW Workbook As Attachment - ABAPRavindra BabuNo ratings yet

- Wolfe WaveDocument3 pagesWolfe Wavemohamed ibrahimNo ratings yet

- 11 4 17Document30 pages11 4 17immadzaffNo ratings yet

- Unlock Firestick BootloaderDocument2 pagesUnlock Firestick BootloaderGlenn MartynNo ratings yet

- Optimizing C C++ CompilerDocument201 pagesOptimizing C C++ CompilerZeynep Emirhan ŞenyüzNo ratings yet

- Caesar Cipher ExampleDocument3 pagesCaesar Cipher Exampleoguiniandc19No ratings yet

- Amber Tucker 2019-2020 ResumeDocument1 pageAmber Tucker 2019-2020 ResumeAmber TuckerNo ratings yet

- A Quantitative Performance Analysis Model For GPU ArchitecturesDocument12 pagesA Quantitative Performance Analysis Model For GPU ArchitecturesheyanithaNo ratings yet

- Mistserver V2.7 Manual: DdvtechDocument38 pagesMistserver V2.7 Manual: DdvtechWork UtilityNo ratings yet

- Rtems Installation ProcedureDocument6 pagesRtems Installation ProcedureConstantine Giotopoulos100% (1)

- Information Technology Training Needs Analysis (Sample)Document4 pagesInformation Technology Training Needs Analysis (Sample)Junalyn Ban-eg0% (1)

- 12 - Exception Handling and Text IODocument49 pages12 - Exception Handling and Text IOHanNo ratings yet