Professional Documents

Culture Documents

Annexure

Uploaded by

Om JadhavCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annexure

Uploaded by

Om JadhavCopyright:

Available Formats

Annexure- A

CERTIFICATE

This is to certify that Mr./Ms..............................................................................................

from (institute)......................................................having Enrollment No……………..…

has completed Project Planning Report having title……………………………………..

Individually/ in a group consisting of……………Candidates under the guidance of the

Faculty Guide.

Name & Signature of Guide......................................................

Name & Signature of HOD:…………………..........................

LES Polytechnic,Sangli Page No.1

ACKNOWLEDGEMENT

First of all I would like to thank Prof. (Name of Guide) who is presently

working as a (Designation of Guide) of (Name of Department, Name of College) for

guiding me through this project work. I am extremely grateful to him for all his

invaluable guidance and kind suggestions during all the phases of my project work. His

ever encouraging attitude, guidance and whole hearted help were biggest motivation for

me in completing this project work.

I am very grateful to (Name of Principal), Principal, (Name of Vice Principal),

Vice Principal, of L. E. S. Polytechnic, Sangli for motivating me for this project work.

Also I am thankful to Prof. (Name of H.O.D.), Head, Department of (Name of

Department) Engineering for providing necessary facilities for completion of this

project work. I am also thankful to (Name of other members who helped in completion

of dissertation work) for supporting me in completion of this project work.

Lastly I thank all the persons who have guided and helped me directly or

indirectly.

LES Polytechnic,Sangli Page No.1

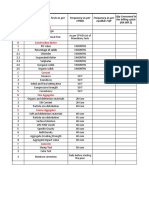

Format of content

Ch. No. Topic Page No.

Acknowledgement

Content

Abstract

Chapter 1 INTROUCTION

1.1 Introduction

1.3 Objectives

Chapter 2 LITERATURE REVIEW

2.1 Introduction

Chapter 3 METHODOLOGY: MATHEMATICAL/

EXPERIMENTAL/STUDY TYPE

3.1 Introduction

Chapter| CONCLUSIONS

REFERENCES

List of Publications

LES Polytechnic,Sangli Page No.1

Abstract

Curing determines durability of concrete and so it is most important post casting

activity (manufactures litreture & Is 456 ) .But there is no data available about curing

water quantity and now a days water has became costlier .So to calculate expance of

water and to ensure proper curing of the concrete we determined the approximate

quantity of water required for curing.

Concrete is a composite material composed of cement, fine and coarse aggregate and

water that hardens over time.

Hydration is a chemical reaction in which the major compounds in cement form

chemical bonds with water molecules and become hydration products. The hydration is

exothermic reaction and it is necessary to keep surface cool for gaining of strength in

concrete. Concrete curing is the process of maintaining adequate moisture in concrete

within a proper temperature range in order to aid cement hydration at early ages.

Millenium21 is a new admixture product in market and is used as internal curing

compound in this experimental study. In this experimental study the effects of

Millenium21 were studied on strength with different dosage of admixture.

IndexTerms – concrete, internal curing , hydration, millenium21, curing.

LES Polytechnic,Sangli Page No.1

Chapter 1

Introduction:

LES Polytechnic,Sangli Page No.1

Chapter 2

Litreture Survey:

Study And Analysis Of Self Curing Concrete Using Millenium

211Basavaraj.S.Balapgol,2Varad Khot,3Prachay Dani, 4Kunal Dhadiwal , 5Raunak

Dembra1Proffessor,2UG Student,3UG Student, 4UG Student, 5UG

Student1Department Of Civil Engineering, 1D.Y. Patil College of Engineering, Akurdi,

Pune, India.

Abstract: Concrete is a composite material composed of cement, fine and coarse

aggregate and water that hardens over time. When aggregate is mixed with dry Portland

cement and water, the mixture forms a fluid slurry that is easily poured and molded into

required shape. The cement reacts with the water and other ingredients to form a hard

matrix that binds the materials together into a durable stone-like material that has many

uses. Hydration is a chemical reaction in which the major compounds in cement form

chemical bonds with water molecules and become hydration products. The hydration is

exothermic reaction and it is necessary to keep surface cool for gaining of strength in

concrete. Concrete curing is the process of maintaining adequate moisture in concrete

within a proper temperature range in order to aid cement hydration at early ages.

Millenium21 is a new admixture product in market and is used as internal curing

compound in this experimental study. In this experimental study the effects of

Millenium21 were studied on strength with different dosage of admixture.

Experimental Investigations on Effects of Millenium 21 Admixture (Internal Curing)

On Durability and Strength Parameters of ConcreteDhananjay A.S(1), Puneet

Bhutna(2), Dhaval Shah(2),Shweta Patil(2)and Pratik Kotadiya(2)1 Assistant Professor,

Department of Civil Engineering, Sinhgad Academy of Engineering, Pune2Student of

Civil Engineering Department, Sinhgad Academy of Engineering, Pune.

Abstract: As per the previous studies of various internal compounds, the durability and

strength of the internally cured specimens is much greater than the conventionally cured

specimens. Millenium21 is new product in market and thus is used as internal curing

compound in this experimental study. The quality of structure does not solely depend

upon strength gain only. Thus the durability has to be studied. In this experimental

study the effects of Millenium21 were studied on strength and durability of concrete.

Internal curing compound is used in concrete which will acquire uniform curing using

minimal amount of water which is not possible with conventional curing techniques that

in turn leads to improper curing and development of cracks. Therefore Millenium 21 is

mixed in concrete to gain long term durability access.

Keywords: Carbonation, Durability, Internal curing, Millenium 21, Strength.

LES Polytechnic,Sangli Page No.1

Objectives

1. To check quantity of water required for curing the sample concrete block.

2. To collect and study information about M20 concrete and Millenium 21 admixture.

3. To prepare sample concrete block for experimental work.

4. To check workability and compressive strength of concrete block.

5. To compare the different test result of samples.

LES Polytechnic,Sangli Page No.1

Chapter 3

Proposed Detailed

Methodology

1. Collecting and studying information of materials used, standard mix proportion,

water cement ratio, method of mixing, method and period of curing, method and

No. of days required for preparing sample concrete block of M20 grade

2. Collecting and study of information about advantages, applications, properties

(chemical), application method, dosage of Millenium21 High preformation

admixture used in concrete.

3. Preparing concrete for casting of 18 samples concrete blocks (9 blocks with

admixture content and 9 blocks without admixture content) For 3,7 and 28 days

test and to check workability by sample cone and compaction factor test in our

colleg’s concrete technology lab

4. For curing of sample blocks and determining quantity of water required for

determining quantity of water required for proper curing to gain required

strength, arranging system of

5. Checking compressive strength of sample blocks for 3, 7 and 28 days (3 Blocks

with admixture content and blocks without admixture content for each test) in

our concrete technology lab by using C.T.M.

6. Comparison of result of blocks obtained by C.T.M with standard strength of M20

grad concrete and finalizing water quantity required for curing.

LES Polytechnic,Sangli Page No.1

You might also like

- Maharashtra State Board ofDocument22 pagesMaharashtra State Board ofutkarshdeshmukhNo ratings yet

- Acknowledgement: P.G.TEWARI For Giving Us An Opportunity To Take Up This Project WorkDocument3 pagesAcknowledgement: P.G.TEWARI For Giving Us An Opportunity To Take Up This Project WorkAbhishek MBNo ratings yet

- CuringmethodsarticleDocument5 pagesCuringmethodsarticledoaa alfallahNo ratings yet

- Dire Dawa University Institute of Technology: Prepared By: Id - NoDocument25 pagesDire Dawa University Institute of Technology: Prepared By: Id - NoAbnet BeleteNo ratings yet

- DocumentationDocument35 pagesDocumentationSiva Vadi100% (1)

- Analysis of The Pressure Strength and Drying Time of Concrete Using An Integral Waterproof Mixture and Adding Fly Ash As A Cement Replacement MaterialDocument8 pagesAnalysis of The Pressure Strength and Drying Time of Concrete Using An Integral Waterproof Mixture and Adding Fly Ash As A Cement Replacement MaterialOkto ZaiNo ratings yet

- Tugas Akhir M.radinalDocument82 pagesTugas Akhir M.radinalSepNo ratings yet

- OMM SEMINAR Plastic BricksDocument25 pagesOMM SEMINAR Plastic BricksOm ZakardeNo ratings yet

- Fully Edited Document Mini Project Sem 4Document32 pagesFully Edited Document Mini Project Sem 4Sahil Jadhavar (Sahil)No ratings yet

- Experimental Studies of Coconut Shell Ash Composites in ConcreteDocument4 pagesExperimental Studies of Coconut Shell Ash Composites in ConcreteaswathyNo ratings yet

- CPP PROJECT REPORT 6TH SEMESTER FinalDocument40 pagesCPP PROJECT REPORT 6TH SEMESTER FinalRoopshree Shelke100% (5)

- Case StudyDocument29 pagesCase StudyLouies UngriaNo ratings yet

- New Project UploadDocument69 pagesNew Project UploadNahid AbubakrNo ratings yet

- Progress ReportDocument5 pagesProgress ReportSyed SyedamirulNo ratings yet

- Polyeurythane Foam On ConreteDocument21 pagesPolyeurythane Foam On ConreteDave BalbiranNo ratings yet

- Major Project Part A.Document32 pagesMajor Project Part A.SHUBHAM NILESH PATILNo ratings yet

- Self AdvantageDocument16 pagesSelf Advantagebhai status officialNo ratings yet

- Investigationof Mechanical Propertiesof Coconut Shell Dust Epoxyand Fly-Ash CompositesDocument36 pagesInvestigationof Mechanical Propertiesof Coconut Shell Dust Epoxyand Fly-Ash CompositesTeja shivraj DandeNo ratings yet

- Investigationof Mechanical Propertiesof Coconut Shell Dust Epoxyand Fly-Ash CompositesDocument36 pagesInvestigationof Mechanical Propertiesof Coconut Shell Dust Epoxyand Fly-Ash CompositesTeja shivraj DandeNo ratings yet

- Experimental Study On Bacterial Concrete: April 2019Document7 pagesExperimental Study On Bacterial Concrete: April 2019Ammulu 123No ratings yet

- RG05 Chapter 1final Noel Et AlDocument55 pagesRG05 Chapter 1final Noel Et AlMichael Joshua MacasarteNo ratings yet

- Minor Project - No Fine ConcreteDocument24 pagesMinor Project - No Fine ConcreteMr.Bhaskar WabhitkarNo ratings yet

- De Report Format 2019 Sem III (1) Light WeightDocument16 pagesDe Report Format 2019 Sem III (1) Light WeightdNo ratings yet

- 1181 FinalDocument17 pages1181 FinalKoneti MounikaNo ratings yet

- A Study Rheological Properties of Internal Curing Concrete (Icc)Document4 pagesA Study Rheological Properties of Internal Curing Concrete (Icc)prashanthNo ratings yet

- Water Absorption of DCC Cubes by Is atDocument8 pagesWater Absorption of DCC Cubes by Is atJeba RajNo ratings yet

- HP ThesisDocument16 pagesHP ThesisPaul Justine AbelarNo ratings yet

- Review On Self Healing ConcreteDocument108 pagesReview On Self Healing Concreteanunciano GuterresNo ratings yet

- Phase 1 ReportDocument20 pagesPhase 1 ReportUjju BhagatNo ratings yet

- CE2317 (Akshay Dhodi) PBL ReportDocument20 pagesCE2317 (Akshay Dhodi) PBL Reportswarup babalsureNo ratings yet

- Sawdust Brick A Quantitative Study On Sawdust Substitute For Concrete Brick ProductionDocument21 pagesSawdust Brick A Quantitative Study On Sawdust Substitute For Concrete Brick ProductionChristian Andre FloresNo ratings yet

- Curing Concrete Literature ReviewDocument7 pagesCuring Concrete Literature Reviewn1dihagavun2100% (2)

- Concrete Research Paper TopicsDocument5 pagesConcrete Research Paper Topicsgw2xyzw9100% (1)

- ReportDocument7 pagesReportrohitkittur00No ratings yet

- Research Skill and Project Introduction - (Pranay Satpute and Lokesh Naktode) FINALDocument29 pagesResearch Skill and Project Introduction - (Pranay Satpute and Lokesh Naktode) FINALPranay SatputeNo ratings yet

- Research Status of Self-Healing Concrete: IOP Conference Series: Earth and Environmental ScienceDocument9 pagesResearch Status of Self-Healing Concrete: IOP Conference Series: Earth and Environmental ScienceMuhammad SholehNo ratings yet

- Fatigue Behaviour of ConcreteDocument31 pagesFatigue Behaviour of Concretedeekshith gowdaNo ratings yet

- Lab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbDocument23 pagesLab Report For Epoxy Resin Polymer Concrete by GroupbbbbbbbBetelhem KifleNo ratings yet

- Comparative Analysis of The Compressive Strength of Concrete UnderDocument11 pagesComparative Analysis of The Compressive Strength of Concrete UnderIsnaldo Barros OviedoNo ratings yet

- Scientific Inquiry and Review (SIR) : ArticleDocument16 pagesScientific Inquiry and Review (SIR) : ArticleUMT JournalsNo ratings yet

- P: Planning Before The WorkDocument5 pagesP: Planning Before The WorkRicky RickxNo ratings yet

- Me136p Exp7 Design of Concrete MixDocument14 pagesMe136p Exp7 Design of Concrete MixJohn Henry SalvadoNo ratings yet

- MainDocument208 pagesMainMR. ESHAN GHARPURENo ratings yet

- Lime Stabilization On Expansive Soils For PavementsDocument106 pagesLime Stabilization On Expansive Soils For PavementsPriyadarshini DasNo ratings yet

- Effect of Concrete Grade Enhancer Admixture On Structural Design of High-Rise Building Using Reinforced Concrete at SemeraDocument266 pagesEffect of Concrete Grade Enhancer Admixture On Structural Design of High-Rise Building Using Reinforced Concrete at SemeraAldinoSangJuaraNo ratings yet

- Bubble Deck Mini Project SEM V 2021-22Document17 pagesBubble Deck Mini Project SEM V 2021-22Saud ShaikhNo ratings yet

- Project Study 2Document41 pagesProject Study 2James AlcariaNo ratings yet

- Concretepaper UKIERIDocument8 pagesConcretepaper UKIERILoren CayasaNo ratings yet

- Sustainable Construction Material ReportDocument10 pagesSustainable Construction Material ReportCik bintangNo ratings yet

- Plastic Tile Material TestingDocument18 pagesPlastic Tile Material TestingA Manuel GirmaNo ratings yet

- An Experimental Study On Strength Behaviour of Cement Concrete With Use of Plastic FibreDocument6 pagesAn Experimental Study On Strength Behaviour of Cement Concrete With Use of Plastic FibreJefrey PeraltaNo ratings yet

- Project Report Group 24Document21 pagesProject Report Group 24kccvinodkNo ratings yet

- Construction and Building MaterialsDocument11 pagesConstruction and Building Materialscesar arangoNo ratings yet

- Ast 318-Cost Analysis and Estimate Module 1Document21 pagesAst 318-Cost Analysis and Estimate Module 1Edgar Jose MonterosoNo ratings yet

- Self-Curing Concrete - Literature ReviewDocument3 pagesSelf-Curing Concrete - Literature ReviewAvinash AviNo ratings yet

- Major Project Final, GroupDocument54 pagesMajor Project Final, Groupkannankannan0539No ratings yet

- Project ReportDocument41 pagesProject ReportAashu chaudhary100% (1)

- First Page ThesisDocument8 pagesFirst Page ThesismayasNo ratings yet

- Tran Vu Dung FulltextDocument175 pagesTran Vu Dung Fulltexthassan eijyNo ratings yet

- IsoDocument1 pageIsoOm JadhavNo ratings yet

- WRE Micro ImagesDocument1 pageWRE Micro ImagesOm JadhavNo ratings yet

- Cad 1Document1 pageCad 1Om JadhavNo ratings yet

- Eac 8Document5 pagesEac 8Om JadhavNo ratings yet

- Cte Micro III SemDocument24 pagesCte Micro III SemOm JadhavNo ratings yet

- Annexure BlankDocument8 pagesAnnexure BlankOm JadhavNo ratings yet

- Design of Steel Structures Vol 1Document931 pagesDesign of Steel Structures Vol 1Ravi Shah100% (8)

- A Quick Guide To Green Roofs - International Green Roof AssociationDocument20 pagesA Quick Guide To Green Roofs - International Green Roof AssociationHalley CruzNo ratings yet

- CENTAC Bill of Materials This Data Has Been Tabulated For Serial Number C12629Document15 pagesCENTAC Bill of Materials This Data Has Been Tabulated For Serial Number C12629diego fernando salgado devia100% (1)

- Maps Showing Seismicity Regions: Appendix ADocument34 pagesMaps Showing Seismicity Regions: Appendix AcesarNo ratings yet

- NEC 2011 - Table 314.16 (A) Metal BoxesDocument1 pageNEC 2011 - Table 314.16 (A) Metal BoxesJeremiah Gilbolinga100% (5)

- BN-S-UC001 Standard Checklist For Plant CompletionDocument3 pagesBN-S-UC001 Standard Checklist For Plant Completionwisnu_bayusaktiNo ratings yet

- ASTM 666 - 03 Stainless SteelDocument7 pagesASTM 666 - 03 Stainless Steelisaias_esparzaNo ratings yet

- Updated Study Guide PDFDocument44 pagesUpdated Study Guide PDFrendaninNo ratings yet

- Gantry Cranes-Design ProcedureDocument29 pagesGantry Cranes-Design ProcedurePoulami Guchhait100% (5)

- Quality Tests RequirementDocument6 pagesQuality Tests RequirementSandip PaulNo ratings yet

- LAB 4 - Forces in Trusses 1Document8 pagesLAB 4 - Forces in Trusses 1zaim100% (1)

- Local Flange Bending and Local Web Yielding Limit States in Steel Moment-Resisting ConnectionsDocument11 pagesLocal Flange Bending and Local Web Yielding Limit States in Steel Moment-Resisting ConnectionsMuhammad irfan javaidNo ratings yet

- TRYSTAR Welding CatelogDocument18 pagesTRYSTAR Welding CatelogFederico Pérez de LeónNo ratings yet

- Hydro-Mechanical Verification ReportDocument11 pagesHydro-Mechanical Verification ReportAnkit GautamNo ratings yet

- Capral - WERS BookletDocument58 pagesCapral - WERS BookletLEONARDONo ratings yet

- Pipe Dimensions and Weights Data Sheet enDocument6 pagesPipe Dimensions and Weights Data Sheet enhaidderNo ratings yet

- Monthly Construction Status Report TemplateDocument22 pagesMonthly Construction Status Report TemplatePopescu Mircea IulianNo ratings yet

- Identitas Barang Rehab R.kerja KH LT1 1Document2 pagesIdentitas Barang Rehab R.kerja KH LT1 1Erwin Alcapone0707No ratings yet

- Costing SheetDocument32 pagesCosting SheetSachin ShindeNo ratings yet

- Marble Dimension Stone: Standard Specification ForDocument2 pagesMarble Dimension Stone: Standard Specification ForLyu SiteNo ratings yet

- Section 4. Bidding FormsDocument24 pagesSection 4. Bidding Formsfilomeno martinsNo ratings yet

- PSC Deficiencies Fire FightingDocument6 pagesPSC Deficiencies Fire FightingPrashant RamdasNo ratings yet

- 945 3757 1 PBDocument20 pages945 3757 1 PBipooNo ratings yet

- Guidelines For Telecommunications Structures v1.0 - NSW GovernmentDocument29 pagesGuidelines For Telecommunications Structures v1.0 - NSW GovernmentruayoNo ratings yet

- TZPILE-Technical ManualDocument74 pagesTZPILE-Technical ManualNiccolò ValimbertiNo ratings yet

- Wis 4 34 04 PDFDocument16 pagesWis 4 34 04 PDFNitinNo ratings yet

- Supervised Industrial Training Report Mes (Military Engineering Services)Document78 pagesSupervised Industrial Training Report Mes (Military Engineering Services)Adeel Aslam RajpootNo ratings yet

- British Standard: A Single Copy of This British Standard Is Licensed ToDocument35 pagesBritish Standard: A Single Copy of This British Standard Is Licensed Toandrey25100% (2)

- Buckling C ChannelDocument2 pagesBuckling C ChannelНемања КараклајићNo ratings yet

- Hawle CatalogueDocument26 pagesHawle Catalogueklatheesh72No ratings yet

- Nuclear Energy in the 21st Century: World Nuclear University PressFrom EverandNuclear Energy in the 21st Century: World Nuclear University PressRating: 4.5 out of 5 stars4.5/5 (3)

- The Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Post-Transition Metals, Metalloids and Nonmetals | Children's Chemistry BookNo ratings yet

- The Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookFrom EverandThe Periodic Table of Elements - Alkali Metals, Alkaline Earth Metals and Transition Metals | Children's Chemistry BookNo ratings yet

- Physical and Chemical Equilibrium for Chemical EngineersFrom EverandPhysical and Chemical Equilibrium for Chemical EngineersRating: 5 out of 5 stars5/5 (1)

- Phase Equilibria in Chemical EngineeringFrom EverandPhase Equilibria in Chemical EngineeringRating: 4 out of 5 stars4/5 (11)

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersFrom EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNo ratings yet

- Process Plant Equipment: Operation, Control, and ReliabilityFrom EverandProcess Plant Equipment: Operation, Control, and ReliabilityRating: 5 out of 5 stars5/5 (1)

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- Understanding Process Equipment for Operators and EngineersFrom EverandUnderstanding Process Equipment for Operators and EngineersRating: 4.5 out of 5 stars4.5/5 (3)

- An Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksFrom EverandAn Introduction to the Periodic Table of Elements : Chemistry Textbook Grade 8 | Children's Chemistry BooksRating: 5 out of 5 stars5/5 (1)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Gas-Liquid And Liquid-Liquid SeparatorsFrom EverandGas-Liquid And Liquid-Liquid SeparatorsRating: 3.5 out of 5 stars3.5/5 (3)

- The HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesFrom EverandThe HAZOP Leader's Handbook: How to Plan and Conduct Successful HAZOP StudiesNo ratings yet

- Operational Excellence: Journey to Creating Sustainable ValueFrom EverandOperational Excellence: Journey to Creating Sustainable ValueNo ratings yet

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationFrom EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationRating: 4 out of 5 stars4/5 (18)

- Pharmaceutical Blending and MixingFrom EverandPharmaceutical Blending and MixingP. J. CullenRating: 5 out of 5 stars5/5 (1)

- Guidelines for the Management of Change for Process SafetyFrom EverandGuidelines for the Management of Change for Process SafetyNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Pharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryFrom EverandPharmaceutical Excipients: Properties, Functionality, and Applications in Research and IndustryOtilia M. Y. KooNo ratings yet

- Biopolymers: New Materials for Sustainable Films and CoatingsFrom EverandBiopolymers: New Materials for Sustainable Films and CoatingsDavid PlackettNo ratings yet