Professional Documents

Culture Documents

TDS PSR-4000 BN DI Colors October-6-2020

Uploaded by

Ash VigilOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TDS PSR-4000 BN DI Colors October-6-2020

Uploaded by

Ash VigilCopyright:

Available Formats

TECHNICAL DATA SHEET

PSR-4000BN DI Colors

(UL Name: PSR-4000BN / CA-40 BN)

LIQUID PHOTOIMAGEABLE SOLDER MASK

Screen or Spray Application

Designed for the latest DI Technology

Available in Black, Blue, White, Clear, Red,

Yellow, Purple or Orange Semi-Gloss Finish

Best in Class for Small Hole Clearing

RoHS Compliant

Compatible with Lead-Free Processing

Wide Processing Window

Withstands ENIG & Immersion Tin

Low Odor

1|Page Revised October 6, 2020

Copyright © 2015 Taiyo America, Inc. All Rights

Reserved.

TECHNICAL DATA SHEET

PROCESSING PARAMETERS FOR PSR-4000BN DI COLORS

PSR-4000BN DI Colors includes Black, Blue, Clear, Red, White, Yellow, Orange or

Purple. They are two- component, alkaline developable LPI solder mask products for flood

screen and spray application methods. The products are designed to be user friendly

with wide processing latitudes, low odor, fast developing and good resistance to alternate

metal finishes such as ENIG and immersion Tin while maintaining fine dams. PSR-4000BN

DI Colors meet or exceed the requirements of IPC SM-840E Class H and Class T,

Bellcore GR-78-CORE Issue 1, and has a UL flammability rating of 94V-0. All Taiyo

America products comply with the Directive 2002/95/EC of the European Parliament and of

the Council of 27 January 2003 on the Restriction of the use of certain Hazardous

Substances (RoHS) in electrical and electronic equipment.

PSR-4000BN SERIES COMPONENTS PSR-4000BN DI Colors/ CA-40BN DI

Mixing Ratio 100 parts 43 parts

Color Black, Blue, Clear, Red, White, White

Yellow, Orange or Purple

Mixed Properties PSR-4000BN DI Colors

Solids 77%

Viscosity 175-225ps

Specific Gravity 1.39

MIXING PSR-4000BN DI Colors is supplied in pre-measured containers with a mix

ratio by weight of 100 parts PSR-4000BN DI Colors and 43 parts CA-

40BN DI. PSR-4000BN DI Colors can be mixed by hand with a mixing

spatula for 10 – 15 minutes. Mixing can be done with a mechanical mixer at

low speeds to minimize shear thinning for 10 – 15 minutes. Also, mixing

can be done with a paint shaker for 10 – 15 minutes. Pot life after mixing is

72 hours when stored in a dark place at ≤ 20C (68F).

PRE-CLEANING Prior to solder mask application, the printed circuit board surface needs to be

cleaned. Various cleaning methods include Pumice, Aluminum Oxide,

Mechanical Brush, and Chemical Clean. All of these methods will provide a

clean surface for the application of PSR-4000BN DI Colors. Hold time

after cleaning the printed circuit board should be held to a minimum to reduce

the oxidation of the copper surfaces.

2|Page Revised October 6, 2020

Copyright © 2015 Taiyo America, Inc. All Rights

Reserved.

TECHNICAL DATA SHEET

PROCESSING PARAMETERS FOR PSR-4000BN DI COLORS

SCREEN PRINTING Method: Single Sided and Double-sided Screening

• Screen Mesh: 83 – 110

• Screen Mesh Angle: 22.5 Bias

• Screen Tension: 20 - 28 Newtons

• Squeegee: 60 – 80 durometer

• Squeegee Angle: 27 – 35

• Printing Mode: Flood / Print / Print

• Flood Pressure: 20 – 30 psi

• Printing Speed: 2.0 – 9.9 inches/sec

• Printing Pressure: 65 – 100 psi

TACK DRY CYCLE The Tack Dry step is required to remove solvent from the solder mask

film and produce a firm dry surface. The optimum dwell time and oven

temperature will depend on oven type, oven loading, air circulation,

exhaust rate, and ramp times. Excessive tack dry times and temperature

will result in difficulty developing solder mask from through holes and a

reduction in photo speed. Insufficient tack dry will result in artwork

marking and/or sticking. Typical tack dry conditions for PSR-4000BN DI

Series are as follows:

• Oven Temperature: 150 - 185F (65 - 85C)

• For Single-Sided (Batch Oven)

1st Side: Dwell Time: 15 - 20 minutes

nd

2 Side: Dwell Time: 25 - 45 minutes

• For Double-Sided (Conveyorized or Batch Oven)

• Dwell Time: 40 - 65 minutes

EXPOSURE PSR-4000BN DI Series uses UV-LED curing technology to define

solder mask dams and features. The spectral sensitivity is in the area of

365 nm – 405nm. Exposure times will vary by power, light source,

wavelength and age of the light source. Below are guidelines for

exposing.

• Exposure Unit: Direct Imaging Exposure Unit

• Stouffer Step 21: Clear 8 minimum (on metal)

• Energy: 250mJ / cm2 minimum

3|Page Revised October 6, 2020

Copyright © 2015 Taiyo America, Inc. All Rights

Reserved.

TECHNICAL DATA SHEET

EXPOSURE (continued)

PSR-4000 BN DI Color Exposure Energy Stouffer Step Range

2

Black Minimum 800 mJ/cm 9 – 11

2

Blue Minimum 300 mJ/cm 10 – 12

2

Clear Minimum 200 mJ/cm 9 – 11

2

Red, Orange, Minimum 300 mJ/cm 10 – 12

Purple

White

2

10 – 12

Minimum 800 mJ/cm

2

Yellow Minimum 800 mJ/cm 10 – 12

DEVELOPMENT PSR-4000BN DI Series is developed in an aqueous sodium or

potassium carbonate solution. Developing can be done in either a

horizontal or vertical machine.

• Solution: 1% by wt. Sodium Carbonate or 1.2% Potassium Carbonate

• pH: 10.6 minimum, to

• Temperature: 85 - 105F (29 - 41C)

• Spray Pressure: 25 - 45 psi

• Dwell Time in developing chamber: 45 - 90 seconds

• Water rinse is needed to remove developer solution followed by a

drying step

PRE-CURE (OPTIONAL)

This step may be required if the vias remain tented on both sides after

developing due to the board design. The added drying cycle will

prevent out-gassing of the vias. This phenomenon can cause the solder

mask over the vias to peel or pop and may also exhibit a degree of

oozing due to the entrapped solvent. The required drying cycle is 100 -

110°C for 40 to 60 minutes. An extended time may be required on the

higher aspect ratio.

FINAL CURE PSR-4000BN DI requires a thermal cure to insure optimal final property

performance. Thermal curing can be done in a batch oven or conveyorized

oven.

• Temperature: 275 – 300F (135 – 149C)

• Time at Temperature: 45 – 60 minutes

For Process Optimization please contact your local Taiyo America Representative

4|Page Revised October 6, 2020

Copyright © 2015 Taiyo America, Inc. All Rights

Reserved.

TECHNICAL DATA SHEET

FINAL PROPERTIES FOR PSR-4000BN DI COLORS

IPC-SM-840E, Class H & T, Solder Mask Vendor Testing Requirements

SM-840

TEST REQUIREMENT RESULT

PARAGRAPH

Visual 3.4.8 Uniform in Appearance Pass

Curing 3.4.5 Ref: 3.6.1.1, 3.7.1 and 3.7.2 Pass

Non-Nutrient 3.4.6 Does not contribute to biological growth Pass

Dimensional 3.4.10 No Solder Pickup and Withstand 500 VDC Pass

Pencil Hardness 3.5.1 Minimum “F” Pass – 8H

Adhesion 3.5.2 Rigid – Cu, Ni, FR-4 Pass

Machinability 3.5.3 No Cracking or Tearing Pass

Resistance to Solvents

3.6.1.1 Table 3 Solvents Pass

and Cleaning Agents

Hydrolytic Stability and No Change after 28 days of 95-99°C

3.6.2 Pass

Aging and 90-98% RH

Solderability 3.7.1 No Adverse Effect J-STD-003 Pass

Resistance to Solder 3.7.2 No Solder Sticking Pass

Resistance to Solder 3.7.3 No Solder Sticking Pass

Simulation of Lead Free

3.7.3.1 No Solder Sticking Pass

Reflow

Dielectric Strength 3.8.1 500 VDC / mil Minimum 2800 VDC/mil

Thermal Shock 3.9.3 No Blistering, Crazing or De-lamination Pass

Specific Class “H” Requirements

SM-840

TEST REQUIREMENT RESULT

PARAGRAPH

Flammability 3.6.3 UL 94V-0 Pass – File #E166421

Insulation Resistance 3.8.2

8 12

Before Soldering 5 x 10 ohms minimum Pass (2.02 x 10 ohms)

8 12

After Soldering 5 x 10 ohms minimum Pass (3.18 x 10 ohms)

Moisture & Insulation Resistance 3.9.1

8 9

Before Soldering–In Chamber 5 x 10 ohms minimum Pass (4.97 x 10 ohms)

8 12

Before Soldering–Out of Chamber 5 x 10 ohms minimum Pass (1.13 x 10 ohms)

8 9

After Soldering-In Chamber 5 x 10 ohms minimum Pass (4.08 x 10 ohms)

8 12

After Soldering-Out of Chamber 5 x 10 ohms minimum Pass (2.61 x 10 ohms)

6 12

Electrochemical Migration 3.9.2 >2.0 x 10 ohms, no growth Pass (1.34 x 10 ohms)

Specific Class “T” Requirements

SM-840

TEST REQUIREMENT RESULT

PARAGRAPH

Flammability 3.6.3 Bellcore 02 Index – 28 minimum Pass – 74

Insulation Resistance 3.8.2

8 12

Before Soldering 5 x 10 ohms minimum Pass (1.12 x 10 ohms)

8 11

After Soldering 5 x 10 ohms minimum Pass (7.15 x 10 ohms)

5|Page Revised October 6, 2020

Copyright © 2015 Taiyo America, Inc. All Rights

Reserved.

TECHNICAL DATA SHEET

FINAL PROPERTIES FOR PSR-4000BN DI COLORS

Specific Class “T” Requirements

SM-840

TEST REQUIREMENT RESULT

PARAGRAPH

Moisture & Insulation Resistance 3.9.1

8 9

Before Soldering–In Chamber 5 x 10 ohms minimum Pass (1.94 x 10 ohms)

8 11

Before Soldering–Out of Chamber 5 x 10 ohms minimum Pass (9.65 x 10 ohms)

8 9

After Soldering-In Chamber 5 x 10 ohms minimum Pass (2.18 x 10 ohms)

8 12

After Soldering-Out of Chamber 5 x 10 ohms minimum Pass (1.48 x 10 ohms)

Electrochemical Migration 3.9.2 < 1 decade drop, no dendritic growth Pass

Additional Tests / Results

TEST REQUIREMENT RESULT

Halogen Level Black, Clear and White Halogen Free if <900 ppm 300 ppm

Blue Halogen Free if <900 ppm 625 ppm

Red Halogen Free if <900 ppm 634 ppm

Yellow Halogen Free if <900 ppm 1000 ppm

Purple Halogen Free if <900 ppm 567 ppm

Orange Halogen Free if <900 ppm TBD

Electroless Nickel / Immersion Gold Resistance Nickel (85C/30 min) Tape Test Adhesion Pass

Solvent Resistance Acetone: No attack – 24 hours Pass

MEK: No attack – 24 hours Pass

IPA: No attack – 24 hours Pass

PMA: No attack – 24 hours Pass

Acid Resistance HCI – 10%: No attack – 30 Minutes Pass

H2SO4 – 10%: No attack – 30 Minutes Pass

Base Resistance NaOH – 10%: No attack – 30 Minutes Pass

Boiling Water Resistance: No attack – 15 Minutes Pass

Solder / Flux Resistance Alpha 857 water soluble: No attack – 1 x 10 sec float (260C) Pass

NR060 no-clean: No attack – 1 x 10 sec float (260C) Pass

3355-NB rosin-based: No attack – 1 x 10 sec float (260C) Pass

NR-3000A4 no-clean: No attack – 1 x 10 sec float (260C) Pass

Solder / Flux Resistance(Multicore) X32-10M no-clean: No attack – 1 x 10 sec float (260C) Pass

X32-06I no-clean: No attack – 1 x 10 sec float (260C) Pass

Solder/Flux Resistance-(Sanwa) SR-270 rosin-based: No attack – 1 x 10 sec float (260C) Pass

Conformal Coating Adhesion: Humiseal 1 B31 acrylic: Crosscut (10/10) after tape 100/100

Humiseal 1A20 urethane: Crosscut (10/10) after tape 100/100

Dow Corning 3-1753 silicone: Crosscut (10/10) after tape 100/100

Glue Dot Adhesion – Loctite 3609 Adhesion of Glue Dot to PSR-4000BN Excellent

Taiyo America, Inc. (TAIYO) warrants its products to be free from defects in materials and workmanship for the specified warranty period

(PSR-4000BN DI C o l o r s / CA-40BN DI Warranty period is 12 Months) provided the customer has, at all times, stored the ink at a

temperature of 68oF(20C) or less. TAIYO accepts no responsibility or liability for damages, whether direct, indirect, or consequential,

resulting from failure in the performance of its products. If a TAIYO product is found to be defective in material or workmanship, its liability

is limited to the purchase price of the product found to be defective. TAIYO MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED,

AND MAKES NO WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR ANY PARTICULAR PURPOSE. TAIYO'S obligation under

this warranty shall not include any transportation charges or costs of installation or any liability for direct, indirect, or consequential

damages or delay. If requested by TAIYO, products for which a warranty claim is made are to be returned transportation prepaid to

TAIYO'S factory. Any improper use or any alteration of TAIYO'S product by the customer, as in TAIYO'S judgment affects the product

materially and adversely, shall void this limited warranty.

6|Page Revised October 6, 2020

Copyright © 2015 Taiyo America, Inc. All Rights

Reserved.

You might also like

- NC-559-ASM, No-Clean Solder Paste: Product Data SheetDocument2 pagesNC-559-ASM, No-Clean Solder Paste: Product Data SheetAkhmad MukhsinNo ratings yet

- Carboguard 635 Thinned 50% - Sealer PDSDocument5 pagesCarboguard 635 Thinned 50% - Sealer PDSjakeNo ratings yet

- rma-223Document2 pagesrma-223Sergio ChicNo ratings yet

- Zn03-Pv. Epoxy Zinc Primer Qd-EngDocument2 pagesZn03-Pv. Epoxy Zinc Primer Qd-EngANIBALLOPEZVEGANo ratings yet

- Product Data Sheet SP-6888Document5 pagesProduct Data Sheet SP-6888rmfpereiraNo ratings yet

- User Guide - Aqua-Vanilla 8K ResinDocument19 pagesUser Guide - Aqua-Vanilla 8K ResinAdrián Tirado CalleNo ratings yet

- Simarine Bitumen: Product Data SheetDocument2 pagesSimarine Bitumen: Product Data SheetPerseroan MustikaNo ratings yet

- 1040 Stangard (ST) Epoxy Mastic-ImpDocument6 pages1040 Stangard (ST) Epoxy Mastic-ImpThenamudhan sakthivelNo ratings yet

- Simarine Deck Paint: Product Data SheetDocument2 pagesSimarine Deck Paint: Product Data SheetPerseroan MustikaNo ratings yet

- Altablue Touch Series Large Format Adhesive MeltersDocument2 pagesAltablue Touch Series Large Format Adhesive MeltersPah AraújoNo ratings yet

- AltaBlue Touch Large MeltersDocument2 pagesAltaBlue Touch Large MeltersPah AraújoNo ratings yet

- AltaBlue Touch Large MeltersDocument2 pagesAltaBlue Touch Large MeltersPah AraújoNo ratings yet

- XV 750Document7 pagesXV 750marius tanjalaNo ratings yet

- Carboguard 690: Selection & Specification Data Selection & Specification DataDocument2 pagesCarboguard 690: Selection & Specification Data Selection & Specification DataImran AhmadNo ratings yet

- Carboxane 2000 PDSDocument4 pagesCarboxane 2000 PDSBERSE MAJU INDONESIANo ratings yet

- DPF 390 FlexDocument3 pagesDPF 390 FlexCESAR GUERRERONo ratings yet

- Alpha: No-Clean Solder Paste (9098T)Document3 pagesAlpha: No-Clean Solder Paste (9098T)behzadNo ratings yet

- Alpha Rma 7 Flux GelDocument2 pagesAlpha Rma 7 Flux GelAdrian NoslacanNo ratings yet

- Carboguard 636 XT PDSDocument4 pagesCarboguard 636 XT PDSCarlos Rojas HandalNo ratings yet

- Carboguard 880 MIO PDSDocument4 pagesCarboguard 880 MIO PDSHerman EngelbrechtNo ratings yet

- Sec J 9Document1 pageSec J 9Musaddaq HussainNo ratings yet

- TDS Kliar-Cb1 EngDocument3 pagesTDS Kliar-Cb1 Engphistore19No ratings yet

- Carboguard 891 Product Data SheetDocument4 pagesCarboguard 891 Product Data SheetPrakashNo ratings yet

- TDS Ep100-20Document2 pagesTDS Ep100-20radule021No ratings yet

- CV1 - PR - B - Mipa TDSDocument2 pagesCV1 - PR - B - Mipa TDSradule021No ratings yet

- TDS PUFFIN COOKWARE STOVING DoneDocument3 pagesTDS PUFFIN COOKWARE STOVING DoneYoga RahadianNo ratings yet

- QALEX Pre Qualification 2019 2Document76 pagesQALEX Pre Qualification 2019 2Abdul BasithNo ratings yet

- FDT01en12 KRIONDocument6 pagesFDT01en12 KRIONkumaranNo ratings yet

- SteriBelt Modules Increase Conveyor Belt DisinfectionDocument4 pagesSteriBelt Modules Increase Conveyor Belt DisinfectionHayat ChekiriNo ratings yet

- Pro-Line 4800: Prothane H.S. PolyurethaneDocument2 pagesPro-Line 4800: Prothane H.S. PolyurethaneJahir GomezNo ratings yet

- Compact SEM Coater DSR1Document3 pagesCompact SEM Coater DSR1mohamadazareshNo ratings yet

- Technical Coating for Metal SurfacesDocument2 pagesTechnical Coating for Metal Surfacessljiva11No ratings yet

- Zinc Clad II (85) : Inorganic Zinc Rich CoatingDocument2 pagesZinc Clad II (85) : Inorganic Zinc Rich CoatingANA CABRERANo ratings yet

- Silva Spar No.500Document1 pageSilva Spar No.500Anonymous cossY9FNo ratings yet

- Capacitive Proximity Sensor For Object Detection and Fill Level DetectionDocument36 pagesCapacitive Proximity Sensor For Object Detection and Fill Level DetectionRendy Adam FarhanNo ratings yet

- Thermaline 450 EP PDSDocument3 pagesThermaline 450 EP PDSdgambhavaNo ratings yet

- Lexan™ Exell D STP - Sheet DatasheetDocument2 pagesLexan™ Exell D STP - Sheet DatasheetAmritraj CharlesNo ratings yet

- VpCI 389Document2 pagesVpCI 389Harshad DholariyaNo ratings yet

- Pa 10Document3 pagesPa 10LymeParkNo ratings yet

- Millad NX 8000 Tds - UpdatedDocument2 pagesMillad NX 8000 Tds - UpdatedRakibul HaqueNo ratings yet

- PCM Systems Guide v7Document27 pagesPCM Systems Guide v7IliyanPetrovNo ratings yet

- ALPHA-RMA-7-Paste-Flux-EN-26FEB21-TBDocument4 pagesALPHA-RMA-7-Paste-Flux-EN-26FEB21-TBSergio ChicNo ratings yet

- 4300 lf4300 TFDocument2 pages4300 lf4300 TFArguetaManuelNo ratings yet

- Nukote Har: DescriptionDocument4 pagesNukote Har: DescriptionMarco Dos Santos NevesNo ratings yet

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua Sua100% (1)

- A2 - Painting Procedure PDFDocument2 pagesA2 - Painting Procedure PDFJuan Carlos Sua SuaNo ratings yet

- Epofine 221 - Finehard 964 - Accelerator 070Document4 pagesEpofine 221 - Finehard 964 - Accelerator 070Karishma PrabhuNo ratings yet

- 1604-01 Simatherm HR Primer ATP 600CDocument2 pages1604-01 Simatherm HR Primer ATP 600CBagusRekaNo ratings yet

- Plasite 7159 HAR abrasion resistant epoxyDocument4 pagesPlasite 7159 HAR abrasion resistant epoxyRobertoNo ratings yet

- Technical Data Sheet: Water-Proofing Paint SR-100 WHITE Davies Sun & Rain Odourless ElastomericDocument1 pageTechnical Data Sheet: Water-Proofing Paint SR-100 WHITE Davies Sun & Rain Odourless ElastomericarchieNo ratings yet

- KODAK SONORA XTRA Process Free Plate Brochure ENDocument6 pagesKODAK SONORA XTRA Process Free Plate Brochure ENAlex GonzalezNo ratings yet

- 1000 Liter Ion Exchange GalleriaDocument5 pages1000 Liter Ion Exchange GalleriaBiswajit SahooNo ratings yet

- ISO 9001, ISO 14001 & OHSAS 14001 Certified Acrylic Finish Product Data SheetDocument2 pagesISO 9001, ISO 14001 & OHSAS 14001 Certified Acrylic Finish Product Data SheetSAEFUDDIN SAEFUDDINNo ratings yet

- 1402-00 Simazinc EP PrimerDocument2 pages1402-00 Simazinc EP PrimerMuhammad Mulya JatiNo ratings yet

- Tankguard 412Document5 pagesTankguard 412abdulgafoor54No ratings yet

- Epofine 404 - Finehard 2404Document3 pagesEpofine 404 - Finehard 2404Karishma PrabhuNo ratings yet

- Technical data sheet for acrylic removable coatingDocument5 pagesTechnical data sheet for acrylic removable coatingsidwalNo ratings yet

- Technical Data Sheet: Acrylic Removable CoatingDocument5 pagesTechnical Data Sheet: Acrylic Removable CoatingsidwalNo ratings yet

- MTR 1902 34 10 28Document1 pageMTR 1902 34 10 28Ash VigilNo ratings yet

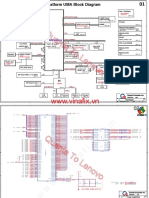

- ThinkPad E145 DALI2KMB8D0 Schematic DiagramDocument38 pagesThinkPad E145 DALI2KMB8D0 Schematic DiagramAsh VigilNo ratings yet

- L19 2branchesDocument49 pagesL19 2branchesAsh VigilNo ratings yet

- Schematic 2.4G Telecontrol Board 2021-07-15Document1 pageSchematic 2.4G Telecontrol Board 2021-07-15Ash VigilNo ratings yet

- 185hr DatasheetDocument3 pages185hr DatasheetAsh VigilNo ratings yet

- JROTC Program Organization and Operations ManualDocument261 pagesJROTC Program Organization and Operations ManualAsh VigilNo ratings yet

- 16X2 LCD Shield With LMD18201 Motor DriverDocument3 pages16X2 LCD Shield With LMD18201 Motor DriverAsh VigilNo ratings yet

- Question Bank MCQ MouldsDocument72 pagesQuestion Bank MCQ MouldsThilak P Gowda100% (2)

- Rockwell Hardness Tester Model 3814 Setup GuideDocument15 pagesRockwell Hardness Tester Model 3814 Setup GuidecdokepNo ratings yet

- IOSK 72,5 .550 KV: Instructions For Assembling and Maintenance of Current Transformer TypeDocument17 pagesIOSK 72,5 .550 KV: Instructions For Assembling and Maintenance of Current Transformer TypeRonald MoreiraNo ratings yet

- Décembre 1995: Boutique AFNOR Pour: Solios Carbone Client 8319200 Commande N-20100112-383554-TA Le 12/1/2010 16:25Document15 pagesDécembre 1995: Boutique AFNOR Pour: Solios Carbone Client 8319200 Commande N-20100112-383554-TA Le 12/1/2010 16:25Mahesh Kumar BandariNo ratings yet

- Intermittent Rail Support Soleplates - GantrexDocument2 pagesIntermittent Rail Support Soleplates - GantrexMichal KowalczykNo ratings yet

- Effect of Tungsten in Mechanical Properties of Resuced Activation Ferriitic Martensitic SteelDocument7 pagesEffect of Tungsten in Mechanical Properties of Resuced Activation Ferriitic Martensitic SteelshouldNo ratings yet

- Anchor Bolts, Steel, 36, 55, and 105-Ksi Yield Strength: Standard Specification ForDocument8 pagesAnchor Bolts, Steel, 36, 55, and 105-Ksi Yield Strength: Standard Specification Forsafak kahramanNo ratings yet

- MBX - Amoladora Quita OxidoDocument6 pagesMBX - Amoladora Quita OxidoomarNo ratings yet

- Engineers India - EIRI HiTech Magazine - May 2018Document17 pagesEngineers India - EIRI HiTech Magazine - May 2018Sunesh SharmaNo ratings yet

- BS en Iso 2553-2019Document64 pagesBS en Iso 2553-2019kevin peña100% (1)

- Blazing Vs SolderingDocument2 pagesBlazing Vs SolderingAsif HassanNo ratings yet

- Design Guidance For Producibility PDFDocument419 pagesDesign Guidance For Producibility PDFElJeremiasNo ratings yet

- Hindalco Novelis AcquisitionDocument18 pagesHindalco Novelis Acquisitionpratikmms100% (1)

- AWS D1.1:2020 - Changes To Structural Welding Code - SteelDocument1 pageAWS D1.1:2020 - Changes To Structural Welding Code - SteelVuong Tran VanNo ratings yet

- Technical Specification For FlangesDocument13 pagesTechnical Specification For FlangesRahul GangulyNo ratings yet

- Katalog 2 enDocument1,060 pagesKatalog 2 enmunhNo ratings yet

- 102 Welding QualificationsDocument27 pages102 Welding Qualificationsdayalram100% (1)

- MPL Pre FeasibilityReportDocument30 pagesMPL Pre FeasibilityReportATLAS ScaffoldingNo ratings yet

- Primetals Brochure ENDocument16 pagesPrimetals Brochure ENMario RossiNo ratings yet

- Flowserve Durco CatalogDocument36 pagesFlowserve Durco CatalogbryandownNo ratings yet

- MATERIALS and SelectionDocument3 pagesMATERIALS and SelectionRohit ShahNo ratings yet

- Module 1 - Welding TechnologiesDocument39 pagesModule 1 - Welding Technologieschemical labNo ratings yet

- PQR DT Macro 60mm Smaw Astm A 516 Gr60Document4 pagesPQR DT Macro 60mm Smaw Astm A 516 Gr60Boran YelkenciogluNo ratings yet

- Heavy Weld ShopDocument6 pagesHeavy Weld Shopyogendra singhNo ratings yet

- ISO 10642 - Hexagon Socket Countersunk Head Cap ScrewsDocument5 pagesISO 10642 - Hexagon Socket Countersunk Head Cap ScrewswillianNo ratings yet

- Astm D 1654 PDFDocument3 pagesAstm D 1654 PDFrapidremiNo ratings yet

- Vanguard Steel Product ManualDocument158 pagesVanguard Steel Product ManualRajaSekarsajjaNo ratings yet

- Expansion Joints: For Heat ExchangerDocument10 pagesExpansion Joints: For Heat ExchangerAzher ANo ratings yet

- Basic Material Science Lecture - 1Document22 pagesBasic Material Science Lecture - 1Mustafa Enes KırmacıNo ratings yet

- CGI Roofing SpecsDocument2 pagesCGI Roofing SpecsYeshaswee VaidayNo ratings yet