100% found this document useful (1 vote)

318 views5 pagesQuality Control Procedure Overview

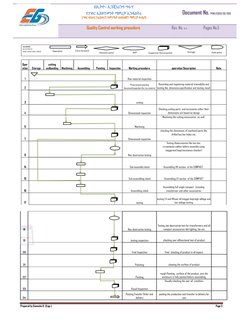

This document outlines quality control procedures for an Ethiopian power and engineering group. It describes the quality control process, which involves inspection of raw materials and products at various stages by quality controllers. The goals are to assure product quality, minimize defects, and improve customer satisfaction. Key steps include maintaining quality equipment, standards, and records like inspection reports. The procedures apply to all production lines and are described in further detail in supplemental documents.

Uploaded by

Meskela MarachiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

318 views5 pagesQuality Control Procedure Overview

This document outlines quality control procedures for an Ethiopian power and engineering group. It describes the quality control process, which involves inspection of raw materials and products at various stages by quality controllers. The goals are to assure product quality, minimize defects, and improve customer satisfaction. Key steps include maintaining quality equipment, standards, and records like inspection reports. The procedures apply to all production lines and are described in further detail in supplemental documents.

Uploaded by

Meskela MarachiCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Quality Control Involvement

- Introduction and Scope

- Performance Management

- Definitions & Abbreviations

- Procedure Details

- Supplementary Information

- Appendix