Professional Documents

Culture Documents

Igus Motor Driver Manual

Uploaded by

Dhimas PaksiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Igus Motor Driver Manual

Uploaded by

Dhimas PaksiCopyright:

Available Formats

igus® motion Plastics®

dryve D3, DC-Motor Control System

Manual V 1.1

Website Shop Videos/Tutorials

www.igus.eu/D3 www.igus.eu/dryve/tutorial

Operating Manual dryve D3 - V1.1 1/15

Table of contents

Table of Contents

1 Safety Instructions, Protective Measures and Guidelines............................ 3

1.1 Important Instructions ........................................................................ 3

1.2 Qualified Personnel ........................................................................... 3

1.3 Maintenance ...................................................................................... 3

1.4 Safety Instructions ............................................................................. 4

1.4.1 Classification of Information .............................................................. 4

1.5 Electromagnetic Compatibility ........................................................... 4

2 Product Overview ............................................................................................. 5

2.1 Technical Data .................................................................................. 5

2.1.1 Dimensions ....................................................................................... 5

2.1.2 Mechanical Data ............................................................................... 5

2.1.3 Electrical Data ................................................................................... 5

2.1.4 Environmental conditions .................................................................. 5

3 Installation ........................................................................................................ 6

3.1 Mechanical Installation ...................................................................... 6

3.2 Electrical Installation.......................................................................... 6

3.2.1 Pin Assignment ................................................................................. 7

4 Initial Operation ................................................................................................ 8

4.1 Operational Controls ......................................................................... 8

4.2 Motor Direction .................................................................................. 9

4.3 Limit Switch ....................................................................................... 9

4.4 External Motion Control ....................................................................10

4.5 Basic Settings ..................................................................................10

4.5.1 Operating Modes ..............................................................................10

4.5.2 Limit Switch Control..........................................................................11

4.5.3 Acceleration Type and Ramps .........................................................11

4.5.4 Motor Settings ..................................................................................13

4.5.5 Table Basic Settings.........................................................................13

4.5.6 Speed ...............................................................................................14

4.5.7 Force Setting ....................................................................................14

5 Troubleshooting ..............................................................................................15

6 Accessories .....................................................................................................15

7 Service .............................................................................................................15

Operating Manual dryve D3 - V1.1 2/15

Safety Instructions, Protective Measures and Guidelines

1 Safety Instructions, Protective Measures and Guidelines

1.1 Important Instructions

Read this manual carefully before operating the dryve D3 motor control system. Familiarise with the safety instructions and

ensure that the required safety measures are followed.

This manual was created according to the best of our knowledge and belief. It is used for technical documentation and for

assisting the user during the initial operation. The warnings, cautions and instructions issued by igus® regarding the dryve D3

motor control system must in any case be passed on to the end user if the dryve D3 motor control system is used as part of an

overall system.

igus® undertakes warranties only for igus® products in accordance with the standards, norms and specifications given in this

manual. The guarantee covers only the replacement or repair of a defective dryve D3 motor control system. There is no liability

for consequential damage and consequential errors. igus ® does not take any responsibility for the integration of the dryve D3

motor control system into the overall system. The responsibility for it lies with the plant designer or the end user. Please observe

the instructions under "Qualified Personnel". igus® assumes no liability for personal injury or damage to property resulting from

misuse or unauthorised technical modification of the dryve D3 motor control system.

igus® reserves the right to make changes and improvements to the product or the technical documentation at any time without

prior notice.

The dryve D3 motor control system must only be used if:

- All information and safety instructions in this manual have been observed.

- No changes have been made to the dryve D3 motor control system and it is in a technically flawless condition.

- The operating limits that are specified in technical data (p.5) are complied with.

- Necessary measures, if called for, have been taken for radio interference suppression depending on the operating

environment.

- All used connecting cables have been relieved of strain.

1.2 Qualified Personnel

The operation of the product must only be carried out by qualified personnel.

Personnel must:

- Have read and understood this manual and documentation on the installed motor, axis and accessories.

- Be familiar with all relevant applicable standards, provisions and accident prevention regulations.

- Be able, due to their training, to anticipate or recognise any hazards that may arise when using the control system.

- Ensure the safety of persons and objects when using the motor control system in the overall system.

1.3 Maintenance

The dryve D3 motor control system is maintenance-free.

Never open the housing of the dryve D3 motor control system independently, even in the event of a malfunction.

Opening the housing will void the warranty.

Operating Manual dryve D3 - V1.1 3/15

Safety Instructions, Protective Measures and Guidelines

1.4 Safety Instructions

1.4.1 Classification of Information

The degree and type of hazard are assigned to one of the following classes.

DANGER!

Safety instructions marked with DANGER indicate an imminently hazardous situation.

A disregard of the notice inevitably leads to a serious or even fatal accident.

WARNING!

Safety instructions marked with WARNING indicate a potential hazardous situation.

Failure to observe this notice is likely to result in a serious or fatal accident or property damage.

CAUTION!

Safety instructions marked with CAUTION indicate potential danger.

Failure to comply with the notice may possibly result in an accident or property damage.

NOTE

Safety instructions marked with NOTE indicate a potential hazardous situation.

Disregard of the notice may possibly result in property damage.

1.5 Electromagnetic Compatibility

WARNING!

• Risk of injury due to interference with signals and devices

Disturbed signals can cause unforeseen device reactions. Carry out the wiring in accordance with the EMC measures.

Failure to follow these instructions can result in death, serious injury, or material damage

Measures for EMC Effect

Device assembly Use cable clamps for the shield support, Good conductivity due to surface contact.

connect metal parts over a large area.

Switching devices such as contactors, relays Reduce mutual interference couplings.

or solenoid valves with interference

suppression units or spark suppressors (e.g.

diodes, varistors, RC elements)

Wiring Keep cables as short as possible. Avoid capacitive and inductive interference.

Operating Manual dryve D3 - V1.1 4/15

Product Overview

2 Product Overview

Ready to use immediately

Connect the voltage source and the motor: you are ready to start. No complicated software installation or complex wiring of

various additional switches and sensors.

Easy control

The intuitively operated rotary elements allow you to set the speed and force limit of the connected motor without prior

knowledge. A travel movement can be started by the two buttons on the front of the dryve D3.

2.1 Technical Data

2.1.1 Dimensions

The hatching indicates the distance for neighbouring components.

2.1.2 Mechanical Data

D x W x H dryve D3 in mm 116 x 27 x 126

Weight 150 g

D x W x H angle adapter in mm 137 x 30 x 120

Weight 315 g

2.1.3 Electrical Data

Voltage supply 24 V, ± 2 V

Motor types DC motor

Continuous motor current Max. 2.5 A

Motor output frequency Switch 4 off 8 kHz

Switch 4 on 1 kHz

Power output Max. 60 W

Cable lengths Max.3 m

Cable cross-sections 0.34 mm² to 1.5 mm²

Limit switch Voltage UB at X2.1

Current Max. 10 mA

External travel movement Voltage 5V

Current 5mA

2.1.4 Environmental conditions

Ambient temperature Operation -20 °C to +45 °C

Transport -40 °C to +60 °C

Bearing -40 °C to +60 °C

Relative humidity ≤ 90 %, non-condensing

Protection class IP 30

Degree of soiling according to EN 61010 1

Operating Manual dryve D3 - V1.1 5/15

Installation

3 Installation

3.1 Mechanical Installation

WARNING!

• Danger of malfunction

• Fire hazard

• Explosion hazard

Never operate the dryve D3 motor control system in water or in an aggressive, flammable or explosive atmosphere. Always

pay attention to the environmental conditions (p.5)

- Installation in a switch cabinet can be done on a TS 35 support rail (EN 50022) by mounting on the separately available

angle adapter.

- The installation site must be free of extreme vibrations or shocks.

- The dimensions for adjacent components can be found in the drawing at dimensions (p.5)

- The heated air flow of other devices and components must not be led through the area of the dryve D3.

3.2 Electrical Installation

The dryve D3 motor controller is constructed for use with direct currents.

Every voltage mentioned in this manual can be regarded as direct current.

WARNUNG!

• Risk of sudden movements

To ensure that the dryve D3 can be operated without interference, the voltage supply must not be executed as a PELV wiring

(Protection by Extra Low Voltage- primary safety earth potential connected to secondary ground).

WARNING!

• Risk of injury

Make sure that an emergency shutdown can be performed at all times.

CAUTION!

• Danger of electrical voltage

• Danger of electric arcs

Always turn off the power before disconnecting or making electrical connections in the system. Secure the power supply

against restart.

After switching the device off, wait at least 5 minutes. Check for the absence of voltage before working on the system.

Danger of improperly mounted electrical connections.

Do not allow cables to be unmounted and ensure that all connections are secure.

CAUTION!

• Electromagnetic alternating fields

Electromagnetic fields around the live wires may cause interference. Lay the supply and motor cables separately from the

control cables. Use the shortest possible cable lengths. Follow the instructions for electromagnetic compatibility (p.5)

NOTE

An operating voltage above the voltage specified in the technical data, as well as a voltage reversal might destroy the dryve

D3 motor control system.

Select an operating voltage within the voltage range specified in the technical data.

Operating Manual dryve D3 - V1.1 6/15

Installation

3.2.1 Pin Assignment

The connectors must be wired according to your application. For this purpose, use the detailed illustrations below for each

individual connector.

The terminals are connected as follows:

1. Insulate the cores over a length of 8 mm

2. Press the white spring of the core opening by hand

or with a screwdriver into the terminal block.

3. Push the core deep into the opening.

4. Remove the white spring out of the

connector again.

Operating Manual dryve D3 - V1.1 7/15

Initial Operation

4 Initial Operation

The following describes the initial operation, which makes the start easy.

You can find informative videos on the initial operation at igus.eu/D3

Interconnect the whole system according to EMC guideline (p.4)

Minimum equipment

To control a motor with the D3 dryve, a minimum equipment has to be provided by the user:

1. Voltage source with 24 V and connecting cables

2. Motor with suitable cable

DANGER!

• Danger of falling load

Never work under unsecured vertical axes and loads.

Secure the axis or load against falling by a mechanical safety device or other approved safety method.

WARNING!

• Fire hazard

Faulty settings of the dryve D3 motor control system can lead to extremely high motor temperatures.

NOTE

A faulty connection can damage or destroy the dryve D3 or drive.

4.1 Operational Controls

Operating Manual dryve D3 - V1.1 8/15

Initial Operation

4.2 Motor Direction

For a proper operation, it is necessary that the motor rotates in a defined direction.

For determination, please use the following procedure:

1. View onto drive shaft

2. Actuation of the button S2 for clockwise rotation

3. Clockwise rotation corresponds to a right-hand rotation

If the motor rotates counter clockwise, the polarity of the motor connecting cables must be changed.

4.3 Limit Switch

Two different types of limit switches can be connected to the dryve D3.

• Passive mechanical switches with NC functionality (NC - Normally Closed)

• Active electronic proximity switches with NC functionality (NC - Normally Closed), PNP characteristics

Connected limit switches are supplied with the same voltage as supplied to X2.1.

For both types, different connection options must be considered.

Mechanical switches

The switches are connected to a voltage output and the respective signal input.

The right limit switch is connected to X3.1 and X3.2, the left to X3.4 and X3.5.

Electronic switches

The switches must be connected to a voltage output, the signal input and 0 V respectively.

The supply voltage of the right limit switch is connected to X3.1, the output signal to X3.2 and 0 V to X3.3. The supply voltage of

the left limit switch is connected to X3.4, the output signal to X3.5 and 0 V to X3.6.

To guarantee a logical and safe function, the limit switches must be assigned correctly to the respective running direction. A

correctly connected, not set limit switch is indicated by a green LED below the respective direction button.

If a limit switch is set, the LED below the respective direction button goes out. Please check that the LED 1 below the button “S1

left” turns off if the left limit switch is set. A test can be executed without driving the motor. If the connections are not correct, the

positions of the limit switches must be interchanged.

Operating Manual dryve D3 - V1.1 9/15

Initial Operation

4.4 External Motion Control

Movements can be remotely controlled via an external wiring.

For this purpose, normally-open (NO) passive switching contacts are connected to X4.1 and X4.2 as well as X4.3 and X4.4.

These switching contacts can be push buttons, relays and optocouplers. A higher-level control system can be used via

potential-free contacts. The function is identical to the function of the buttons S1 and S2.

If a button combination for left-hand/right-hand rotation with only 3 connecting wire is used, X4.2 and X4.4 must be bridged. The

common wire of the button combination must be connected to these bridged connections.

The buttons for left and right are connected to X4.1 and X4.3 respectively

NOTE

No external potential must be connected to X4 as this may destroy the dryve D3.

4.5 Basic Settings

In its delivery condition, all switches are set to "off" (down position).

4.5.1 Operating Modes

Tip mode

The motor is moved to the left or right when button S1 or S2 is pressed. If the button is not pressed, the motor stops.

Start to end mode

The motor is moved to the left or right after pressing button S1 or S2.

The motor stops only when:

1. One of the two buttons are pressed

2. The movement encounters a block whose resistance is greater than the force (p.14) the motor is allowed to apply

3. The limit switch (p.9) at the end of the movement direction is triggered

Operating Manual dryve D3 - V1.1 10/15

Initial Operation

4.5.2 Limit Switch Control

Limit switch

A travel movement is automatically stopped if:

1. The limit switch is triggered in the direction in which the movement is executed

2. The movement encounters a block whose resistance is greater than the force (p.14), the motor is allowed to apply

Block travel

A travel movement is automatically stopped if:

1. The movement encounters a block whose resistance is greater than the force (p.14), the motor is allowed to apply

NOTE

This operating mode is only suitable for drives/motors which, due to their own torque, cannot damage the mechanical

structure of the axis! Powerful drives with incorrectly adjusted force limitation, may damage or destroy the mechanical

structure of the axis! The suitability can be resolved by checking the motor data sheet and the axis parameters.

In this mode, the motor travels until the set force is reached (P1 force limit) and then shuts off. For this reason, it is important

that the force limitation (p.14) is set correctly.

4.5.3 Acceleration Type and Ramps

The maximum achievable acceleration depends on the connected motor, a possible mounted gearbox and the connected linear

or rotary axis as well as on the load to be moved.

Basically, the deceleration cannot be influenced by the settings of the dryve D3. This is determined by the mechanical

properties of the combination of the motor, a possible mounted gearbox and the connected linear or rotary axis and the load to

be moved.

Maximum acceleration

The motor is maximally accelerated to the pre-set speed.

Acceleration ramps

The motor is accelerated according to the selected ramp.

It is possible to set 5 different accelerations.

In the delivery state, the acceleration ramp 3 is set.

Operating Manual dryve D3 - V1.1 11/15

Initial Operation

Setting the acceleration:

1. Initiation of the acceleration change mode by simultaneously pressing buttons S1 and S2 for at least 5 seconds (LED

7 lights up red) -> LEDs 4 to 7 flash 5 times.

2. Release both buttons

3. LED 7 flashes at intervals -> number of flashes represents the set acceleration ramp

4. Change the acceleration by pressing button S1 until LED 4 "Motor running" lights up

5. Release the button S1 -> The next acceleration is set and LED 7 flashes repeatedly corresponding to the selected

acceleration ramp number

6. After acceleration ramp 5, acceleration ramp 1 is repeated

7. To exit the acceleration ramp change mode, press the S2 button for at least 3

seconds -> the LEDs 4 to 7 flash 5 times

Initial set up videos available a twww.igus.eu/dryve/tutorial and igus.eu/D3.

Operating Manual dryve D3 - V1.1 12/15

Initial Operation

4.5.4 Motor Settings

DC motors with low inductances

If the operating mode for highly inductive motors is used with this type of motor, it can lead to an increased noise level as well

as not reaching the maximum speed.

DC motors with high inductances

If the operating mode for low inductive motors is used with this type of motor, it can lead to an increased noise level as well as

not reaching the maximum speed.

4.5.5 Table Basic Settings

Basic Settings Dip switch Function

Operating modes Tip mode

Start to end mode

Limit switch control Limit switch

Block travel

Acceleration Maximum acceleration

Acceleration ramps

Motor settings Low inductances

High inductances

Operating Manual dryve D3 - V1.1 13/15

Initial Operation

4.5.6 Speed

The motor speed can be adjusted continuously from 0% to 100% via the potentiometer P2. At 50% of the achievable speed, a

lock is available for more precise settings.

The maximum achievable speed depends on the connected motor, a possible mounted gearbox and the connected linear or

rotary axis as well as the load to be moved.

4.5.7 Force Setting

The maximum force of the drive, i.e. the maximum current output, should always be set correctly to suit the respective

mechanical structure. This also applies to the use of limit switch operation.

To determine and test the ideal setting for the limitation, select the operating mode Tip mode (p.10) and the maximum

acceleration (p.11).

Setting the optimal force limit:

1. Turn the potentiometer for force limit P1 and the setpoint speed P2 clockwise to the end stop

2. Move the connected motor, including the load, in a free direction

3. Reduction of the permissible force by a counter clockwise rotation to the end stop of the potentiometer P1

4. The current limit LED 5 (yellow) lights up and the over current LED 6 (red) flashes

5. Increase the force limitation in small steps by turning the potentiometer P1 clockwise till LED 5 (yellow) and LED 6

(red) will turn off permanently

6. Run the motor across the whole axis in both directions

7. The motor moved across the whole axis and LED 5 (yellow) lights up for a less than a 1 second.

The force setting is applied successfully.

If the motor doesn’t move across the whole axis, please proceed with step 8

8. The Motor stops prior to reaching the axis end, LED 5 (yellow) lights up for 1 second, the Motor Running LED 4 (blue)

turns off and LED 6 (red) lights up permanently.

Increase the force limit P1 in small steps. Please proceed with step 6

Optional settings “Start to end mode”

9. Force setting Re-test. If the motor is not able to be moved across the whole axis the force limit P1 must be increased

in small steps. Please proceed with step 6

10. When the motor is being blocked at the axis end, the LED 5 (yellow) lights up a 1 second, LED 4 (blue) will turn off

and LED 6 (red) will light up constantly.

The force setting is applied successfully.

If LED 4 (blue) stays on the whole time the force limit P1 is set to high. Please proceed with step 11

11. Decrease the fore limit P1 in small steps. Please proceed with step 6. Switching to “Tip Mode” is not necessary

Operating Manual dryve D3 - V1.1 14/15

Service

5 Troubleshooting

Problem Description Remedy

The motor control system does not When the buttons S1 or S2 are Please contact customer service

perform any movements actuated, a colour change of the LED

3 from green (function OK) to red

(defect) is to be observed

6 Accessories

AK-DCCON-D3-0001 Top-hat rail mounting adapter kit

7 Service

Customer service

dryve@igus.de

+49 (0) 2203-9649-845

Technical support for igus dryve motor control systems

Videos/Tutorials

www.igus.eu/dryve/tutorial

Video guides explaining the functional range and the set up of the dryve D3

Additional product videos

Website Shop

http://www.igus.eu/D3

Download the dryve D3 firmware, manual and specifications

Ordering of further motor control systems

Website drylin E

www.igus.eu/drylinE

Download data sheets of the electric drive technology

Ordering of motors, limit switches and other accessories

Website drylin drive technology

www.igus.eu/drivetechnology

Download data sheets of the mechanical drive technology

Ordering of axes, linear robots and accessories

Contact

www.igus.eu

info@igus.eu

+49 (0) 2203-9649-0

Imprint

All rights reserved:

igus® GmbH

Spicher Str. 1a

51147 Cologne, Germany

© 2018

Operating Manual dryve D3 - V1.1 15/15

You might also like

- Om E0834e002Document54 pagesOm E0834e002Budiman RusdiNo ratings yet

- 57-600.22 Eclipse Model 705 Io PDFDocument68 pages57-600.22 Eclipse Model 705 Io PDFtuanbrotherNo ratings yet

- 4P543053-1B - DBP - BRC2E61 - Controle Com Fio SimplificadoDocument36 pages4P543053-1B - DBP - BRC2E61 - Controle Com Fio SimplificadoIocas SoluçõesNo ratings yet

- Wired Remote Controller: Installation and Operation ManualDocument36 pagesWired Remote Controller: Installation and Operation ManualewothjogNo ratings yet

- IOM - Enhanced - Model - 705 - Io PDFDocument64 pagesIOM - Enhanced - Model - 705 - Io PDFNUR AFIFAHNo ratings yet

- Unidrive m300 Control Quick Start Guide English Iss3 (0478-0281-03) - ApprovedDocument60 pagesUnidrive m300 Control Quick Start Guide English Iss3 (0478-0281-03) - ApprovedgryzzlyNo ratings yet

- Ultrasil Polymer Insulated D 73p Disconnect Switches Installation Instructions Mn008004enDocument12 pagesUltrasil Polymer Insulated D 73p Disconnect Switches Installation Instructions Mn008004enTom GewinnNo ratings yet

- Guided Wave Radar Level Transmitter: Enhanced Model 705Document68 pagesGuided Wave Radar Level Transmitter: Enhanced Model 705JAC 91No ratings yet

- 705Document69 pages705Karim AhmedNo ratings yet

- D 73p3 Bypass Switches Installation Instructions - Mn008005enDocument8 pagesD 73p3 Bypass Switches Installation Instructions - Mn008005enTom GewinnNo ratings yet

- PD User Manual InverterDocument60 pagesPD User Manual InverterDwi Bagus JatmikoNo ratings yet

- S2801043 - Form 4D Recloser Control Communications - 2012Document88 pagesS2801043 - Form 4D Recloser Control Communications - 2012CesarNo ratings yet

- Manual DM6000Document52 pagesManual DM6000thiago silvaNo ratings yet

- Magnetrol Level TransmitterDocument60 pagesMagnetrol Level TransmitterKelvin Anthony OssaiNo ratings yet

- DMC8000 Video Wall Controller Quick Guide-V1.00Document23 pagesDMC8000 Video Wall Controller Quick Guide-V1.00Birthley RagasaNo ratings yet

- Manual Burkert 1078-1 1078-2 PDFDocument35 pagesManual Burkert 1078-1 1078-2 PDFVũ PhongNo ratings yet

- Series: 30 W / Operating ManualDocument44 pagesSeries: 30 W / Operating ManualMuhammad Adam Rustam PasaribuNo ratings yet

- Recloser Nova S280441-1 CooperDocument28 pagesRecloser Nova S280441-1 CooperGerson Ariel Garcia RodasNo ratings yet

- Perating Nstructions: Movitrac B KeypadDocument32 pagesPerating Nstructions: Movitrac B Keypaddrdmg22No ratings yet

- Magnetrol R95Document48 pagesMagnetrol R95Alexander Garcia DiazNo ratings yet

- Control Techniques SM Resolver User GuideDocument38 pagesControl Techniques SM Resolver User GuidejorgeNo ratings yet

- User Manual: Easylogic™ Dm6000H / Dm6200H SeriesDocument50 pagesUser Manual: Easylogic™ Dm6000H / Dm6200H SeriesLucio SalesNo ratings yet

- Profibus Card 590P 690PDocument34 pagesProfibus Card 590P 690PjamazaNo ratings yet

- UserManual Omniksol-3k&4k&5k-TL2 en Built-In Card V1.2 20190109Document76 pagesUserManual Omniksol-3k&4k&5k-TL2 en Built-In Card V1.2 20190109Pablo BettancourtNo ratings yet

- Transmisor Analítico - Rosemount 1066Document132 pagesTransmisor Analítico - Rosemount 1066Guzmán AlmandosNo ratings yet

- User Manual: This Document Supports Firmware Version 2.2 and AboveDocument162 pagesUser Manual: This Document Supports Firmware Version 2.2 and AboveDamian FulgoniNo ratings yet

- GSK DAT2030 User ManualDocument124 pagesGSK DAT2030 User ManualArturo FuentesNo ratings yet

- Brc1e62 1Document28 pagesBrc1e62 1ابو حمزةNo ratings yet

- SERVOSTAR CD Series UL PacketDocument24 pagesSERVOSTAR CD Series UL PacketLimosh BsNo ratings yet

- SIFANG CSC-326 V1.00 Numerical Transformer Protection Equipment Manual 2010-08Document211 pagesSIFANG CSC-326 V1.00 Numerical Transformer Protection Equipment Manual 2010-08MarkusKunNo ratings yet

- Instalación Ventilador Motor CDDocument12 pagesInstalación Ventilador Motor CDcarcruparkNo ratings yet

- Fx3ge Quick Start ManualDocument30 pagesFx3ge Quick Start ManualAlberto Suazo Basaez0% (1)

- (نسخة) TAL Installation and maintenanace manual-TAL044Document32 pages(نسخة) TAL Installation and maintenanace manual-TAL044Mahmood NabilNo ratings yet

- Leroy Somer TAL-A42Document32 pagesLeroy Somer TAL-A42ArnelNo ratings yet

- M1M15 User ManualDocument36 pagesM1M15 User ManualRomulo GonzalezNo ratings yet

- Woodward 2301a Manual (9905, 9907)Document52 pagesWoodward 2301a Manual (9905, 9907)ЕвгенийNo ratings yet

- GD300 16 Inverter For HVAC Operation Manual V2 0Document136 pagesGD300 16 Inverter For HVAC Operation Manual V2 0Ngọc Thiện NguyễnNo ratings yet

- EasyLogic™ PM2200 SeriesDocument86 pagesEasyLogic™ PM2200 SeriesMiguel Huaccha ArmasNo ratings yet

- Installation and User Manual: For Frequency Inverters ELDIDocument33 pagesInstallation and User Manual: For Frequency Inverters ELDImynanick0% (1)

- Leroy SOmer TAL042 Installation and Maintenance ManualDocument32 pagesLeroy SOmer TAL042 Installation and Maintenance ManualAhmed Mohammed TahounNo ratings yet

- Haier: Service ManualDocument52 pagesHaier: Service ManualAndres AlegriaNo ratings yet

- Product Manual 02303 (Revision B, 9/2015) : 2301A Load Sharing and Speed ControlDocument46 pagesProduct Manual 02303 (Revision B, 9/2015) : 2301A Load Sharing and Speed ControlGaston MendozaNo ratings yet

- GW Type 7 Controller ManualDocument53 pagesGW Type 7 Controller Manualstudent_ujjwol3163100% (1)

- Belt Conveyor - 20111202171201Document36 pagesBelt Conveyor - 20111202171201Henwi Adi CahyoNo ratings yet

- QGH1329903 02 enDocument70 pagesQGH1329903 02 enfadliNo ratings yet

- Drtech EVS 4343 / EVS 4343G: Safety and Regulatory Information With User's ManualDocument108 pagesDrtech EVS 4343 / EVS 4343G: Safety and Regulatory Information With User's Manualqazxsw100% (1)

- COM100D/COM100E Smart Communication Box User ManualDocument42 pagesCOM100D/COM100E Smart Communication Box User ManualrolandogaraysalazarNo ratings yet

- Manual - Tx. Nivel Radar R82 - MagnetrolDocument64 pagesManual - Tx. Nivel Radar R82 - MagnetrolSpike SpikeNo ratings yet

- P30 Manual PDFDocument214 pagesP30 Manual PDFgeorge_cpp2No ratings yet

- DVR-462 4-Ch H.264 Digital Video Recorder: User's ManualDocument85 pagesDVR-462 4-Ch H.264 Digital Video Recorder: User's ManualtingNo ratings yet

- Manual Targeta Reguladora Wood Ward. 2100Document25 pagesManual Targeta Reguladora Wood Ward. 2100wilsonNo ratings yet

- Exhibit D Users Manual Per 2 1033 b3 314895Document48 pagesExhibit D Users Manual Per 2 1033 b3 314895GUSTAVO MENDOZANo ratings yet

- EasyLogic™ PM2100 series-EN PDFDocument92 pagesEasyLogic™ PM2100 series-EN PDFMiguel Huaccha ArmasNo ratings yet

- CoDeSys Manual V2p3Document48 pagesCoDeSys Manual V2p3Lac le VanNo ratings yet

- Vector: VB Series Use's ManualDocument72 pagesVector: VB Series Use's ManualTrương NgôNo ratings yet

- Cho LocDocument38 pagesCho LocTien Dang ThanhNo ratings yet

- Low Voltage Alternator - 4 Pole: Installation and MaintenanceDocument32 pagesLow Voltage Alternator - 4 Pole: Installation and Maintenanceabdo elsayedNo ratings yet

- HM-5114-2EDocument40 pagesHM-5114-2EHuynh Tien ThinhNo ratings yet

- Chainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesFrom EverandChainsaw Operator's Manual: Chainsaw Safety, Maintenance and Cross-cutting TechniquesRating: 5 out of 5 stars5/5 (1)

- Safe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsFrom EverandSafe Use of Smart Devices in Systems Important to Safety in Nuclear Power PlantsNo ratings yet

- IO Actuator ManualDocument80 pagesIO Actuator ManualDhimas PaksiNo ratings yet

- BES Binari InputDocument160 pagesBES Binari InputDhimas PaksiNo ratings yet

- 6ES72344HE320XB0 Datasheet enDocument4 pages6ES72344HE320XB0 Datasheet enjbaltazar77No ratings yet

- v3 Driver SchematicDocument1 pagev3 Driver SchematicDhimas PaksiNo ratings yet

- ICOM IC-80AD BrochureDocument4 pagesICOM IC-80AD Brochuregus289No ratings yet

- PROSOFT PLX8x EIP 61850 User ManualDocument167 pagesPROSOFT PLX8x EIP 61850 User Manualjuanjovm77No ratings yet

- RF Engineer ResumeDocument3 pagesRF Engineer ResumemadhubaddapuriNo ratings yet

- Linear Phased Array Antenna2Document19 pagesLinear Phased Array Antenna2AnilLazyNo ratings yet

- ITE101 - Lesson 1Document12 pagesITE101 - Lesson 1Jabelle Mae DoteNo ratings yet

- Seminar On Industrial TrainingDocument36 pagesSeminar On Industrial TrainingRahul KumarNo ratings yet

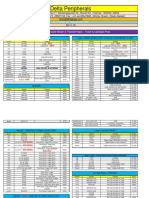

- Printers DeltaperperalDocument4 pagesPrinters DeltaperperalParid RidwanNo ratings yet

- SWT 3000 TeleprotectionDocument12 pagesSWT 3000 TeleprotectionZamfir ConstantinNo ratings yet

- Chapter # 19 The Atomic NucleusDocument7 pagesChapter # 19 The Atomic NucleusSIR USMAN KHAN100% (2)

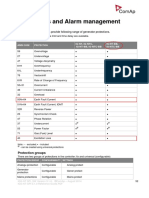

- College Engineering Lab Builds Theft Alarm Proximity SensorDocument10 pagesCollege Engineering Lab Builds Theft Alarm Proximity Sensordebasish behera100% (1)

- 06 - Flexi WCDMA BTS and Module Overview (WN5.0 - RU10)Document113 pages06 - Flexi WCDMA BTS and Module Overview (WN5.0 - RU10)GauravSwami100% (14)

- Modeling and Simulation For An 8 KW Three-Phase Grid-Connected Photo-Voltaic Power SystemDocument10 pagesModeling and Simulation For An 8 KW Three-Phase Grid-Connected Photo-Voltaic Power SystemLuis Alberto Valverde SánchezNo ratings yet

- ISA RP60.6 Nameplates, Labels, and Tags For Control CentersDocument44 pagesISA RP60.6 Nameplates, Labels, and Tags For Control CentersfmnguestNo ratings yet

- NAND Chip Mask ROM Mode Short LocationDocument8 pagesNAND Chip Mask ROM Mode Short LocationmrtuktukNo ratings yet

- KHM Herbie The Mousebot ManualDocument20 pagesKHM Herbie The Mousebot ManuallocoidonNo ratings yet

- Verilog ExamplesDocument61 pagesVerilog ExamplesSanam Nisar100% (1)

- Pages From IGS-NT-SPI-3.1.0 Reference Guide2Document1 pagePages From IGS-NT-SPI-3.1.0 Reference Guide2Mohamed MossadNo ratings yet

- Metrology CoordinateDocument24 pagesMetrology Coordinate김상동No ratings yet

- Comp2024 Btest-12 (Adv) PhysicsDocument15 pagesComp2024 Btest-12 (Adv) PhysicsThe Music VaultNo ratings yet

- Tca 785 PDFDocument16 pagesTca 785 PDFrrebollar100% (1)

- Automatic Circuit Recloser BrochDocument12 pagesAutomatic Circuit Recloser BrochsanNo ratings yet

- Soundcraft Si Compact 24Document6 pagesSoundcraft Si Compact 24Johannes RacNo ratings yet

- Nikon Metrology API v3.7 - Reference ManualDocument30 pagesNikon Metrology API v3.7 - Reference ManualQuangNguyenDuyNo ratings yet

- CT7TP em IndexDocument10 pagesCT7TP em IndexMichałNo ratings yet

- Isolation TransformersDocument9 pagesIsolation TransformersAdrian Enrique MaldonadoNo ratings yet

- MCB LeafletversoDocument1 pageMCB LeafletversoMostafa Hazem EL NemrNo ratings yet

- 7 - GEH-6370 MK V Time SynchronizationDocument44 pages7 - GEH-6370 MK V Time SynchronizationBouazzaNo ratings yet

- UEE QesDocument4 pagesUEE QesSravan KumarNo ratings yet

- Precision Oil and Solid Dielectric Analyzer: FeaturesDocument3 pagesPrecision Oil and Solid Dielectric Analyzer: FeaturesKaren SimsNo ratings yet

- Lab # 3 Analysis of Uniform and Non Uniform Quantization of Speech Signals (U-Law and A-Law)Document13 pagesLab # 3 Analysis of Uniform and Non Uniform Quantization of Speech Signals (U-Law and A-Law)zain islamNo ratings yet