Professional Documents

Culture Documents

AOAC 989.04 Al 05-2013

Uploaded by

Miguel V0 ratings0% found this document useful (0 votes)

74 views3 pagesThis document provides details on the Babcock method for determining the fat content of raw milk. It describes the key equipment needed like Babcock bottles, pipettes, centrifuges, and dividers. It specifies parameters for the bottles like dimensions, graduations, and errors. It also gives procedures for testing the accuracy of bottles and pipettes, adding sulfuric acid to milk in the bottles, and centrifuging to separate the fat for quantification. Parameters are provided for centrifugation speed based on the centrifuge diameter.

Original Description:

Original Title

AOAC 989.04 al 05-2013

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides details on the Babcock method for determining the fat content of raw milk. It describes the key equipment needed like Babcock bottles, pipettes, centrifuges, and dividers. It specifies parameters for the bottles like dimensions, graduations, and errors. It also gives procedures for testing the accuracy of bottles and pipettes, adding sulfuric acid to milk in the bottles, and centrifuging to separate the fat for quantification. Parameters are provided for centrifugation speed based on the centrifuge diameter.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

74 views3 pagesAOAC 989.04 Al 05-2013

Uploaded by

Miguel VThis document provides details on the Babcock method for determining the fat content of raw milk. It describes the key equipment needed like Babcock bottles, pipettes, centrifuges, and dividers. It specifies parameters for the bottles like dimensions, graduations, and errors. It also gives procedures for testing the accuracy of bottles and pipettes, adding sulfuric acid to milk in the bottles, and centrifuging to separate the fat for quantification. Parameters are provided for centrifugation speed based on the centrifuge diameter.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

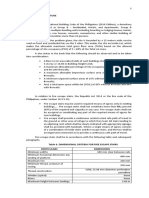

33.2.27 Table 989.04.

Proper rate of centrifuge rotation for known

AOAC Official Method 989.04 diameter of wheel to achieve 164 ´ g

Fat in Raw Milk Diameter of wheel, cm Diameter of wheel, in. rpm

Babcock Method

35.6 14 909

Final Action 1920

Revised First Action 1989 40.6 16 848

Revised First Action 1997 45.7 18 800

Final Action 2000 50.8 20 759

(Applicable to raw, whole milk.) 55.9 22 724

Results of the interlaboratory study supporting acceptance of the

61.0 24 693

method (for sections A–D):

sr = 0.037; sR = 0.047; RSDr = 0.901%; RSDR = 1.147%; r = 0.105;

R = 0.133

A. Principle (3) Testing.—Accuracy of each bottle shall be determined before

Known weight of milk is placed into Babcock bottle and H2SO4 is use (usually by manufacturer or certified laboratory). Bottle

added. Generated heat releases fat, which is then isolated by calibration accuracy is determined by placing bottle upside down on

centrifuging and addition of H2O. Fat is quantitated in graduated Babcock bottle calibration apparatus (Nafis tester or modified Nafis

portion of Babcock bottle. Result is expressed as % fat by weight. tester) that is capable of delivering known volumes of Hg into

Babcock bottle neck. Bottle calibration apparatus delivery is

B. Reagents

cal ibrated and vol ume of Hg contained be tween 8 and 4%

(a) Sulfuric acid.—Specific gravity 1.82–1.83 at 20°C. (0.800 mL), 4 and 0% (0.800 mL), and 8 and 0% (1.600 mL) marks

(b) Mercury.—Purity ³99.99%. Used for testing accuracy of is de ter mined. Ac cu racy of bot tle neck cal i bra tion may be

Babcock bottles. determined before or after attachment to bulb. Accuracy should be at

C. Apparatus least ±0.04% on scale of 18 g milk-test bottle. [Reference: J. AOAC

(a) Standard Babcock milk-test bottle.—8%, 18 g milk-test Int. 78, 463(1995).]

bottle, total height 160–170 mm (6.3–6.7 in.). Bottom of bottle is (b) Pipet.—Stan dard milk pipet con forms to fol low ing

flat, and axis of neck is vertical when bottle stands on level surface. spec i fi ca tions:

(1) Bulb.—Capacity of bulb to junction with neck is ³45 mL.

Bulb may be either cylindrical or conical. If cylindrical, od of base Total length . . . . . . . . . . . . . . . . . . . . . . . £350 mm

must be 34–36 mm; if conical, od of base must be 31–33 mm, and OD of suction tube . . . . . . . . . . . . . . . . . . . . 6–8 mm

maximum diameter, 35–37 mm. Length of suction tube. . . . . . . . . . . . . . . . . . . 130 mm

(2) Neck.—Cylindrical and of uniform diameter from ³5 mm OD of delivery tube [must fit into bottle, (a)] . . . . . 4.5–5.0 mm

below lowest graduation mark to ³5 mm above highest. Top of neck Length of delivery tube

is flared to diameter of ³10 mm. Graduated portion of neck is (slightly longer than bottle neck, must not touch

³75 mm long and is graduated in whole %, 0.5%, and 0.1% from 0.0 milk test portion when delivered) . . . . . . . . . 105–125 mm

to 8.0%. Graduations may be etched, with black or dark pigment Distance of graduation mark above bulb . . . . . . . . 15–45 mm

annealed to graduation, or may be unetched black or dark lines Nozzle parallel with axis of pipet, but slightly

constricted so as to discharge in 5–8 s when filled

permanently annealed to glass. Graduation line widths £0.2 mm.

with H2O

Tenth % graduations are ³3 mm long; 0.5% graduations are ³4 mm

Graduation, marked to contain 17.6 mL H2O at 20°C

long and project 1 mm to left; and whole % graduations extend at

when bottom of meniscus coincides with mark on

least half way around neck to right and project ³2 mm to left of 0.1% suction tube

graduations. Each whole % is numbered, with numeral placed to left

Maximum error in graduation . . . . . . . . . . . . . . £0.05 mL

of scale.

Vertical line must be etched and annealed with black or dark

To test pipet, place tip of pipet against firm rubber surface, clamp

pigment or must be etched into dark stripe permanently annealed to

pipet in vertical position, and use buret (Class A—graduations

glass. Etched vertical line is located 1 mm to right of 0.1%

£0.05 mL) to fill pipet to graduation mark with H2O (at 20°C).

graduation marks and extends ³1 mm above 8% line and ³1 mm

(c) Acid measure.—Device used to measure H2SO4 should deliver

below 0% line. If vertical line is etched into dark vertical stripe, then

in range from 10 to 20 mL. Use device that can be set to consistently

dark vertical stripe must extend ³1 mm above the 8% line and

deliver appropriate amount of acid to obtain desired milk acid

³1 mm below 0% line. Dark vertical stripe should be £2.0 mm wide reaction temperature in D.

and etched line must be £0.2 mm wide.

(d) Centrifuge or “tester.”—Standard centrifuge, however

Zero line (£0.2 mm wide) must be etched and annealed with black

driven, must be constructed throughout and so mounted as to be

or dark pigment, or not darkened but etched into dark horizontal

capable, when filled to capacity, of rotating at necessary speed with

stripe (£2.0 mm wide) permanently annealed to glass. Zero and

minimum vibration and without liability of causing injury or

vertical etched lines, with or without annealed pigment, should be of

sufficient depth to hold point of dividers. accident. Centrifuge must be heated, electric or otherwise, to

Capacity of neck for each whole % on scale is 0.200 mL. 46°–51°C during centrifuging. It must be provided with speed

Maximum error of total graduation or any part thereof must not indicator, permanently attached, if possible. Proper rate of rotation

exceed 0.008 mL. may be determined by reference to Table 989.04. Rotation speed

ã 2005 AOAC INTERNATIONAL

with full centrifuge should be checked periodically with tachometer. (c) Testing milk test portions.—To test bottle from (a) containing

“Diameter of wheel” means distance between inside bottoms of tempered milk, add appropriate amount of H2SO4 [as determined in

opposite cups measured through center of rotation of centrifuge (b)] by delivering acid in one delivery that washes all traces of milk

wheel while cups are horizontally extended. Relative centrifugal into bulb and cleanly layers acid under milk. Immediately shake

bottle by hand rotation as in (b), until all traces of curd disappear.

force is approximately 164 ´ g.

Place bottle in Babcock bottle shaker set at medium speed. Continue

(e) Dividers or calipers.—For measuring fat column.

to add acid to all test portions, and then shake full set 1 additional

(f) Water bath for test bottles.—Provided with thermometer and

min. Temperature of milk plus acid in first bottle should not be less

device to maintain temperature of fat column at 48° ± 1°C. than 50.5°C at time bottles are transferred to centrifuge.

(g) Wa ter bath for tem per ing milk sam ples prior to Place bot tles in heated cen tri fuge, coun ter-balance, and

weighing.—Provided with thermometer and device to maintain centrifuge 5 min after proper speed is reached. Add distilled water at

temperature of milk at 38° ± 1°C. 50°–52°C until bulb of bottle is filled. Centrifuge 2 min. Add

(h) Supply of hot water added after 1st and 2nd

distilled water at 50°–52°C until top of fat column approaches 7%

centrifugations.—Provided with thermometer, device to maintain

mark on bottle neck. Centrifuge 1 min longer at ca 51°C. Transfer

temperature of distilled H2O at 50°–52°C, and device to deliver H2O

bottle to water bath maintained at 48° ± 1°C, immerse bottle to level

into Babcock bottles.

slightly above top of fat column, and leave in water bath until

(i) Bottle shaker.—Variable speed and matched to maximum

column is at equilibrium and lower fat surface assumes final convex

capacity of centrifuge.

form (³5 min).

(j) Digital thermometer for measurement of milk-acid reaction

Remove 1 bottle from bath, wipe dry, and with aid of reading light

temperature.—Capable of reading temperature to the nearest degree

and magnification, C(k), use dividers or calipers to quickly measure

in range of 100°–120°C. Use acid-resistant probe, with small

fat column (before it begins to cool and contract). Place caliper

diameter (£0.5 mm) to ensure rapid response time. Length of

points in vertical line on neck of bottle, with 1 point at lowest surface

temperature probe should be such that its tip is ca 1 cm above bottom

of lower meniscus and other point at top of upper meniscus. Without

of bottle, when fully inserted.

changing distance between 2 points on calipers, move calipers down

(k) Reading light with magnifying glass.—As background when bottle neck until lower point rests in etched horizontal graduation

measuring fat columns. Light should be diffused (soft white color) mark at 0%. Place upper point of calipers against bottle graduation

and provide illumination from angles above and below level of fat and read test in % to nearest 0.05%. Repeat for each bottle.

column. Magnification device must be used to aid reading.

Fat column, at time of measurement, should be translucent,

(l) Tachometer.—For determining rotation speed of centrifuge

golden-yellow or amber, and free of visible suspended particles.

(capable of measuring between 600–1000 rpm).

Reject all tests in which fat column is milky or shows presence of

D. Determination curd or charred matter, or in which meniscus is indistinct or

(a) Test sample preparation and temperature adjustment.—Place distorted; repeat test, adjusting volume of H2SO4 added, to obtain

test sample in water bath at 38° ± 1°C. Level of H2O should be at or proper color and milk-acid reaction temperature.

above milk level. Mix test sample 10´ by inversion. If fat line References: JAOAC 8, 4(1924); 8, 471(1925); 56, 1401(1973);

remains on inside surface of container, run hot tap water (ca 58, 949(1975); 71, 898(1988).

50°–60°C) over outside surface for 15–20 s. Mix test sample J. AOAC Int. 80, 845(1997).

thoroughly by inversion and pipet immediately. Do not allow test

E. Alternative Apparatus (First Action 1986; Final Action 1991)

samples to remain in water bath more than 15 min after reaching

38°C. (a) Gercock-style milkfat test bottle.—(Available from Forcoven

With pipet, C(b), transfer 17.6 ± 0.05 mL prepared test portion at Products, Inc., PO Box 1556, Humble, TX 77338, USA.) 5%,

38°C to milk-test bottle. Also, transfer 17.6 ± 0.05 mL milk at 38°C 162 ± 3 mm high. Bottom of bottle is flat, and axis of flat graduated

to another milk test bottle for measurement of milk-acid reaction tube is vertical when bottle stands on level surface. Quantity of milk

temperature. Blow out milk in pipet tip ca 30 s after free outflow charge is 18 g; 18 g is acid-etched and pigmented in clear space

above 5% graduated line. Specifications:

ceases. Adjust temperature of milk in bottle to 20°–22°C. Adjust

(1) Bulb.—Capacity of bulb to junction with neck must be

temperature of H2SO4 to 20°–22°C.

³45 mL. Shape of bulb is cylindrical, 36 ± 0.5 mm od. Wall thickness

(b) Mea sure ment of milk-acid re ac tion tem per a ture and

determination of amount of H2SO4 to use.—Before testing group of 1.4 ± 0.2 mm. Word “Sealed”, manufacturer’s number or name, and

test portions, determine correct amount of acid to be used in analysis matted marking spot must be legibly and permanently marked on

by measuring milk-acid reaction temperature. Add 17.5 mL H2SO4 surface.

to bottle from (a) containing tempered milk test portion prepared for (2) Side filling tube.—8 mm od, 0.1 mm wall thickness. To enter

measurement of milk-acid reaction temperature. Add acid in one bulb below junction of bulb and neck of flat graduated tube along

delivery that washes all traces of milk into bulb and cleanly layers curved portion of bulb and with minimum angle extend to center of

acid under milk. Fully insert digital thermometer probe down bottle bulb and maintain vertical axis for 40 mm to height of 3 ± 2 mm

neck and immediately shake by hand rotation until all traces of curd above bottom of bottle.

disappear. Peak reaction temperature should be 108° ± 2°C. Adjust (3) Neck.—Graduated portion of flat tube is uniform cross

amount of H2SO4 added, until reaction temperature is within this section ³4 mm beyond extremes of graduated scale. Length of

range and fat column is translucent golden-yellow to amber. graduated portion of flat neck ³75 mm. Graduated at whole %, 0.5,

Amount of acid required may vary between technicians and between 0.1, and 0.05%. Graduations are acid-etched, with black pigment

batches of acid. annealed to graduation. Graduation widths ³0.2 mm. Each whole %

ã 2005 AOAC INTERNATIONAL

and 0.5% line is numbered on left above line and these lines extend Length of nozzle . . . . . . . . . . . . . . . . . . . . 15–20 mm

across flat surface. Smallest graduated line is ³2.5 mm. Intermediate Delivery time . . . . . . . . . . . . . . . . . . . . . . . . 5–8 s

graduation line extends 1 ± 0.2 mm equally on both sides of smallest

graduated line. Graduation:

For raw milk. . . . . . . . . . . . . To deliver 17.6 mL at 20°C

(4) Vertical line.—Vertical line is acid-etched and pigmented on

when bottom of meniscus coincides

right side of graduated flat tube. This line touches intermediate lines

with mark on suction tube

at their extreme right end and extends beyond 0 and 0.5% lines

For processed milk . . . . . . . . . To deliver 17.6 mL at 38°C

³3 mm. Width of vertical lines £0.2 mm. when bottom of meniscus coincides

(5) Error.—Maximum error of total graduation or any part with mark on suction tube

thereof must not exceed volume of smallest unit of graduation (= Maximum error . . . . . . . . . . . . . . . . . . . . £ 0.05 mL

0.01 mL). Permanent markings on bulb:

(b) Gercock-style pipet for raw and processed milk.—To conform For raw milk . . . . . . . . . . . . . . . . . . . . . “Sealed,”

to following specifications: manufacturer’s No. or name,

TD 17.6 mL at 20°C,

Total length: tolerance 0.05 mL, 5–8 s

For raw milk . . . . . . . . . . . . . . . . . . . . . £280 mm For processed milk . . . . . . . . . . . . . . . . . . . “Sealed,”

For processed milk . . . . . . . . . . . . . . . . . . ³280 mm manufacturer’s No. or name,

TD 17.6 mL at 38°C,

Suction tube diameter . . . . . . . . . . . . . . . . 7 ± 0.2 mm od

tolerance 0.05 mL, 5–8 s

Wall thickness . . . . . . . . . . . . . . . . . . . 0.9 ± 0.04 mm

Suction tube length . . . . . . . . . . . . . . . . . . . . 130 mm

Reference: JAOAC 69, 831(1986).

Delivery tube diameter . . . . . . . . . . . . . . . 5 ± 0.2 mm od

Distance of graduation mark above bulb . . . . . . . . 15–45 mm Revised: March 2002

ã 2005 AOAC INTERNATIONAL

You might also like

- Soldering electronic circuits: Beginner's guideFrom EverandSoldering electronic circuits: Beginner's guideRating: 4.5 out of 5 stars4.5/5 (9)

- July 2014 GEARSDocument76 pagesJuly 2014 GEARSRodger BlandNo ratings yet

- Slickline TallybookDocument29 pagesSlickline Tallybookpitia100% (3)

- Geotextiles and Geomembranes HandbookFrom EverandGeotextiles and Geomembranes HandbookT.S. IngoldRating: 5 out of 5 stars5/5 (1)

- States of Matter LessonDocument4 pagesStates of Matter Lessonapi-280793165No ratings yet

- Chapter 5 Assessment, Solution Manual, Electrons in Atoms, Glencoe, ChemistryDocument9 pagesChapter 5 Assessment, Solution Manual, Electrons in Atoms, Glencoe, Chemistrypumeananda100% (3)

- D4530Document5 pagesD4530rimi7al100% (1)

- Almugea or Proper FaceDocument5 pagesAlmugea or Proper FaceValentin BadeaNo ratings yet

- Test For BentoniteDocument3 pagesTest For BentoniteNay Win SheinNo ratings yet

- Sepa and PartechDocument5 pagesSepa and Partechdiana bunagan0% (1)

- Human Resource Development Multiple Choice Question (GuruKpo)Document4 pagesHuman Resource Development Multiple Choice Question (GuruKpo)GuruKPO90% (20)

- Effulent Treatment Plant: A Presentation By-Nishith Shekhar TripathiDocument16 pagesEffulent Treatment Plant: A Presentation By-Nishith Shekhar TripathianadinathNo ratings yet

- MT 165 Ultraviolet Absorption Test For Evaluation of Ethylenebis (Dithiocarbamate)Document29 pagesMT 165 Ultraviolet Absorption Test For Evaluation of Ethylenebis (Dithiocarbamate)Felipe NavarreteNo ratings yet

- A Research Paper On DormitoriesDocument5 pagesA Research Paper On DormitoriesNicholas Ivy EscaloNo ratings yet

- Particulate Technology Quiz: (Questions)Document7 pagesParticulate Technology Quiz: (Questions)Yushene Sarguet100% (1)

- Grade 8 For Demo Cigarette SmokingDocument3 pagesGrade 8 For Demo Cigarette SmokingSteven TaperoNo ratings yet

- Lab Manual For Drilling FluidDocument13 pagesLab Manual For Drilling FluidLemony Snickit100% (1)

- MT 158 Determination of Mercury On Treated Seeds: Miscellaneous Techniques and ImpuritiesDocument18 pagesMT 158 Determination of Mercury On Treated Seeds: Miscellaneous Techniques and ImpuritiesFelipe Navarrete100% (1)

- Raw Board Battle Round 1Document13 pagesRaw Board Battle Round 1Maridil Joy IsidroNo ratings yet

- May 2021 Examination Diet School of Mathematics & Statistics ID5059Document6 pagesMay 2021 Examination Diet School of Mathematics & Statistics ID5059Tev WallaceNo ratings yet

- T236Document4 pagesT236Rishi Gupta100% (1)

- 16.1.02 AOAC Official Method 970.66 Light and Heavy Filth: General First Action 1970 A. Definition of TermsDocument2 pages16.1.02 AOAC Official Method 970.66 Light and Heavy Filth: General First Action 1970 A. Definition of TermsMiguel VNo ratings yet

- LV SWBDQualityInspectionGuideDocument72 pagesLV SWBDQualityInspectionGuiderajap2737No ratings yet

- Aoac 989.04 17 EdiçãoDocument3 pagesAoac 989.04 17 EdiçãoTiago Antonio Marmentini lopesNo ratings yet

- 33.2.27A AOAC of Fi Cial Method 2000.18 Fat Con Tent of Raw and Pas Teur Ized Whole MilkDocument2 pages33.2.27A AOAC of Fi Cial Method 2000.18 Fat Con Tent of Raw and Pas Teur Ized Whole MilkJavier muñoz100% (1)

- UOPS 2 - Part 2Document3 pagesUOPS 2 - Part 2Jeoh SilangNo ratings yet

- Alternative Photographic Processes: Simple Cyanotype ©mike Ware 2019Document11 pagesAlternative Photographic Processes: Simple Cyanotype ©mike Ware 2019Mariel PretellNo ratings yet

- Mud Kit - Slurry Kit ManualDocument8 pagesMud Kit - Slurry Kit ManualAlok SinghNo ratings yet

- Vacuum Filter Description in Sugar Industry - Optimization of Sugar LossDocument8 pagesVacuum Filter Description in Sugar Industry - Optimization of Sugar LossYounas Sardar100% (1)

- Manuflo MES LCD5Document3 pagesManuflo MES LCD5ابزار دقیقNo ratings yet

- Viscosity Measurement Using CANNON-FENSKE ViscometersDocument2 pagesViscosity Measurement Using CANNON-FENSKE Viscometersb3ltaNo ratings yet

- ANSI (ST) - III Centrifugal 16042020Document25 pagesANSI (ST) - III Centrifugal 16042020marcio_limaNo ratings yet

- An Experience of Sugar Losses ReductionDocument9 pagesAn Experience of Sugar Losses ReductionOpal Priya WeningNo ratings yet

- Methods For Sampling & Analysis: Nitrogen Dioxide (NO) PrincipleDocument16 pagesMethods For Sampling & Analysis: Nitrogen Dioxide (NO) PrincipleMuhd ArifNo ratings yet

- MAN0015751 2162579 89877-8 89882-3 89889-94 89807-8 Zeba Desalting UGDocument3 pagesMAN0015751 2162579 89877-8 89882-3 89889-94 89807-8 Zeba Desalting UGyhquisNo ratings yet

- Measuring Instrument For Drilling MudDocument12 pagesMeasuring Instrument For Drilling Mudrony asmNo ratings yet

- H-3860D - Man - 0816 DesgasteDocument8 pagesH-3860D - Man - 0816 Desgastealvaro almendarezNo ratings yet

- 19 Drilling-Grade Xanthan Gum: 19.1 PrincipleDocument3 pages19 Drilling-Grade Xanthan Gum: 19.1 Principlealberto fonsecaNo ratings yet

- Method SsDocument16 pagesMethod SsMuhd ArifNo ratings yet

- Equipments Lab, Sup-TecDocument68 pagesEquipments Lab, Sup-TecplacideNo ratings yet

- Determination of AbsoluteDocument2 pagesDetermination of Absoluteaakash singhNo ratings yet

- Sugar Milling G Research InstituteDocument5 pagesSugar Milling G Research InstituteTinayeshe NgaraNo ratings yet

- Testing of Cut-Back AsphaltDocument35 pagesTesting of Cut-Back AsphaltEvaresto Cole MalonesNo ratings yet

- Viscometer, Ofi, 8-Speed, Model 800 PART No. 130-10Document5 pagesViscometer, Ofi, 8-Speed, Model 800 PART No. 130-10Bella NabilaNo ratings yet

- 990 - 22freezing PointDocument3 pages990 - 22freezing Pointswa bumNo ratings yet

- 10.1.02 AOAC Official Method 985.22 Organochlorine and Organophosphorus Pesticide ResiduesDocument0 pages10.1.02 AOAC Official Method 985.22 Organochlorine and Organophosphorus Pesticide ResiduesTruong Hoai ThanhNo ratings yet

- DLAB Manual-Pipettes Micropipette-Plus ManualDocument20 pagesDLAB Manual-Pipettes Micropipette-Plus ManualMax MustermannNo ratings yet

- Department of Transportation: California Test 214 August 2010Document7 pagesDepartment of Transportation: California Test 214 August 2010Diana MoscosoNo ratings yet

- Data Sheet Series B - Dosing PumpDocument2 pagesData Sheet Series B - Dosing PumpVeldaa AmiraaNo ratings yet

- Vacuum Filter Description in Sugar Industry - Optimization of Sugar LossDocument19 pagesVacuum Filter Description in Sugar Industry - Optimization of Sugar Lossवैभव धुरीNo ratings yet

- Experiment NO. 5 KINEMATIC VISCOSITY OF ASPHALT PDFDocument6 pagesExperiment NO. 5 KINEMATIC VISCOSITY OF ASPHALT PDFsaifNo ratings yet

- Manual Instrucciones Polarimetro Automatico Modelo Plra2bDocument9 pagesManual Instrucciones Polarimetro Automatico Modelo Plra2bdéborah_rosalesNo ratings yet

- Vacuum TC Measurement Kit Instructions V3.1Document20 pagesVacuum TC Measurement Kit Instructions V3.1Francisco javier DiazNo ratings yet

- Automatic Sampling System - DoedijnsDocument2 pagesAutomatic Sampling System - Doedijns4122acaNo ratings yet

- Walklab: Digital Dissolved Oxygen Meter Hd9030Document8 pagesWalklab: Digital Dissolved Oxygen Meter Hd9030AinizaNo ratings yet

- Chapter Three PDFDocument104 pagesChapter Three PDFOmar Albakhit Bany SakherNo ratings yet

- Process Equipment Design: PART-1Document5 pagesProcess Equipment Design: PART-1Souvik PaulNo ratings yet

- Guia de Usuario Omega Hx15Document12 pagesGuia de Usuario Omega Hx15microsoda8No ratings yet

- Kranzle 895 1165Document52 pagesKranzle 895 1165szerelNo ratings yet

- 8550A223ADocument2 pages8550A223ALTurboNo ratings yet

- 08.53 Calcimeter: Operating InstructionsDocument6 pages08.53 Calcimeter: Operating InstructionsBogdanNo ratings yet

- Sizing of StrainerDocument20 pagesSizing of StrainerMASOMESE KIKILENo ratings yet

- Dissolved Oxygen Sensor: Models 499A DO and 499A DO-VPDocument8 pagesDissolved Oxygen Sensor: Models 499A DO and 499A DO-VPNIRINTSOA Samoelinica Nanah SidonieNo ratings yet

- Soundness Test On Cement by Le - Chatelier MethodDocument4 pagesSoundness Test On Cement by Le - Chatelier MethodShahrukh NiazNo ratings yet

- Water Meter IND-H4000Document2 pagesWater Meter IND-H4000Abdulvasea SaaitNo ratings yet

- T122 TorsionalDocument6 pagesT122 Torsionalprabin kumar ashishNo ratings yet

- Manual EastechDocument24 pagesManual EastechLessing Cárdenas DíazNo ratings yet

- AA990 Graphite Furnace Autosampler ManualDocument20 pagesAA990 Graphite Furnace Autosampler ManualHaiat AlsuwaidiNo ratings yet

- P3960 BioPetteDocument11 pagesP3960 BioPettearchivo_lcNo ratings yet

- Shuttle Series PDFDocument40 pagesShuttle Series PDFIvan IvanovicNo ratings yet

- 16.1.01 AOAC Official Method 945.75 Extraneous Materials (Foreign Matter) in ProductsDocument4 pages16.1.01 AOAC Official Method 945.75 Extraneous Materials (Foreign Matter) in ProductsMiguel VNo ratings yet

- AOAC 2014.009 Pesticides (2022)Document6 pagesAOAC 2014.009 Pesticides (2022)Miguel VNo ratings yet

- AOC 963.07 Ethoxyquin in Animal FeedDocument1 pageAOC 963.07 Ethoxyquin in Animal FeedMiguel VNo ratings yet

- SThe Electric Double LayerDocument1 pageSThe Electric Double LayerDrishty YadavNo ratings yet

- Remote Sensing: Carbon Stocks, Species Diversity and Their Spatial Relationships in The Yucatán Peninsula, MexicoDocument18 pagesRemote Sensing: Carbon Stocks, Species Diversity and Their Spatial Relationships in The Yucatán Peninsula, MexicoSara EspinozaNo ratings yet

- Headworks & Barrage: Chapter # 09 Santosh Kumar GargDocument29 pagesHeadworks & Barrage: Chapter # 09 Santosh Kumar GargUmer WaheedNo ratings yet

- PSY502 OLd PapersDocument6 pagesPSY502 OLd Paperscs619finalproject.com100% (4)

- Chemistry Project Paper ChromatographyDocument20 pagesChemistry Project Paper ChromatographyAmrita SNo ratings yet

- Final PaperDocument12 pagesFinal PaperReikooNo ratings yet

- G120D Getting Started 0418 en-USDocument94 pagesG120D Getting Started 0418 en-USHamadi Ben SassiNo ratings yet

- Renaissance QuestionsDocument3 pagesRenaissance QuestionsHezel Escora NavalesNo ratings yet

- Definition, Scope and Nature of EconomicsDocument29 pagesDefinition, Scope and Nature of EconomicsShyam Sunder BudhwarNo ratings yet

- Additional Material On CommunicationDocument15 pagesAdditional Material On CommunicationSasmita NayakNo ratings yet

- Dyn ST 70 Ser 2Document12 pagesDyn ST 70 Ser 2alexgirard11735100% (1)

- International Trade SyllabusDocument3 pagesInternational Trade SyllabusDialee Flor Dael BaladjayNo ratings yet

- Catholic Social TeachingsDocument21 pagesCatholic Social TeachingsMark de GuzmanNo ratings yet

- Nteq Lesson PlanDocument4 pagesNteq Lesson Planeva.bensonNo ratings yet

- The Logistics of Harmonious Co-LivingDocument73 pagesThe Logistics of Harmonious Co-LivingKripa SriramNo ratings yet

- UntitledDocument41 pagesUntitledLinear Algebra & Multivariate CalculusNo ratings yet

- Catalog ITEM - Pdf4a3667894b315Document552 pagesCatalog ITEM - Pdf4a3667894b315Domokos LeventeNo ratings yet

- (Dust of Snow) & 2 (Fire and Ice) - NotesDocument3 pages(Dust of Snow) & 2 (Fire and Ice) - NotesdakshNo ratings yet

- Comparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterDocument4 pagesComparison of Plate Count Agar and R2A Medium For Enumeration of Heterotrophic Bacteria in Natural Mineral WaterSurendar KesavanNo ratings yet

- Floor DiaphragmDocument24 pagesFloor DiaphragmChristian LeobreraNo ratings yet