Professional Documents

Culture Documents

Pump Management System

Uploaded by

Fuad JahićCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pump Management System

Uploaded by

Fuad JahićCopyright:

Available Formats

Pump Management System

In excavators with double engine drive each drive unit is equipped with a load limit regulator

(GLR Boxes). The GLR boxes process the signal from the load sensors an switchesand send a

proportional mA signal to the main pump proportional valves. With no functions being

operated the GLR boxes will send a minimum of 225mA - the maximum will be 850mA. The

GRL boxes are not interchangeable with one another and must be programmed to each

machine on installation. 225mA - 850mA PMS current is displayed in the hydraulic menu on

the board control system in the cab.

The main pump proportional valves are supplied with 60 bar servo oil. Each proportional

valve receives a mA signal from the appropriate GLR box, Master to the Left proportional

valve and main pumps 1 & 2 and the Slave to the right proportional valve and main pumps 3

& 4. The proportional valves have an operating range between 7 - 42 bar this is PMS pressure

and displayed in the hydraulic menu on the board control system. The PMS pressure from the

proportional valves is supplied to the X1 port on main pumps. By varying the pressure

supplied to the X1 port, the main pump flow can be adjusted between 0-100% flow.

Both engines are equiped with a magnetic pickup to sense engine speed, this signal is then

processed by the relevant GLR box. The pump management system has been programmed

with the minimum engine speed setting (1780 RPM). Once the engine speed has dropped to

1780 RPM the GLR box will start to decrease the mA signal to the proportional valves which

reduces the generated PMS pressure and therefore destroke the pumps. As the load comes off

the engine due to the main pumps destroking, the engine RPM will increase and the pump

management system will increase PMS current (mA) and PMS pressure. The PMS will

balance the hydraulic load at an engine speed of 1780 rpm.

The engine and hydraulic oil temperature sensors supply 4 - 20mA signal to the GLR boxes

which have the maximum temperature parameters programmed into them. As the temperature

exceeds this parameter the pump management system will start decreasing mA to the

proportional valves which will destroke the main pumps taking the load off the engine or

hydraulic system allowing the temperature to fall below the maximum limit. The operator will

be advised about the temperature overshoot and reduced output.

Power control switch allows the operator to select between the two preset power ranges for

the hydraulic system.

Low is 80% output from the pump management system or 680mA. Full power is 100% or

850mA.

You might also like

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SFrom EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Panda Injection DescriptionDocument20 pagesPanda Injection DescriptionmvrhtNo ratings yet

- 16M Motor Grader Systems GuideDocument22 pages16M Motor Grader Systems GuideDouglas GomesNo ratings yet

- Curso Cat Fan System STMGDocument79 pagesCurso Cat Fan System STMGSilas F Pimenta100% (14)

- Descritivo de Manutenção - Guindaste Appleton Marine - SWL 30 TonsDocument9 pagesDescritivo de Manutenção - Guindaste Appleton Marine - SWL 30 TonsSérgio Meneses VieiraNo ratings yet

- Monnet - Recommended Scheme and Write Up of Auto ControlsDocument34 pagesMonnet - Recommended Scheme and Write Up of Auto ControlsDipti BhanjaNo ratings yet

- 2.3.2 GT DetailsDocument40 pages2.3.2 GT DetailsSarah Cohen100% (3)

- Boiler ControlsDocument27 pagesBoiler ControlsMY NAME IS NEERAJ..:):)No ratings yet

- Recommended Schemes & Writeup of Auto ControlsDocument25 pagesRecommended Schemes & Writeup of Auto ControlsShirshendu RoyNo ratings yet

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Fuel System DescriptionDocument4 pagesGE Energy LM2500+ G4 Operation and Maintenance Manual: Fuel System DescriptionAndrea CupelloNo ratings yet

- Boiler Combustion Control 2 02042016Document6 pagesBoiler Combustion Control 2 02042016ravipedapudiNo ratings yet

- STI Camden 5 (Automat)Document8 pagesSTI Camden 5 (Automat)somod95239No ratings yet

- The Hystat System Is Very Sensitive To Its Pressure SettingsDocument6 pagesThe Hystat System Is Very Sensitive To Its Pressure SettingsSamsul Hadi Wong NenjapNo ratings yet

- B767 ATA 29 Student BookDocument61 pagesB767 ATA 29 Student BookElijah Paul Merto100% (8)

- Eeg RT-12-6Document3 pagesEeg RT-12-6tmt IngNo ratings yet

- Bosch Motronic ME7.9.10Document32 pagesBosch Motronic ME7.9.10paulyvon.dicuNo ratings yet

- 06 NFC Pump Control SystemDocument31 pages06 NFC Pump Control Systempiteng1945100% (36)

- Engine Room Simulator Automation & Control GuideDocument34 pagesEngine Room Simulator Automation & Control Guider0x0rNo ratings yet

- Scavenge LimiterDocument13 pagesScavenge LimiterMario Andrew100% (1)

- FCMDocument4 pagesFCMMansoor Ahmad100% (1)

- Me SystemsDocument29 pagesMe Systemskarthick_mariner92No ratings yet

- Technical Service Information3Document4 pagesTechnical Service Information3JoseNo ratings yet

- Grasso Frequency ControlDocument3 pagesGrasso Frequency ControlSeekPTNo ratings yet

- Manual de Garcia EliasDocument4 pagesManual de Garcia EliasEmilio Alfonso Garcia EliasNo ratings yet

- Check The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001Document5 pagesCheck The OLTC Position For Startup Condition On 9 Step Position. Closed 10BBA10GS001, 10BBA10GS010, 10BBA30GS001jose Alberto uribe Minier100% (1)

- ERS MAN B&W 5L90MC-L11 Machinery & Operation MC90-V Automation & ControlDocument36 pagesERS MAN B&W 5L90MC-L11 Machinery & Operation MC90-V Automation & ControlJøn Bilbao Mallona100% (1)

- 41tes PDFDocument8 pages41tes PDFJuanortegaNo ratings yet

- Fuel Control SystemDocument21 pagesFuel Control SystemPremragunathan D (Instrumentation)No ratings yet

- Cis Information DiagnosisDocument17 pagesCis Information DiagnosisrezakecilNo ratings yet

- Perguntas ANAC PROVA GMPDocument4 pagesPerguntas ANAC PROVA GMPLucas LaurentinoNo ratings yet

- Stag-200 and Stag-300 Controller Connection and Programming ManualDocument22 pagesStag-200 and Stag-300 Controller Connection and Programming ManualionutsteNo ratings yet

- Analog Control SystemDocument11 pagesAnalog Control SystemYoginder KumarNo ratings yet

- UG 10 MAS Governor P7: ApplicationsDocument4 pagesUG 10 MAS Governor P7: Applicationsabelsg100% (1)

- Iveco Daily Euro 4 2006Document1 pageIveco Daily Euro 4 2006Zlatan BraticNo ratings yet

- SAAB For DummiesDocument25 pagesSAAB For DummiesMateusz FurmanNo ratings yet

- Construction of The Ai-9V EngineDocument8 pagesConstruction of The Ai-9V EngineYosif NorendoNo ratings yet

- HP-LP Bypass System Quickly Starts TurbinesDocument13 pagesHP-LP Bypass System Quickly Starts Turbinesshashank das100% (1)

- MODULE 14 Instrument System PDFDocument5 pagesMODULE 14 Instrument System PDFastikNo ratings yet

- Module 14 Propulsion Notes-3 PDFDocument5 pagesModule 14 Propulsion Notes-3 PDFastikNo ratings yet

- Dodge Challenger NAG1 5-Speed Automatic Transmission RefresherDocument4 pagesDodge Challenger NAG1 5-Speed Automatic Transmission RefresherEdBunge100% (1)

- Control Cummins Diesel EngineDocument8 pagesControl Cummins Diesel EngineAnkit Vyas100% (2)

- 1986 Mercedes Benz Cis-E Fuel Injection System-1Document23 pages1986 Mercedes Benz Cis-E Fuel Injection System-1Jen Steel100% (8)

- Cloradores GammaDocument24 pagesCloradores GammaOxiel Carrizo PozoNo ratings yet

- Bombardier Learjet-Hydraulics and Landing GearDocument23 pagesBombardier Learjet-Hydraulics and Landing GearMohamedAlAmine100% (1)

- Tr7-8fi ManualDocument82 pagesTr7-8fi ManualClint CooperNo ratings yet

- 418000E4422 R0 Write Up On Electro Hydraulic ControllerDocument10 pages418000E4422 R0 Write Up On Electro Hydraulic ControllerkoinsuriNo ratings yet

- Framo Hydraulic Cargo Pumping System On ShipsDocument3 pagesFramo Hydraulic Cargo Pumping System On ShipsKunal SinghNo ratings yet

- GE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionDocument4 pagesGE Energy LM2500+ G4 Operation and Maintenance Manual: Generator Lube Oil System DescriptionAndrea CupelloNo ratings yet

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Document23 pagesIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNo ratings yet

- Governing System, DebmalyaDocument12 pagesGoverning System, DebmalyaDipti Bhanja100% (1)

- Compact Setup Software ManualDocument26 pagesCompact Setup Software ManualToniNo ratings yet

- 3.5 Paragramer Mode 3.5 Transformer Monitoring Module TMM: Reg-Da Voltage Control RelayDocument1 page3.5 Paragramer Mode 3.5 Transformer Monitoring Module TMM: Reg-Da Voltage Control Relayspam02024294No ratings yet

- Turbine Control Software: ITS-Industrial Turbine Services GroupDocument19 pagesTurbine Control Software: ITS-Industrial Turbine Services GroupSyed Mohammed Hussain100% (1)

- Detroit-Diesel-DD-Three-Filter-SystemDocument170 pagesDetroit-Diesel-DD-Three-Filter-Systemcristian picadoNo ratings yet

- CMCDocument7 pagesCMCwasim_scribed100% (3)

- Map Sensor Drivability SymptomsDocument15 pagesMap Sensor Drivability SymptomsmichaelsilvaNo ratings yet

- KurtaDocument1 pageKurtaFuad JahićNo ratings yet

- PCU400e Datasheet 051007Document2 pagesPCU400e Datasheet 051007Fuad JahićNo ratings yet

- Process Communication Unit monitoring and control with PCU400Document3 pagesProcess Communication Unit monitoring and control with PCU400Fuad JahićNo ratings yet

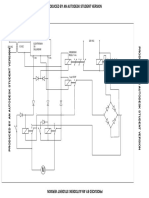

- Autodesk student version schematic diagramDocument1 pageAutodesk student version schematic diagramFuad JahićNo ratings yet

- PCU400 General Data SheetDocument2 pagesPCU400 General Data SheetFuad JahićNo ratings yet

- CourseSchedule Spring2009 755032 ENnDocument2 pagesCourseSchedule Spring2009 755032 ENnFuad JahićNo ratings yet

- PowerLogic PFC Capacitors - BLRCH500A000B44Document2 pagesPowerLogic PFC Capacitors - BLRCH500A000B44MirzaNo ratings yet

- Osigurači Na RH 120Document2 pagesOsigurači Na RH 120Fuad JahićNo ratings yet

- Data Acquisition PCU400 Network Manager Rel1Document41 pagesData Acquisition PCU400 Network Manager Rel1Fuad JahićNo ratings yet

- MR 8MCR Plan 7205089Document1 pageMR 8MCR Plan 7205089Fuad JahićNo ratings yet

- SIMEAS1Document2 pagesSIMEAS1Fuad JahićNo ratings yet

- MFT200 6002819Document2 pagesMFT200 6002819Fuad JahićNo ratings yet

- Bucket Volume 4.2 M - 9.0 M Bucket Capacity 8,000 KG Operating Weight 24,600 KG Peak Net Power 320 HPDocument10 pagesBucket Volume 4.2 M - 9.0 M Bucket Capacity 8,000 KG Operating Weight 24,600 KG Peak Net Power 320 HPFuad JahićNo ratings yet

- 701201UKDocument3 pages701201UKFuad JahićNo ratings yet

- Modicon TM3 - TM3TI4Document9 pagesModicon TM3 - TM3TI4Fuad JahićNo ratings yet

- HURGADA AVIONOM IZ SARAJEVA I BEOGRADA Detaljna Ponuda 1Document1 pageHURGADA AVIONOM IZ SARAJEVA I BEOGRADA Detaljna Ponuda 1Fuad JahićNo ratings yet

- Modicon M241 - TM241CEC24TDocument15 pagesModicon M241 - TM241CEC24TFuad JahićNo ratings yet

- CCU!Fssps!Dpef!Nje!TJF!FYDBWBUPST!Fssps!DpeftDocument8 pagesCCU!Fssps!Dpef!Nje!TJF!FYDBWBUPST!Fssps!DpeftFuad Jahić100% (1)

- Buena Vista D.O.O. Zenica - Podruznica Sarajevo Cjenovnik HotelaDocument1 pageBuena Vista D.O.O. Zenica - Podruznica Sarajevo Cjenovnik HotelaFuad JahićNo ratings yet

- EcoStruxure Power Build - Rapsody Installation GuideDocument5 pagesEcoStruxure Power Build - Rapsody Installation GuideFuad JahićNo ratings yet

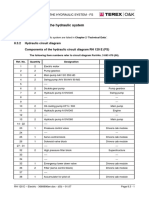

- Section 3 Hydraulic SystemDocument2 pagesSection 3 Hydraulic SystemFuad JahićNo ratings yet

- 3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPDocument2 pages3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPLượng Nguyễn XuânNo ratings yet

- 2. الدائره الرئيسيةDocument3 pages2. الدائره الرئيسيةالمهندسوليدالطويلNo ratings yet

- Test Secondary Current Injection SetDocument3 pagesTest Secondary Current Injection SetJulio SantacruzNo ratings yet

- 8.3 Description of The Hydraulic System: 8.3.1 Technical DataDocument12 pages8.3 Description of The Hydraulic System: 8.3.1 Technical DataFuad JahićNo ratings yet

- 8.5.2 Pressure Cut-Off: 8.5 Description of Hydraulic CircuitsDocument2 pages8.5.2 Pressure Cut-Off: 8.5 Description of Hydraulic CircuitsFuad JahićNo ratings yet

- Liebherr France SAS 30/07/09Document8 pagesLiebherr France SAS 30/07/09Fuad JahićNo ratings yet

- Ferromagnetic Hysteresis PDFDocument4 pagesFerromagnetic Hysteresis PDFFuad JahićNo ratings yet

- An Open Source Power System Analysis Toolbox: 7% (%#/#,) "3 ? @AB A@C AD@Document56 pagesAn Open Source Power System Analysis Toolbox: 7% (%#/#,) "3 ? @AB A@C AD@Chandan KumarNo ratings yet

- Sustainable Development & Environmental Assessment QuizDocument2 pagesSustainable Development & Environmental Assessment QuizramananNo ratings yet

- Introduction of Hris Chapter No.1: Tayyaba IqbalDocument16 pagesIntroduction of Hris Chapter No.1: Tayyaba IqbalmahnooorNo ratings yet

- Hershey's Milk Shake ProjectDocument20 pagesHershey's Milk Shake ProjectSarvesh MundhadaNo ratings yet

- Mid Test (OPEN BOOK) : Swiss German UniversityDocument5 pagesMid Test (OPEN BOOK) : Swiss German Universityaan nug rohoNo ratings yet

- Maharishi Dayanand University, Rohtak Haryana: Project Report OnDocument62 pagesMaharishi Dayanand University, Rohtak Haryana: Project Report OnHitesh Yaduvanshi100% (1)

- Lecture 4Document10 pagesLecture 4unknownuser14.1947No ratings yet

- What Makes Online Content ViralDocument15 pagesWhat Makes Online Content ViralHoda El HALABINo ratings yet

- Compile C/C++ in Atom editorDocument2 pagesCompile C/C++ in Atom editorNishant KeswaniNo ratings yet

- Best Practices for 802.11 Radios on 70 Series and CK3R/X DevicesDocument4 pagesBest Practices for 802.11 Radios on 70 Series and CK3R/X DevicesHilber Ricardo MoyanoNo ratings yet

- Inspector Vision Sensors: The Intelligent Vision Solution in An Easy-To-Use Sensor PackageDocument30 pagesInspector Vision Sensors: The Intelligent Vision Solution in An Easy-To-Use Sensor PackageANDRICO ANTONIUSNo ratings yet

- Top Triangle Bikini Kinda PatternDocument5 pagesTop Triangle Bikini Kinda PatternVALLEDOR, Dianne Ces Marie G.No ratings yet

- Turbo Charger and GasketDocument2 pagesTurbo Charger and GasketDavid NguyenNo ratings yet

- Article 20 Salary Scales 10-Month Teachers 2019-2020 (Effective July 1, 2019)Document10 pagesArticle 20 Salary Scales 10-Month Teachers 2019-2020 (Effective July 1, 2019)Robert MaglocciNo ratings yet

- Prog GuideDocument29 pagesProg GuideOmar L'fataNo ratings yet

- ChatroomsDocument4 pagesChatroomsAhmad NsNo ratings yet

- BSC6900 GSM Technical Description (V900R012C01 - 02)Document113 pagesBSC6900 GSM Technical Description (V900R012C01 - 02)Mohammad Mosabbirul IslamNo ratings yet

- Assignment Two: Dennis Wanyoike DIT-035-0022/2009 2/7/2010Document8 pagesAssignment Two: Dennis Wanyoike DIT-035-0022/2009 2/7/2010Dennis WanyoikeNo ratings yet

- String & Math FunctionsDocument38 pagesString & Math FunctionsThanu shreeNo ratings yet

- Company Profile: Our BeginningDocument1 pageCompany Profile: Our BeginningSantoshPaul CleanlandNo ratings yet

- The 10 Most Influential Business Women Making A Difference, 2022Document40 pagesThe 10 Most Influential Business Women Making A Difference, 2022The Inc MagazineNo ratings yet

- Martial Law Experience of a Filipino GrandmotherDocument2 pagesMartial Law Experience of a Filipino GrandmotherarellanokristelleNo ratings yet

- Course: Basic Technical English Teacher: Lic. Victor Matienzo BustamanteDocument11 pagesCourse: Basic Technical English Teacher: Lic. Victor Matienzo BustamanteSelene FloresNo ratings yet

- Cylinder Heads & ValvesDocument95 pagesCylinder Heads & ValvesFrank MosesNo ratings yet

- Orientation and TrainingDocument31 pagesOrientation and TrainingSyurga FathonahNo ratings yet

- RBS LogDocument1,351 pagesRBS Logsalman7467No ratings yet

- B757-767 Series: by Flightfactor and Steptosky For X-Plane 11.35+ Produced by VmaxDocument35 pagesB757-767 Series: by Flightfactor and Steptosky For X-Plane 11.35+ Produced by VmaxDave91No ratings yet

- Dengue Fever PresentationDocument11 pagesDengue Fever Presentationhira khanNo ratings yet

- Marquez Vs Comelec GR 112889Document1 pageMarquez Vs Comelec GR 112889JFA100% (1)

- Exam 2 Guidelines 2019Document6 pagesExam 2 Guidelines 2019Sri VeludandiNo ratings yet

- Logistics Supply Chain Multiple Choice QuestionsDocument183 pagesLogistics Supply Chain Multiple Choice QuestionsSanjay sadafule100% (1)